What Is a Fire Wall? It Depends On Variety of Construction Designs

“A rose is a rose is a rose,” and the same is true for a fire wall. The problem is that the rose comes in many colors and varieties. The same is true for fire walls.

Many codes mention occupancy separations, area separation walls, draft stop partitions, fire partitions, fire barriers and fire walls. Each code normally defines the meanings of the terms. However, this definition usually covers only the fire resistance rating.

The Uniform Building Code addresses only the fire resistance ratings of walls and partitions. This code does not define a fire wall or partitions. Fire resistive construction is defined as construction to resist the spread of fire. Many factors are left unanswered.

The Uniform Building Code does define “fire separation” as construction of rated fire resistance or the maintenance of clear area to resist the spread of fire.

Structural stability

The Building Officials & Code Administrators (BOCA) code does define fire walls as walls having structural stability under fire conditions to allow collapse of construction on either side without collapse of the wall. The National Building Code follows this basic definition.

Outside the Factory Mutual System, the above type of wall is seldom found. Admittedly, the codes do not specify design criteria, but losses throughout the country show that code-built fire walls are not meeting the code definitions. The Factory Mutual System in 1976 decided to issue technical data sheets, numbered 1-22 and 1-23, outlining the criteria for fire walls and protection of openings. Admittedly, these are not code written, but they do provide the base for a sound design of a stable fire wall.

Fire walls or space separation became the last line of defense in catastrophic losses. The Factory Mutual System has designated these walls as “maximum foreseeable loss” (MFL) walls.

Building codes specify fire walls because of occupancy hazards or occupancy classification changes. The insurance industry specifies fire walls because of occupancy hazards or dollar values exposed to a single fire. The insurance industry must look at dollar exposures that not only include physical damage but also business interruption exposures. The loss of all production facilities at one location could affect production at several plants across the country.

Protection Mutual Insurance Co.

Must resist collapse

The key element, as defined in the BOCA Code, is stability and strength. The wall must be intact when construction collapses on either side. A wall built to FM standards must be able to resist a lateral loading throughout it’s entire height.

The fire resistance rating for an interior FM MFL wall is generally four hours. An exterior wall is generally of three-hour fire resistance. The fire resistance could be less for the interior wall if the exposing hazard was of a low hazard industrial operation. The designer’s responsibility is the selection of materials that will meet this requirement.

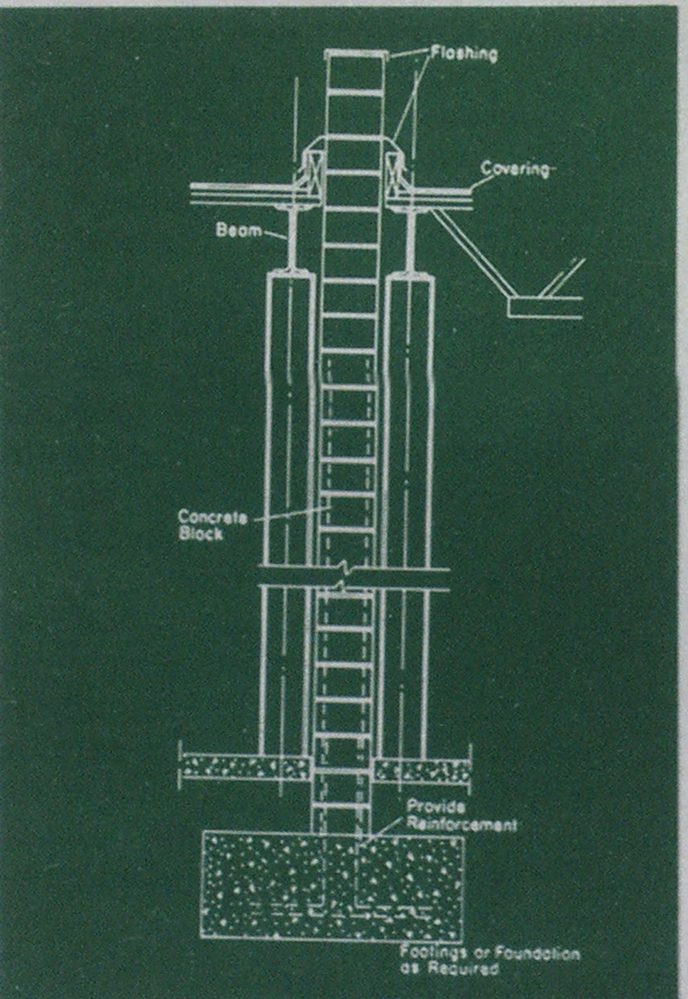

Most walls today are built of concrete block. These walls are generally 12 inches wide. Concrete blocks used should consist of more than 70 percent solids. There are 98 companies that make concrete blocks with certified fire resistance ratings as listed in the “Fire Resistance Directory,” 1979 edition, published by Underwriters Laboratories.

Protection Mutual Insurance Co.

