Structurally speaking, beams and girders are very similar. They are horizontal structural elements designed to capture an imposed load and transfer said load laterally to columns or walls, which in turn transfer the load downward into the ground. The main difference with respect to firefighting is how they fail and, more importantly, the subsequent result of that failure. The beam is the oldest known element of any structure; over the years they have taken on different forms and design types. It would be impossible to hit on every single type and design of beams without giving you an intermission. Let’s focus on the most common materials, how they take on loads, the reaction to loads, and failure.

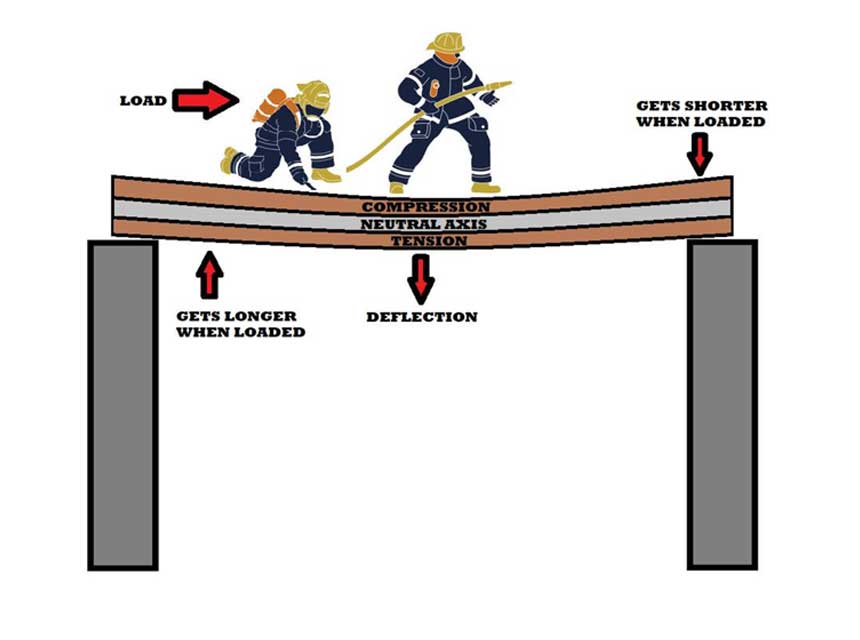

A beam transmits forces in a direction perpendicular to such forces to the reaction points (points of support). A girder is any beam of any material that supports other beams. Consider for a moment a load placed on a floor beam. The beam receives the load, turns it laterally, divides it, and then delivers it to the reaction points. When a beam is loaded, it deflects or bends downward. The initial load is the beam’s own dead weight, while the load placed on it is the superimposed load. (1) Deflection causes the top of a beam to shorten so that the top is in compression. The bottom of the beam elongates and thus is in tension. The line along which the length of the beam does not change is the neutral axis or plane. Along this line the material is doing the least work, and material can be most safely removed. This is why we often see engineered products such as a truss, I-joist, or C-joist substituting for the mass of a product for geometry along the neutral axis.

A simple beam is supported by at two reaction points. A continuous beam is supported at three or more reaction points. Go in to a “big box” store and look up. You’ll see a huge girder that is supported by multiple columns. That’s a continuous beam. A cantilever beam is supported at one end, but is rigidly held into position at that end, such as you would see on a balcony. Grillage is a series of closely spaced beams designed to support a particularly heavy load. A flitch plate girder is a beam in which a steel plate is sandwiched between two elements of structural lumber.

RELATED FIREFIGHTER TRAINING

Mass Timber Construction in High-Rise Residential Structures: How Safe Is It?

Tall Wood Buildings: Maximizing Their Safety Potential

The most common types of beams we see are constructed of wood, steel, or a composite. Composite beams use concrete and steel, wood and steel, or engineered lumber such as glue laminated lumber (glulam, or adhesive and wood).

