BY BRIAN LUKUS

Medical marijuana businesses began to be licensed and regulated in Colorado in 2010, and retail marijuana businesses followed in January 2014. This new industry has posed several challenges to the Denver Fire Department (DFD) regarding fire code compliance, fire safety inspections, and first responder safety since its inception. Although marijuana legalization, including consumption and business regulations, has been passed at the Colorado state level, the location and regulation of marijuana businesses (sales, growing, infused products, and testing) require local jurisdiction approval. Some Colorado jurisdictions have not allowed marijuana businesses within their city limits. Denver was the first city to allow recreational sales in Colorado. Now, with well over 800 marijuana licenses in Denver, the industry is booming. This article conveys how the DFD has adapted to this new industry so other fire jurisdictions with legalized marijuana can benefit from this information. DFD marijuana industry guidelines and policies are available at www.denvergov.org/DFDMarijuanaInfo.

Marijuana businesses are regulated by several Denver and Colorado state agencies as either medical or retail licensed businesses. However, for fire code compliance, medical and retail businesses are one and the same.

There are four types of marijuana businesses in the city and county of Denver licensed by the Denver Department of Excise and Licenses; each is issued as a medical or a retail business. They can be stand-alone locations or combined with all functions at one location:

- Marijuana Center, Store, or Dispensary. This is a location for the sale of marijuana. It can sell medical, retail marijuana, or both, depending on the type of licenses obtained.

- Lab. This is a testing lab for recreational marijuana to determine potency and the presence of other trace materials regulated by Colorado state laws.

- Optional Premise Cultivation (OPC) or Grow Facility. This is where plants are grown. A single location can hold several licenses, depending on the size of the operation and whether it grows just medical, retail marijuana, or both.

- Manufacturer of Infused Product (MIP). This is where plant oil is extracted or where marijuana-infused food products are manufactured. As with all other business types, an MIP must obtain the appropriate licenses-medical, retail marijuana, or both.

Fire Code Compliance

Fire code regulation of the marijuana industry has been a challenge since 2010 when medical marijuana businesses were first legalized. Denver adopted the 2009 International Fire Code as the base fire code with amendments, known as the “2011 Denver Fire Code (DFC).” There is no “marijuana” chapter within the fire code to provide any guidance. It has been the DFD’s goal, where possible, to try to mirror code regulations for similar industries to fairly regulate the marijuana industry. Each of the licensed marijuana business types noted above has its own unique safety hazards.

Marijuana Centers

Of the four types of licensed marijuana business locations in Denver, marijuana centers are typically occupancies with the least number of fire code violations seen during inspections. Typically, they are small mercantile occupancies about the size of a coffee or sandwich shop. Because the sale of marijuana is not legal under federal law, some operators have difficulty obtaining banking services and operate as all-cash businesses. Between marijuana inventory and cash on hand, security is a big concern for retail centers. Noncompliant means of egress are typically the cause of fire code violations during inspections. Dead-bolted doors or electronically secured doors must comply with fire code requirements to allow free egress for occupants at all times.

Labs

Retail marijuana businesses are required to test marijuana for potency, pesticides, and trace substances as required by Colorado state law. Marijuana testing labs perform this function, typically using gas chromatography. Thus far, the DFD has observed small amounts of hazardous materials in marijuana testing labs such as hydrogen, nitrogen, and alcohols in quantities that are below DFC maximum allowable quantities.

Optional Premise Cultivation

Plant cultivation locations, or the slang term “grows,” have many safety concerns that are regulated through the DFC. Working closely with the Denver Building Department during the construction review and permitting process, grows, including greenhouses, are regulated as F-1 occupancies in the Denver Building Code. Greenhouses are traditionally regulated as U occupancies in the International Building Code (IBC); however, the hazards are different in a marijuana grow than in a standard vegetable greenhouse. The F-1 occupancy classification was determined based on high electric demand for grow lamps, fumigation operations, carbon dioxide (CO2) enrichment, maze-like room layouts, and the fact that most grows in Denver are located in former storage occupancies (warehouses) and can have neighboring tenants potentially affected by these operations. Also, growing marijuana is labor intensive; the occupant load of workers is higher than one would expect in a typical U occupancy greenhouse. Larger grow operations can have more than 100 employees, and they operate around the clock.

Most grows go through the change-of-occupancy process, requiring that the building be brought up to current code requirements. F-1 occupancies of more than 12,000 square feet are required to be sprinklered. Unsprinklered occupancies are subject to the opening requirements of DFC 903.2.11.1, which requires window or door openings every 50 lineal feet so a defensive fire attack can be initiated if necessary. We have also seen the use of intermodal box containers (IBCs) as grow rooms. Use of these IBC containers falls under the same building and fire code requirements for occupancy classification, egress door hardware, and sprinklering of the containers if the building is required to be sprinklered.

