By LOUIS SCLAFANI

I was probably like many other firefighters when I was first assigned to learn the “aerial truck”—super excited! After all, it was the biggest, most technical and expensive piece of equipment our department owned (as it is in most departments that operate trucks). It was going to be my responsibility, and what a responsibility it was. One of the first things most new truck operators are shown is how to “set up” the truck. This article will look at what is undoubtedly the most important aspect of setting up the truck: stabilization.

The Ins and Outs of Basic Aerial Operations

For a truck operator, few things are scarier than having a truck tip over because it wasn’t stabilized properly. In my discussions with students in my aerial classes, the following five stabilization topics are regularly discussed.

Leave the Tires On or Off the Ground?

This may be one of the most common questions new truck operators ask. Some trucks are set up with the tires on the ground, while others have the tires entirely off the ground. So, what’s the deal?

Simply, if you take the tires off the ground, all the vehicle’s weight will be on the stabilizer jacks; as a result, this is considered the most stable setup. The jacks, with all the weight applied to them, are now the widest part of the vehicle. You may see this referred to as “ballast weight.” If a truck’s weight is now distributed over a wider span, it is more stable no matter its design or manufacturer. This setup best prevents tipover and would be most beneficial if you needed to operate at full extension off the side of your truck at low elevations with a load on your device.

(1) The most stable position is with the tires off the ground. You only need to fit a piece of paper between the tire and ground for optimum stability. (Photos by author.)

(2) Deploy stabilizer jacks on a hard, firm surface. If you are setting up off pavement, is it worth the risk-benefit? How firm is this grassy area? What is underneath it?

If operating in a hilly environment, consider leaving the tires on the ground and just take the bulge out of the tire. Here, if you are concerned that your truck may slide or move because you are operating on an incline, the more points of friction you have touching the ground, the better. Additionally, be sure to apply the front axle brake if so equipped to help prevent any movement. If setting up in a snowy or icy environment, you may want to leave the tires on the ground here as well. If sliding downhill is of no concern, set up in the most stable position with the tires off the ground. All manufacturers will give direction on how their trucks should be set up, and you should follow them. I have found that most (but not all) allow both options. At least one brand available today is designed so that the front tires must be kept on the ground.

Set Up Off the Pavement and On the Grass?

While at FDIC International, I walked the exhibit floor and asked every manufacturer displaying aerial trucks this question. Each time, I was referred to their engineer, who then responded that we should set up on a hard, firm surface. When pressed with the question of setting up on the grass, they said yes, as long as the ground can support up to 75 pounds per square inch (psi). I am confident that most people reading this article are firefighters and not geologists, so determining 75 psi in the field isn’t easy or common.

So, what should we do? This is actually a risk-benefit question. In other words, do we have to set up and deploy our device in the first place? Life safety is always considered the first priority on the fireground. If deploying your device means a life will be saved, we will sacrifice machine and material every time. However, if no life is to be saved, is it worth the risk of tipping over the truck because of poor ground stabilization just for real estate? That’s your call at that moment in time.

(3) Reduce your ladder loads by 50 percent if your level indicator is in the “yellow.”ground when you rotate to the opposite side, you are still safe and stable.

(4) All “Jack Down” lights must be activated before it is safe to raise your device out of the bed.

If you decide to set up and deploy off the pavement, there are a few things you can do to reduce your risk. First, always set up with your stabilizer pads. The use of additional cribbing under these pads could also be beneficial. Be sure to use cribbing that is wider than your stabilizer pads. This will increase your footprint distributing the weight better. If possible, deploy your device off the front or rear of the truck as opposed to its side. A truck is much more likely to tip over sideways than in any other position. If you must work off the side, keep the device retracted and vertical as much as possible. The more you reach out to the side, the greater the risk you have of tipping over; retraction and elevation reduce this risk. Depending on your location during certain times of the year, the ground may be frozen. Frozen ground is harder and firmer than thawed ground. Even if the ground is frozen, watch for fireground runoff, which can destabilize the ground around the truck.

