By Brad French

Recognizing exterior fire department connections (FDCs) intended for use by an engine company would seem to be a relatively straightforward task for firefighters and pump operators arriving on the scene of an incident involving a building with a sprinkler or standpipe system. In the urban environment, the relentless volume of false alarms in high-rise residential towers caused by burning food and in commercial buildings by the tripping of flow switches by pressure surges in the domestic water supply can foster complacency. Preincident planning will prepare an engine company for efficiency at these addresses.

|

| (1) With a large-diameter storz FDC, volume delivery is maximized through a four- or five-inch opening. This type of FDC is most beneficial in a low-rise occupancy with a high fire load, such as an industrial building or a storage facility. (Photos by author.) |

Spotting the apparatus close to the building’s FDC and the nearest water supply should be a routine part of engine company operations. Knowledge of the building’s fire protection systems will quickly lead the crew to the fire alarm panel, interior standpipe connections, floor control isolation valves, and other critical features in a working incident. But, do we really always know what we’re looking at on the outside of the building? Firefighters are taught early in their careers about assisting pump operators with making hose connections to the FDC to supplement the water pressure in the building’s fire protection system. However, many training programs fail to properly address the variety of possibilities in which exterior hose connections can present themselves to firefighters.

FDC Rules of Thumb

Following are a number of rules of thumb about FDCs firefighters should know and practice:

- Configuration. FDCs come in variety of configurations: mounted straight into an exterior wall; mounted on a post near the building; or as a single 2½-, double 2½- (i.e., Siamese), or large-diameter four- or five-inch storz fitting, for example.

- Threads. Threaded FDCs will be female swivels, indicating their function as an intake into the system. There are a variety of pros and cons up for discussion related to the operational benefits of multiple 2½-inch connections compared to a single four- or five-inch storz connection. However, bear in mind that in high-rise buildings, we are concerned mostly about issues related to pressure and in large commercial and industrial buildings, with very high fire loads; our concerns are more related to volume. The higher pressures possible with double-jacketed 2½- or three-inch hose, coupled with the redundancy of multiple lines in the setting of potentially falling glass, make 2½-inch connections the most sensible option for high-rise buildings. The significantly increased water volume potential with large-diameter hose (LDH) supplying four- or five-inch storz connections (photo 1) makes that option more preferable for wide, large-area buildings with sprinkler systems covering dense storage, combustible products, and other high-hazard materials frequently found in that environment.

-

Connections. There may be multiple sets of connections on a structure for different high and low zones in a high-rise building (photo 2) or for different risers in separate areas on large commercial buildings or parking garage dry-pipe systems. Multiple FDC sets may also be interconnected throughout the structure, and supplying any nearby FDC would benefit the overall system pressure. On some buildings, there may be separate FDC hookups for the sprinkler system and the standpipe system, or a building may have a combination system that supplies the sprinkler and standpipe systems at the same time. Only thorough preplanning will let an engine company know about all of these system components for sure.

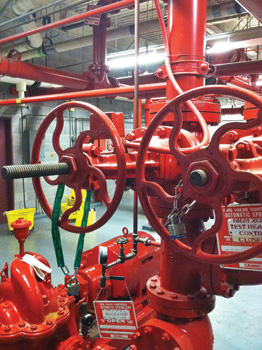

(2) This FDC set indicates that the inlets supply two system zones. However, no specific floor ranges are marked on the signage. Determining the appropriate connections to supply a particular floor would be problematic for an engine company that hasn’t preplanned the building. - Fire Pump. Water-based fire protection systems are ultimately limited by their design, piping diameter, and water supply. In many cases, a built-in stationary fire pump is installed in the building (usually the basement) to kick on and boost pressure if there is significant water flow somewhere in the building. Fire pumps should be identified during preincident planning, and building maintenance personnel should instruct firefighters on how to ensure that the fire pump is functioning, how to activate the emergency run switch if necessary, and how to shut down the unit and any associated outside screw and yoke (OS&Y) valves when appropriate.

-

Test Header. On a response to a building that has not yet been preplanned or a building that is outside of an engine company’s first- or second-due response area that is unfamiliar to the crew, the existence of a fire pump is typically obvious because of the presence of a test connection, or “test header,” mounted on the exterior of the building. There are exceptions, of course; the test connections are sometimes down in the basement with the pump itself or in some other remote area on the property, and, therefore, no obvious exterior indication of a fire pump is present. Generally, fire pump test headers are presented as multiple 2½-inch male threaded connections-one 2½-inch connection for each 250 gallons per minute (gpm) of pump capacity. The headers often have control wheels, similar in appearance to a standpipe outlet (photo 3). The male threaded connections are used to flow test the fire pump annually. These connections are outlet components of the fire protection system; they are not intended to be supplied by an engine company.

