COLLAPSE SEARCH AND RESCUE OPERATIONS: TACTICS AND PROCEDURES

Part 3: Box Cribbing

This article, the third in a series on collapse search and rescue operations (see Parts 1 and 2 in the May and June 1993 issues of Fire Engineering), begins a discussion on cribbing techniques as part of an ongoing discussion on collapse voids, hazards and safety, and shoring techniques.

After the void team officer has determined that the void is safe to enter, the void entry firefighter enters the area and starts to clear any loose debris. As debris removal continues and the void opening is expanded, the void must be safely supported, since the threat of secondary collapse is always present. Box cribbing is the strongest, quickest, and most stable ty pe of shoring you can erect. As a rule of thumb, if the height of the void opening is three feet or less, use the box cribbing. If die opening is more than three feet high, you have the option to use vertical shoring. In some cases, the vertical shore can be erected more quickly than a large crib and will leave you more room within which to work.

INITIAL “QUICK” SHORING

As the debris is removed from the void and after the area to be cribbed has been determined, a “quick” shore should be installed. By placing a screw-type or pneumatic-type shore with a swivel-type locking collar, you will afford the rescuers a degree of safety while the crib is being erected. When using these shores, the main function will be to support the existing structural elements (generally beams or joists). Directly supporting these elements will be the most effective method; however, this is not always possible. If this is the case, then solid blocking can be used with these shores to help transfer the load stresses to adjoining structural elements.

Place the quick shore near the area to be cribbed and tighten up enough to firmly support the load. Do not overtighten and lift the material—this could cause debris to shift and possibly could cause a secondary collapse. Anchor the shore in place to guard against any accidental contact that may knock the shore loose. This shore must be monitored continually while the crib is being erected to make sure the shore is still supporting the load safely.

MATERIAL AND CAPACITIES

In the typical brick-and-joist or wood-frame construction, four-byfour-inch lumber will be sufficient to shore up the void between two floors. Six-by-six-inch lumber also can be used, particularly in much larger buildings and in those with more substantial structural elements, such as steelor concrete-erected buildings. Always use good-quality, construction-grade lumber. Douglas fir and southern pine make excellent cribbing materials. Spruce and hem fir are softer materials and have less loadbearing capabilities; they should not be used if possible. Hard woods such as oak and maple, although excellent for strength, are heavier and can crack under strain, thus reducing their effectiveness. The hard woods give little advance warning of material failure. They will split suddenly through their axes, causing total failure and giving rescuers very little time to evacuate the void. On the other hand, softer woods tend to crush slowly and give some type of advance warning that the lumber is reaching its failure point. You then have the option to recrib with more lumber or to vacate the void, a decision that will be made on the scene by the void officer. A “two-by” crib (each layer of cribbing is called a tier. The name of the crib is based on the number of pieces of shoring material per tier. For example, if you use two pieces of four-byfour per tier, it is a “two-by” crib; if you use three pieces, it is a “three-by” crib, and so on) erected of goodgrade, four-by-four-inch lumber can withstand more than 12 tons of pressure, and a two-by crib of six-by-sixinch material will withstand more than 30 tons of pressure.

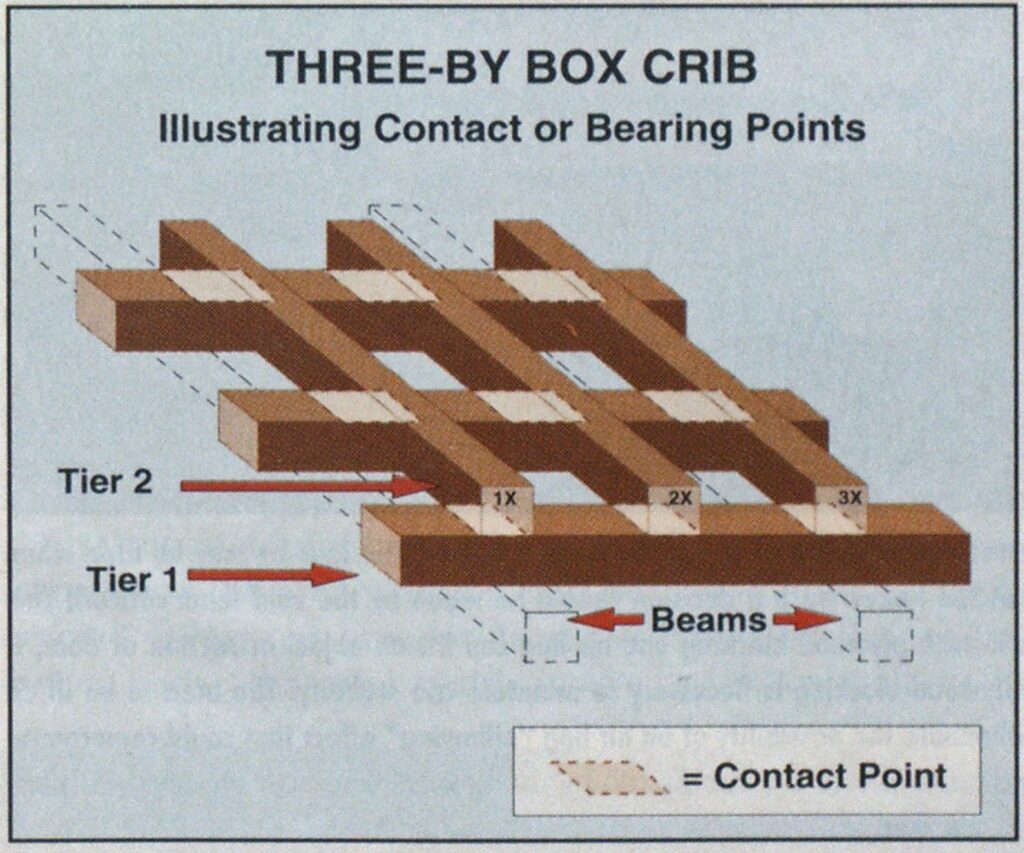

A crib’s capacity to support weight is based on its bearing points, the areas of contact from one tier of cribbing to the other. A two-by crib has four bearing points, regardless of how high it is stacked. A three-by crib has nine bearing points. This type of crib generally is the best one to erect: It is twice as strong as a two-by crib and yet uses only two additional pieces of lumber (six instead of four), and it takes very little time to add the additional pieces of material. The solid crib is the strongest and most stable of all the cribs; however, it uses substantially more material and takes longer to erect.

