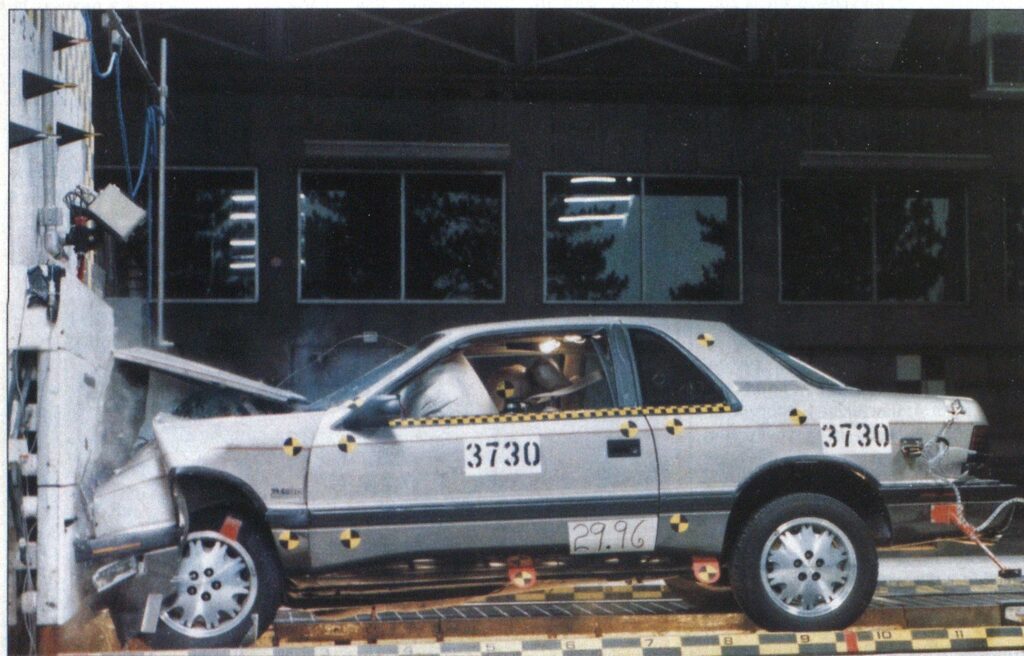

(Photo supplied by Chrysler Motors Corporation.)

Air Restraint Bags: Not Just a Lot of Hot Air

RESCUE

AS RESCUERS, WE ARE constantly faced with the problems of keeping up with the changes and hazards that go hand in hand with new technology, This is quite evident when dealing with automobiles that either are involved in accidents or are burning. Every year brings us new technological advances and hidden hazards such as shock-absorbing bumpers, dangerous gases from burning plastics, and pressurized fuel systems. It seems that as cars get safer for the occupants, rescuers have more to worry about.

A major change in vehicle design brought about by federal law is nowsurfacing: By the 1990 model year, all automakers are required to provide a passive restraint system in every passenger car sold in the United States. This passive restraint system can be either automatic motorized seat belts or air bags combined with manual seat belts. Most manufacturers now produce cars with these lifesaving devices as standard equipment. Chrysler Corporation has even equipped many of its 1989 models with airbag modules.

Chances are the general public will not widely accept motorized seat belts. Many who now drive cars equipped with such belts complain the car “ties them up” when the door is closed. Air restraint bags are gaining in popularity, probably since they are stored away until they are needed.

SAFETY IS IN THE BAG

The air restraint bag system is a safety feature that can save countless lives and prevent serious injury to the driver of a vehicle involved in a frontal or nearfrontal collision. Yet in spite of its benefits in terms of driver safety, the air bag can pose problems for the uninformed rescuer.

A typical air bag restraint system is located on the driver’s side in the steering wheel hub and, when so equipped, on the passenger side underneath a plastic bolster on the dash. The presence of an unusually large steering wheel hub indicates that a driver’s-side air bag system is present.

