Effect of Nozzles on Fires Studied In Terms of Flow Rate, Droplet Size

features

Despite the almost universal use of plain water dispersed by nozzles during fire fighting operations, there still remains considerable uncertainty regarding how much water it takes to extinguish a fire.

Ideally, one would like to estimate the total quantity, application rate, and form of water which would effectively suppress a given fire; and one would also like to identify and understand which factors significantly affect fire suppression effectiveness and fire fighter safety. In the past, the judgment of fire officers, surveys of operational experience and case-specific experimental tests provided limited answers to some of these questions. Such results do not always provide enough insight to understand how fire suppression effectiveness and fire fighter safety are affected by such things as the characteristics of the fire risk, fire suppression equipment, manning levels and tactics.

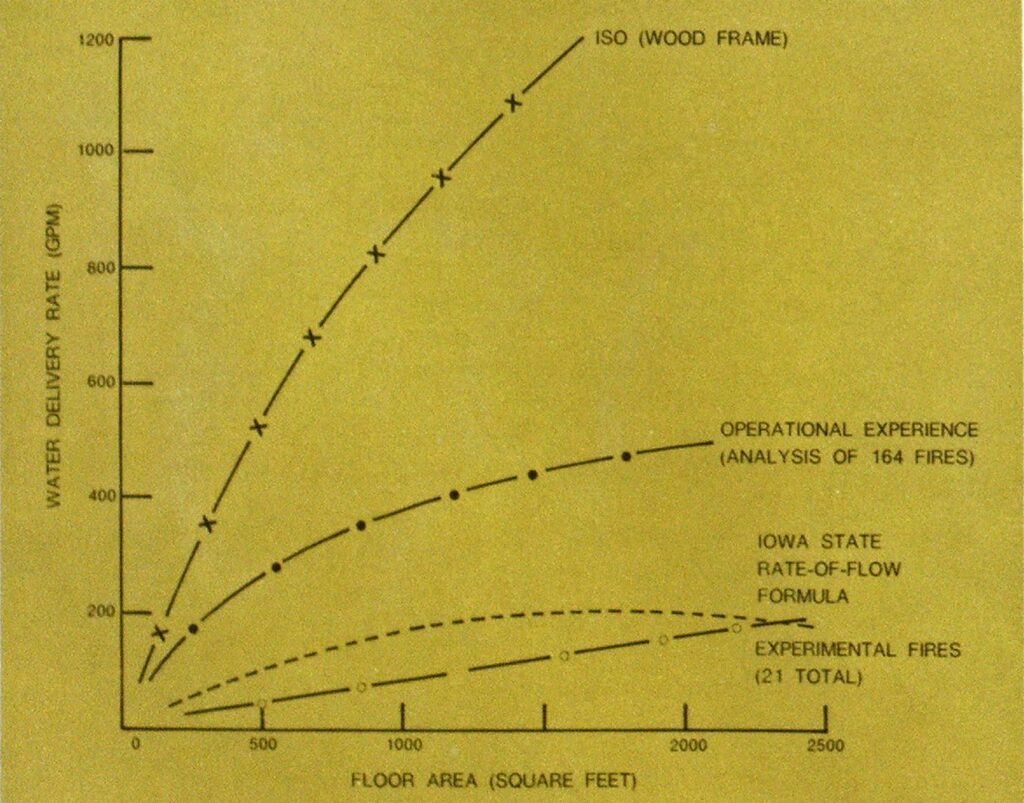

To illustrate, figure 1 displays several generalized estimates of required water delivery rates for control of residential fires as related to the involved area. These curves illustrate the wide variability of estimates. The Insurance Services Office (ISO) curve, though based on operational experience, is conservative and probably represents a bounding line on the worst cases of the data observed. An average of the data is represented by the curve labeled operational experience. By contrast, the much lower water requirements obtained from experimental fires must reflect the absence ot many of the difficulties and uncertainties of operational fire fighting. The Iowa State formula is a simple, theoretical estimate which demands a rate of water flow sufficient for cooling the heat generated by consumption of all the oxygen in the compartment volume within 30 seconds (i.e., this reduces to the volume of the compartment in cubic feet divided by 100). The wide diversity of these estimates may reflect the inherent uncertainties in the problem, but they are also attributable to the coarseness of the descriptions which attempt to relate required water flow to only some of the factors (i.e., involved floor area) and which do not account for other factors known to affect water demand. These other factors include:

