By William C. Peters

With great expectations, thousands of eager firefighters lined the halls outside the Indianapolis Convention Center and Lucas Oil Stadium ready to examine the latest apparatus and equipment on display at the 2014 Fire Department Instructors Conference (FDIC). Many had backpacks and carried briefcases to hold the reams of brochures that they were expecting to collect.

At 10 a.m., when the booming voice announced, “Welcome to FDIC 2014; the exhibits are now open,” the firefighters poured into the convention center exhibit hall, much like shoppers on “Black Friday”! Some had exhibit floor maps in hand that guided them to specific booths, and others just began systematically going aisle by aisle in the enormous hall.

Outside, in the area between the convention center and Lucas Oil Stadium, vendors were demonstrating dozens of apparatus of all descriptions. All varieties of aerial devices were set up and operating. Live burn mockups were also being demonstrated.

Inside Lucas Oil Stadium, another large area of apparatus and equipment displays took up the whole stadium. After making that walk, I was happy to discover the booth where young ladies were giving away samples of 5-Hour Energy boosters! I needed it! Pierce Manufacturing had the largest display and did a whole product unveiling, accompanied by the drum line of the Indiana Pacers!

Several manufacturers unveiled updated and redesigned cab configurations. Pierce released the new and updated versions of its Saber and Enforcer chassis (photos 1 and 2). The Saber has been Pierce’s most popular industry standard, mid-size engine chassis since 1992. The Enforcer is more customizable and allows for a larger 500-horsepower (hp) engine. The redesigned cabs on both include additional occupant space, better visibility with a single wrap-around windshield with three wipers, ergonomically designed steps, better seat belt access, adjustable seating against the rear wall, and an improved turning angle.

|

| (1) The Pierce redesigned Saber cab. (Photos by author.) |

|

| (2) The Pierce redesigned Enforcer cab. |

Pierce had several other apparatus on display at Lucas Oil Stadium (photos 3 and 4). An interesting unit was an Arrow XT with a Snozzle Articulating/Telescoping aerial water tower. In addition to the fog nozzle, the water tower has a piercing nozzle to inject foam inside an aircraft or truck body and remote-control capabilities. Water and foam are supplied by a Hale 2,000-gpm single-stage pump and a Husky 60 industrial foam system. The unit carries 750 gallons of water and has a 300-gallon foam tank.

|

| (3) The Pierce Arrow XT Snozzle for the Elizabeth (NJ) Fire Department. |

|

| (4) The fog nozzle and the piercing nozzle on Pierce’s Snozzle apparatus. |

Pierce also displayed its TAK-4 3 mechanical independent rear suspension system that uses coil springs (photo 5). The unit boasts an improved turning radius and increased maneuverability and safety.

|

| (5) The newly designed Pierce TAK-4 3 mechanical independent rear suspension system. |

E-ONE also had several pieces of apparatus on display in the convention center. One that caught my eye was the newly designed Quest cab (photo 6). When E-ONE unveiled the original Quest a few years ago, it appeared to be more “futuristic” looking than most rugged, standard fire apparatus. The redesign has a bold stainless steel grille and the typical quad headlight units separated by a single row of bright white light emitting diodes (LEDs). The dashboard was lowered, and the overhead console was raised to give better visibility from the large sloping windshields. The cab interior has red ambient lighting and red floor lighting in addition to white LED lights that can be activated when needed.

|

| (6) E-ONE displayed its redesigned Quest cab. |

The Quest has increased cab storage, additional options, improved ergonomics, the availability of a 360-degree camera system, front and side air bags, and collision warning and mitigation controls.

Smeal displayed two units, one pumper and one aerial, with newly redesigned cabs. The pumper incorporated Smeal’s new CORE concept, where all of the pump suction and discharge connections are low and to the front of the CORE module with the preconnects above (photos 7 and 8). The OMNI fully electronic pump panel swings out of the first compartment to allow the operator to control everything from valves to the pump pressure governor, all on a small touch screen. Even the remote controls for the TFT monitor are contained in the OMNI pump panel control. The pump panel controller can be unplugged and moved to other locations on the apparatus. The CORE pumper chassis is 96 inches wide and can handle up to a 450-hp engine.

|

| (7) Smeal’s CORE concept pumper. |

|

| (8) All hose connections are low for easy connection on the CORE pump module. The fully electronic pump panel swings out of the first compartment. |

