Modern turnout gear was designed-primarily-to provide protection from heat and flame exposure. And statistics now show that this works! Line-of-duty deaths (LODDs) continue to show an encouraging downward trend. The 64 LODDs recorded in 2014 represent the second lowest since the National Fire Protection Association (NFPA) study began in 1977. Of those 64 LODDs, only three percent were caused by burns. The leading cause of LODDs in 2014 was overexertion/stress/medical (at 58 percent). All but two deaths in this category were characterized as “sudden cardiac death.”

Recognizing this risk, many innovative personal protective equipment manufacturers are looking at ways to reduce the weight of equipment firefighters wear in the field without compromising performance attributes. Self-contained breathing apparatus, helmets, and boots are getting lighter, and so is turnout gear. The challenge with making lighter-weight and more flexible turnout gear composites is maintaining high levels of thermal and flame protection. PBI Performance Products, Inc. has accomplished this through its PBI Lightweight Gold™ System.

Without compromising the protection firefighters expect from their turnout gear, this new system was designed specifically to combat the heat-stress issues that firefighters face every day. Expanding beyond just the outer shell, the PBI Lightweight Gold™ System now brings the high-performance properties of PBI fiber to all layers of the structural ensemble. By adding the thermal stability properties of PBI fiber, this system reduces the weight of each layer by about a half-ounce per square yard as compared to traditional structural ensembles.

Clothing comfort and its impact on heat stress are a combination of many factors; fabric weight is just one of them. Another aspect, which is sometimes more difficult to quantify objectively, is flexibility. If you are constantly fighting your gear to move, you’re creating more heat stress. The more force required to flex the gear means more work from the muscles to move in the gear. More work from muscles leads to more body heat generation.

To evaluate this stiffness property, PBI Performance Products commissioned the services of North Carolina State University’s Physical Testing Lab. There, the PBI Lightweight Gold™ System was tested for stiffness according to ASTM D4032. In this test, fabrics were pushed through a uniform orifice, and the force required to do so was measured. Stiffer fabrics require more force to be pushed through, just as stiffer fabrics require more force (i.e., heat-generating work from muscles) to move in a garment. Comparing results of fabrics with this test allows you to quantify differences in fabric stiffness.

On average, the PBI Lightweight Gold™ System requires only 14.2 pounds of force in this stiffness test. Compare that to a very common traditional-weight turnout gear composite with all aramid-based fabrics, and the results are clear: With a required force of 26.7 pounds, the common composite is nearly twice as stiff as the PBI Lightweight Gold™ System. This equates to greater ease of movement in the gear and, ultimately, lower heat stress.

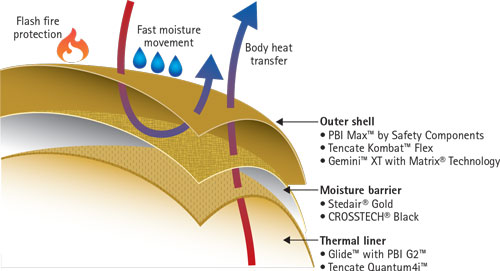

Firefighters can choose from the following components of the PBI Lightweight Gold™ System:

Outer Shells:

- PBI Max™ by Safety Components Tencate Kombat™ Flex.

- Gemini™ XT with Matrix® Technology.

Moisture Barriers:

- Stedair® Gold.

- CROSSTECH® Black.

Thermal Liners:

- Glide™ with PBI G2™.

- Tencate Quantum4i™.

This system provides firefighters with the ultimate protection at a much lighter weight without compromising protection. Laboratory test data can go only so far to tell the story of the improved comfort offered by this system. The real proof is in the field; wear the gear, and compare it to your current gear.

BRIAN SHIELS is the senior development engineer for PBI Performance Products, Inc. He sits on technical committees in the National Fire Protection Association, ASTM International, and the American Association of Textile Chemists and Colorists. He has worked for more than 10 years in testing and development of protective clothing and equipment. He has a BS degree in chemistry and an MS degree in textile chemistry.

Fire Engineering Archives