- The intensity of the fire which, in turn, is affected by:

- The extent of the involved area

- How long the fire had been burning and whether it has reached flashover

- The amount of venting

- The type, quantity and location of the fuel

- The number of attack points on the fire which, in turn, depends on the number and performance characteristics of available pumpers, manning strategies, fireground tactics, access to the fire, etc.

- Whether the attack is intended to prevent fire spread (i.e., exposure control) or to directly extinguish the fire.

- The reach or standoff distance required at an attack point. This, together with other tactical and accessibility factors, determines whether direct extinguishment of the fuel at the point of burning is possible, or whether an indirect attack is required.

- The water flow rate and “form” (e.g., straight stream, fog or high pressure fog) produced by the nozzles at each attack point. This affects the nozzle reaction, cooling efficiency of the spray, and the amount of water actually used in fire control and the amount that ends up wasted.

- Limitations imposed by fire fighter safety in dealing with nozzle reactions, high gas and steam temperatures, and smoke.

Changes in one of the above factors can significantly affect all the others. All the major factors and sources of uncertainty need to be examined in more depth.

Nozzle committee formed

Two related projects have been in progress to gain insight into these factors. The first, in progress since 1974, has the objectives of developing a procedural guide to aid fire officials in the justification, specification, and purchase of pumpers and in identifying areas offering improvement in suppression equipment performance. This project was initially sponsored by the National Science Foundation under its Research Applied to National Needs Program, but in 1977, it was transferred to the National Fire Prevention and Control Administration, now the United States Fire Administration. The project is being carried out by a team consisting of engineers at Mission Research Corporation in Santa Barbara, Calif., working with a 25-member national advisory committee composed of fire chiefs from both metropolitan and rural fire departments and representatives of equipment manufacturers, the International Association of Fire Fighters, the ISO, the National Fire Protection Association (NFPA), and various state and federal government agencies, including the United States Fire Administration (USFA) and the Center for Fire Research at the National Bureau of Standards (NBS). The resulting “Guide for the Specification of Fire Pumper Apparatus” is described in articles appearing in the May and June 1979 issues of Fire Engineering. The guide will be available for distribution late this year”.

The second project involves a new NFPA fire hose nozzle committee formed to develop standards and acceptance tests for nozzle purchase specifications. The committee is also comprised of fire service representatives from all over the nation, and representatives of nozzle manufacturers, testing laboratories, the USFA, and the Center for Fire Research at NBS.

The above two projects have overlapping objectives. For example, one section of the pumper specification guide contains a step-by-step procedure for fire department personnel to determine pumping system requirements, considering the characteristics of the fire risks and fire fighting tactics used in a community. The procedure is a form of pre-fire planning where department personnel choose a set of representative fire risks and then lay out a kind of pre-fire plan on paper according to local tactics. Composite pumping system and other payload requirements (i.e., pump capacity, power required to drive the pump, tank size, nozzle complement, supplementary equipment) are determined from these attack plans for all risks.

Nozzle is key to problem

In the course of developing these procedures, it becomes evident that without dependable guidelines on the amount, rate and form of water required to control a fire, the procedure could not provide a way of eliminating faulty tactics or inadequate equipment performance.

Much of the work, therefore, was focused on understanding the factors that affect fire attack water requirements. From this work, the nozzle emerged as a key technology that directly affects the reach of the stream and the amount of water required for effective fire control. Presently, there are no accepted standards or tests that the fire service can use to assure that equipment is performing adequately. It was only recently that the new NFPA fire-hose nozzle standard committee was formed to develop minimum performance standards and tests of nozzle flow rates, cooling efficiencies, effective reach and other factors.