The other chassis on display had a 105-foot rear-mount aerial ladder and the new 100-inch-wide cab (photo 9). This unit has a Cummins 550-hp ISX 15 engine, 2,000-gpm Waterous pump, traditional pump panel, 480-gallon water tank, and 20-gallon foam tank. The aerial tip load is listed at 750 pounds dry or while flowing 1,500 gpm.

|

| (9) Smeal’s 105-foot aerial on its 100-inch-wide cab. |

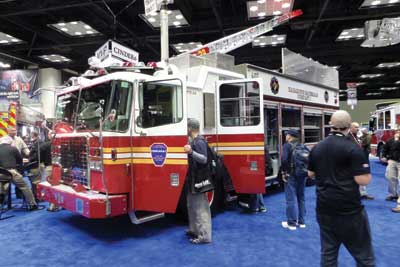

Several pieces of apparatus built for the Fire Department of New York (FDNY) were on display (photos 10 and 11). KME displayed an FDNY 2,000-gpm pumper with a severe duty, six-person steel cab and stainless steel body. This is one of 91 units under contract for FDNY. The unit has many “FDNY features” that have been developed over the years, such as a low hosebed, a variety of four suction hoses to be used either at the hydrant or while drafting, recessed hand rails, split tilt cab for accessibility to the engine, and dual suctions on the right side—one for drafting and one for hydrant connection. The unit has all crank valves and 4½-inch discharges in the front and rear.

|

| (10) KME’s pumper for the Fire Department of New York (FDNY). |

|

| (11) The FDNY pumper has all crank valves and four different suction hoses. |

Ferrara had an FDNY rear mount ladder on display (the last of the current contract) as well as FDNY Hazardous Materials Unit #1 (photo 12). The haz-mat unit is in the style of a large rescue. Like the other FDNY units, it has a stainless steel cab and body coated with Line-X paint. It is powered by a Cummins ISX 500-horsepower engine and has a 20-kW Onan hydraulic generator. A Will Burt Night Scan 5,400-watt light tower is mounted to the cab roof. A 200-cfm air compressor and electric rewind air reel are also installed.

|

| (12) Ferrara’s FDNY Haz-Mat Unit. |

Firovac Power Systems had an aluminum vacuum tanker (tender) on display (photo 13). The reinforced aluminum tank is coated with a polymer interior coating for long tank life. The unit uses a vacuum pump that acts like a huge primer to produce a negative pressure in the tank. When the gate is opened, the tank, which is under vacuum, fills with water at 1,000 to 1,500 gpm. The pump is then reversed, and the water is discharged under pressure at the same flow rate, enhancing the speed of operations dramatically. An onboard fire pump also allows for standard or pump-and-roll operations. This unit also had dual folding tanks in a power equipment rack for speedy deployment.

|

| (13) Fireovac’s aluminum vacuum tanker. |

Midwest Fire displayed an “All-Poly” (body and tank) tanker (tender) with a lifetime warranty on the body and tank (photo 14). The unit on display had an integral 3,000-gallon water tank and a 1,000-gpm fire pump. Three Newton dump valves were provided for off-loading, one on each side and one at the rear. Many of the chassis functions are controlled from a multiplex screen in the center console of the cab. Midwest also displayed an aluminum brush truck.

|

| (14) Midwest Fire’s 3,000-gallon tanker with an all-poly integrated tank and body. |

The Spartan booth in the convention center had several pieces of apparatus on display. One that caught my eye was the Platform on Demand (POD) (photo 15). PODs are not a new concept but seem to be making a resurgence in popularity. The unit on display was a mobile command unit that featured a command communications area and a command briefing room. The communications area has three work stations; computers; a DVD recorder; a radio and telephone management system; and a multifunction fax, printer, and copier. The briefing room featured radios, flat screen TVs, magnetic boards, and table and chairs. Some of the other POD applications are for haz-mat operations, breathing air supply, hose supply, foam supply, rehab station, mass casualty, and mass decon. The module can be transported by hook lift, air lift, or military forklift.

|

| (15) Spartan’s command Platform on Demand (POD). |

One of the Spartan pumpers on display had an auxiliary power unit (APU), which seems to be picking up traction with fire departments lately (photo 16). When the apparatus is on scene, if it is not pumping, the main engine shuts down and the APU takes over, powering the apparatus with a smaller diesel engine. It keeps the apparatus functioning including cab heating and cooling, maintains the warning lights, and charges the chassis batteries. When the engine is started, power switches back to the main engine and the auxiliary unit shuts down. Departments that use APUs report significant fuel savings, especially when the apparatus makes a number of EMS runs a day.