Fire inspectors ensure that all construction permits, including electrical permits, have been obtained and final inspections have been conducted prior to allowing occupancy of any new business. Electrical demands to serve the numerous grow lamps typically operating at 1,000 watts each are very high. Several fires have occurred as a result of the melting of the overhead electrical service. Although the inside electrical system was sized correctly and inspected, the electric utility service from the transformer was never upgraded. A closer working relationship with the electric utility Xcel Energy solved this problem.

The demand for space to grow plants is increasing. With most growing performed in former warehouse buildings, vertical building height already exists in their space. We are now seeing the progression to vertical plant growing on tiers of storage racks up to 30 feet in height. At this time, the DFD is assessing whether to regulate these operations as high-pile storage or something different.

CO2 Enrichment

CO2 enrichment is a method used to enhance plant growth and leads to a faster and higher plant yield (photo 1). Nationally, CO2 systems have become a concern because of recent deaths from beverage dispenser leaks; the 2015 International Fire Code has new code language addressing these systems. However, CO2 enrichment systems found in marijuana grow rooms are different in that they intentionally flood the grow rooms with CO2. These systems present potential asphyxiation hazards and are regulated by operational and system installation permits issued by the DFD Fire Prevention Division. Growers typically keep CO2 levels in rooms at less than 1,500 parts per million (ppm). For context, the Occupational Safety and Health Administration (OSHA) eight-hour permissible exposure limit (PEL) is 5,000 ppm. These systems are required to have a local CO2 detection system in each enriched room set to alarm at 5,000 ppm and a master control valve to shut off the flow of CO2 at the source. Warning signs are also required. Typical CO2 enrichment can be in the form of compressed/liquefied CO2 systems or a CO2 generator supplied by natural gas. Compressed/liquefied CO2 systems can be as small as a few cylinders located inside each grow room or as large as a bulk tank located outdoors. CO2 generators operate from a fuel-fired source that, as a part of the combustion process, off-gases CO2 and carbon monoxide (CO). Because of the CO hazard, this appliance is regulated by the Denver Mechanical Code as a nonvented fuel-fired appliance and requires a CO detector interlocked to an exhaust fan that operates on high levels of CO. The DFC does not permit the use of portable propane tanks and cylinders to supply these generators. If used, they are required to be supplied from the building natural gas system.

|

| Photos by author. |

Fumigation

Fumigation is an operation regulated by the DFC and requires an operational permit to perform. Under this permit, hazard signage is posted at entrances, and the type of occupancy is reviewed for any potential threat to adjacent tenants. This has proven difficult to enforce, as growers sometimes fumigate overnight without the appropriate permits. The methods of most concern are sulfur burners (photo 2) to control powdery mildew and CO2 fumigation to control pests. Sulfur burners heat elemental sulfur, creating sulfur dioxide. If inhaled, sulfur dioxide can create sulfuric acid in the presence of moisture and can burn the respiratory tract. CO2 can be used to fumigate at levels above OSHA’s immediately dangerous to life or health level of 40,000 ppm to control pests. Both of these operations are of concern to workers entering the space, adjacent tenants unaware of this fumigation activity, and first responders entering after hours.

Marijuana-Infused Product Kitchens

Manufacture of MIPs is becoming more prevalent as the industry seeks a more concentrated form of tetrahydrocannabinol (THC)-the principal psychoactive component of the marijuana plant that can be extracted in highly concentrated oil-in oil extracts. The oil is used in edible goods or balms, and the extract oil can be smoked or vaporized. There are many ways to extract oil, most of which use hazardous materials. The DFD reviews the extraction process and issues a marijuana extraction operational permit to ensure it is performed in compliance with the DFC.

Extraction using butane is the most cost effective yet the most dangerous method used. The DFC prohibits open releases of butane to the atmosphere during the extraction. Several manufacturers produce equipment that cycles butane around a closed-loop system passing through the plant material (photo 3). The butane under pressure in liquid form acts as a solvent and breaks the THC from the plant. The butane is then recollected, and oil can then be retrieved. DFC 2703.2.3 requires equipment processing hazardous materials to be listed or approved. Currently, there are no listings [such as an Underwriters Laboratories (UL) listing] for this equipment to verify it has been constructed adequately to process a liquefied flammable gas. Therefore, the approval process for extraction equipment is based on DFC 104.7.2: an engineering analysis, signed and sealed by a licensed professional engineer, is submitted for DFD approval. Typically, the basis of the engineering analysis is National Fire Protection Association 58, Liquefied Petroleum Gas Code. Businesses using this equipment are required to have a hazardous exhaust system installed to capture any potential release of butane, and the Colorado state marijuana laws require that the operation be in a dedicated room. Additionally, a local hydrocarbon detector is required to alert the operator of butane leaks. Requiring closed systems and an equipment-approval process is critical to safely perform extractions using butane. There have been seven butane explosions in Denver since January 2014 caused by using unapproved butane open-blast extraction methods. This method releases butane to the atmosphere with the user standing in a cloud of flammable gas. Because this extraction can be performed so cheaply, it is used in both businesses and residential settings.

