By George Potter

An early-morning 911 call from a neighbor informs firefighters of an alarm bell sounding from a commercial building nearby. He gives the street and number and also says that he has seen unusual illumination inside. The dispatcher informs the corresponding station, giving added information from computerized files: The building houses several mixed-merchandise establishments on the first three floors, and the remaining three floors are offices. There is no information about human occupation at this particular hour. The building is fully sprinklered.

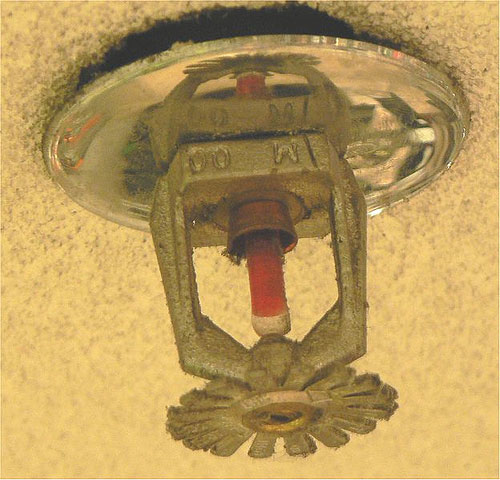

(1) A fire sprinkler head.

The assigned response of an aerial, two engines, an ambulance, and a battalion chief (BC) get on the road. As the chief, the incident commander (IC), approaches the building and observes the illumination through the windows and wisps of smoke from the roof. What does he do?

If the department has standard operating procedures (SOPs) or standard operating guidelines (SOGs), the IC would request the following information from dispatch or, if he has a set of data files on specific hazards in his area, check the file on the building:

- The exact location of the building

- The dimensions and type of construction

- The presence of any exposures

- Access points to the building

- Possible occupancy

- Specific hazards: nature, quantities, and locations

- The closest hydrants for primary and secondary water supply

- The location of the fire department connections (FDCs)

- The type of sprinkler system or systems installed

- Any other automatic extinguishing installations

If the IC has this information before he arrives, he will gain valuable time to perform size-up and establish his intervention plan to take full advantage of his resources, those on the scene and others he may consider necessary. Based on this information, he can opt for a second or third alarm to bring more material and personnel onto the scene. If the sprinkler system has operated as it was designed to operate, it may be possible that only the first response team will be needed to complete extinguishment of the fire, verify the extinguishment, and perform salvage and other loss-reduction actions, block off the activated sprinkler heads, and return the system to an operational status until the property maintenance personnel can replace the heads and evaluate the damage.

If the IC does not have at least this information before arriving, he will have to spend precious time and energy doing size-up and evaluation; getting his attack plan in order; finding the FDC (if he intends to hook up to guarantee the water supply to the sprinkler system), and get the attack teams inside to find the fire and attack, contain, control, and extinguish it. More than likely, he will have requested a second and even a third alarm.

Again, if the sprinkler system in the building is in proper operating conditions, it is quite likely that this system would at least contain the fire, impeding its propagation and intensity during the response-time frame. However, the IC would have wasted significant time and would unnecessarily placed personnel and material in possible compromising conditions as well as have “permitted” unnecessary property loss.

Until not too many years ago, and based on the initial precepts of fire sprinkler systems, the protection of property, machinery, and merchandise were the foremost arguments in favor of installing this mode of protection in properties, based principally on the insurance companies’ offers of considerable premium reductions and more favorable loss claims adjustments.

However, full-scale live fire tests carried out in several countries during the latter half of the 20th century (such as the Fire Research Station in the United Kingdom and Operation San Francisco, among others) have shown that automatic fire sprinklers can make significant contributions to the improvement of conditions in fire environments, lowering temperatures, diluting fire gases, and improving visibility, substantially increasing time available to occupants of a burning building to successfully evacuate the premises. Every day, more and more properties are being protected by these “mechanical firefighters”: commercial shopping complexes, warehouses, factories, hotels, office buildings, and even residences. Worldwide statistics on fires and losses virtually agree (a point above or below) on the following:

- In some 70 percent of fires that strike sprinkler-protected properties (properly maintained and functional systems), three sprinklers were sufficient to contain and control the fires.

- In 90 percent of fires, 10 sprinklers were able to contain and control the fires, impeding greater property losses and contributing to life safety.

Many firefighters do not completely understand the functional or operational mechanics of automatic fire sprinklers, although they may well be aware of their existence in their response areas. Incorrect or inadequate actions performed by firefighters in a fire-damaged building protected by sprinklers could contribute to an increase in damage and subsequent losses, whereas correct procedures could well contribute to further reductions of losses as well as improve safe conditions for firefighters during their intervention.

