By Jeremy Rifflard

Swing stage, or two-point suspended, scaffolding refers to scaffolding that travels up and down two suspended cables. This type of scaffolding is erected to Occupational Safety and Health Administration (OSHA) standards, Title 29 of the Code Federal Regulations (CFR) Part 1926, Subpart L. Requirements for swing stage scaffolding include platform construction and load requirements, outrigger beam requirements, use of primary anchors for the outrigger beams, backup anchors for the outrigger beams and suspension cables, provision of an independent lifeline for each worker, and the mandatory use of a personal fall arrest system (PFAS). These components must be inspected by a competent person daily and before use [OSHA 29 CFR 1926.451 (f)(3)].

|

| (1) A two-point swing stage scaffold. (Photos by author unless otherwise noted.) |

Understanding the two-point suspended scaffolding components will make responders familiar with what they should see when they arrive at an emergency that involves a full or partial scaffold collapse. You must assess every damaged or missing component when developing a rescue plan. Locate the on-site person, who should be trained to be competent in and familiar with the scaffold assembly.

The Platform

|

| (2) The motor assembly attached to the platform. |

The swing stage scaffold platform is the structure on which the workers stand. The platform deck must be rated for the anticipated load of the workers, tools, and materials and must have railings and a kick plate to prevent tools from rolling off. The platform has rated motors for movement. These motors require electrical power that will move the span from the highest to the lowest point that the platform travels. Modern motors have a leveling sensor that will cease movement if the platform exceeds a number of degrees from being level.

The electrical components must be grounded to prevent electrocuting workers. Swing stage scaffolds have become stuck on the sides of buildings simply because the power cord became disconnected or a breaker switch was tripped. When developing a plan to resolve the situation, look for the simplest fix first.

|

| (3) Counterweights can be stacked on outriggers as a primary anchor for swing stage scaffolding. |

Cables, Cantilever Beams, and Tieback Anchors

Cantilevered beams hold the suspension cables over the side of the building. The beams are part of the primary anchor system and are typically secured using one of several methods. Outriggers may be secured with parapet clamps or stacked counterweights. The counterweights must be four times the tipping moment load. They cannot be a flowable material such as sand, gravel, or water [OSHA 29 CFR 1926.451 (d)(3)(ii)].

|

| (4) A parapet clamp is the primary anchor for this cantilever beam that anchors the wire rope. All anchor systems must be tied back with a second inline anchor. |

The tiebacks should be in line with the beam and without slack. A single tieback must be installed perpendicular to the face of the building or structure. Two tiebacks installed at opposing angles are required when a perpendicular tieback cannot be installed [OSHA 29 CFR 1926.451(d)(3)(x)]. The secondary anchors are usually parapet clamps, cornice hooks, or wire rope.

The PFAS and the Lifeline

|

| (5) A cornice hook. |

All workers on a suspended swing stage scaffold must wear a PFAS. This system includes a class three body harness that encompasses the waist and shoulders. It also includes a shock-absorbing lanyard attached to the harness with a carabiner and rope grab, which is a device attached to the lifeline that will not move when a downward force is applied to it.

The lifeline must be anchored to a structural component of the building different from where the primary anchor is secured [OSHA 29 CFR 1926.451 (g)(3)(iii)] so that if the primary anchor fails, the falling scaffold will not take the lifeline with it.

|

| (6) A wire rope used as an inline tieback anchor. |

Swing Stage Accidents and Their Rescue Procedures

Swing stage accidents may be one of five categories:

|

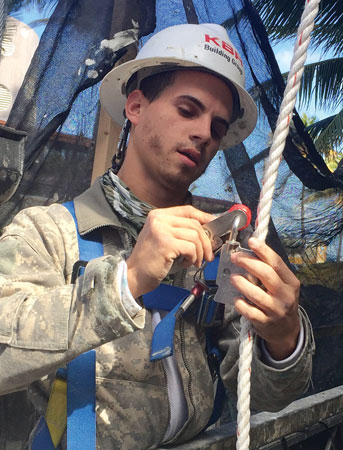

| (7) The worker is attaching his shock-absorbing lanyard to the rope grab on the lifeline. |

Category 1: The worker falls off the scaffold to the ground; he was not secured to the lifeline or the lifeline failed.