Wood beams are dependent on their mass and depth. The depth or height of a beam gives the structural strength. The deeper a beam, the larger the load it can carry. For example, take a 2x4x8 and set it on two points horizontally on its height, which you could most likely stand on without compromise. If you take that same 2x4x8 and lay it on its width, the deflection and compromise is almost certain. Wood is subject to fire damage, rot, insect damage, water damage, dry-rot, and overloading. We often see wood beams or girders with lateral cracks, which dry wood will certainly be subject to over time. To the layperson, these structural members are holding the load and are of no concern; to firefighters, however, this can indicate premature failure if subject to attack by fire.

Rotting due to moisture usually occurs next to load bearing walls, foundation walls, or beneath water sources such as bathrooms and kitchens. This can weaken the wood over time and cause failure at such points or disconnect from floor sheathing. Insect damage can go unseen. When a superimposed load, live load, or impact load such as that of firefighters working above is applied, the beams beneath may crumble.

Wood girders—be they LVL, built-up beams, structural composite lumber, or flitch plate girders—will certainly take much longer to burn through but are subject to failure if the girder sits on a column or wall improperly. Collapse can occur if a column fails leaving the girder to be overloaded, or in cases such as with a flitch plate girder where unprotected steel can be heated, expand, buckle, and pull apart the connections. If you were to ask a firefighter from wildfire-prone areas how worried they would be if the forest had no rain for two years, they would probably have to pick their jaw up off the floor. Why then have we have become accustomed to having confidence in structural wood within buildings that has not been rained on in some cases 50+ years Fire will consume this wood much faster as it loses all of its moisture, add loads, dry rot, etc.…you get the point!

Steel used as beams and girders is certainly not new. Steel can be engineered to certain sizes and depths and is different than wood in that it can regain strength when cooled. It also has different strength to weight ratio and elasticity. It does, however, have its limitations. It is susceptible to fire damage, corrosion, buckling under high compressive forces, and stress cracking. Steel beams usually fail in four ways: Shear failure, flexural failure, compression failure, and tensile failure. Shear failure occurs between connections, i.e. girder to column, beam to girder. Flexural failure occurs for example when fire attacks a more slender steel beam, causing it to buckle and become displaced from its seat, as we see when bar joist trusses under attack by fire buckle and fall from the girder. Compressive failures cause a steel member to loosen and fall from its reaction point. Else, subsequently during the heating of fire attack, the compression between supports will have a negative reaction at one more of the distal reaction points, causing lateral loads upon walls or columns. Tensile failures occur when the steel member has reached its yield or failure point at the section with the least cross section area, i.e. the web or the bottom chord of a truss. This can cause the member to crack or pull the lower member from its connections.

Composite materials such as reinforced concrete can spall and expose cold drawn steel members to fire, which can cause tensile failure. This can also be the case when progressive collapse causes subsequent impact loads to the beams. After being exposed to long duration fires, glulam can be susceptible to release at the finger joints or deflection as fire consumes the material.

Generally speaking, girder failure is worse than beam failure. Girder failure can cause global collapse, whereas beam failure usually causes local collapse. As firefighters make progress inside buildings that are impacted by fire, we must analyze structural members such as girders and beams to ensure we are not passing heavily damaged structural elements. It is also worth noting that not all beam failures are due to fire. As previously stated, the material itself can become weak over time as it ages, and fire will only exacerbate the inevitable failure.

SALVATORE ANCONA is a deputy chief fire instructor at the Nassau County (NY) Fire Service Academy; a member of the Seaford (NY) Fire Department; a former captain and training officer for the Bellmore (NY) Fire Department; and a paramedic supervisor in Queens, New York. He has an A.S. degree in fire science from Nassau Community College and is in the emergency services administration undergraduate program at John Jay College of Criminal Justice. Ancona is the author of the building construction page “The Sons of Brannigan” on Facebook and was a recipient of the 2019 FDIC International Honeywell DuPont Scholarship.

MORE

Firefighters and Construction: Primer on Collapse in Noncombustible Buildings

Firefighters and Construction: The Cockloft

Firefighters and Construction: Row Frames

Firefighters and Construction: Podium Wood-Frame Multiple Dwellings