Many communities in this country have at least one property protected by automatic sprinklers, and thousands of towns and cities have dozens or hundreds of establishments equipped with partial or full sprinkler systems. It is essential that every firefighter in the community–not just the officers, but each and every firefighter–has fundamental knowledge of the concepts of automatic sprinklers and is familiar with the diverse systems they may encounter and what actions they should perform and in what sequence. Fire department training officers should have adequate references of contacts they can approach for help in developing and delivering training programs on fire department operations in sprinkler-protected properties.

Basic information personnel should have is what hazards exist in their response area, the nature of these hazards, the amounts of the hazards, and their locations. This information should already be on file and available to commanders, initially in the central alarm reception and dispatch facility as well as in each commander’s station, preferably in a portable archive (specific file cards) or in an instantly available portable computerized database. There are a number of formats for these files; the department should have selected the one most appropriate for its needs. It is essential that as many firefighters as possible visit sample sprinkler-protected properties to get hands-on knowledge of the systems, their components, and what they should and should not touch when they respond to fires in these establishments.

The data in these files will give the IC the information he needs to perform size-up and formulate his initial attack plan. The file should indicate which hazard locations are protected with automatic sprinklers, the type of system(s), the locations of alarm check valves and post indicator valves in the water supply system, the location of the fire pumps and their controls, and other information. A great part of this information should also be included in the sprinkler training program.

Although it is probably not necessary that firefighters know the complexities of the hydraulic calculations involved in sprinkler engineering design, they should be familiar with the multitude of hazard classifications as per National Fire Protection Association (NFPA) 13, Standard for the Installation of Sprinkler Systems, the distinct types of sprinkler systems and sprinkler heads they may encounter, and the water flow alarm and control valves incorporated.

HAZARD CLASSIFICATIONS ACCORDING TO NFPA 13

NFPA 13 establishes three global categories of hazards. Two are subdivided according to specific criteria, and the other classification covers commodities and products. The following are examples of the vast number of activities within the hazard classifications:

LIGHT HAZARDS

– Churches

– Hospitals

– Hotels*

– Libraries

– Museums and art galleries

– Nursing homes

– Offices

– Restaurant seating areas

– Schools

ORDINARY GROUP 1

– Automobile parking

– Bakeries

– Electronic plants

– Laundries

– Restaurant service areas

ORDINARY GROUP 2

– Barns and stables

– Cereal plants

– Chemical plants – ordinary (low combustible risks)

– Dry cleaners

– Machine shops

– Paper and pulp mills and paper process plants

– Post offices

– Textile manufacturing

– Wood machining and wood product assembly

EXTRA HAZARD GROUP 1

– Aircraft hangers (except as per NFPA Standard 409, Standard of Aircraft Hangars*)

– Die casting

– Plywood and particle board manufacturing

– Saw mills

EXTRA HAZARD GROUP 2

– Asphalt saturating

– Flammable liquid spraying

– Manufactured home or modular buildings with combustible contents

– Open oil quenching

– Plastic processing

– Solvent cleaning

– Varnish and paint dipping

The commodity classes I, II, III, and IV depend mainly on the combustibility or noncombustibility of the products and their packaging and on specific characteristics of plastics.

Now, as seen in these classifications, hotels are classified as LIGHT HAZARD occupancies. However, let’s look further into this classification.

Guest rooms Light Hazard

Corridors Light Hazard

Meeting rooms Light Hazard*

Toilet rooms Light Hazard

Restaurant seating areas Light Hazard

Kitchen Ordinary 1

Parking garage Ordinary 1

Machinery rooms Ordinary 1

Electric rooms Ordinary 1

Storage rooms Ordinary 2

Ballroom Ordinary 2*

* In some hotels, the ballroom may be used as an exhibition space. If the ballroom were to be classified as a light hazard occupancy (meeting room), the hotel would not legally be permitted to use the ballroom as an exhibition site. Interpretation of hazard classifications is difficult and, at times, confusing because of the way various hazard classifications are defined. Although these finite details may not concern the average firefighter, officers and commanders must be familiar with them, and they should be included in the sprinkler training program so that all participants can be somewhat familiar with them and the firefighters can at least differentiate between more common activities and occupancies. Many state fire authorities have established specific hazard ratings which may not exactly coincide with the NFPA ratings, but they are never less than the NFPA categories.

SRINKLER SYSTEM ENGINEERING, DESIGN, AND SPECIFICATIONS

This “chapter” is most assuredly the most complicated as in covers a multitude of aspects, mathematics, hydraulic calculations, pipe dimensions and characteristics, system types and configurations, valve characteristics, sprinkler head types, position, temperature ratings, dimensions, the discharge rate of a nozzle (K-factor), and so on. Again, it is not necessary that all firefighters are capable of designing a sprinkler system, but again there are concepts that they should know and understand. These include:

SPRINKLER SYSTEM TYPE CHARACTERISTICS

- Wet Pipe Systems: All piping is pressurized with water. This is the simplest and generally considered as most reliable. Wet pipe systems are installed in the majority of hazard classifications.