To reach the maximum capacity of the material, you must have full bearing on whatever size lumber it is. It may be necessary due to space and access considerations to construct the crib on an angle. Full capacity and stability are realized with an angled box crib so long as full bearing on each member is maintained. It also is possible to create a box crib-air bag ensemble. A solid crib should be used with an air bag; under no circumstances should an air bag be used with less than a four-by or three-by crib. (See photos.)

STABILITY

Box cribbing’s stability is excellent. Depending on the type of cribbing being erected, the height of the crib can be as much as two to three times the width of the crib before it becomes unstable. The two-by crib is the least stable, because it has the least number of contact or bearing points; while the solid crib is the most stable, affording the greatest surface area contact (the most contact points) between tiers.

The major physical force that will be applied to the crib is that of compression. When the crib is erected on an angle, which happens quite often, some lateral stress also will Inapplied to the crib. When the collapsed floors you are supporting are on an angle, try to erect a level shore. If necessary, shim or wedge the bottom and the top of the crib to help achieve this. In this way, the crib can remain stable and also transfer the weight evenly through itself, thus utilizing its full load-bearing capacity.

(Photos by author.)

SAFETY FACTORS

As alw ays, the safety of rescuers and victims is of paramount importance. One of the most important considerations when erecting the box crib is to ensure you have determined your route for removing the victim. Make sure the crib will not close off that route or hinder extrication procedures. If you are installing multiple cribs, make sure you constantly check that each crib remains tight.

It also is possible for debris removal to be conducted above the void operation. Recheck the crib as the weight is taken up off the shore, since the crib will loosen from the pressure relief. When you are erecting the crib, make sure you use the proper-size material. If in doubt, go to a larger-size crib or to heavier material. Always play it safe; do not be afraid to “overshore.”

When erecting the cribbing, always shore from a safe area into an unsafe one, giving yourself a stable and safe position from which to work. When erecting the crib, it is imperative that you do not put any part of your body—hands, fingers, etc.—between the crib and the point of contact. If debris shifts or a secondary collapse occurs, you could be pinned and become one of the victims. Use a piece of lumber or a wedge to slide elements of the crib into place w henever there is a possibility of bodily contact. This is particularly important as the crib reaches its load point and you’re putting the final piece into place.

Store the lumber you plan to use in a well-ventilated area. This will help keep the material in the best condition for use. Try to keep the lumber dry and do not paint it, as this masks rot and deterioration that can make the lumber unsafe for use. Do not use treated lumber; the chemical treatment lowers the material’s compression strength and promotes splitting, checking, and warping, making the lumber useless for rescue purposes.

Before you carry out any void operations, conduct a six-point survey of the area. Examine the top, bottom, and all four sides. Check the area above for any loose or hanging debris and for signs of possible secondary collapse. Check all sides of the void area for possible additional access to the victim’s location and for the stability of the collapsed area. The bottom survey is also very important: If you are going to attempt to crib or shore or to carry out extensive operations, you must examine the area underneath the collapsed floor. If possible, erect a vertical shore under the void operation for added stability and safety. This will help transfer any additional impact loads to stabler elements and will absorb any stresses created by the operation.

STEP BY STEP

- After determining crib placement, clear the area where it will be erected. Clear an area at least 18 inches wider than the width of the

- crib —this will keep any debris from falling back into your way and also will enable you to slide the shore back and forth several inches to get a good fit. It is important to tty to determine the location of the floor beams and to support at least two of them. In the case of larger voids with less debris, it may be possible to catch more than two beams without interfering with void access. By catching at least two beams, the crib will be more stable and will be able to transfer additional impact loads more evenly through the flooring. If only one beam is supporting the crib, it may not be enough to absorb the load stresses and could fail. When spanning two beams, your cribbing must be long enough to extend beyond the contact points.

- For the best stability, it generally

- is better to lay the first tier at a right angle to the floor beams, catching as many as possible. As you assemble the shore, bring the edges of the second tier flush with the outside face of the bottom tier to maximize contact surface and, therefore, stability. An exception would be in a case where the first tier members span and overlap two beams; in such a situation, set the bearing points of the crib over the beams.

- Toenailing tier to tier is done to stabilize the crib unit as it is being erected —it has nothing to do with a crib’s strength to withstand a load. It should be performed only when there’s adequate room and with a pneumatic nailer to minimize vibrations. At this time, do not nail the bottom tier to the floor; you want to be able to slide the crib from side to side slightly for ease of inserting wedges. Nail each successive tier to the one below it by toenailing in at least two places and wherever possible. This will lock the crib together and make it function as one integral unit.

- Have sufficient wedges and shims sent into the void. Ibis will ensure that, as the crib reaches the beams of the floor above, you will be able to solidly block out to the beams and correctly transfer the loads from above. At this time, shifting the crib slightly will help the wedges fit properly and will make it a little easier for a good fit to occur. At this time, nail the crib to the floor and to the ceiling above. Constantly monitor these cribs as you install them so they do not loosen; if this occurs, the crib will have to be retightened.