PPV ON THE FIRE GROUND

Technological advances recently have increased the effectiveness and potential applications of the traditional smoke ejector. Increased power and improved design have combined to produce power blowers that, when used in pressurized ventilation operations, allow fire suppression personnel to improve foreground environments and fire suppression operations. The concept is simple: Fresh air is forced into a structure or confined area to expel a contaminated atmosphere.

REVIEW OF NPV AND PPV

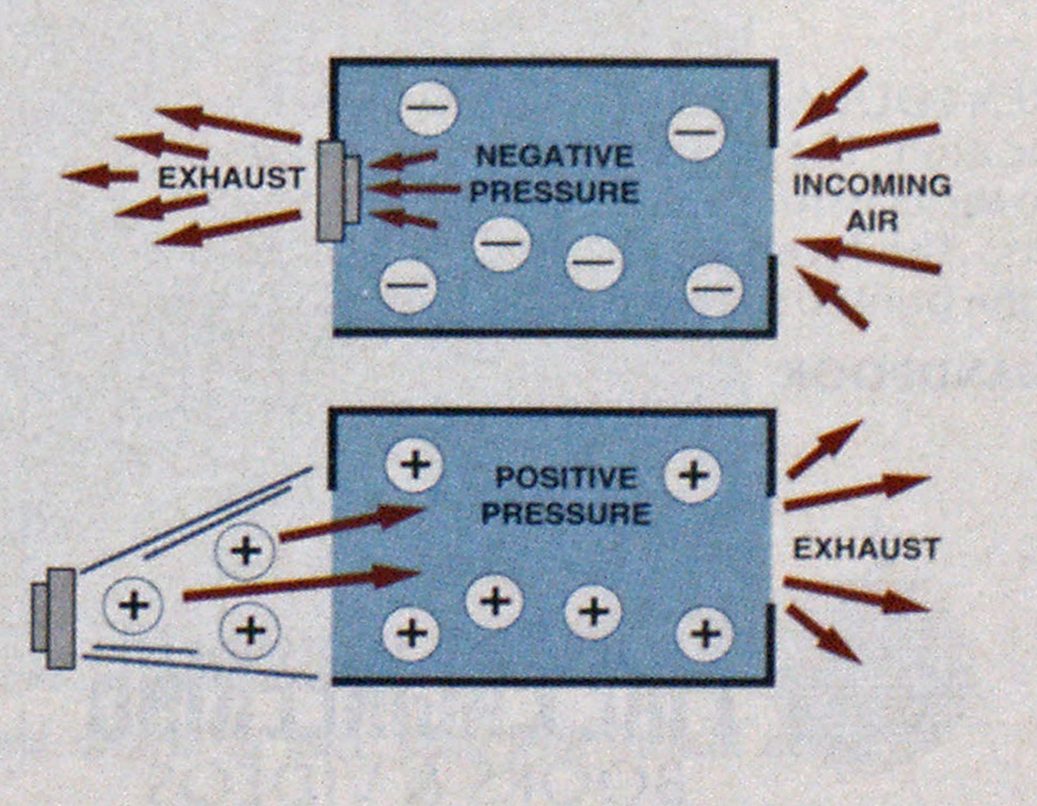

Traditionally, the fire service has used negative-pressure ventilation (NPV) to remove smoke and associated by-products after a fire has been extinguished. This process is based on the principle of positioning a smoke ejector inside a contaminated area to exhaust contaminants. This draws contaminants through a smoke ejector and exhausts them to the exterior of a structure by creating a negative pressure in a contaminated area. Although this method has performed satisfactorily for more than 50 years, it has exhibited some drawbacks:

- Contaminants are drawn through the smoke ejector, creating additional cleanup and maintenance.

- Personnel usually are exposed to hazardous contaminants while positioning the smoke ejector.

- Interior smoke ejectors are not efficient in removing contaminants at the top of a contaminated area.

- Smoke ejectors placed in entrance openings can hinder personnel entry and exit.

- To be effectively positioned, smoke ejectors must be placed at the top of exhaust openings, which requires additional equipment.

- Smoke ejectors placed inside a contaminated area can add to the noise of the incident and hinder communications.