When setting up off pavement, other hazards to watch out for include septic tanks, oil tanks, drain fields, sinkholes, utility easements, and so on. There is no way for us to know what’s under our jacks. Make sure the benefit is worth the risk you will take.

What Does a Yellow Level Indicator Mean?

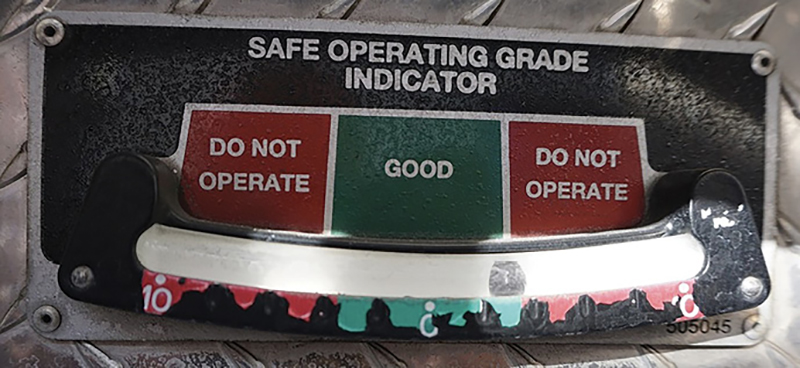

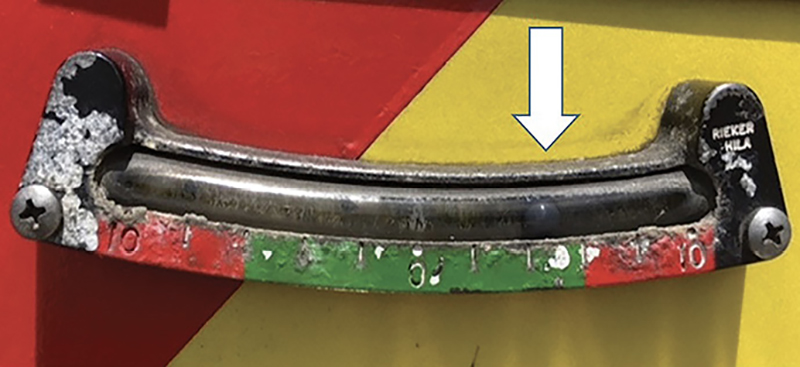

Depending on the manufacturer, level indicators come in either two or three colors. The two-color indicators use green and red; this is a simple “Go/No-Go” type of indicator. If, after you stabilize your truck and the indicator is in the green, you are good to go. If it is in the red, you are not, and you need to reposition. This is pretty cut-and-dry.

(5) Stabilizer jacks on both sides of the truck must be firmly planted before lifting the device from the bed. If the stabilizer jack comes off the ground when you rotate to the opposite side, you are still safe and stable.

(6, 7) The front stabilizer jacks are fully stroked down. The rear jacks are down just enough to activate the “Jack Down” light. The level indicator is still in the green. (

(8, 9) The left stabilizer jack is fully stroked down, while the right jack is down just enough to activate the “Jack Down” light. The level indicator is still in the green.

A three-color indicator uses the colors green, yellow, and red. On these, green and red mean the same as on the two-color indicator: “Good to go” or “Reposition,” respectively. However, if, after you set your jacks, you see that the indicator is in the yellow range, what does this mean? The answer to this is not just an ambiguous “be careful” or “use extra caution.” It has a specific meaning, and it’s in your vehicle’s manual. It simply means whatever your aerial device loads are, cut them in half. So, if you normally have a tip load of 500 pounds, a yellow reading means you now have 250 pounds. When operating in the yellow, it’s imperative that the operator knows and remembers this. Ask your operators this question and see what they say. Hopefully, they know that it’s a simple 50 percent reduction.

How Stable/Safe Is the Truck When a Jack Comes Off the Ground?