CO2 extraction is another method of producing marijuana oil. The equipment must follow the same DFD approval and permitting process as the butane equipment. Although there is no explosion risk as with butane, the systems can run at pressures as high as 10,000 pounds per square inch (psi); consequently, the equipment must be reviewed to ensure it is constructed appropriately. Businesses using this equipment are required to perform the extraction in a dedicated room, and a local CO2 alarm is required to alert of CO2 leaks.

Another extraction method is an alcohol distillation or heated evaporation process. Although alcohol is common, any flammable liquid can be used. Marijuana is soaked in alcohol and then the liquid is boiled off, leaving the oil behind. Larger operations recapture the alcohol in a distillation process for reuse. This process can also be used as a refinement after a CO2 or butane extraction. A number of methods and types of equipment can be used for this extraction process, and the DFC requirements are the same for each. A hazardous exhaust hood is required over the extraction process to capture any flammable vapors released, and equipment must be rated for heating flammable liquids. The one exception is a piece of equipment called a “solvent distillation unit” that is regulated in International Fire Code 3405 and has a UL listing specifically for distilling solvents.

The Denver City Council is considering an ordinance to limit the types of extractions conducted outside of licensed businesses, including residential settings. This includes prohibiting dangerous butane extractions and limiting extractions using flammable liquids.

Inspections

In the city and county of Denver, marijuana businesses are inspected at the time of first licensure and biannually thereafter by the DFD Fire Prevention Division inspectors certified to NFPA fire inspector II. Fire inspections are also performed routinely from referrals by other agency or public requests. An inspection is required as part of the business licensing process to ensure all appropriate permits have been obtained, including any change of occupancy building upgrades, prior to the business operating.

Fire code violations are more prevalent in marijuana-related occupancies than in any other occupancy type in Denver. Violations include overloaded electrical systems, noncompliant construction (e.g., unpermitted construction, noncompliant locks), using unapproved marijuana extraction equipment, unapproved CO2 enrichment systems, and occupying a space without a certificate of occupancy. Fire code violations are processed by the issuance of a written Order to Comply and/or a court summons for a general violation.

The number of inspections has increased substantially since 2010. Today, the DFD has three uniformed fire inspectors dedicated for marijuana-related inspections. Fire operations crews conduct preplans for these facilities as they do for any other commercial building in Denver, highlighting any hazards specific to that site. Businesses operating legally (i.e., with correct licenses and fire permits) are not identified as target hazards. (This article discusses legal marijuana business regulations, not the illegal side of the industry.)

Firefighter Safety

First responders should be aware of several hazards associated with marijuana-related occupancies when responding to these facilities:

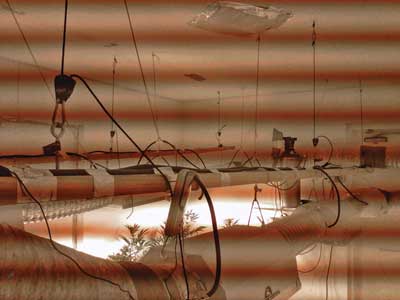

- In a fire incident, know what is above you. Grow lighting systems (photo 4) are often installed on suspension systems that are lowered to the ground when plants are small and then raised as the plants grow taller. These lighting systems would be a serious entanglement hazard if they were to fall on the firefighters operating below.

- CO2 enrichment systems have the potential to fail and become asphyxiation hazards, and CO2 generators can result in high CO levels. This could be a medical emergency with a down person or on-site workers with headaches.

- Fumigation activities can be hazardous and occur when growers are not on site. Sulfur dioxide produced from sulfur burners is hazardous if inhaled. The rotten egg smell of sulfur and burning of the respiratory tract are signs this fumigation can be in operation.

- Marijuana growers typically do not grow in a building with one large open room. They need to isolate the plants that are at different stages of growth. Large converted warehouses can be maze-like with multiple rooms. The DFD requires a graphic map (floor plan) at the main entrance whenever these maze-like conditions exist; a posted graphic map is also required for occupancies with a fire alarm panel.

- Modified electrical systems are always a concern in grow operations. Power may be run from neighboring buildings. If main power is shut off during an incident, notice if lights are still on in portions of the building.

BRIAN LUKUS, P.E., a seven-year member of the Denver (CO) Fire Department, is a licensed fire protection engineer in the Fire Prevention Division. He has a master of science degree in fire protection engineering from Worcester Polytechnic Institute. He also has five years of private fire protection consulting experience, served 10 years as a firefighter, and has Fire Officer I Pro Board certification.

Additional Links

Responding to a Clandestine Drug Laboratory

Marijuana Oil Production Concerns Colorado Fire Officials

Fire EMS: Bath Salts and Synthetic Marijuana : An Emerging Threat

Firefighter Safety: Firefighters Responding to California Fire Find Booby-Trapped Marijuana Grow

Fire Engineering Archives