(3) This is a common exterior connection setup. It includes a fire pump test header with four male-threaded 2½-inch connections, a typical double 2½-inch female-threaded FDC, and a control valve. -

Signage. FDCs and test headers should be clearly marked with accurate signage to aid the engine company in making the appropriate hose connections. Signage should also indicate any specific operational issues related to the fire protection system, such as an FDC that is supplying sprinklers (SPKR) only, standpipe (STDP) only, combination SPKR/STDP, partial system only serving certain areas, or dry systems that will require water supply into the connection prior to any water being available in the system at all (photo 4). In some cases, tactical decisions will be made based on the characteristics of the system noted on the signage and the situation presented. For example, an exterior rope stretch or extended manual hoselay from the engine may be more efficient than charging an FDC to supply the dry standpipe risers and piping system throughout a large-area parking garage for a car fire on a lower floor.

(4) Noting the signage is critical to the engine company connecting to the FDC. Items indicated by the signage can include which areas or zones the FDC supplies; the type of system (sprinkler, standpipe, or combination) present; and other key factors such as the presence of dry-pipe risers.

The potential operational problem in this environment lies with the confusion that may occur when exterior connections don’t fit the typical models described above. Confusing an FDC with a pump test header could lead to a catastrophic tactical error. Fire pump test headers are almost always male threads, but you may encounter exceptions (photo 5).

|

| (5) A female-threaded fire pump test header. It is uncommon and may confuse a firefighter/pump operator who is not familiar with it. |

In the dark of night at 0400 hours, it’s entirely possible that an unknowing firefighter could make a 2½-inch hose connection to a female-threaded fire pump test header. In this scenario, the line would be charged and appear to be functioning but in fact would be stopped dead at a closed OS&Y valve in the basement. The piping leading to the pump test header is carried in the closed position and is opened only once each year when the contractor shows up to test the system (photo 6). The incident could suffer significantly from this error before it is realized and corrected. When exterior connections are grouped together, recognizing the difference between the FDC and the test header is usually quite simple. However, when the FDC and test header are in different areas, a female-threaded test header could provide the recipe for disaster for a firefighter quickly noting the female threads and making the hookup (photo 7).

|

| (6) Note the open OS&Y valve to the main riser piping and the closed valve to the fire pump test header. Mistakenly pumping into the test header connection would be pumping to a dead end. |

It is critical that pump operator training programs include this information. Also, firefighters should carefully read the signage and mounting rings or plates that surround exterior hose connections as they approach (photo 8).

|

| (7) Two exterior connections are visible on this structure, on different sides. Both are identical double 2½-inch female swivel connection sets. One is the FDC; one is the fire pump test header. Firefighters need to carefully read the faded marking plates to determine the proper connection to supply. |

Three recent incidents within weeks of each other in my department illustrated the critical importance of properly operating sprinkler systems containing working fires in large commercial buildings prior to the advancement of attack lines. Understanding these fire protection systems and recognizing problems if they arise are critical firefighter skills in the modern built environment. Training should include frequent engine company drills that cover issues such as overcoming broken or seized-up female swivel connections, deploying hose from standpipe outlets, isolating sprinkler piping with floor control valves after fire containment (or with cold-weather pipe bursts), and engaging in emergency operations involving fire pumps.

|

| (8) This connection on a post at street level from a distance would appear to be an FDC with a missing female swivel. However, closer inspection reveals that this is in fact a fire pump test header. An engine company that would use adapters to attach hoses and charge this connection would be making a major tactical error. |

You may frequently be called to respond to buildings that have these built-in protection features. Is your engine company prepared to show competence and effectiveness in these situations instead of having complacency creep in and set your crew up for operational failure?

BRAD FRENCH is a lieutenant with the Dayton (OH) Fire Department (DFD), where he is assigned to a downtown engine company. He is a 15-year member of the fire service and has degrees in fire science and fire administration. He is a lead instructor at the DFD Training Center and a member of the board of directors for the International Society of Fire Service Instructors and an instructor in its “Principles of Modern Fire Attack” program.

Fire Department Connections: Start to Finish

The Challenges of Fire Department Connections

Fire Protection Engineers in the Fire Service