However, fire suppression personnel have discovered through a combination of experimentation and practical experience that positioning of equipment dramatically can alter the effectiveness of pressurized ventilation operations. Removal of the same contaminants can be effectively increased simply by changing the location of the equipment. Positioning the same smoke ejector (which now becomes a blower) outside a structure forces clean, fresh, pressurized air inside the same contaminated area and creates a positive pressure, resulting in contaminants from all portions (of the contaminated area) exhausting to the exterior. Compared with NPV, positive-pressure ventilation (PPV) has these advantages:

- Contaminants are not drawn through blowers, resulting in minimal cleanup and maintenance.

- Personnel are not exposed to hazardous interior contaminants whilepositioning blowers.

- Exterior blowers do not depend on additional equipment for proper placement and operation.

- Blowers do not block entry to or exit from a contaminated area.

- Exterior blowers minimize additional noise and confusion in a contaminated area.

- Based on fire department testing and industrydata, PPV is at least twice as efficient as NPV in removing contaminants.

When evaluating NPV and PPV ventilation methods, people generally ask the following questions:

Why is PPV more effect ire than NPV’? A negative pressure is created inside the contaminated area when the smoke ejector is activated in concert with opening the window-. However, most of the air flow in the contaminated area will be directly between the smoke ejector and the window, as the flow of air is similar to the flow’ of electricity and water (it follows the path of least resistance). Therefore, there wall be little (if any) air flow and smoke removal at the top and bottom of the contaminated area. Conversely, when the blower is activated outside the structure, a positive pressure is created inside the contaminated area that is equal at the top, middle, and bottom portions (similar to blowing up a balloon). When the window is opened, the pressurized contaminants from all portions of the contaminated area are exhausted to the exterior (similar to piercing a balloon), which results in contaminants being exhausted more efficiently and more quickly.

Are special blowers necessary for PPV operations? Implementing PPV does not depend on using a specific type of blower. The basic difference between NPV and PPV is the location or placement of blowers (inside vs. outside a structure). However, blower manufacturers offer an array of equipment that can improve and enhance PPV ventilation operations, as compared with equipment that was available only a few years ago.

METHOD OF IMPLEMENTATION

To effectively implement PPV, take into account the following considerations:

Entrance opening. Position the blower so that the cone of pressurized air it issues completely covers the structure’s entrance opening and prevents contaminants from being forced back through the unsealed portions of the entrance opening and reintroduced into the structure. Optimum placement varies according to the size of the entrance opening, the size of the blower, and the appropriate distance required between the blower and entrance opening.

Multiple blowers can increase air flow volume and reduce the time necessary to complete a ventilation operation. For standard doorways (3 by 6.5 feet), placing two blowers in line with each other is most efficient. Blower A is placed about two feet from the doorway (illustration opposite page, top right). This ensures that all of the pressurized air enters the structure and yet allows sufficient room for ingress/egress of personnel. Blower B is positioned behind blower A. The proper distance for blower B is determined by the distance necessary to seal the doorway with pressurized air. Blower B is used to seal the doorway, force additional pressurized air into the structure, and increase the capacity of blow er A by 10 percent. If using tw o blowers of unequal size in the in-line position, place the larger blower near the doorway and use the smaller blower to seal the doorway. You also can stack multiple blowers in front of an entrance opening. Position the blowers about two feet back from the doorway. This allows all of the pressurized air from both blowers to pressurize the doorway and the interior of the structure.

Use multiple blowers in a parallel (sidc-by-side) configuration to seal larger entrance openings (loading dock doors) with pressurized air. The size of the opening dictates the number of blowers necessary to seal the opening with pressurized air. If raised porches do not allow you to properly position a blower back from a doorway, you still can adequately pressurize the doorway and structure by positioning a blower on the porch, in front of and as far back as possible from the doorway.

Flow of pressurized air between the entrance opening and exhaust opening. You must control and direct the flow or path of pressurized air between an entrance opening and exhaust opening to achieve effective ventilation. If you direct pressurized air from an entrance opening to an exhaust opening without diverting it to other openings, you will remove contaminants with the pressurized air in a minimal amount of time.

Exhaust openings. The size of an exhaust opening can determine the effectiveness of a PPV operation. Generally, PPV is most efficient when an exhaust opening is between ¾ and twice the size of an entrance opening. This variance is due to the number and cfm of the blowers used and can be summarized as follows:

- A single blower powered by a ⅛to three-horsepower-motor engine is most efficient when used with exhaust openings that are ¾ or slightly less than the size of the entrance opening.