Procedure: The worker is on the ground level and can be directly accessed by emergency personnel. Scene safety is a priority. If the worker fell because a primary anchor system collapsed, you may have a 1,000-pound dangling scaffold above the area where the rescuers are providing care. Tools could slide off a leaning platform. Paints, solvents, or materials can pour off the platform. The worker under these hazards must be moved to a safe zone.

![(8) A collapsed scaffold anchor has caused two workers to fall onto their lifelines. One worker fell a great distance, possibly because of slack between the rope grab and the anchor. Designate the area below this 1,000-pound scaffold a no-entry, fall zone. <i>[Photo courtesy of the Fort Lauderdale (FL) Fire Department.] </i>](https://emberly.fireengineering.com/wp-content/uploads/2017/09/1709FE_Rifflard-Scaffold-Photo_8.jpg) |

| (8) A collapsed scaffold anchor has caused two workers to fall onto their lifelines. One worker fell a great distance, possibly because of slack between the rope grab and the anchor. Designate the area below this 1,000-pound scaffold a no-entry, fall zone. [Photo courtesy of the Fort Lauderdale (FL) Fire Department.] |

A hasty, dirty rescue that involves the rescuers rapidly moving the patient to a safer position may be needed. Designate a no-entry, fall zone below the unsecured scaffolding. Establishing barriers with fire line tape will make the off-limit area more visible. After the patient is in a safe area, stabilize the scaffolding by securing it to a structural member of the building with rated rigging. Have law enforcement keep workers and bystanders away from the area until accident investigators can review the scene.

Category 2: The worker is not injured but is stranded on the stalled swing stage scaffold. Usually, the reason is that the motor malfunctioned, the breaker switch tripped, or the power cord became disconnected.

|

| (9) This scaffold has failed at a connection point on the scaffold platform. |

Procedure: No injuries need to be addressed in this scenario. The primary issue is accessing the stranded worker. Gather as much intelligence to formulate your rescue plan. To prevent a risky self-rescue attempt, keep the worker informed of your activities. For example, if the stalled scaffold is a few feet from a balcony, discourage the worker from disconnecting from his lifeline to attempt a jump off the scaffold to the adjacent balcony.

One of the first things that should take place is to evaluate the stranded worker’s PFAS and lifeline. The worker should be wearing the harness, lanyard, and rope grab that is on the lifeline. The upper end of the lifeline should be securely anchored to a nonmovable anchor. If the lifeline is not in place or if the lifeline rope is severely worn, lower a life safety rope to replace the damaged/missing lifeline. Have the worker attach it to his harness.

![(10) Fort Lauderdale firefighters must make this rescue being mindful of the weight of the scaffold. One anchor point has already failed. The failure of the second anchor could shear their ropes if the other anchor fails. <i>[Photo courtesy of the Fort Lauderdale (FL) Fire Department.]</i>](https://emberly.fireengineering.com/wp-content/uploads/2017/09/1709FE_Rifflard-Scaffold-Photo_10.jpg) |

| (10) Fort Lauderdale firefighters must make this rescue being mindful of the weight of the scaffold. One anchor point has already failed. The failure of the second anchor could shear their ropes if the other anchor fails. [Photo courtesy of the Fort Lauderdale (FL) Fire Department.] |

Review all of the options for accessing the worker – replacing a power source, bringing an adjacent scaffold or ladder to the worker, bringing the worker through a window, or using a top-down rope rescue system to pick the worker off the two-point suspended scaffold, for example.