- Dry Pipe Systems: Installed where low ambient temperatures would cause freezing of water in piping: non-heated properties in cold climate regions, cold storage facilities, and the like. The piping from the water flow alarm and control valve is pressurized with air. Dry pipe systems are more expensive and complex than wet pipe systems.

- Deluge Systems: All sprinkler heads are open and no water or compressed air is in the piping. Activation is by smoke, heat, or flame detection, which provokes the operation of flow valves; the system can also be operated manually. Deluge systems protect specific hazard areas and are often used to protect evacuation routes.

- Preaction Systems: Used in the protection of very specific Hazards such as museums and similar locations. The sprinkler heads are sealed, and the piping is charged with water as with wet pipe systems. Activation is generally by an interface with a detection system which provokes the discharge of special preaction sprinkler heads.

- Foam Water Sprinkler Systems: Applies low expansion foam spray. The system can be wet or dry pipe and is used principally to protect flammable liquid hazards, aircraft hangers, and so on.

- Water Spray: This is similar to the deluge system but incorporates fine spray nozzles instead of standard-type sprinkler heads. These spray nozzles, often not standardized, are designed to discharge specific spray forms or patterns. They are generally installed to protect three-dimensional hazards such as electric power transformers with cooling oil or containers of highly flammable liquids or gases with the objective of preventing a boiling liquid-expanding vapor explosion (BLEVE).

All responding firefighters should be able to identify the type of system installed and the locations of the basic components.

SPRINKLER HEADS

The sprinkler heads or discharge devices are specially designed and fabricated to project water in a predetermined flow shape over a specific area at a determined discharge rate (back to engineering and hydraulic calculations). The sprinkler heads are fitted into the piping at calculated distances and may be in an upright or suspended position or along walls or over doors in a side-wall situation. The heads may be fitted to piping that is hidden by a suspended ceiling with only the arms and deflectors visible. They may be installed on piping that runs through storage racks in warehouses at possibly mid-height with another installation over the tops of the storage racks.

The sprinkler heads may be fitted with metallic fusible links or with glass bulbs containing a non-flammable type of alcohol, both of which are thermal sensitive and made in such a way as to break at certain predetermined temperatures, permitting water flow. There are small- and large-orifice sprinklers and the relatively new Early Suppression Fast Response (ESRF) sprinklers, designed to fully suppress a fire that is within the design limits of the piping system.

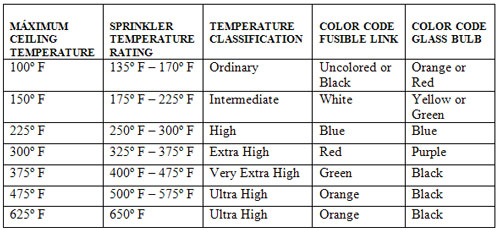

There are six temperature ratings for sprinkler heads in accordance with the hazard classifications:

The maximum ceiling temperature relates to the temperature at the ceiling generated by a fire; the sprinkler temperature rating is the temperature range in which the head is designed to discharge. The temperature classification determines the hazard classification the sprinklers are destined to protect. The ratings are all relative to the expected intensity of a fire in any given hazard category–the higher the hazard class, the hotter the fires will burn. The color codings facilitate installation and replacement of activated heads or indicate what heads should be used if any changes occur to the hazard classifications of a given location. Here again, it may be necessary to recalculate water discharge rates in certain circumstances.

FIRE PUMPS

A sprinkler system should be supplied with a group of standardized and classified specifically designed fire pumps. The configuration is normally a low-flow jockey pump that serves to maintain pressure in the system; a principal pump, normally electric-powered and designed to meet the calculated flow; and a backup diesel-powered pump of identical flow characteristics designed to maintain discharge demands in case of electric power failure or to augment flow if demand exceeds the primary pump’s capacity. The pumps are normally single stage, split case centrifugal types. Electric driven backup pumps may be acceptable if (1) the electric power source is totally independent from the power source of the primary pump; (2) electric power is by an autonomous electric generator.

The fire system pumps must be capable of supplying the hydraulically calculated demands of a determined number of activated sprinklers and supply adequate flow to a determined number of handlines. The pump assembly is usually housed in a specific facility, often a pump house some yards away from the protected building or inside a protected pump room within the building. The pumps are equipped with a complete installation of controls, adequate diesel fuel for the diesel pump, battery chargers, and exhaust tubing to the exterior of the pump location. Normally, the pump house or room is equipped with an independent automatic extinguishing system, usually CO2 or any one of the clean agents.