One might think that every jack must be contacting the ground at all times for a stable and safe operation, but this isn’t always true. Modern trucks have sensors that prevent us from doing stupid things like not setting up properly and working in an unsafe position. When lowering your jacks for setup, lower them until at least the “Jack Down” (or other similar) indicator light illuminates on your panel; this is the minimum distance you must lower the jacks for stabilization. At this position, the tires will still be on the ground and the truck will be safe and stable for use, just not as stable as if the tires were off the ground as previously discussed.

The “Jack Down” light comes on when a sensor or interlock switch senses or measures that you have met the minimum lowering distance of that jack for a safe operation. If one of these lights does not come on, the truck will not allow you to raise the device out of the bed. So, as long as you can raise the device out of the bed normally (no overrides) and your indicator light is green or yellow, you can operate the device safely. Note: If the indicator is in the red, most trucks do not prevent you from raising the device.

At this point, the tires are on the ground and you can raise the device out of the bed. Raise, rotate, and extend your device to one side until it is fully extended at a very low level. This is considered the truck’s weakest position and, as a result, will also have its lowest load ratings. The tires and jacks on the side the device deployed are supporting most of the truck’s weight. If you look at the tires and the jack on the other side of the truck, you will likely find the tires on the ground and the jack off the ground. So, if you need to fully deploy off to one side of your truck for a low level fire attack or some sort of low level rescue attempt and you see the tires come off the ground on the opposite side, it may look concerning but, in reality, it is not; the truck is still stable and safe to use.

The concept is much like short-jacking. As long as you work on the deployed side and avoid the opposite side, you are safe to go. As you retract or rotate the device back, the opposite side will lower, and the jack will return to the ground. (Note: Never operate off to the side if the jack on that side isn’t touching the ground.) When I have asked about the potential for damage because of a twisting motion with one jack on the ground and the other off, manufacturers have said it’s not a problem and within design parameters.

Is It Safe to Set Up Trucks at Extreme Angles?

Over the past few years, photos on social media have shown up of trucks set up at an incident where a vehicle was off a bridge or in a deep ravine and crews needed to go further below grade than normal. The images show the truck either tilted over to one side (graded or sloped) or with the front of the truck way off the ground with the rear of the truck still on the ground (longitudinal tilt). These positions are not commonly seen and, as a result, spark plenty of discussion. Many commenters say this is too stressful for the truck and chassis and shouldn’t ever be attempted. However, is this true? Is it too stressful for the truck and chassis or is it safe to set up this way?

No matter the subject, I typically hesitate to get my technical answers from social media. I prefer to get them from more knowledgeable sources; in this case, it’s once again the manufacturers. All have indicated to me the same basic message—the least stressful position would have the level indicators set perfectly at “0,” which most operators shoot for and we are familiar seeing. Any position other than “0” would add stress. This is considered into the design of the truck and is part of the reason you must operate with the level indicators in the green or yellow, not in the red. Therefore, any position other than “0” adds stress. However, as long as you are not in the red, you are not overstressing the truck, making it safe to use and operating within its design criteria.

On a typical four-jack truck, this includes fully stroking the front jacks all the way down, resulting in the lifting of the front of the truck way off the ground and then just lowering the rear jacks to the point the “Jack Down” light illuminates. This setup will give you that big longitudinal tilt. On a two-jack truck, you would fully stroke one side and just lower the other side until the “Jack Down” light comes on. Obviously, on a two-jack truck, the front wheels will always be on the ground.

There is at least one exception on a four-jack truck. As mentioned earlier, one manufacturer requires the front wheels to be on the ground at all times, but this truck can still be tilted to the side if needed or desired. If you have never set up your truck in these positions and are concerned about its validity, contact a representative of your brand of truck to confirm. Older trucks or certain models may have other restrictions.

Once your truck is properly stabilized, it’s amazing what modern trucks can do compared to older models. However, you must set up and stabilize them properly and within their design criteria. Know the limits of what your trucks can and can’t do. Remember, stabilization starts from the ground up.

LOUIS SCLAFANI retired as a district chief from the Pinellas Park (FL) Fire Department after 30 years of service. He is an adjunct fire instructor and the lead aerial instructor at St. Petersburg College. Sclafani has also presented on aerials at FDIC International, and will do so again in 2022.