Early in our careers, firefighters are taught how to use a set of irons (a halligan tool and an ax or maul) to force inward- and outward-opening doors with conventional techniques. We’re also taught a host of other tactics in forcible entry, from using power saws to cut roll-down gates, overhead garage doors, padlocks, and security bars to using the K-Tool to pull lock cylinders on doors. Today, there are smaller size saws and cutters that operate off rechargeable batteries. Their operational procedures differ a little from their larger counterparts that run off a fuel mixture, but they still accomplish the same tasks. Although many of the forcible entry tactics we’re taught work very well when operating on a flat surface at ground level or inside a structure, we’ll need alternative tactics when we’re operating inside the tower ladder bucket. Plus, we should always be wearing an approved safety belt while working in the bucket during any firefighting operation.

(1) Note the difference in the color of the bricks under the lintel. This former garage had an exterior wall installed in the former garage door opening. (Photos 1-3 by Megan Ciampo.)

(2) Firefighters will encounter another type of block in structures. You can remove glass blocks with the back of the ax or a maul for ventilation or master stream penetration.

Bricked-Up Windows

Many vacant buildings have windows and doorways bricked up with cinder or concrete blocks to thwart entry by people trying to break in to steal pieces of the building’s piping systems, architectural woodwork, windows, and doors. Securing the buildings this way is also designed to keep out the homeless so they don’t accidentally burn the building down or if hoarders move materials into these buildings.

During the years when buildings with large windows were nonenergy-efficient, a sudden retrofit of closing in many of the windows with bricks or blocks made these buildings more energy-efficient. When you look at some of the buildings that were retrofitted, you’ll see different brick patterns in comparison to the walls (photo 1). Also, large lintels may point you in the direction of where the windows once were and where you may be able to quickly open them up with power and hand tools for entry, ventilation, or flowing the master stream into the structure. Don’t be surprised, though, if you find stock racks and machinery on the inside. You can find these retrofitted windows in factories, old car dealerships turned into other types of occupancies, and stores that front more than one street.

When we were taught basic forcible entry tactics for entry level doors or ground-floor windows secured with blocks, we were told we didn’t have to break open each individual block. We were also told to let the weight of the bricks help us do our job quickly and more efficiently. Whether using the back of the flathead ax or a maul, we’ll take power swings, like a baseball player swinging a bat, at the middle of the door or window. It’s important to know that most cinder or concrete blocks have open cavities in them, known as cores. Striking the blocks in the area of the cores will break them faster and easier than striking them in the solid structural web portion. These web portions will be more substantial and take longer to break open. Some installations may have concrete inside the cores, making them more substantial and difficult to force (photo 2).

Once you have made a hole in one or two blocks in the center of the opening, continue to work on removing these blocks entirely. Be aware of pieces of brick falling on the ground in your work area so you don’t slip on them—don’t be in such a rush to force entry that you forget. Firefighters have slipped on this debris while swinging the tool and struck the door frame, wall, or brick with their hands, receiving injuries that they could have avoided if they cleared the area of debris prior to swinging.

Once you remove two blocks, you will have a rectangular opening. Start striking the adjoining bricks in that row. Some firefighters will use a battering ram motion with the ax or maul’s head to remove them—this pushes the bricks inward and hopefully keeps the rest of them going in the same direction.

Once you have removed an entire row, keep in mind that the upper blocks are now unsupported and could collapse downward at any moment. If they haven’t fallen, use caution and strike the next upper row of blocks somewhere in the middle or at the edge of the opening. The force from the striking motion and removal of another block will normally make the rest of the blocks collapse. That is the objective because it’s less work and cuts down on the time it takes to gain entry. Always keep an eye on the upper portion of blocks that are unsupported; they are heavy and can fall outward toward you and cause injury. If the blocks fall inward, you’re less likely to get struck but more prone to twisting an ankle when climbing over the loose pieces of the scattered debris when entering the structure. Prior to entering the structure, remove all the unsupported blocks that are still secured or hanging overhead in the doorway. You don’t want other firefighters advancing a line or making entry under the blocks to be struck by them if they collapse.

When working on ground level, this is the method many use on blocked-up windows and doors. However, when operating in a tower ladder bucket in an elevated position on an upper floor, this shouldn’t be the preferred method of forcible entry. If a firefighter started “opening up” the blocks on the third floor of a four-story building and the blocks were to suddenly collapse, they could severely injure or kill an unsuspecting firefighter or civilian below. If they bounce off an architectural building feature and go flying outward, they too could injure someone.