Category 3: The worker has fallen off the scaffold and is suspended by his lifeline. This tipping of the swing stage scaffold could be caused by the failure of a primary anchor, the platform’s breaking in half, a runaway motor on the platform, or the worker’s slipping off the platform.

|

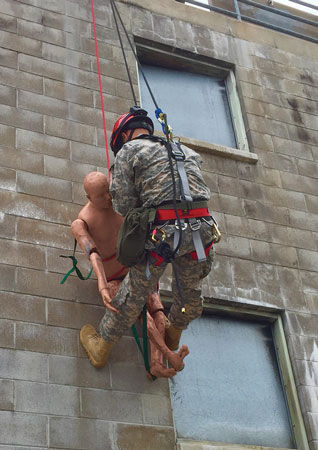

| (11) This Michigan National Guard soldier is practicing a pickoff of a worker who had fallen onto his lifeline. The rescue team is using a top-down rope rescue system. |

Procedure: You have two issues to be concerned about. First, you have a worker in a harness suspended by the lifeline. Second, there may be a scaffold or damaged anchor system above or in the vicinity of the worker.

Persons suspended in a harness for a long time may experience suspension harness syndrome, a condition in which toxins can build in the body distal to where the tensioned harness is reducing blood flow. The release of the harness tension can send a swarm of toxins flowing to the heart and vital organs. Consider medical interventions to reduce the effect of the toxin release. This may include the delivery of sodium bicarbonate or other medications intravenously before the tension is removed from the worker’s harness. Each rescue is unique. Defer to the highest medical authority to determine which drugs should be administered, and when.

|

| (12) Coral Springs (FL) Regional Institute of Public Safety students practice moving a worker with a spinal injury into a Stokes basket. |

If the damaged scaffold system is above the worker, a heavy structure may be dangling above the rescuer and the victim. In a single-anchor failure, often the scaffold has turned from a horizontal presentation to one that is hanging vertically downward. The worker may be clinging onto the platform. Wind may be swinging the scaffold from side to side with the potential to shear the worker’s lifeline or your ropes that are lowering rescuers.

In most situations like this scenario, rescuers need to execute a top-down rope rescue. After rescuer safety, the top considerations in priority order are the following: (a) evaluate the worker’s lifeline to make sure it is protected from rough edges and does not need replacement; (b) secure the unstable anchors or platform assembly without standing, kneeling, or adding weight to the platform; and (c) rescue the worker in a safe, timely manner with a redundant rope rescue system.

|

| (13) Each rescuer needs an independent lowering rope and belay rope. This can be confusing. Using ropes of assorted colors will make it easier to identify a specific rope that needs tension or slack. |

Category 4: The worker is injured on the scaffold platform, and the swing stage scaffold cannot be moved to ground level. Commonly, this occurs because the scaffold platform or one of the primary anchors had a partial failure. The jolt from movement has injured the worker.

Procedure: This scenario presents a worker who is injured and lying on an unstable, mostly horizontal platform. The best patient packaging device for spinal or femur injuries may be the Stokes basket. It is vital to resist the urge to have rescuers stand on the platform during the patient-packaging operation. The additional weight could overload the anchors and cause a catastrophic collapse of the system. The weight of the falling platform can easily shear rescue ropes and lifelines.

|

| (14) A multipurpose device used to lower the rescuer. |

Lower one or more rescuers near the patient and platform. The rescuers will be working from their ropes, being cautious not to weight the platform. Lower the Stokes basket on main and belay ropes. Attach the patient to a belay line and then carefully relocate him into the Stokes basket. Lash the patient to the Stokes basket with webbing. After the patient is secured, lower the basket to the ground or another balcony.

Category 5: The scaffold has been energized by electrical wires.

|

| (15) A brake bar rack used for lowering rescuers. (Photo by Kevin Yannayon.) |

Procedure: The electrified platform is the primary concern. Do not attempt rescue until power is shut down/secured and lock-out/tag-out procedures have been followed. The local electric company should shut down the power. After the scene is safe from the risk of electrocution, proceed with one of the four rescue methods described above.