|

| (16) The auxiliary power unit mounted over the pump compartment in a Spartan pumper. |

In the outside demonstration area, Spartan displayed its new Multi-Function Pumper Aerial (MPA) 65. The 65-foot mid-mount aerial has a three-section Gimaex ladder with a 500-pound tip load rating and 1,000-gpm waterway. It sets up with a narrow 12-foot, 10-inch outrigger stance. The single-axle chassis has a low 10-foot, six-inch travel height. The unit has a 1,250-gpm pump and a 300- to 500-gallon water tank.

HME-Ahrens-Fox introduced its line of aerial products. The first one I examined had a 50-foot telescoping water tower with a ladder on top and a 3,000-pound winch below (photo 17).

|

| (17) The HME Ahrens-Fox 50-foot telescoping water tower unit. |

The HME 80-foot three-section steel aerial unit on display had a 1,500-gpm pump and 400-gallon water tank (photo 18). The aerial has full multiplex controls and has egress steps on both sides of the apparatus. The stainless steel body can hold 1,300 feet of five-inch hose.

|

| (18) The new HME Ahrens-Fox 80-foot three-section aerial unit. |

HME also redesigned its cab for additional space and better visibility for the driver (photo 19).

|

| (19) HME’s redesigned 100-inch cab. |

Spencer Manufacturing had a unique unit on display in Lucas with a top rear-mount pump operator’s position (photo 20). Two sets of steps lead up to the controls at the center of the top where the hosebed would normally be. The hose is stacked on either side of the pump operator and plays out over a roller bar on each side behind the steps.

|

| (20) Spencer Manufacturing’s unique top rear-mount pump operator’s position. |

Rosenbauer had a number of apparatus on display. It offers a full line of its own fire pumps; two cutaways were on display (photos 21 and 22). The N-Series is a single-stage pump rated between 500 and 1,500 gpm. The NH-Series is a single-stage 500- to 1,500-gpm pump, coupled with a 600-psi 100-gpm four-stage high-pressure pump on one common shaft. The pump is capable of volume and high-pressure flows simultaneously.

|

| (21) A Rosenbauer N-Series single-stage fire pump. |

|

| (22) A Rosenbauer NH-Series combination single-stage/four-stage high-pressure pump. |

A Rosenbauer quint built for the Greenwood (DE) Fire Department had a “green” theme—green paint job, green LED rope lighting up the inside of the aerial, and green LED illuminated hand rails (photos 23 and 24).

|

| (23) Rosenbauer’s quint for the Greenwood (DE) Fire Deparment had green LED lights illuminating the climbing area of the ladder. |

|

| (24) Green LEDs illuminate the hand rails on the Rosenbauer quint. |

Will-Burt had several scene lights available (photo 25). The Night Scan Xtreme is a roof-mounted fold-down light tower that does not require any interior vehicle space. The unit is air operated and can raise either 20 or 25 feet, depending on the model.

|

| (25) Will-Burt had several light towers on display. |

Power Arc, the original creator of the oscillating LED light head, showed several configurations of individual lights and light bars. A new product for 2014 is the Predator dual-head remote-control scene light that is part of the light bar (photo 26). It raises two LED light heads up 18 inches and has the ability to rotate and tilt the lights. This is excellent for a low-profile application.

|

| (26) Power Arc’s “Predator” raised scene light that mounts to the light bar. |

Performance Advantage Company had a trailer with all kinds of tool-mounting solutions (photo 27). The latest was the FASTLOK Adjustamount kit. The adjustable strap and supports can be configured for almost any piece of equipment.

|

| (27) Performance Advantage Company displayed tool-mounting solutions. |

Two companies displayed automated units for rolling hose, especially five-inch large-diameter hose. The first was the Sidewinder Reloader (photo 28). The roller is available with either an electric or a gas motor that drives the hose pickup apparatus. A battery model is in production as well. A companion piece is the Rookie Reloader that transports and plays out rolled hose for reloading.

|

| (28) The Sidewinder electric hose rewinder. |

The guys from ROLLNRACK made me tired just watching them display their product! They were continuously rolling out and rewinding a length of five-inch hose (photo 29)! Their battery powered unit rolls the hose, and the companion piece takes the rolled up length and allows it to be loaded on the apparatus effortlessly.