- A single blower powered by a five-horsepower engine is most effective when used with exhaust openings the same size or slightly larger than the size of the entrance opening.

- A single blower powered by a sevenor eight-horsepower engine is most effective when used with exhaust openings about I Vi times the size of the entrance opening.

- Multiple blowers powered by five-horsepower (or larger) engines in parallel or in-line configurations are most effective when used with exhaust openings approximately twice the size of the entrance opening.

Remember, these guidelines are generalized; optimum efficiency is easily obtained through a combination of training and experience.

Training and communication. Effective PPV depends on controlling the entrance opening, the path of the interior air flow, and the exhaust opening. These factors can be achieved in their proper relationship only if all personnel engaged in a PPV operation have been properly trained, are aware of the goal of the intended operation, and maintain an open line of communication.

Sequential ventilation. Effective PPV requires sequential ventilation of contaminated areas in a structure (or other contaminated area). This process provides the maximum amount of pressurized air from a blower to ventilate each contaminated area and results in maximum efficiency and minimal overall time for ventilation. During PPV, do not open the structure up, as is common practice. This reduces the flow of pressurized air through contaminated areas and increases the overall time for ventilation. For example, assume the dwelling in the illustration below is charged with smoke, all doors and windows are closed, and a blower has been positioned to cover the front door with pressurized air in concert with a prevailing wind. As indicated, by opening and closing appropriate doors and windows, the living room, dining room, and kitchen would be cleared first. Then in numerical order, bedroom 1, bathroom I, bedroom 2, bathroom 2, and bedroom ⅜ would be cleared.

STRUCTURAL APPLICATIONS

Based on practical experience, let’s highlight the current common applications of PPV in structures. Contaminants (smoke, etc.) quickly can be removed from structures as follows:

Basements. If a basement has openings that can be used for exhaust openings (cellar door, windows, etc.), position a blower to cover an appropriate opening to the basement (doorway to basement, structure, etc.) and use appropriate openings as exhaust openings. If a basement does not have suitable exhaust openings, you can use several methods to provide exhaust openings. If a frame-wood structure has ship-lap siding, you easily can remove the two bottom ship-lap boards (next to the plate on the foundation), exposing the opening between the ends of the floor joists and the opening between the floor and plate that can be used as an exhaust opening. If this operation is not possible, use one blower to pressurize the structure and create a flow of air through it and out an exhaust opening (as per normal PPV operations). Next, place an additional blower in the doorway to the basement. This w ill pressurize the basement and force contaminants out of the upper portion of the doorway, which are removed by the blower used to pressurize the structure.

Multiple story. Ventilate multiplestory structures by starting at the lowest level and ventilating toward the top by sequentially ventilating each floor. If stair shafts are present, use them to channel pressurized air to each floor as necessary by pressurizing appropriate stair shafts.

Co m m ere ialin du stri a l. Th e s e buildings are diverse in size, height, and type of occupancy. However, do the following when considering PPV for these types of buildings:

- Determine the effectiveness of removing contaminants vertically or horizontally, depending on the type of building, location of fire, and different construction features, including windows, doors, vents, skylights, shafts, etc.

- When possible, divide large areas into smaller areas that can be sequentially ventilated by a preplanned, coordinated operation.

- If necessary, pressurize stair shafts for multiple-story buildings and use to ventilate appropriate floors, starting from the ground and ventilating toward the top of a structure.

- Since large structures or areas within a structure require increased air volumes to remove large quantities of contaminants, consider using large blowers for these applications. Multiple in-line, parallel, or stacked blowers also will provide additional air flow and enhance the removal of contaminants. In addition, use multiple blowers to pressurize large entrance openings (loading dock doors, etc.).

High rise. Of the various types of structures, high-rise structures can be the most challenging. However, you can use PPV effectively, with the following considerations:

- Vertical ventilation. By opening the bottom and top door to a stair shaft, you quickly develop a natural upward flow of air. Use blowers to augment this flow’ of air, regardless of building height. Use this process to remove accumulated contaminants and keep a stair shaft clear or to keep contaminants from accumulating in a stair shaft (if the roof opening is kept closed). The Los Angeles City (CA) Fire Department currently uses this operation, requiring that first-alarm truck companies be responsible for pressurization of vertical stair shafts in high-rise buildings with fire. Emphasis is placed on stair shafts that will (or are) used by fire attack personnel, as this can assist in clearing a stair shaft of heat and contaminants and enhance fire attack operations.

