Putting Preconnects on Old Apparatus

Using a little ingenuity and some basic mechanical skills, members of the Hampden Township, Pa., Volunteer Fire Department installed two preconnected lines on a front-mount pump and put additional preconnected lines on a 1250-gpm pumper and a squad truck.

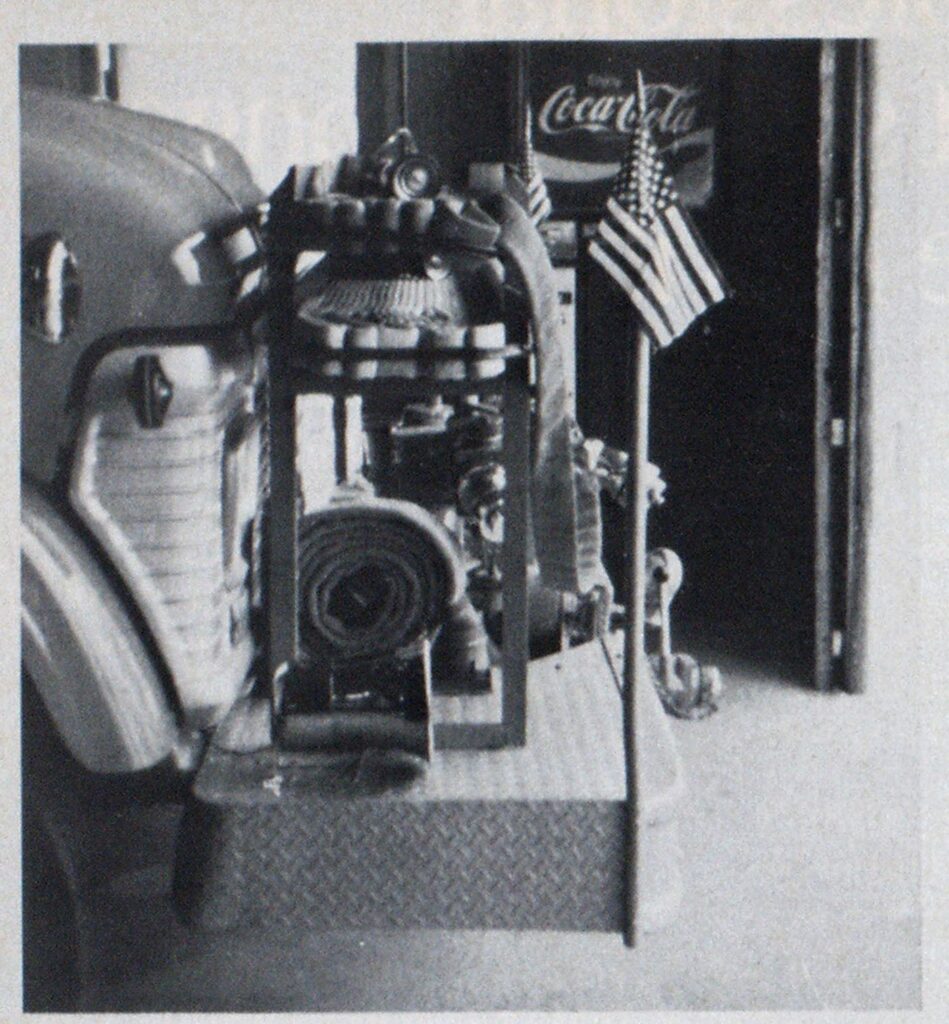

The front-mount pump on our 1000-gallon tanker gave us our greatest problem. It first looked as though it would be impossible to install preconnects without doing an expensive piping job. However, one of our fire fighters came up with the idea to build a rack to hold two hose trays above the pump. Other volunteers with appropriate mechanical skills then built the trays to hold two 150-foot lengths of U/2-inch preconnected hose.

Our squad truck, which responds to all accidents involving injuries along with the township ambulance, was purchased in 1972 with piping for one 150-foot, U/2-inch, preconnected line. We wished to have more and shorter preconnects on this piece.

The squad’s 350-gpm PTO pump and its discharge gates are enclosed in two cabinets, so first we donut-rolled a 50foot length of 1 ½ -inch hose and coupled it to a discharge gate. To put this line in service, all a fire fighter has to do is grasp the nozzle and walk toward the fire as the line unrolls behind him.

In the cabinet on the opposite side of the apparatus, we made up a preconnected line by coupling two 50-foot donut rolls together. A fire fighter can either grasp the nozzle and walk toward the fire, allowing both donut rolls to uncoil, or he can take the top donut roll with him, dropping it only after the bottom roll in the cabinet has been pulled straight.

Our 1250-gpm pumper had two transverse boxes over the midship pump that would each hold 200 feet of 1 ½ -inch hose. However, these boxes were too wide and their sides were too low to hold any kind of an effective shoulder load.

Hose box for six lines

Our first step was to replace the booster reel in that area with a 5-kw generator. Then we removed the hose boxes and made one of ¾ exterior plywood that was designed with four trays for 150-foot, 1 ½ -inch lines and two trays for 100-foot, 2 ½ -inch lines. Three trays opened to the left side and three to the right side of the pumper. The two pipes that serviced the original two preconnected lines were altered to fit the new hose box and the two 1 ½ -inch lines that are pulled from the left side of the pumper were coupled to these pipes. This left four more lines to be connected.

The 2½-inch line on the left side was coupled to a discharge gate on the pump panel. This left the three lines that are pulled off on the right side to be connected. A gated wye connected to one of the two discharge gates on that side was used for the two 1 ½-inch lines, and the remaining 2 ½-inch line was coupled directly to the other 2½-inch gate. A couple of feet of slack was pulled form each line that came down to the hose gates on the side so that the cabinet doors could be opened. The slack is held in a small bundle by old vacuum cleaner drive belts. When the hose is stretched to a fire, the belts drop off.

Hose box over suction

We then built a hose box for a 100foot, lVk-inch preconnect above the upper length of hard suction carried on the left side. We also slid a folded length of 1 ½-inch hose into the upper hard suction and connected both lines to a gated wye on a 2 ½-inch discharge on the pump panel. We find that the 50foot preconnect is handy for trash fires and washdowns.

We next rebuilt the hose bed so that we could have one 200-foot, D/a-inch preconnect and one 150-foot, 2 ½-inch preconnect on each side of the bed. In the center, we carry a divided load of 2000 feet of 3-inch hose. There were four outlets in the rear, so we used two for the 2 ½-inch lines and one with a gated wye for the 1 ½ -inch lines. This left one outlet free.

This arrangement gave us 12 preconnected lines, eight of them 1 ½ -inch and four of them 2’/2-inch. The fact that they are of various lengths, from 50 to 200 feet, and in various locations give us great gives versatility in attacking a fire.

The entire conversion cost less than $200, and we feel that it was the best investment we could have made to modernize our pumper.