By Ricky Riley

Tower ladders, towers, ladder towers, aerial towers—whatever you call them—are all aerials that serve a purpose on the fireground when positioned correctly. These rigs are some of the most expensive pieces of apparatus you can purchase. Just a few years ago, we thought that $1 million was outrageous for a tower ladder. Now they can cost more than $2 million. With a price tag like that, members of the company had better know how to get it in position—and positioned correctly—to do the job that the fireground dictates.

- The Tower Ladder: Tactical Tips for Playing Offense While on Defense

- Tower Ladders: Positioning Tips and Techniques

- Forcible Entry from the Tower Ladder

While towers are special rigs with some operational advantages compared to straight ladders, they both require trained and competent chauffeurs/operators who take pride in their ability to properly get that expensive and critical piece of apparatus in the right spot. This article will cover some operations and positioning of the mid-mount tower ladder. A lot of the information applies to rear-mount towers and regular ladder trucks as well.

History and Design

A functional and valuable tower starts with its design and specifications. To date, undeniably the most proficient tower ladder design was completed by the Fire Department of New York (FDNY). Those original rig designs from the 1960s and 1970s, which were battle tested and proven, still live on in the current rigs that the FDNY purchases and so many of us emulate in our tower designs. FDNY purchases with a focus on the mid-mount design with little obstructions in the way of a below-00 deployment and with a vast sidewalk sweep potential as well an above-grade deployment reach. These attributes are the core functions of a true tower ladder.

Conversely, mid-mount designs sacrifice compartment space between the turntable and rear of the rig and eliminate obstructions amid the turntable and the cab. Even if your rig requires more compartments or equipment obstructions, an experienced and well-trained chauffeur/operator can still achieve a respectable scrub area with good positioning.

1. A midship-mounted tower ladder, the newest design version of the tower ladder. (Photos by author unless otherwise noted.)

2. An early 1980s FDNY tower ladder assigned to Ladder 120. This design was battle tested and proven on many firegrounds in New York City. It set the standard for tower ladder designs through today. (Photo by John A. Calderone.)

Chauffeur Responsibility

Training for the chauffeur/operator should begin with factory training from the rig’s manufacturer. This information will help the chauffeur/operator fully understand how all the levers and buttons work and the systems that make the tower work in the first level of operation. They will learn what to do if they need to go to an emergency power unit (EPU) or second level of operation, which both require paying close attention to the apparatus and the boom, as almost all safety features and crush zone programming are not available, and there is the chance the operator may damage the apparatus and jeopardize the safety of personnel. Almost every placard, warning label, and pictogram displayed on the rig has a story behind it where the apparatus was used incorrectly and caused injuries or death to personnel. So it is important to pay full attention and heed these warning labels.

Once the tower is in the firefighter’s hands, it is now the chauffeur’s/operator’s responsibility to fully understand the rig and learn the feel of the apparatus while responding, positioning, and operating. This feel comes from constant repetitions and equipment checks. Any chance you get to operate the tower and understand the controls; the feel of the boom; and, more importantly, the deescalation of the boom as it get near objects will only make you better on the fireground when you have time constraints in critical situations. Luckily, many of today’s apparatus are equipped with controls that allow three speeds: slow or creeper, medium, and fast, which allow easier control of the boom.

Driving the apparatus is a monumental responsibility for the chauffeur/operator. The weight, length, and width of towers require a skill set that has to be practiced and trained on with diligence and dedication. These massive rigs take up road space and require a keen sense of knowing where the front bumper is and where the rear swingout is going to go while making turns. When ordering a rig, many departments ensure that they have front marker bumper poles and rear flexible marker lights installed to help the chauffeur/operator judge the apparatus while maneuvering it. Because of its size and weight, the tower’s stopping distance can be very great and is nothing like engines or any other apparatus we drive. So, you also have to put time and effort into perfecting your driving skills.

3. A tower ladder from the Hampden Township (PA) Fire Department operates a master stream in the cockloft of a commercial building. Proper positioning is the key to operational success. (Photo by Jason Coleman-Cobb.)