- Horizontal ventilation. Cross-ventilate a contaminated floor by using blowers to pressurize a stair shaft — direct pressurized air across a contaminated floor and out appropriate exhaust openings. Use windows on the leeward side of a building, if possible. Direct contaminants, if necessary’, to an opposing stair shaft that opens to the roof. The exhausting contaminants from the affected area will be vertically exhausted from the opposing unpressurized stair shaft with the roof access door open.

- The preceding cross-ventilation operations are effective up to 25 floors in a high-rise building. If crossventilating floors above the 25th floor, it may be necessary to position an additional blower in the pressurized stair shaft to supply additional pressurized air to the floor to be ventilated. Note: These operations may require personnel on the roof and ground for proper coordination.

FIRE ATTACK

You can use PPV as an initial fire suppression technique prior to introducing hoselines when considering confined fires. Although this is a relatively new concept, numerous fire departments across the country have experienced the following in an involved confined area:

- Smoke and heat are significantly reduced.

- Visibility is improved.

- Internal temperatures in a confined area are reduced.

- There is reduced potential for flashover conditions.

- The time it takes to place attack lines in operation and put water or foam on a fire is reduced.

- When water is placed on a fire, the resultant steam is carried away from personnel on the attack line.

- Personnel usually can enter an involved area and do not have to crawl on the floor to advance attack lines.

- Firefighter safety is enhanced.

Similar to other fireground operations, this technique must be used within the following parameters to ensure a successful operation:

- A technical and practical operational knowledge of PPV is essential.

- This technique is most effective when used on confined fires. However, carefully evaluate attic fires prior to introducing pressurized air.

- Backdraft (or potential backdraft) conditions must not be present. Know the warning signs!

- Two in-line or stacked blowers, each capable of at least 7,000 effn, provide the most effective results.

- Pressurized air from blowers must seal the appropriate entrance opening.

- The exhaust opening should be placed as close to the seat of a fire as possible. Horizontal (window or door) or vertical (roof) exhaust openings can be used.

- Attack lines should be advanced approximately five to 15 seconds within implementation of PPV.

Although PPV can be used effectively with an attack line in many applications, it cannot be applied to every confined fire. This technique will achieve satisfactory results only through proper training and judicious implementation.

When evaluating the various applications of PPV, consider the following:

Location of fire. When the location of a fire is unknown, carefully analyze the use of PPV (particularly on fire attack operations). If a structure is small and relatively simple (i.e., 1,500-square foot, single-story, singlefamily dwelling), the success of using PPV to exhaust contaminants or enhance fire attack operations is greatly increased due to the simplicity of the structure.

However, as the size and complexity of a structure (and fire) increase, so does the potential for an unsuccessful PPV operation. In addition, if there are multiple areas of fire in a structure, implementing PPV will affect only heat, smoke, and fire that are in the path of pressurized air traveling toward an exhaust opening. As an example, the use of PPV on the living room, dining room, and kitchen in the illustration below (when only the front and back doors are open) will have little (if any) effect on the bedrooms of this structure until windows are opened in the bedrooms. Heat, smoke, and fire are not affected until there is air movement.

Balloon construction. Unlike platform construction, balloon construction can allow the unrestricted vertical travel of fire through a wall into an attic. The application of PPV can enhance this process if an exhaust opening is not opened prior to initiating PPV. However, if an exhaust opening is created prior to implementing PPV, most of the pressurized air will flow toward the exhaust opening (path of least resistance) and will have little impact on enhancing fire spread in open walls. When encountering potential fire extension in balloon construction, the key is to create an exhaust opening before implementing PPV.

Attic fires. Evaluate the implementation of PPV in structures with attic fires in combination with the presence and size of attic vents. If fire has extended into an attic with attic vents that are of sufficient size to allow a significant flow of pressurized air that can spread fire, do not use PPV. However, the absence of attic vents normally will allow PPV to pressurize a structure (and attic) without spreading an existing attic fire. Remember that any roof ventilation openings are attic vents!

