By ALLEN MAPLES

One of the biggest challenges that firefighters face when responding to an emergency scene is the impact of heat stress on their ability to function effectively. Gore offers certified moisture barrier technologies that provide the highest levels of breathability across the broadest range of conditions such as advancements like the CROSSTECH® black moisture barrier. However, in high-heat stress situations, the body can produce more heat than it is able to lose, which increases the body core temperature. Human studies have shown that what might seem like small increases in body core temperature can impair decision making, muscle control, and hearing accuracy, eventually leading to heat exhaustion, all of which can compromise firefighter safety and effectiveness.

National Fire Protection Association (NFPA) 1971, Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting, currently uses the Total Heat Loss (THL) test to evaluate breathability of turnout composites. This test is conducted in a relatively moderate environment (i.e., 77°F and 65 percent relative humidity)-an environment that does not represent all of the conditions that firefighters actually encounter. When evaluated in environments beyond these moderate conditions, products start to react differently. For example, two composites that had similar THL numbers can perform much differently in warmer conditions or in those with low-level radiant heat such as heat from the sun, a hot roadway, or a tar roof that needs to be vented. As a result, Gore continues to focus its research on developing new technologies that help reduce the impact of broader fireground conditions on body core temperature.

| Figure 1. The GORE® PARALLON™ Liner System |

|

| Figure courtesy of W.L. Gore & Associates. |

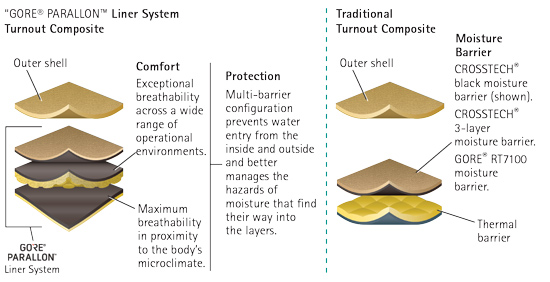

Although CROSSTECH® moisture barriers provide the highest level of breathability in traditional turnout gear, the new GORE® PARALLON™ liner system increases the breathability of turnout gear beyond what is available in today’s conventional NFPA 1971-compliant turnout gear. It achieves the highest breathability across a broad range of conditions in which firefighters operate, helping to reduce the physical strain of working in turnout gear and minimizing potential increases in their body core temperature.

At the same time, this new technology also enhances thermal protection by helping to address a significant issue: water. When water (particularly sweat) finds its way into the turnout gear layers, it can change the gear’s thermal protection. Wet gear simply does not perform the same as dry gear. The new GORE® PARALLON™ liner system reduces the ability of water to penetrate the composite layers of the gear and, when moisture does get into the composite, the liner system manages its impact better. When tested at ordinary fireground heat exposure (i.e., 0.2 cal/cm2sec), wet conventional gear lost 34 percent of its thermal protection compared to when it was dry. In the same test conditions, the GORE® PARALLON™ liner system lost only four percent, remaining relatively unchanged after it became wet.

To provide this new level of breathability and thermal protection, Gore completely reengineered the turnout composite by replacing the conventional thermal liner/moisture barrier combination (Figure 1). The inner barrier of the GORE® PARALLON™ liner system has been optimized to deliver the highest breathability in its position next to the body, and the other layers in the system provide high breathability across a wide range of operational environments. The proprietary technologies incorporated into this unique multibarrier configuration enable the GORE® PARALLON™ liner system to deliver more consistent thermal protection.

The GORE® PARALLON™ liner system is certified with a wide range of available outer shells, enabling fire departments to choose what works best for them.

ALLEN MAPLES is a product specialist in W. L. Gore & Associates’ Fire & Public Safety team. He has been with Gore for 22 years. Maples focuses on research and new product development for fabric technologies. Prior to joining Gore, Allen received a bachelor of science degree in engineering and master’s degrees in science and business administration.