|

| (29) Rollnrack hose rolling equipment was operated continuously during the exhibit hours. |

Waterous was holding classes on its One-Touch compressed air foam system (photo 30). Each time I passed, the seats were full of eager firefighters wanting to learn all the benefits of the system.

|

| (30) Waterous held well-attended classes on its One-Touch compressed air foam system. |

Kussmaul Electronics had a vast display of apparatus charging systems and electronic controls. Its new 30-amp air/electric auto eject combines enough shore line power for battery chargers as well as accessory chargers such as hand lights, portable radios, gas detection meters, power tools, thermal imaging cameras, and an air supply to keep air brake systems topped off for an immediate response (photo 31). When the apparatus starts, the single electric/air plug is ejected for a quick response.

|

| (31) Kussmaul Electronics’ new combination 30-amp electric/air supply auto-eject. |

Sutphen displayed a pumper for the Columbus (OH) Fire Department (photos 32 and 33). Several compartments were lined with marine-grade varnished plywood for easy tool mounting, and the well-organized hosebed holds a wide variety of attack and supply lines at a manageable level.

|

| (32) The Columbus (OH) Fire Department’s Sutphen pumper with plywood mounting surfaces. |

|

| (33) The hosebed on the Columbus unit held a good selection of supply and attack hoselines. |

Fort Garry Fire Trucks displayed its Custom Crusader pumper with a Spartan chassis and a formed aluminum body (photo 34). The price without options was extremely competitive for a custom pumper.

|

| (34) Fort Garry Fire Trucks built this aluminum pumper on a Spartan chassis. |

This year, a number of ambulances and EMS vehicles were on display, including this pink one for Prince George’s County, Maryland (photo 35).

|

| (35) A number of EMS vehicles were on display. |

This Darley ZSE portable pumping trailer is designed for moving large quantities of water (photo 36). The unit is National Fire Protection Association rated at 3,000 gpm @ 165 psi or Industrially rated at 3,500 gpm @ 100 psi. The trailer has a self-contained 500-hp diesel engine with integral fuel tank.

|

| (36) Darley’s high-volume self-contained pumping unit. |

TFT displayed its Hytrans Fire System (HFS) mobile water system (photo 37). One of the system’s components is a submersible pump for relaying water to the unit. This can be used to supply water for firefighting or major dewatering operations such as in subway tunnels. The second component is the HydroSub Power Pack. The diesel-driven pump can deliver between 396 and 11,880 gpm. Options include a booster pump and foam proportioner. The third component is the large-diameter hose storage. The unit can be supplied with from six- to 12-inch hose. The fourth component is a mechanized hose laying and hose recovery system for the large-diameter hose. Several models and configurations of this system are available.

|

| (37) TFT’s Hytrans Fire System (HFS) mobile water system. |

Illumi-Door displayed a back-in safety guidance system for fire stations (photo 38). A panel of yellow and red LEDs is displayed on the outside corners of the apparatus bay door. When the apparatus is backing in, electric eyes monitor the orientation of the apparatus. If it starts wandering toward the edge of the door, the yellow flashing panels turn to solid red to warn the driver to stop, pull forward to realign, then to back in again.

|

| (38) The Illumi-Door back-in safety guidance system. |

Several vehicles had LED strip lights mounted to the door interior to warn passing vehicles that the door is open (photo 39).

|

| (39) LED strip warning lights on the interior of an ambulance door. |

This is just a small sampling of the many vendors who demonstrate their wares at FDIC 2014. In addition to all of the apparatus manufacturers, dozens of companies showed the latest in rescue equipment, personal protective equipment, boots, self-contained breathing apparatus, and scene and warning lights. The FDIC is truly the marketplace to attend for anything fire or EMS related. See you there next year!

WILLIAM C. PETERS retired after 28 years with the Jersey City (NJ) Fire Department, having served the past 17 years as battalion chief/supervisor of apparatus. He served as a voting member of the NFPA 1901 apparatus committee for several years and is the author of the Fire Apparatus Purchasing Handbook, the apparatus chapters in The Fire Chief’s Handbook, and numerous apparatus-related articles. He is a member of the Fire Engineering and Fire Apparatus & Emergency Equipment editorial advisory boards and of the FDIC executive advisory board.

Fire Engineering Archives