All fire departments across our nation respond to odors of natural gas and releases of other explosive gases. The vast majority of these turn out to be minor and pose no threat to us or civilians. We get complacent at these alarms because nothing ever happens—until it does, and then it is devastating.

Explosive gas releases leading to explosions have a nasty history of killing and injuring firefighters and civilians.

- In 2018, Sun Prairie (WI) Fire Department Captain Cory Barr was killed, several firefighters were critically injured, and a dozen other people were injured by debris when a building exploded.

- In New York City in 2014, eight civilians were killed and 50 were injured after a gas explosion.

- In 2016, nine Seattle (WA) firefighters were hospitalized after a response to a natural gas emergency.

- In 2012, two West Haverstraw (NY) firefighters were seriously injured after gas leaked into a locked building, found an ignition source, exploded and shredded the home, and destroyed two other homes.

RELATED FIREFIGHTER TRAINING

Natural Gas Emergency Strategy and Tactics

Training for Natural Gas Emergencies

Tactical Size-Up of Natural Gas Emergencies

What do these deadly incidents have in common? Your tactics and fireground success will be based on how you use your air monitoring tools for an effective size-up. Your size-up will determine if the leak is a major or minor emergency. It’s natural to get complacent: Your dispatcher calls it an odor of gas or a gas leak. You think of it as another annoying “smells and bells” call. You should call it and run your procedures that treat it like what it is: a response to an explosive gas until you size-up and prove through air monitoring that it is not a threat to civilian or firefighter lives, just like you do for any alarm of fire. Assume the worst until you prove otherwise.

(1) This explosive gas detector uses an MOS and makes ticking sounds to alert you to very low levels of many explosive gases and vapors from flammable liquids. (Photos by author.)

(2) The long wand allows you to reach up near the ceiling, where the highest concentration of natural gas may be present, or down near the floor, where propane may accumulate.

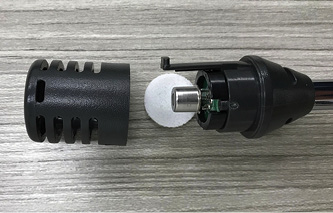

(3) The plug-in MOS with the filter and protective cap removed.

(4, 5) Some MOS-based instruments will automatically change the display from ppm to percent LEL, sound an alarm, and have a tick function to allow you to locate the source of a small leak and low concentrations of gas.

What follows will help you in that mission. This article explains the value of pairing up your four-gas monitor with an explosive gas detector with a metal oxide sensor for an effective size-up. This combination of tools will help you meet your mission of providing life safety at explosive gas emergencies.

Training Gap

You may find the following information very useful, maybe even lifesaving, for you and your crew. This is because it is very likely that none of this critical information was included in any of your training. It is a training gap that nearly killed me and my captain at a release of explosive gas. What we did not know nearly killed us!

The fact is, we all have gone to too many explosive gas emergencies without adequate procedures, adequate training, the right tools, and a full understanding of the strengths and weaknesses of our meters. This training gap is a nationwide fire service problem. Explosive gas calls can kill you in a microsecond. If plan A fails, you have no plan B. Your plan A is that the size-up of the release of explosive gas and your tactics must work perfectly. This article fills a small portion of the training gap.

For this discussion, we will consider both natural gas and propane as primary type responses to explosive gases. For both gases, the fire department responses including size-up, tools used, procedures, and tactics are similar except as modified by the properties of the escaping explosive gas. The properties are as follows: Natural gas goes up (vapor density is less than air), propane goes down (vapor density is greater than air), and flammable ranges vary a little—natural gas flammable range is 5-15% and propane is 2-9% gas in air.

Natural gas and propane are the most common explosive gas calls, but we often encounter other explosive and flammable gases such as acetylene, carbon monoxide, anhydrous ammonia, and hydrogen. Don’t forget to consider liquids like gasoline, acetone, ethanol, and crude oil that, because of their high vapor pressure, create flammable/explosive vapor/air mixtures.

What tools are best for size-up when we respond to explosive gas releases? Let’s look at an alternative that complements our trusty four-gas meter.

Metal Oxide Sensor

The metal oxide sensor (MOS) is often misunderstood and underused by the fire service. Its real strength is its ability to detect very low levels of combustible gases and vapors almost instantly. Some departments call MOS-based instruments explosive gas detectors. A metal oxide sensor-based explosive gas detector paired with or built into your four-gas air monitor will greatly speed up your size-up of gas emergencies.

Advantages. Advantages of the MOS include the instant ability to detect and provide data. Especially important is its ability to detect at much lower levels than a catalytic bead or Wheatstone bridge sensor built into the typical four-gas meter. Best practice is to pair the four-gas meter with an explosive gas detector to provide a fast response even at the lowest concentrations of combustible gases. Simultaneous use of two technologies is a common method for hazmat teams to target unknown gases (and liquids and solids) and confirm concentrations or identities. MOS-based units are inexpensive, reliable, and durable and are made by several manufacturers.

In his excellent book Hazardous Materials Air Monitoring and Detection Devices, Chris Hawley describes the MOS in detail: “The MOS is a semiconductor in a sealed unit that has a Wheatstone bridge surrounded by a metal oxide coating. Heater coils provide a constant temperature. When the sample gas passes over the heated bridge, it combines with a pocket of oxygen created from the metal oxide. Anything that enters the sensor house is burned off, and this reaction causes an electrical change, which produces the reading. The MOS picks up dust, dirt, and other particulates, moisture in the air, flammable gases, combustible gases, or just about any chemical with enough vapor pressure to get it into the air.”

On the emergency scene, the wide range of contaminants it will detect is both a positive and a negative for us. On the positive side, it detects explosive gases/vapors in the 0-990 parts per million (ppm) range, which is much lower than other sensors currently in use. Therefore, it will detect very small leaks that utilities call “fuzzers”—those we may smell but cannot detect with a four-gas meter. Civilians often call us because they can smell the odorant in gas, but it may be difficult for us to find without MOS-based units.

Many MOS-equipped units have a Geiger counter-like ticking sound to alert the user to relative amounts of gas it is detecting. Some units have higher ranges and automatically switch from ppm to percent lower explosive limit (LEL) and show the concentration as a numerical readout. This function is especially useful when sizing up an explosive gas call. It provides both early warning (low detection level) and a numerical reading of the concentration of explosive gas present.

MOS-based instruments will respond instantly to common spilled or leaking flammables including propane and gasoline. This makes it a very useful tool for urban, suburban, and rural departments. The MOS will detect the following and other airborne contaminants: acetone, alcohol, ammonia, butane, ethylene oxide, gasoline, halon, hydrogen, industrial solvents, jet fuel, lacquer thinner, methane, propane, and some refrigerants. It can act as a poor man’s photo ionization detector (PID) for departments with tight budgets. It will tell you if something is there or not but, like a PID, not what it is. If your MOS detects something in the atmosphere, check your oxygen reading. Your oxygen reading will go down if there is a contaminant reducing the oxygen concentration.

We often need to find the source of the odor of gas so we can shut off the leaking appliance and resolve the call. It may be a broken flex line behind the stove or clothes dryer or a minor leak at a union on the gas meter for the building. The MOS sensor with the tick function on will tick faster the closer you get to the point of escaping gas. You can use it to find those very small leaks. Most standard operating procedures (SOPs) direct units to shut off the closest gas valve to the appliance. Use this “find and fix” strategy only after your size-up has ruled out a major gas emergency and it is in compliance with your department SOP.

Disadvantages. Obviously one weakness is that it will not tell you the concentration (% LEL) of explosive gas after finding and confirming its presence. Your SOP should have an action level (typically 10% LEL for mandatory evacuation) to provide guidance on tactics when certain levels of explosive gas concentration are present.

Like all sensors that you have calibrated, a MOS has correction factors for other gases it detects other than what you have calibrated it to “know.” For example, if your instrument is calibrated to methane (natural gas) and you are using it to find gasoline or hydrogen, the percent LEL reading needs a correction factor applied to get the actual LEL percentage of hydrogen or gasoline. Correction factors vary by manufacturer; read the manual.

Street Use

Say you respond to a natural gas odor in a home or an apartment. You and your crew enter with your four-gas monitor, and it shows 0% LEL. You and the homeowner smell gas. What is going on?

It is all about the lowest level your instrument can detect. The numbers tell the story. Most normal/healthy humans can smell gas (the odorant actually) at about 1 ppm. Your four-gas meter cannot detect or provide a reading below 1% LEL, which is 500 ppm of gas. So, your instrument is blind up to its lowest detection level. You should pair up your four-gas meter with an explosive gas detector that will give you an instant detection of gas at very low levels. I did not understand why some large urban departments use this detector. In my mind, it told us that gas was present but not what amount, and it is the amount that dictates our tactics—minor or major emergency. Of course, the value is fast detection at low levels; then you can follow up with your four-gas meter.

Recall the LEL for natural gas is 5% gas or 50,000 ppm. The resolution of a good MOS-based instrument of about 10 ppm is good and a very low detection level that is not available with other technologies. So, the MOS can detect explosive gases—in this case, natural gas near the odor threshold, which is what triggered the civilian to call 911 and initiated our response. The good news is we get the call long before the leak reaches hazardous levels and we can mitigate the hazard before it builds to explosive levels.

Another situation is when the utility company’s detector is detecting natural gas in a building when your four-gas meter is not. Now you know why.

In comparison to our typical four-gas meter, utilities have a metal oxide sensor built into their combustible gas indicator. Utility meters usually automatically switch scales from ppm to percent LEL to percent gas in air. Our four-gas meter does not. In many four-gas meters, the lowest level is 1% LEL and the highest explosive gas level we can detect is 100% LEL. For these reasons, an explosive gas detector with an MOS capability should be part of every department’s air monitoring instruments. Pair it up with your existing four-gas monitor. The interesting question here is, if we consider the utility folks are the experts in explosive gas response procedures and they use an MOS sensor or one that can detect low levels of gas, why don’t we use the same technology?

Scenario: Locked Building

Consider the scenario of a locked building. If gas is escaping into or migrating into the building or apartment (possibly from an underground leak) and you use your four-gas monitor, you will not be able to detect gas below the 1% LEL (500 ppm). So, you put your four-gas meter up against the outside door frame or window and get no reading. No gas, right? Nope, your meter could not detect it below 500 ppm. It just could not see it and tell you gas was present.

An explosive gas detector would have given you a faster and lower level warning that gas was seeping out through the frame of the closed window or door. The obvious life safety concern here is, are there dangerous levels of gas in other parts of the building waiting for an ignition source (that will “blow you up”) while you are waiting for a gas level reading? Did your four-gas meter even detect any gas to give you a warning? In this case, your plan A (a four-gas meter) was not good enough.

If there is no life hazard in the locked building—that is, the occupants are out of the kill box (like the collapse zone, the kill box is the area around or in the building where firefighters are likely to be killed if the situation goes bad—in this case, when the gas finds an ignition source)—the strategy is simple: Keep firefighters out of the kill box. Our job is life safety, not find and fix—that is the utility or plumber’s job. Many utilities have a procedure for the locked building situation. It calls for tactical withdrawal of all firefighters, the utility remotely shuts off the gas and electric service, and together they wait for it to vent down to safe levels on its own.

(1) Crack a window or door and use your explosive gas detector to determine if natural gas or propane has been released into the locked building. (Photo by author.)

These utility procedures assume there may be higher levels of gas in other parts of the building. This is an improvised explosive building: It contains explosive gas, ignition sources, and oxygen. Just add an ignition source for the action to speed up; it may take hours. If the building explodes while you are in the kill box, your life will be changed or over in a microsecond. Waiting is the best strategy here.

What if someone may be inside the building? Clearly, this is a possibility, so should we, like in a fire situation, force the door to this improvised explosive building and search it? Before we immediately risk firefighters, here are a couple of tactical considerations. First, have you ever heard of any person who was asphyxiated by natural gas or propane? CO, sure, but not these gases. This is because the odorant makes people sick at very low levels. They are forced to self-evacuate long before explosive or immediately dangerous to life or health (reduced oxygen) levels are reached. The Centers for Disease Control and Prevention reports that students accidently exposed to 4 ppm of the odorant (methyl mercaptan) experienced headaches and nausea after several hours. These numbers indicate that humans are very sensitive to the odorant and will produce noticeable symptoms at very low levels. Recall the LEL is 50,000 ppm.1

Some utility workers have been asphyxiated on the job, likely trying to make repairs or conduct operations in high-gas environments without adequate breathing apparatus or air monitors. There is a growing trend for utility workers to wear oxygen or four-gas monitors to prevent these situations.

RELATED FIREFIGHTER TRAINING

Improving Response Procedures to Natural Gas Emergencies

Natural Gas Emergency Strategy and Tactics

Tactical Procedures for Responding to Natural Gas Emergencies

In this locked building scenario, the risk to firefighters (explosion) is high if significant gas has accumulated in the building. One ignition source—a thermostat clicks on, the telephone rings, the hot water heater or boiler comes on—and there could be an ignition/explosion that will likely kill your firefighters. They have no plan B, so the risk is high.

What if there is a person inside that locked building who could not get out, like a disabled patient? The questions the incident commander must ask are, “How much risk should I put my firefighters in for a possible rescue? Is there anything I can do to determine the odds of a life in danger in the building? If the person is bedridden, for example, has the family left him alone in the house/apartment? Likely not, but there are no guarantees.

Remember, this is not a fire-based search scenario. You have some time, and there are some judgment calls to make. Ask neighbors and responding police officers and look for clues as to whether someone may be home. Are they vacationing out of town? Are the police watching the house while they are away? Are there cars in the driveway? Can you get the utility to shut down the ignition sources (gas and electric service) before the search? Can you contact the homeowner and ask if anyone is inside? This will minimize but not eliminate the explosion hazard. Clearly, you may have to risk firefighters to save the civilian but consider the above options and odds before hastily and often needlessly risking firefighters. How many line-of-duty deaths occurred on searches when no one was inside—only firefighters?

Endnote:

1. Managing Hazardous Material Incidents (MHMI). Volume III. Agency for Toxic Substances and Disease Registry (ATSDR). 2001. Atlanta, GA: U.S. Department of Health and Human Services, Public Health Service.

What Your Training Didn’t Tell You

Relying solely on a four-gas monitor, as most departments do, is dangerous. A typical four-gas monitor has the following sensors: oxygen, carbon monoxide, hydrogen sulfide, and what we typically call the LEL sensor (the combustible gas sensor). Your training on it was probably minimal at best. Thorough training includes hands-on use of the instruments you are going to use to detect explosive gases at emergencies in a training environment.

Using simple tabletop props, you can see how long it takes your instrument to display gas concentrations and alarms using real gas, how long it takes to recover, and other key traits of your specific meter. You will see, use, and experience cross sensitivities and other critical facts you need to know in the field. You will see what your meter display reads at 100% LEL and what you have to do to get it functioning again. Read the manual that came with it to answer these questions. In short, you will become familiar with the strengths, weaknesses, and limitations of your tools.

(6) MOS-based instruments can provide early warning of natural gas that is migrating into subsurface structures and may find a path into nearby buildings.

(7) A plexiglass home model and a container of natural gas can provide an excellent tabletop training aid that will show your meters’ strengths and weaknesses.

(8) A firefighter trains with a four-gas/combustible gas indicator that has an MOS built into it and sees the red alarm screen.

The four-gas monitors are personnel monitors for personnel protection. They are designed not to find explosive gases but to monitor the air where the person is working or entering a confined space. We use them as explosive gas detectors. They alarm at levels to ensure compliance with confined space regulations. Typically, there is a low alarm at 10% LEL and a high alarm at 20% LEL. Your SOPs must set action levels when you are metering explosive gas levels for life safety. You have an instrument in your hand that will give you a decisive number, just like a clock.

The most common explosive gas sensor type in the four-gas monitor is a catalytic bead sensor. Air is brought into the sensor bowl, where it contacts a catalyst that allows it to burn below its LEL. This heats a small wire coil, and the electrical resistance is raised in this wire from the heat. This resistance is compared to a similar coil without the catalyst, which obviously is not heated by burning explosive gas, and given to you as a percent LEL.

These sensors (the catalyst) are very sensitive to certain common chemicals, which can poison the sensor, destroying it. Some examples of potential poisons are lubricants, silicone, and some adhesives. Keep the gas detector away from cleaning products (including the leather and vinyl cleaners often used in the rigs); seals for gaskets; polishes; cosmetic or medicinal hand creams; caulking; and tetraethyl lead in gasoline and most lubricants.1 Do not “test” or train with this instrument using the exhaust pipe of your chief’s car.

The 500-ppm low detection level (1% LEL) is theoretical, determined in a laboratory under ideal conditions (no wind, no air currents, steady temperatures, etc.) In the real world, your meter may not react and see down to 1% LEL with accuracy because of air currents diluting the sample it is testing. Natural gas is lighter than air; propane is heavier. Are you holding your meter over your head when looking for natural gas and holding it near your feet when looking for propane? That is where the highest concentrations of these gases will be.

Most four-gas meters use a catalytic bead sensor to detect combustible gases. These are very good sensors for many applications, but they have a blind spot for explosive gases. At low ppm, catalytic bead sensors cannot distinguish between sensor noise and actual gas detection. To eliminate erroneous readings, software has been incorporated to prevent the meter from responding until concentrations reach about 2,000 to 4,000 ppm. This causes the blind spot at low concentrations and is the reason the smell of gas may be evident before the detector responds. Using an MOS with the four-gas detector solves this problem.

Most manufacturers provide two models: One is an explosive gas leak finder that will not alarm at the Occupational Safety and Health Administration (OSHA) standard 10% LEL, so it must be used with a four-gas meter that will alarm. The other model is designed to alarm at the 10% LEL to adhere to OSHA standards. Explosive gas detectors with MOS that alarm can be used without another meter.

It is important to be aware of the T90 time for your detector—the time it takes for your instrument to read 90% of the actual concentration. Read the directions for your meter for the T90 time for your instrument. It is likely that in the real world you may not see a 1% LEL reading on your four-gas meter until the actual concentration in the area could be as high as 3,000 ppm. Each instrument can react slightly differently.

Using two technologies to detect, measure, or identify hazardous materials (solids, liquids, and gases) is a common and nationally accepted best practice. Using the four-gas meter in combination with an explosive gas detector (with MOS) ensures we can detect low levels of explosive gases for maximum safety for our firefighters and efficiency for those we are sworn to protect.

Endnote:

JERRY KNAPP is a 44-year firefighter/EMT with the West Haverstraw (NY) Fire Department and the author of House Fires (Fire Engineering). He is a training officer with the Rockland County Fire Training Center and chief of the hazmat team and a technical panel member for the Underwriters Laboratories research on fire attack at residential fires. He is the author of the Fire Attack chapter in Fire Engineering’s Handbook for Firefighter I and II and has written numerous articles for Fire Engineering.