250-hp, Air-Cooled Diesel Used to Repower Pumper

features

DAVE WINDLE

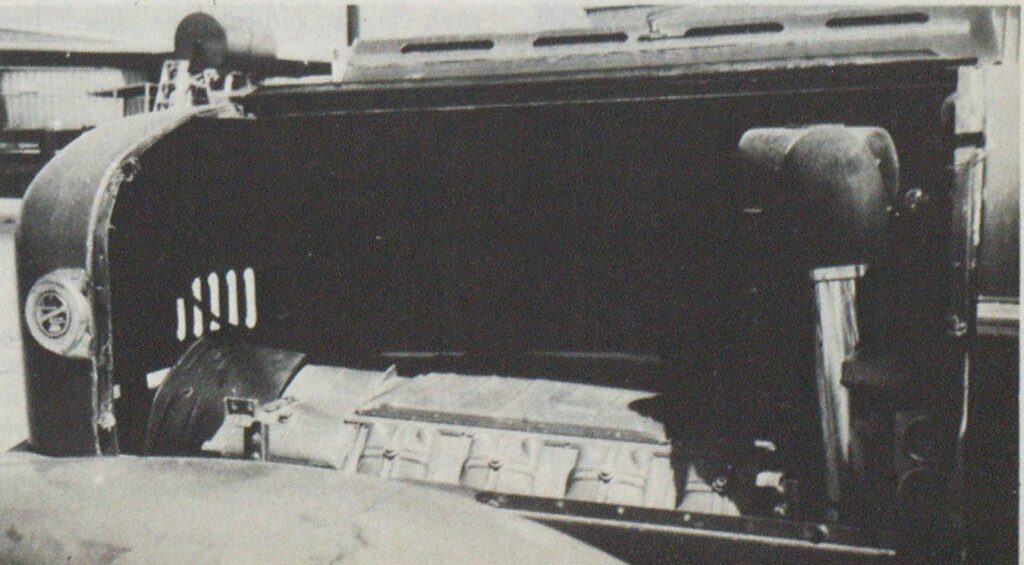

A New Mexico fire department has repowered a pumper with an air-cooled diesel engine made in Germany. The conversion cost, including a new transmission and changing the rear axle gear ratio, was about $14,000.

The eight-cylinder engine is a Deutz Model F8L 413 manufactured by Klockner-Humboldt-Deutz AG of Cologne. With 690 cubic inches displacement, it is rated at 250 bhp at 2650 rpm.

When Ray Castleberry of the Artesia Fire Department decided to repower a 1957 Seagrave pumper, a survey of local diesel motor dealers included one distributing the Deutz engine. Because of its unique design and relative rarity in this country, Artesia City Councilman Fred Mermis, owner of a construction firm that uses numerous types of air and water-cooled engines, volunteered to investigate the Deutz engine.

Used in potash mines

Mermis found the engine in extensive use in potash mines near Carlsbad, N.M., primarily because of its low level of exhaust pollutants. Mine engineers told him that tests of the air-cooled Deutz had been performed in an environmental chamber alongside conventionally cooled diesel engines. With the chamber temperature raised well above that normally encountered, the Deutz engine was still operating successfully under conditions when liquid-cooled engines failed. In addition, maintenance records of all types of engines used in the mines showed that the German unit had a longer mean time between failures than conventional engines. Mermis presented this information to Castleberry and the city council, and the Deutz engine was added to the list of possible power plants.

Although the base price of the Deutz engine was the highest among the bids received, its installation costs were lowest, thereby making the Deutz bid the lowest. The installation savings resulted from avoiding the expense of added pollution control equipment needed on the other engines to meet, emission standards, and the less complicated installation. Air-cooling eliminated the need for a radiator and an auxiliary cooling system.

Along with the engine, a new transmission compatible with the speed range of the diesel engine was installed. Tests of the repowered apparatus disclosed an exceptional amount of torque, so the gear ratio of the pumper’s rear axle was changed to provide a higher top speed and more normal torque. With 500 gallons of water, the apparatus achieves a top speed of 76 mph.

Fuel consumption

When driven to Albuquerque for a pump certification test, the pumper averaged 14 to 15 miles per gallon of fuel during the 235-mile trip at an average elevation of more than 3500 feet above sea level.

The low pollution output of the Deutz engine, said to be typically half of the carbon monoxide and nitrogen oxide levels of a standard diesel engine, is achieved by a two-stage combustion process. In a standard diesel engine, fuel is injected directly into each cylinder. In the two-stage engine, the fuel is first injected into a pre-combustion “swirl chamber” above each cylinder, where high temperature and high pressure combine with a high fuel-to-oxygen ratio to hold down the product of nitrogen oxides. The second stage of combustion occurs in the cylinder in double swirl chambers etched into the top of the piston. Excess air, combined with the strong swirling effect, produces more complete combustion of carbon monoxide, various hydrocarbons, and even carbon particles, giving the engine a lower than normal soot output, also.

The Deutz engine has individual cast cylinder blocks rather than a single engine block. Any cylinder may be removed by the withdrawal of four bolts. The particular model used in the Artesia pumper weighs 1668 pounds and is approximately 50 inches long, 40 inches wide and 34 inches high.

—For More Facts on Emergency One,