By Gregory Havel

Photo as noted

In previous articles, I discussed cross-laminated timber (CLT) used as floor-ceiling assemblies and walls, load-bearing and non-load-bearing. I also discussed connection methods and the International Building Code (IBC) requirement for noncombustible cladding on the exterior.

Heat loss through the building envelope has long been a concern of architects, builders, and engineers. “R-Value” is “the measure of resistance to the flow of heat through a given thickness of material, with higher numbers indicating better insulation properties.”1 (www.merriam-webster.com/dictionary) The R-value can be calculated using formulas for several different systems of measurement. The R-values of the different materials making up a wall or ceiling-roof assembly can be added together to show the R-value of the complete assembly.

Because of the energy crisis in the 1970s and 1980s, the required insulating values in building and heating, ventilating, and air conditioning (HVAC) codes significantly increased. Today’s R-value requirements for different geographic areas are shown in the IBC; NFPA 5000, Building Construction and Safety Code; and the HVAC codes on maps and charts. These requirements are based on geographic and climatic conditions, temperature extremes, prevailing winds, and sun loading. Certification of a building under the Leadership in Energy and Environmental Design (LEED) or another “green building” standard may require even higher R-values.

The R-values of a CLT panel as well as the noncombustible cladding plus the gypsum drywall board will not add up to the required R-value of the wall in many parts of the world. Additional insulation is needed.

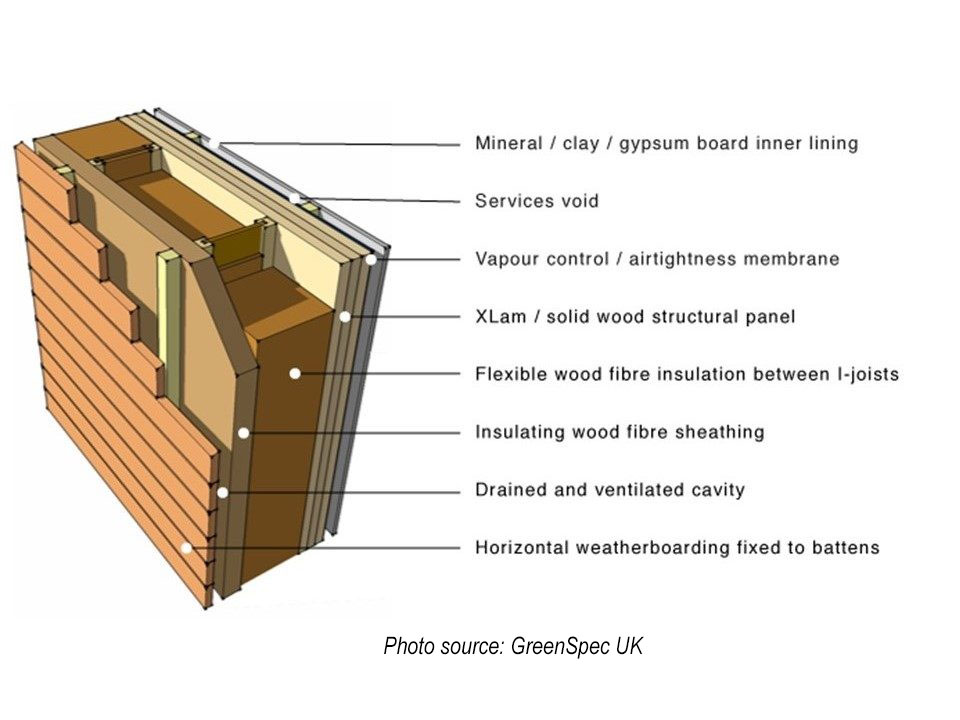

The photo shows a cut-away section of an exterior CLT wall using a system that is common in some parts of Europe. From left to right:

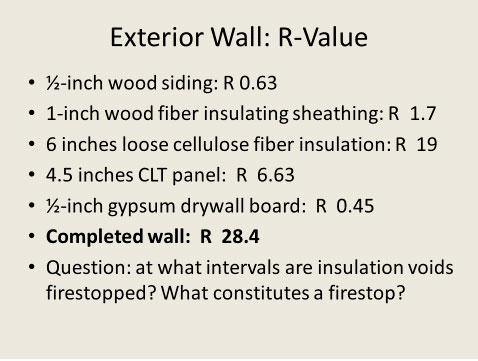

- 0.5-inch (1.27 cm) flame-retardant-treated wood siding: R 0.63

- 1-inch (2.54 cm) wood fiber insulating sheathing R 1.7

- 6 inches (15.24 cm) loose cellulose fiber insulation R 19.0

- 4.5 inches (11.43 cm) CLT panel R 6.63

- 0.5-inch (1.27 cm) gypsum drywall board R 0.45

- Combined R-value of the complete wall: R 28.4

The insulation is usually placed on the outside of the CLT panel to reduce expansion and contraction issues and to make available for use as much of the floor space inside the building as possible.

All of the materials in this wall system are readily available in Europe, North America, and many other parts of the world. As shown, the CLT panel and the exterior insulating sheathing are separated by attaching I-joists vertically to the outside of the CLT, and attaching the sheathing to it. These vertical channels are then filled with loose cellulose fiber insulation.

Other types of insulation may also be used including sprayed foam, foam board, or fiberglass batts or loose fiberglass. Using these may make it impossible to achieve a LEED or other “green” certification because of their use of petroleum products and the large amount of energy required in manufacturing.

Note that the system shown in the photo creates three sets of combustible vertical channels or void spaces within the wall assembly. From the left:

- The spaces enclosed by the flame-retardant-treated wood siding, the wood fiber insulating sheathing, and the wood battens separating them.

- The spaces enclosed by the wood fiber insulating sheathing, the CLT panels, and the I-joists separating them; which space is filled with cellulose insulation?

- The spaces enclosed by the CLT panels, the gypsum drywall board, and the wood battens separating them. This space is commonly used to conceal electrical wiring, data cable, and other utilities.

Vertical void spaces allow fire and products of combustion to develop and travel undetected. You must firestop these spaces at each floor level, but the CLT construction handbooks are unclear on the firestopping intervals or what kind and thickness of material constitutes a firestop. This firestopping will also reduce the amount of settlement per floor of loose cellulose or fiberglass insulation.

Our preincident plans for buildings using CLT panels must indicate this construction material as well as the type of thermal insulation used, its location in the wall and ceiling-roof assemblies, the location of void spaces inside the walls, and their interconnection with any other void spaces (as between ceilings and floors).

Download this article as a PDF HERE (246 KB)

CORRECTION (5/2/2016): The top photo was originally attributed to www.woodworks.org; this has been amended.

Gregory Havel is a member of the Town of Burlington (WI) Fire Department; retired deputy chief and training officer; and a 35-year veteran of the fire service. He is a Wisconsin-certified fire instructor II, fire officer II, and fire inspector; an adjunct instructor in fire service programs at Gateway Technical College; and safety director for Scherrer Construction Co., Inc. Havel has a bachelor’s degree from St. Norbert College; has more than 35 years of experience in facilities management and building construction; and has presented classes at FDIC.

Gregory Havel is a member of the Town of Burlington (WI) Fire Department; retired deputy chief and training officer; and a 35-year veteran of the fire service. He is a Wisconsin-certified fire instructor II, fire officer II, and fire inspector; an adjunct instructor in fire service programs at Gateway Technical College; and safety director for Scherrer Construction Co., Inc. Havel has a bachelor’s degree from St. Norbert College; has more than 35 years of experience in facilities management and building construction; and has presented classes at FDIC.

MORE CONSTRUCTION CONCERNS