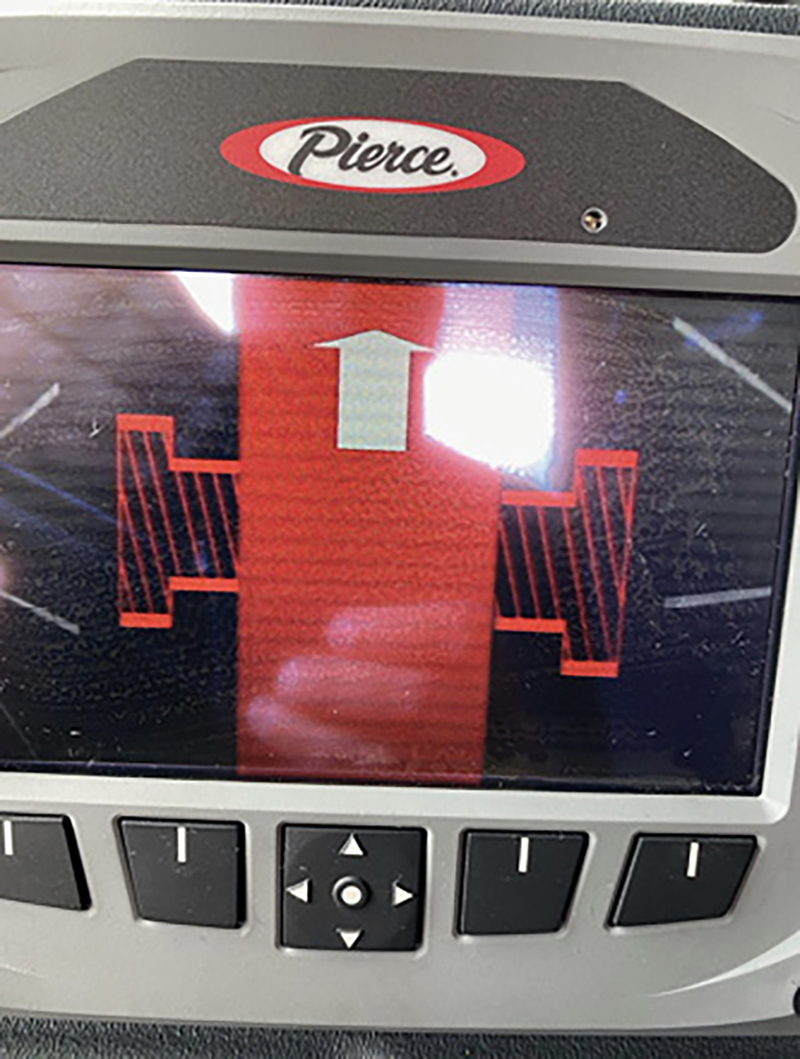

4. Cameras mounted above the jacks increase visibility for jack deployment.

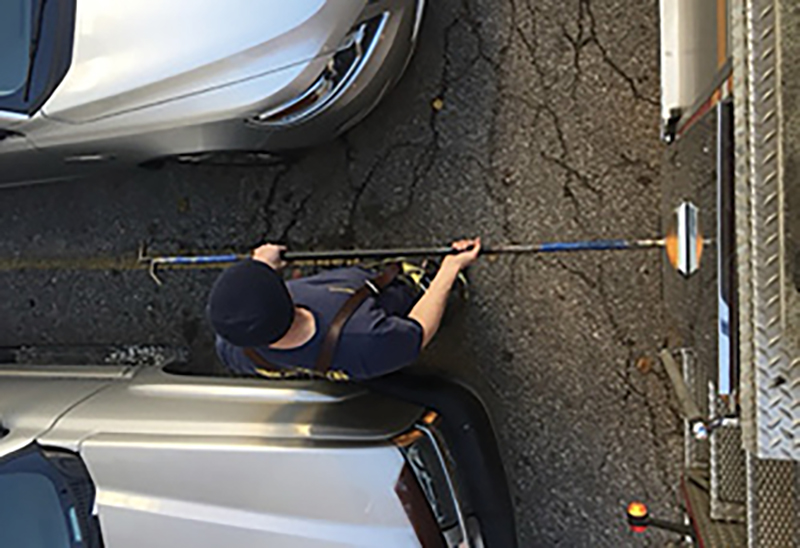

5. & 6. Members of the Wichita (KS) Fire Department use a six-foot hook to measure if the jack will fit between two cars.

Importance of Positioning

Understanding the importance of positioning a tower or any aerial apparatus is the first step in successful operation. Proper positioning enables master stream use to extinguish the fire, which can help save a civilian’s or a firefighter’s life. Being in the right spot on the fireground should not be due to luck but rather due to the chauffeur’s/operator’s preparation, practice, and anticipation. There are many firefighters who can drive a tower, but there are very few tower drivers. Those tower drivers dedicate the time to their craft in all aspects of the rig’s operation and positioning. It takes personal commitment and pride in doing the job right and always striving to make yourself a better operator.

Here are a few more skills that can help you position better on the fireground:

Learn your response area—not just what Siri or Google Maps says, but know the streets, buildings, and complexes. When you hear the dispatch address, picture the area around the building and start to think about your response route and any street or alley that might give you a good position for your tower. This knowledge should extend past just your first-due response area into your second-due truck area or even second-alarm territory. Get out and ride these areas during drill time or even while out doing errands or administrative tasks. You never know where or when you could be called to these areas. Seeing the streets and buildings will help you get that right spot.

Always be tuned to the radio, especially the fireground channel. Listen to how companies are positioning and plan a route into the scene based on direction from the incident commander or your department’s standard operating procedures. As you get closer to the scene, slow the rig down and look at the streets before you commit to a corner or block. See how other rigs are parked and look at where you can fit to get the most advantageous position for the assignment.

Look for hazards that could hamper positioning, such as the following:

- Wires and poles.

- Trees and tree branches.

- Building features.

- Building setbacks.

- Civilian vehicles.

- Fire department apparatus/vehicles.

- Street width.

- Sidewalks.

- