Split-Pipe Simulator Aids LPG Training

features

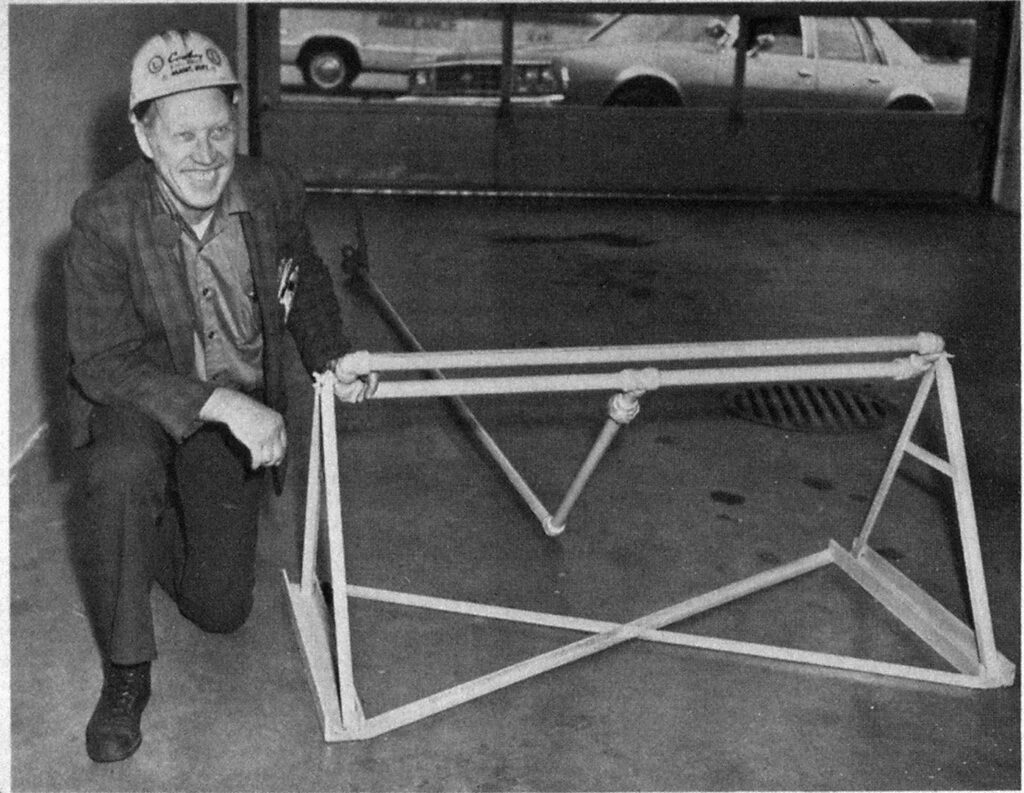

Cudahy, Wis., Fire Department photos

Staff Correspondent

A simple device for training in LPG fire fighting was demonstrated to the Wisconsin Society of Fire Service Instructors at its Milwaukee conference last September 24.

Termed a “split-pipe demonstrator,” the device was developed by Elden McAtee of the Ladish Corp. in Cudahy, Wis., working with Captain Robert Sklander of the Cudahy Fire Department. McAtee, chief of the Ladish Industrial Fire Brigade, has worked with LPG for 30 years.

“Many of these fires,” explained Sklander, “occur because of a split in a pipeline under internal pressure. Tanks or headers rupture by opening up a long narrow crack or split. This device simulates that kind of thing much more realistically than just an open burner or flare.”

Construction of device

The discharge “nozzle” of the splitpipe consists of a closed loop of 1-inch pipe about 6 inches wide by 4 feet long, made from straight lengths joined by 90-degree elbows. Welded to the short ends of the loop are 3/8-inch bolts, which serve as axles that pass through holes in a supporting rack. Rotating these axles and tightening wing nuts on the bolts permitted turning the nozzle structure through various positions during initial trials of the unit.

A 1/32-inch sawcut through the wall of the pipe along the outer surface of one long side of the loop allows gas to escape. Propane is fed to the unit from a remote tank via high pressure hose into 13 feet of pipe attached to a tee in the other long side of the loop. Because it must flow out to the ends of the loop and around before reaching the slit, the gas rushes out uniformly along the full length of the slit rather than at just one point.

When the escaping gas is ignited, the thin but wide flame duplicates the effect of an actual rupture in a propane pipe or header. Ten feet away in the supply line is a quarter-turn shutoff valve. In a training exercise, the objective for fire fighters is proper approach behind open fog nozzles until the valve can be reached. Closing it stops the fire.

“When we first tried it out,” added Sklander, “we had the loop turned so the slit was parallel to the ground. But we found that a wind change could hit the flame and blow it back toward the supply. Safety in training is of the utmost importance, so we tried other angles and settled on a 45-degree upward direction. This permits the flame to maintain its direction fairly even with drastic changes in wind direction.”

McAtee has also developed a “christmas tree” device consisting of a 2-inch pipe, 10 feet high, that branches into a cluster of 18 1/2-inch pipe stubs with nozzles at their ends. This is used in the same way. Fire fighting crews are trained to approach the ignited gas, its cone of flame throwing radiant beat 50 yards, and close the supply valve under cover of fog.

The material for the split-pipe demonstrator, put together in the Ladish shop, cost less than $100. The most expensive item was the Maxon-Okadee shutoff valve.