SEARCH AND RESCUE

When search and rescue operations are conducted in hazardous environments, heat, smoke, and toxic gases can combine to hinder efforts. PPV has the potential to reduce heat and smoke, decrease the presence of carbon monoxide and other toxic gases (which also increases the percent of available oxygen to trapped victims, increasing chances of survival), reduce the potential for flashover, and increase visibility. These facts were graphically demonstrated in tests conducted by the North Carolina Bureau of Insurance and the U.S. Coast Guard (see “Positive-Pressure Ventilation in a Test Setting,” Fire Engineering, December 1989).

How ever, using PPV in conjunction with vent-entry-search (VES) or outside-ventilation-man (OVM) operations can be dangerous unless the application of PPV is carefully coordinated with a VES or OVM operation. When the window near the seat of the fire is opened (vent) and personnel enter to conduct a search, applying PPV (in concert with an attack line) can make the search area untenable for VES personnel near or between the fire and ventilation opening. If VES operations are to be conducted with PPV operations and VES personnel are near or between the fire and ventilation opening, VES personnel should conduct their search and exit the structure before PPV operations are initiated. This operation requires coordination and communication between PPV and VES personnel.

Currently, there is an interesting debate concerning the viability of using PPV in search and rescue operations. It is a fact that PPV has the potential to enhance a search and rescue operation and increase firefighter safety. However, there is also concern that PPV could increase the likelihood of serious injury or death for trapped occupants who may be located between a fire and an exhaust opening. Although both of these viewpoints have merit, it is a fact that most structure fire victims die from smoke inhalation, not burns. Therefore, victims who may be located between a fire and an exhaust opening (when PPV is initiated) most likely would have died before the implementation of PPV, or will be saved by the implementation of PPV as follows:

- Victims who are near the seat of a fire probably will die from heat or contact with the fire. Therefore, although PPV can change the direction of fire and heat toward an exhaust opening, it does not normally contribute to the death of victims near the seat of a fire, who most likely are the victims of high heat, contact with flame, or smoke inhalation.

- The rescue of victims who are still alive can be enhanced by PPV through the introduction of fresh air. Remember that most victims die from smoke inhalation. Therefore, the introduction of air (oxygen) will reduce contaminants (carbon monoxide) and increase the percentage of available oxygen, thus improving a victim’s chance of survival. In addition, PPV has the potential to enhance a search and rescue operation through its ability to increase visibility in the structure/compartment (which enables search and rescue personnel to increase the speed of a search) and reduce the potential for flashover (safety for firefighters and victims).

PPV should not be used —or should be carefully evaluated —for search and rescue operations when a VES (OVM) operation is being used and if the incident commander has any doubts regarding the implementation of PPV. The decision to use PPV to enhance a search and rescue operation must be carefully evaluated in terms of safety, incident conditions, and the amount of time necessary for implementation.

OTHER APPLICATIONS

Dumpster fires. The fire service receives hundreds of calls a day to respond to the common dumpster fire. The extinguishment process is the same today as it was 30 years ago and normally consists of several firefighters dressed in protective equipment (without SCBA) using an attack line to extinguish and overhaul the fire. Although most fire service personnel wear SCBA on fire attack operations, few wear SCBA on dumpster fires because they consider these incidents only rubbish fires. Unfortunately, the content of the modern dumpster has changed since 30 years ago. Now, plastic and fiberglass products, illegally dumped hazardous materials, and other similar materials that produce numerous toxic gases when subjected to fire and that are extremely dangerous when inhaled are common. For example, chlorine is one of the most popular chemicals used as a stabilizer for plastics. When this chemical is present in smoke and inhaled, it combines with moisture in the human respiratory tract and forms hydrochloric acid, which can destroy mucous membranes and cause internal bleeding and possibly death. This was graphically demonstrated at the MGM fire in I.as Vegas in 1980.

PFV can improve the suppression and overhaul phases of dumpster fires by providing a directional flow of pressurized air that allows personnel to operate on the windward (or upwind) side of the flow of air and away from the deadly products of combustion. This can be accomplished prior to initiating suppression operations by placing a blower approximately eight to 10 feet away from a dumpster. The pressurized air flow will force the products of combustion away from personnel. Using two blowers in parallel enhances the effectiveness of this operation. Remember to position the blower(s) in concert with any prevailing breeze or wind; and wear SCBA when encountering any hazardous atmosphere.