Once stability has been designed into the wall, any opening in the wall must be protected. Openings in fire walls are classified as A, B, C or D openings. Automatically closing fire doors with ratings matching the opening classification must be provided. Generally on FM MFL walk, all openings are class A and require class A rated doors.

Factory Mutual experience has shown that openings permitting vehicle passage are subject to mechanical damage. Because of the continuous mechanical damage to such openings two class A rated fire doors are required to be installed at each such opening. This ensures some degree of reliability of one door being in satisfactory operating condition.

Single class A rated doors are satisfactory at all other openings (personnel passages and conveyor openings) unless double fire walls are built. Then two doors are required. Conveyors of all types need special handling and may need special door packs to ensure the integrity of the fire wall.

Three basic types

As stated earlier, fire walls come in various varieties. There are three basic types of walls: cantilever (free standing), tied, and one-way. The type of wall generally referred to in the codes is a cantilever wall. This type is probably the most difficult to design because of penetrations and heights.

Protection Mutual Insurance Co.

Cantilever walls have several factors to consider in their design. The clearance between the wall and the steel frame should be not less than 1½ inches (3.8 mm) or more than 7 inches (178 mm). If the steel frames on each side of the wall are not in line horizontally or vertically, then at least 7 inches (178 mm) of clearance is needed or structural reinforcing is necessary to prevent damage to the wall during initial steel expansion due to extreme heat.

Tied fire walls are fastened to and usually encase members of the steel building frame. The pull of the collapsing steel on the fire side of the wall must be resisted by the strength of the unheated steel on the other side. These walk should preferably be located at the center of strength of the building unit. Exposed steel on either side within a foot of this wall should be fireproofed.

Computation of pull

To compute a reasonable value for maximum horizontal horizontal pull from the collapsing truss or beam, use the formula:

Where: H = horizontal pull, lb (kg)

W = dead load of the roof per linear unit of truss or beam, lb/ft (kg/m)

L = truss or beam span, ft (m)

S = sag that may be assumed as 0.07L or 0.09L, ft (m)*

H=WL2/8s

One-way fire walls are tied to the building frame on only one side and are entirely independent of the frame on the other side. This type of wall is usually used to separate high hazard fire areas from low hazard areas.

Double fire walls consist of two oneway walls back to back. Each of these walls should have at least a three-hour fire resistance rating. If there is no separation between the walls, a layer of building paper or other suitable material should be used to prevent bonding between the walls.

Expansion joints

There are several items common to all walls that must be considered. Fire walls should have expansion joints in line with those of the building frame. The break should be not larger than 2 inches (50 mm) and filled with soft, noncombustible material, such as rock wool held in place by sliding steel cover plates.

To prevent irregular cracking, control joints can be provided at 100 to 150-foot (30 to 46 m) intervals. These can be made by scoring the surface of the block with a saw. After six months, the joints should be checked and filled with an inorganic filter if they exceed 1/16 inch (1.6 mm).

Reinforcing mesh should be laid in every second horizontal joint of concrete block walls for stiffening and shrinkage control.

Penetrations through fire walls can quickly breach the wall’s security and should never be permitted. If penetrations are required, they should be kept to a minimum. The most desirable locations for penetrations is within 3 feet (1 m) of the floor. Cantilever walls are the easiest walls to be damaged by penetrations when collapse of the building occurs. Heating, ventilating and air conditioning ducts should be arranged with a slip joint on each side of the wall as near to the face of the wall as possible. One 3-hour fire damper should be fastened to the wall.

*0.07L should be applied to open-web trusses and 0.09L should be applied to solid-web beams.

Sleeving of penetrations

Pipes, conduits, and cables four inches and larger penetrating fire walls should be sleeved with 1 inch (25 mm) of clearance and packed with mineral wool and covered with a loosely fitting metal collar on each side of the wall.

There should be no flanges, couplings or tight hangers on the pipes within 6 feet (1.8 m) of the wall. Concrete block walls should be provided with mesh reinforcement above and below the pipes. For cable penetrations, provide at least 6 feet (1.8 m) of sag on each side of the wall. If any cables have combustible coverings, noncombustible materials should coat them for 3 feet (1 m) on each side of the wall.

Parapets, end walls and angle exposures must be reviewed and considered On buildings with combustible roofs, parapets should be no less than 30 inches (176 m) high. On buildings with steel decks with a class I rating, a 12-inch (.30 m) parapet is sufficient. The roof surface on either side of the wall for 25 feet (7.6 m) should be gravel or slag. End walls should be blank for 3 feet (1 m) on either side of the fire wall in perpendicular end walls. If a fire wall ends at a place other than a perpendicular exterior wall, consideration must be given to angle exposure. Generally fire walls are carried into directions for at least 20 feet (6 m) at junctions with angle exposures.

Remember a rose is a rose is a rose, but a fire wall is not a fire wall unless it has stability and will not permit an unfriendly fire beyond it’s confines.