The fire fighters on the new NFPA committee have expressed concern about this problem. Their concern stems from actual fireground experience where fires that should have been controlled with the available equipment were not. Subsequent flow-pressure measurements on the nozzles indicated deficiencies, in some cases up to 40 percent fewer gallons per minute than rated flow. Over the years, numerous tests on new nozzles have been conducted, and these deficiencies have been found to be common.

To illustrate, table I shows flow test results for 10 samples of the same make and model 2 1/2-inch fog nozzle. Although this model is rated to deliver 250 gpm at 100 psi nozzle pressure, a range of 196 to 253 gpm was measured. Similar tests using other nozzle sizes and products from a wide range of manufacturers produced similar variations from rated flow.

Droplet size considered

In addition to water flow rate, the pumper project research also showed that the form of the water produced by a nozzle significantly influences fire control performance. Although fire fighters are generally aware of the application difference between straight stream, fog and high pressure fog, the question of what measurable characteristics of the water stream (i.e., droplet sizes, etc.) directly influence nozzle performance, has not been adequately addressed.

To address this question, heat balance calculations were completed, using computer techniques, for high intensity post-flashover fires in compartments of various size, venting and fuel conditions. (Post-flashover fires were chosen as worst case situations that are likely to stress the suppression equipment.) The effects of nozzles emitting water at various flow rates and droplet sizes were examined in terms of gas and surface cooling, steam-induced smothering and direct extinguishment of the fuel.

Figure 2 shows the results for situations where direct extinguishment at the source of the burning fuel is limited because of access or standoff requirements (i.e., for this “indirect” attack situation, gas/surface cooling and steam-induced smothering are the primary mechanisms of fire control). The vertical axis of figure 2 gives the water flow rate required for every 1000 square feet of total interior surface area (walls plus floor plus ceiling) in the burning compartment. The horizontal axis plots the volume-median-drop-diameter of the water stream in millimeters, i.e., half of the water volume in the stream have drops below this size and half above.

The control/failure line (with cross hatching) appearing in figure 2 divides the graph into two regions characterized by combinations of water delivery rate and volume-median-drop-diameter which are successful or unsuccessful in controlling the fire. For the case shown, as the volume-median-drop-diameters increase from 0.1 mm to 1 mm, the bounding control/failure line first slopes downward, achieving a minimum of about 0.2 mm and then increases with drop size.

Form of water critical

The significant V shape of this bounding line shows that the form of the water (i.e., characterized by droplet sizes) as well as the flow rate is important in fire control. This shape indicates that a significant fraction of the drops with sizes less than 0.2 mm are blown away by hot gases and are not effective in achieving fire control. On the other hand, droplets greater than 0.2 mm result in a significant fraction that fail to fully vaporize and, therefore, contribute to water ru_____off. In each case not all the water applied is effectively used (some is wasted) and because of this, total water application rates required for fire control increase.

Although not directly shown in figure 2, the relative downward dip of the bounding cross-hatched line defining the control-failure region is also affected by the fraction of the burning fuel area accessible to direct water impact. If this fraction is high, fuel extinguishment, rather than gaseous cooling and smothering dominates. For this case, the dip of the bounding control-failure line may not be as great as shown in figure 2 since the larger drops penetrate better and carry more water to the burning surfaces. This means that if the seat of the fire is directly accessible, in order to minimize water usage, extinguishment is preferred to cooling and smothering. On the other hand, direct access to the burning fuel may not always be possible in high temperature post-flashover fires.

* For information on how to obtain a copy, phone or write the Umited States Fire Administration Library, Washington, D.C. 20230, 202-634-3913. For information on the technical aspects of the guide, call Mission Research, 805-963-8761.

Although the calculated results shown in figure 2 require additional testing under actual fire conditions, in general one can conclude that both the form (droplet sizes) of the water, as well as the flow rate, directly affect fire control performance. In this regard, it is significant to note that drop size measurements for water streams produced by currently available nozzle equipment have not to our knowledge been completed. At this time we do not know where the operating point of current nozzle equipment is on the horizontal axis of figure 2. These uncertainties should not exist in areas that affect fire fighting effectiveness, manning, tactics, and fire fighter safety in a significant way.