The jockey pump is capable of maintaining pressure in the system up to a determined flow, inferior to that of just one sprinkler head. When a sprinkler head activates and water flow causes a drop in the pressure, the primary fire pump automatically starts and supplies the required flow at the required pressure. Once the fire has been totally extinguished, the primary fire pump must be shut down manually.

It is essential that the IC has information on the fire pump system, for he must assign a firefighter to stand by at the pumps to shut down the operating pumps when the sprinkler system is no longer required and rearm the system once activated sprinkler heads have been blocked and the system can be placed back in service.

WATER SUPPLY, HYDRANTS, PIVs, FDCs, AND FLOW ALARM CONTROL VALVES

Here we go again, back to engineering. The water necessary to supply a fire protection system–be it simply fire hose stations, a hydrant loop, or a complete automatic sprinkler installation–must come from somewhere and be stored in a readily accessible site at the protected property. Municipal water systems can usually feed the water storage system and provide hydrants to which engines can hook up to supply FDCs and handlines. The location(s) of FDCs must be indicated in the file and visually indicated on the building.

Firefighters should practice locating the FDCs and laying supply hoselines to them. However, if the protected property is some distance from municipal water supplies, the facility should have a supply system to a storage tank with a capacity sufficient to meet the calculated demands of the fire protection system. The site may have an underground pipe system, generally in a closed ring or loop form, that may feed various water-alarm control valves that control specific zones within the building (that can be vertical sections of various floors, entire floors for each valve, or various valves controlling specific areas.)

The alarm control valves are essential components of the sprinkler system. They are designed to maintain balanced pressure from the pumps to the pipe grids on which the sprinkler heads are mounted. There may be only one or several of the valves in the system. They are usually, but not always, adjacent to walls or inside the building, and they will have a water motor gong alarm most often on the outside of the wall, close to the valve. The alarm gives audible warning that the system is discharging water somewhere inside the building

Post indicator valves (PIVs) are at determined points along the water main and sectorize the mains, if necessary, to concentrate or limit flows in the system or maintain full protection capacity if one or another section of the main must be shut down for maintenance or any other reason. During a fire operation, the IC should assign firefighters to supervise these PIVs.

Once the fire has been completely extinguished, the IC must verify this and get overhaul and salvage going. Also, the activated sprinkler head(s) must be blocked off with adequate devices to ensure that no water will flow from the head(s) when the system is put back in service. Mechanical blocking devices exist, but frankly, balsa or other soft wood plugs are quite adequate; they can be easily made in any fire station and are very economical. Buy some rods of rectangular balsa wood or soft pine from a local model shop or a do-it-yourself store (see photos). The plugs are inserted into the sprinkler head between the arms and are gently hammered in until they stay stuck. Since the activated heads are no longer usable, they are normally thrown away when replaced, so unless you have an “unlimited” supply of plugs, get them back from the property.

**

The basic operations to be performed by the IC, commanders, and firefighters when responding to a confirmed fire in a sprinkler-protected property are the following:

- Preincident planning: Know where sprinklered properties are located and what types of systems they have, what hazards exist, and where these are located (IC).

- Confirm the existence of a fire, its location, fuels, magnitude, and extension (IC).

- Size-up the incident, determine what sprinkler system is activated, and establish and commence the initial attack plan (IC).

- Assign firefighters to supervise PIVs, alarm control valves, and fire pumps (IC, firefighters).

- Locate the fire, attack if necessary, contain, control, and extinguish the fire (attack teams).

- Verify extinguishment, commence overhaul and salvage (officers, firefighters).

- Close down PIV and alarm control valves; shut down fire pumps to depressurize the system (firefighters).

- Block off activated sprinkler heads (firefighters).

- Rearm fire pumps (firefighters).

- Open alarm valve and PIV (firefighters).

- Incident report for fire department management and action report for property management (IC).

- Replace activated sprinkler heads (property maintenance).

This sequence of operations is basic and should be adapted to each fire department’s specific needs and requirements. Some specific points may not be needed; on the other hand, others not included here perhaps could and should be incorporated.

BUILDING INSPECTIONS

Fire prevention and building inspections can provide a great deal of the information required for the sprinkler response fires. Emergency response plans implemented in companies can be another source of valuable information for the fire department. Sprinkler contractors, consulting firms, and architects are yet more sources. And, of course, the management of protected properties are first-hand sources of information. Fire departments should establish relations with these enterprises to share important, useful, and mutually beneficial knowledge.

George Potter is a former Anne Arundel County (MD) volunteer and served in the United States Air Force as a firefighter, an apparatus driver/operator, and a crew chief. For the past 40 years, he has been involved in fire protection systems, mobile fire apparatus design, and construction and fire safety training for Spanish public fire services and emergency responders in business and industry in Spain, Portugal, and Algeria. He is a Spain-certified fire service instructor and a board member of the Spanish Firefighters Association, ASELF, and the Spanish Fire Protection Engineering Association.