When operating in the tower ladder bucket to force open blocked windows on upper floors, cordon off the area below or have firefighters act as a safety and not allow anyone to operate under the bucket. Then, position the bucket so the firefighter swinging the tool has hand and arm clearance. That’s very important so as not to hit the bucket’s railings, master stream, or controls when swinging. Like playing baseball and getting in the batter’s box, firefighters should take a practice swing to ensure they won’t strike any of these items with their hand or arm. A practice swing will also indicate if the bucket is in the proper position to reach the window with the hand tool.

When striking the blocks, start at the top row of blocks and knock them inward. Starting there allows you to work downward and out of escaping smoke and heat; more importantly, there’s less chance of the blocks collapsing downward onto firefighters below. The battering ram technique will also work to force the blocks inward once you make an initial purchase. There’s always going to be some debris falling downward; firefighters operating on the scene must be aware of operations being performed overhead.

When opening up these windows at vacant buildings, as you knock the first few blocks inward, listen for the “thud” sound when the block hits the floor. When you hear that sound, you’ll know a floor exists inside the structure. If you don’t hear that sound, notify the incident commander and companies on scene that there may not be any floors or that there may be holes in the floors.

When opening up many floors of blocked-up windows, start at the highest level and work down. This gives the firefighters in the bucket better visibility, keeps them out of rising heat and smoke, and limits the chances that they’ll be caught in a smoke explosion or escaping flames from the openings below them.

Security Bars

Security bars on windows are a severe hazard because they cut off another means of egress from the fire building. When sizing up these bars, look for the weakest point on how they are attached to the building. Sometimes just prying them away from the building near the anchors will pull them out of the wall, mortar joint, or brick.

Some tower ladders have a homemade pry bar or “cheater bar,” which has a small piece of angle iron welded near the pry end of the tool. When you place the angle on the wall of the building and the pry end behind the security bars, the angle acts as a fulcrum and allows the pry bar to pivot, pulling the attachment points outward and releasing the device.

Another quick method of removing these bars is to use a power tool. Since the fire service has seen an influx of lightweight cutters, firefighters have the option of choosing what they feel most comfortable operating with as long as the chosen tool can cut the material. It may also be practical to bring up two tools when operating in the bucket, in case a blade or cutting disc breaks or becomes too small to continue cutting.