The Rope Rescue Operation

|

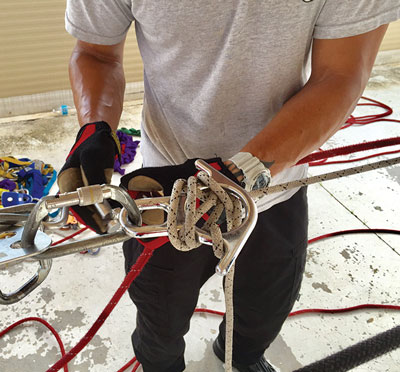

| (16) An 8 plate is used to lock off a rope that is holding a suspended scaffold. |

Rope systems must be anchored to “bombproof” or structural anchors. Do not use the anchors being used by the swing stage scaffold system. These anchors may be damaged or overloaded. Choose a different anchor for your main rope system and for your belay system. If multiple rescuers are being lowered simultaneously, each rescuer will need an independent belay system attached to an independent or bombproof anchor.

During your initial rescue size-up, determine if you will be lowering the worker and rescuer to the ground or if you will be raising them to an elevated position. Raising the rescuer and worker takes training to bring them over the roof safely. In either situation, you may need a haul system to take tension off the lifeline of the suspended worker’s harness.

|

| (17) A tandem prusik belay is used for the rescuer and victim. |

Apply a lowering device to a ½-inch rescue rope that is secured to one anchor. Control the lowering with a bar rack, a multipurpose device, or another rated lowering appliance. Attach a belay device to the second independent ½-inch rope that is secured to a different inline anchor. On the command of the technical rescue team operations officer, the rescuer will be lowered to the level needed to secure the platform or the worker.

If your plan is to lower the rescuer and worker to the ground, a short haul may be needed to take tension off the lifeline onto which the worker has fallen. Be prepared to assemble the haul system before the rescuer goes “on rope” to reduce the time for the total operation. A 3:1 may be a sufficient haul system to raise most personnel. If your rescue team is short of personnel to haul, construct a 5:1 mechanical advantage. After the haul, remove the worker’s lifeline. Convert your system back to a lowering system, and finish the rescue.

|

| (18) Rescuers have backboarded the worker and moved him into a Stokes basket. |

Rescuing elevated workers is a complex and challenging scenario. It is a high-risk, low-frequency rescue. The situation can easily become overwhelming to one technical rescue team. Early in the incident, ask for mutual-aid responders for staffing and equipment. They can always be turned around if you don’t need them. If you do need the additional trained personnel, you will want them on scene as fast as possible.

Practice basic and advanced rope techniques whenever possible. Rope skills are easily forgotten. Survey your response zones to see if there is any swing stage scaffolding on buildings. Ask the building manager if you can view the anchors used to secure the scaffolding and identify the anchors you would use in a rescue situation. It is easier when you preplan for the rescue before it happens.

|

| (19) A 5:1 mechanical advantage system can be constructed to haul the load of a rescuer and victim. After the tension is relieved from the worker’s lifeline, disconnect the system, which will transfer the worker completely onto the rope rescue system. |

JEREMY RIFFLARD is the lead instructor for the Scaffold Rescue Program at Coral Springs (FL) Regional Institute of Public Safety. For the past 15 years, he has been a rope rescue instructor and subject matter expert with ATEC Incorporated for Military Urban Search and Rescue exercises. He is a captain with Fort Lauderdale (FL) Fire Department and a rescue squad officer for the FEMA Urban Search and Rescue team FL-TF2. His most recent task force deployments were to the Haitian Earthquake and Hurricane Ike.

Construction Concerns: Improvised Scaffolds

Construction Concerns: Scaffolds

Scaffolding on Buildings and its Effects on Firefighting Operations

Fire Engineering Archives