The bag itself is made of synthetic materials similar to the typical hypalan salvage cover. On impact, it rapidly inflates with nitrogen, thus absorbing the traumatic impact of the occupants before they reach the steering wheel, dash, or windshield. Air bags are not intended to be absolute protection alone. They must be used in conjunction with manual seat belts for proper performance.

The gas used to fill the bag is produced when sensors, located at strategic points on the vehicle structure, send a signal to the inflator unit that burns approximately 80 grams of the chemical sodium azide. These sensors are set to react to an impact force created by collision at speeds greater than 8 to 14 miles per hour. When ignited, the sodium azide rapidly creates more than enough nitrogen to fill the bag. Since nitrogen is an inert gas, it is a good choice for this application.

Witnesses say the actual ignition of the sodium azide sounds like a 12-gauge shotgun blast. However, strangely enough, very few passengers involved in an accident where the air bag inflated claim to remember the sound—apparently the sound of the accident is louder than the detonation of the air bag system.

The actual sequence of events that takes place when an air bag system is used is as follows:

- The incident. The sensors detect the frontal or near-frontal impact. They react to the negative forces imposed by the impact. If two of the sensors detect the crash, they send an electronic signal to the ignition mechanism.

- Ignition. The ignition assembly receives the signal to fire and ignites the rapid-burning sodium azide.

- Expansion. The sodium azide ignites and immediately produces the nitrogen required to rapidly fill the air bag.

- Deployment. The air bag deploys, coming out from behind a lightweight trim panel, and cushions the occupant from the frontal impact. (The panels are designed to swing out of the way and avoid contacting the occupant.)

- Deflation. Once the air restraint bag does its job, the nitrogen is exhausted through vents on the back of the bag, away from the driver toward his feet.

The first four steps of this sequence of events take about 1/20 of a second— faster than it takes to blink an eye. The last step, deflation, takes a few seconds. The air bag first partially deflates, giving the occupant room to view what is happening, and then completely deflates a few seconds later.

SOME HAZARDS TO BE AWARE OF

If sodium azide comes into contact with water, it burns rapidly with what some call a “loud report” that may be unexpected by those operating at the scene. The entire system is hermetically sealed in an aluminum cannister to reduce the chances of water coming in contact with the chemical; however, sodium azide ignites at temperatures greater than 300°F. A by-product of burning sodium azide is a white, chalky powder that is slightly alkaline, containing a minute amount of sodium hydroxide. Although the quantity of sodium hydroxide is so small that it does not present a hazard itself, contact w ith the chalky powder can cause mild irritation to the eyes, nose, and any open cuts or abrasions that the accident victim or rescuer may have, and rescuers should be careful not to inadvertently contaminate a patient’s wounds after handling the air bag.

Another potential hazard is the accidental deployment of the air bag. If the collision is from the rear or directly from the side, the air bag may not activate. If this is the case, the rescuer should disarm the air bag prior to beginning extrication procedures by disconnecting the negative side of the electrical supply (battery) and waiting anywhere from four seconds to a minute. This is enough time for the capacitor, designed to activate the air bag in case of power failure, to decay and lose its charge. This is the only recommended safe procedure for disarming an air bag system in a rescue situation.

After serving its purpose, the air bag dies a quick death. Once deployed, it cannot be reused. Also, once an air bag is installed in a vehicle, it cannot be removed and installed in another vehicle. According to manufacturers’ technical bulletins, an armed air bag module should be deployed and disposed of just as any other scrap part as soon as a vehicle arrives at a salvage yard. Failure to deploy an air bag in a salvage yard can result in accidental deployment and personal injury.

Air bags can, and will, save countless lives. During the first three months of the 1989 model year, Chrysler Corporation was notified of 140 vehicle accidents in which its air bags deployed. These accidents ranged from minor to very critical, and the most serious injury reported was a broken nose. While this certainly is not a scientific survey, it indicates the potential value of air bags.

While air bags reduce injury, it should be noted that they cannot prevent the metal of a crashing vehicle from twisting and thus trapping the occupants in the tangled wreckage. We still will be called on to perform extrication; however, the victim’s condition and ultimate recovery from the accident will be greatly improved because of the increasing use of this safety device.