Drops can be measured

Future plans are to complete these key drop size measurements with measuring equipment developed for industrial use in applications ranging from insect repellant aerosols to extra-high pressure hydrofracturing sprays used in secondary recovery in oil fields. This equipment consists of a machine that fires a laser beam through a spray pattern to produce shadow images that are picked up on a TV monitor. The video images are stored in an instant replay recorder. These can be replayed later, frame by frame, for drop sizing by means of a ruled scale on the face of the TV monitor.

Flow rates, pressure and drop size measurements for various nozzle types (straight bore, normal fog, high pressure fog), settings (straight stream, narrow and wide angle fog), and locations at the discharge point as well as within the cross section of the spray are planned. Measurements of sprays, produced by the splatter of straight streams on walls and ceilings, will also be measured. Full-scale compartment burns relating fire control performance to these water stream characteristics will complete the initial investigation.

If measurements indicate current suppression equipment is producing drops that, on the average, are either excessively small or large and burn tests verify that large portions of the hose streams are wasted, it may be possible to improve the spray characteristics and ultimately achieve quicker and more effective fire control with less water.

High pressure fog

Fire fighting experience has shown that high pressure (850 psi) fog creates smaller drops that absorb heat more efficiently and, if conditions are right (i.e., short reach requirements with little or no wind or other air flow that can blow these drops away) such equipment may require lower water flow rates to control a fire compared to typical straight bore and low pressure fog nozzles. On the other hand, experience has shown that high pressure fog has limited reach and can create considerable quantities of steam that may injure the fire fighter.

By adjusting the nozzle design or, perhaps, by simply changing the operating pressure (i.e., in general drop sizes decrease with increasing operating pressure), it may be possible to achieve effective fire control without increasing the quantities of steam. The idea is to reduce the fraction of drops that are too small and are blown away before reaching the fire, and the fraction of drops that are too large penetrating the fire without being fully evaporated. If such control can be achieved, the total water flow rates required may be lowered by wasting less water, even though the same amount of water (but a higher fraction of the total) may be converted to steam in controlling the fire. Understanding these tradeoffs between nozzle pressure, the flow rate, and form of the water and the effect they have on hose size, nozzle reaction, stream reach and fire control performance may lead to significant improvements in fire fighting efficiency and safety, and reductions in dollar and life loss. The full implications are discussed in what follows.

Time is the essence in any fire fighting situation where control is still possible on arrival. Within minutes or seconds, a fire can flash over and involve the entire structure. Anything that reduces the time to locate, size up, and deploy companies can mean the difference between immediate fire control or a major loss.

Hose sizes and weights

A significant portion of fire fighting time and effort is expended in stretching hose lines. Since the weight and maneuverability of the line and nozzle reaction are directly related to the hose size, anything that can be done to keep the size small (without reducing fire fighting effectiveness) will directly impact the fire fighting time and effort. For example, the weight of a charged 50-foot length of 1-inch hose is about 29 pounds; a 1 1/2-inch hose, about 65 pounds; and a 2 1/2-inch hose, about 155 pounds. Moreover, water flowing from a 2 1/2-inch hose has a nozzle reaction over six times greater than from a 1 1/2-inch hose and over 70 times greater than from a 1-inch hose.

If smaller hose lines could be used without reducing fire extinguishing effectiveness, the fire fighting tactics might be improved. For example, research indicates that a better utilization of fire fighting resources might be possible if more attack points could be used. These results suggest that (if access permits) many smaller lines simultaneously attacking the fire in separate compartments favorably impact fire control times, water requirements, and ultimate dollar losses.

All the above observations are particularly critical in rural fire fighting, where water supplies are limited. Equipment improvements that reduce water waste, making the best of what is available, would be a welcome innovation to nearly half the nation’s population that lives in rural areas without hydrants or other readily available water sources. Experience suggest these areas tend to have a high loss rate which may, in part, be attributed to poor water supply and/or poor water utilization in fire fighting.