Auto fires. An automobile fire also generally is considered a routine incident that is easily handled. However, the interiors of modern automobiles contain plastics and other similar synthetic materials that produce large quantities of deadly toxic gases when exposed to fire. Unfortunately, many fire service personnel neglect to wear SCBA during fire attack and overhaul operations on automobile fires and inhale toxic gases present in the smoke.

PPV can improve the suppression and overhaul phases of automobile fires by providing a directional flow of pressurized air that allows personnel to operate on the windward side of the flow of air and away from the deadly products of combustion. If using PPV, open the opposing doors on the automobile and place the blow er about eight to 10 feet from the auto. The pressurized air flow will direct the products of combustion and heat away from personnel. One blower is sufficient for a two-door automobile; two blowers in parallel are effective for four-door models.

Remember to position the blow -er(s) in concert with the prevailing breeze or wind, and make sure personnel wear SCBA when encountering hazardous atmospheres.

Salvage. PPV can help in salvage operations as well. Use PPV techniques to reduce or delay the presence of heat and smoke so personnel have time to perform salvage duties safely.

Overhaul. Typically, most blowers are used for ventilation operations after the initial knockdown of a fire and prior to overhaul operations. This allows heat, smoke, and carbon monoxide (and other toxic gases) to accumulate during overhaul operations. Use PPV during overhaul operations to provide a flow of fresh cool air through the overhaul area. This results in the following improvements:

- Humidity and radiated heat in an overhaul area are reduced.

- Smoke in an overhaul area can be substantially reduced (depending on the degree of extinguishment).

- Carbon monoxide and other toxic gases can be significantly reduced.

The effectiveness of PPV during overhaul operations is determined by an overhaul area (size and overhaul materials) and the blowers used for PPV. In general, a moderate flow of air is sufficient to replace smoke, heat, and toxic gases during overhaul.

Note: Never use PPV in place of SCBA. Always use SCBA when encountering hazardous atmospheres.

When using PPV for overhaul operations, concern is frequently expressed over the potential of PPV to spread remaining fire. Practical experience has indicated that PPV does not have a tendency to accelerate or spread fire that may still be in an overhaul area. If fire begins to accelerate or spread, it easily can be controlled bv:

- Shutting the blower off.

- Reducing the rpm of the blower.

- Increasing the distance between the overhaul area and the blower.

- Extinguishing the remaining or accelerating fire.

Marine and aircraft. In marine applications, contaminants from a fire have been isolated by closing bulkhead doors A and B. Appropriate vertical passageways then are used to channel-direct the flow of pressurized air from the blowers to the contaminants and away from the contaminated area as indicated. In aircraft applications, contaminants can be removed by using forward and rear doorways and standard PPV techniques. A PPV test performed on a USAir 737 totally removed smoke in 45 seconds. If an aircraft is connected to a terminal by a jetway, make sure PPV is directed toward the rear of the aircraft to eliminate contaminating the jetway and terminal.

Rehab. During rehab, PPV reduces the body core temperature of personnel (wearing full protective clothing). Tests by the U.S. Coast Guard indicate a reduction of core temperature up to five degrees during fire suppression operations, which is significant from the standpoint of endurance and safety.

PPV also has proven effective in other applications such as removing flammable atmospheres (gasoline, natural gas, butane, etc.) and minimizing contaminated atmospheres in some hazardous materials incidents. In these applications, the ability to place blowers away from flammable atmospheres (and in fresh air) enhances effectiveness and operational safety.

CARBON MONOXIDE

The use of gasoline-powered blowers for PPV can increase the amount of carbon monoxide (CO) inside a structure. However, tests have indicated the average gasoline-powered blower can increase the CO level inside a structure by 50 to 60 parts per million (ppm). This figure is similar to the national average of 50 ppm inhaled each day by the average person. Although CO is accumulative, 50 ppm generally is not considered dangerous. If the exhaust of a gasolinepowered blower is detected inside a structure, this is an indication the exhaust opening (for the PPV operation) is too small and blower exhaust contaminants are accumulating. Increase the size of the PPV exhaust opening, and the exhaust odor and CO should vanish or be significantly reduced.