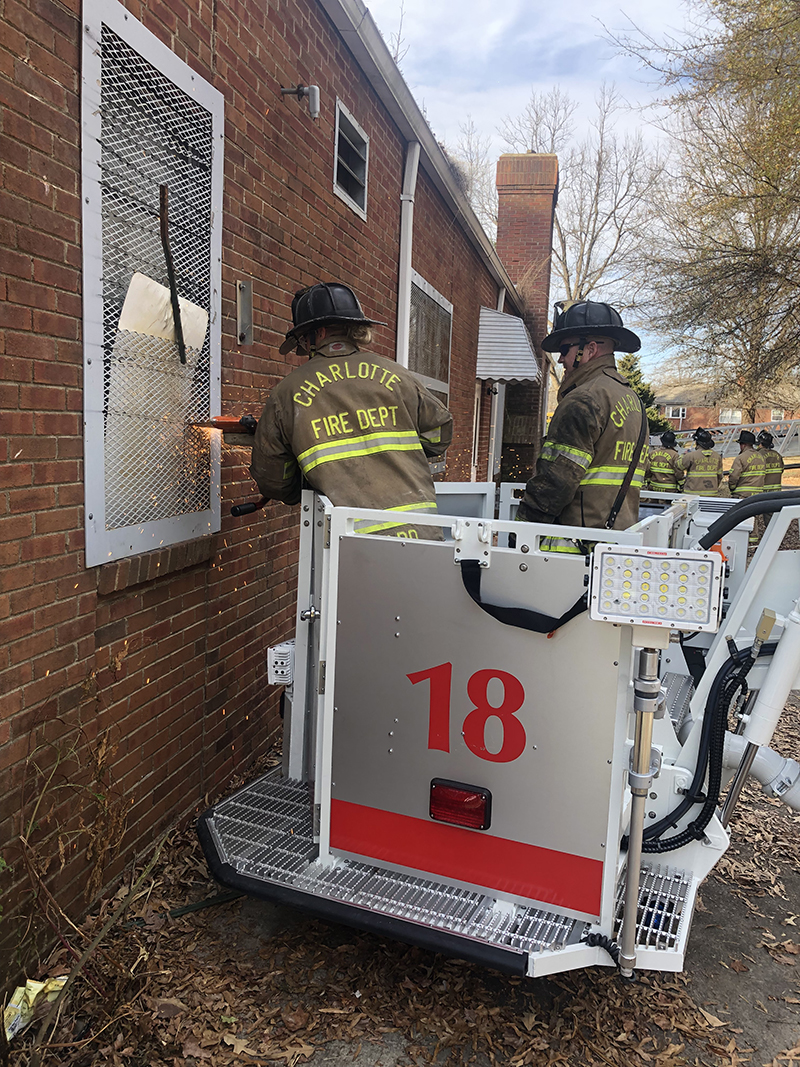

When cutting from inside the tower ladder bucket, ensure any other firefighter operating next to you isn’t in the vicinity of the metal fragments and sparks coming from the saw. Also, if possible, have the bucket’s lip up against the building so if the security bars were to suddenly drop or hinge downward, they might get caught on the lip and not fall to the ground. Again, make sure members do not operate below the bucket or wander into the danger zone (photo 3).

(3) When using the tower ladder to cut open window security devices, consider the area below a danger zone.

Once you have removed the security bars from the window, there are a few options as to where to place them. If the building is vacant and you’re going to use an exterior attack, you can place them back inside the structure instead of dropping them to the ground. In some circumstances, dropping them to the ground may be best as long as nobody is in the vicinity. Some might say it’s best to put the bars inside the bucket, but that becomes a slipping hazard if they’re on the floor. Plus, it’s just more things to get in the way while you’re moving around the bucket performing firefighting operations. There have been instances where firefighters placed a longer section of bars in the bucket, hampering firefighters exiting and entering the bucket. That’s why it’s imperative to size up what you’re doing and where you’re doing it.

(4) Sometimes, reverting to hand tools will release security devices quickly. The pike of the halligan tool slides into the mortar groove and easily pops off the rivet attachments on these screens. (Photos 4-8 by JJ Cassetta.)

Security Screens

Metal screens are another security measure you can remove from a building using the tower ladder bucket. Consider their size, physical makeup, and attachment points when deciding what removal technique will work best. Sometimes, you can simply pop out the attachment point; other times, you may have to use a power saw (photos 4-5). In some instances, it may be easier to cut the center section out, especially if it’s expanded metal (wide mesh grating) mounted inside a large frame. This is easy to do with one firefighter operating the saw while the bucket operator moves the bucket horizontally or vertically. If you cut an upside-down “U” pattern, you can bend the metal or pull it downward. Performing this technique allows entry and unimpeded stream penetration into the structure. It also keeps the screen and frame assembly from falling to the ground and possibly injuring someone below.

(5) These large panels may require the use of a power saw to help remove them to ventilate this structure.

(6) The power saw rests on the master stream device’s handle, helping support it during the cut.

(7) Practice this skill; the speed of the saw and bucket movement must be a coordinated effort.

With the physical makeup of some tower ladders, performing horizontal cuts with the saw can be made easier with some simple techniques. Some master stream appliance handles will allow the saw to sit on it, supporting the saw while cutting. Doing this takes some of the strain off a firefighter’s body—it’s not carrying the entire weight of the saw during the horizontal cuts (photos 6-7).

Another way to do this is by opening one of the stokes basket carrying brackets in front and leaving it at an angle. Now, the saw can sit in between the bucket’s front railing and rest on the angular bracket arm (photo 8). The firefighter only has to worry about operating the throttle of the saw while maintaining the saw’s balance on the bracket.

(8) The power saw rests on the stokes basket carrying brackets, taking the weight of the saw off the firefighter.

When the horizontal cuts are being made, the bucket operator and saw operator must communicate as to the speed at which the bucket is traveling. The speed must coincide with the speed of the saw cutting. This method can also work on roll-down security gates and garage doors. If you use the tower ladder bucket to cut the garage doors at loading docks, the bucket operator must be aware of the lip of the loading dock’s edge and the rubber bumper pads when booming downward. The bucket is a great work platform at this type of structure; drill there before an incident to learn the rig’s capabilities.

The tower ladder provides an excellent work platform for forcible entry operations at elevated heights. However, just because you operate one way on the ground doesn’t mean you operate that way in the air. You must understand your tools and equipment as well as your body mechanics when operating in the bucket—and don’t forget about the safety of others operating on the fireground below.

MICHAEL N. CIAMPO is a 37-year veteran of the fire service and a lieutenant in the Fire Department of New York. Previously, he served with the District of Columbia Fire Department. He has a bachelor’s degree in fire science from John Jay College of Criminal Justice in New York City. He is the lead instructor for the FDIC International Truck Essentials H.O.T. program. He wrote the Ladders and Ventilation chapters for Fire Engineering’s Handbook for Firefighter I and II (Fire Engineering, 2009) and the Bread and Butter Portable Ladders DVD and is featured in “Training Minutes” truck company videos on www.FireEngineering.com.