Multiple dwellings increasing

The fire environment is also changing. Many fire departments today anticipate that the usual type of fire within a few years will shift from detached single family dwellings to apartment and condominium fires. This stems from the fact that in many areas of the country, single family home prices are exceeding the budgets of many families. Increasing numbers of apartments and condominiums are being built to fill the gap.

As this shift occurs, although the initial square footage of the fire may be smaller (800 to 2000 square feet), fire departments can anticipate responding to more severe fires due to more difficult access and added delays in stretching hose lines. Because of some apartment and condominium structural characteristics, fires are likely to have a greater chance of spreading. Also, with the increased use of plastic and hydrocarbon foam-based products in residences, higher intensity fires that flash over more quickly and contribute to rapid fire spread can be expected. Smaller ines and more effective water utilization could help counter these trends.

The more severe fires pose the greatest threat to the life and safety of fire fighters. For example, studies completed by the International Association of Fire Fighters indicate that most fire fighter fatalities occur in multiple alarm or mutual aid fires. Typically, these are structural fires in which the fire has flashed over and is growing in intensity and spreading rapidly.

Every experienced fire fighter has encountered fires that continue to burn and spread even with their hose lines fully applied. In a high intensity, rapidly spreading fire environment, the fire fighter’s safety is directly threatened if the nozzle equipment he is using is not designed properly or is not capable of delivering its rated water flows in a form that control the fire most effectively.

Effect on safety

Fire suppression equipment that achieves improved fire control by delivering rated flows and better utilizing the water would directly impact fire fighter health and safety in ways that include:

- More rapid fire knockdown, which means less physical exertion (i.e., heart attacks) and less time spent in a hostile environment (i.e., burns, smoke inhalation, etc.)

- Less wasted water, which means lower structural loading that contributes to structural collapse.

- For a given hose size, more intense fires would be controllable, which means that the fire fighter would have greater capability to prevent a fire from getting ahead of him.

- Smaller, light, more maneuverable initial attack lines (without reduced fire control effectiveness) would mean shorter attack times and correspondingly less stressful fires to deal with when the water is applied. Again, this means less physical exertion and less time spent in a hostile environment.

- Smaller, lighter, more maneuverable hose lines with less nozzle reaction would also be an advantage in hose operations and would help reduce injuries sustained from lifting and pulling heavy hose lines as well as heart attacks attributed to overexertion.

The computer techniques for calculating water requirements for fire control discussed earlier could be expanded to account for the growth and spread of a fire from compartment to compartment. Fire fighter advance on the fire, timed according to tactical decisions for such functions as equipment and manpower deployment, ventilation, fire knockdown, can also be accurately simulated. Such an expanded computer capability would have important practical applications that include tactical training, prefire planning and fire How estimating.

The training of individuals who must make quick decisions under high risk, stressful conditions is facilitated if the actual dynamics of the situation they face can be simulated in a realistic way and the consequences of their decisions quickly made evident. For this reason, it is common practice in the training of such groups as airline pilots or merchant marine pilots to use computer-based simulators that realistically present the progression of events they can expect to experience, for example, in landing a jumbo jet or piloting a supertanker through a harbor.

The training simulator suggested here is based on the same principles. The essential components of the simulator would consist of a computer operating in conjunction with on-site (in training facilities) or remotely located (in fire stations) user terminals, each including a television-like screen and a light pencil that permits the trainee to communicate his equipment and tactical choices directly to the computer.

The simulator concept might also be used to aid local fire officials in prefire planning for high risk occupancies or in recontructing a suspected arson fire. Moreover, with the rapid advances being made today in microcomputer and bubble memory information storage technology, it may eventually be possible to develop a small, portable simulator concept that could be installed in fire apparatus to support foreground operations.

There is a recognized need to improve the methods of estimating required fire flows for structural fires. Better estimates are needed for applications that include fire protection master planning, community fire insurace ratings and, as discussed earlier, fire equipment purchasing decisions. The simulation might be adapted to allow local fire officers to estimate fire flow requirements for specific fire hazards in their communities within the limits of the fire fighting resources available to them.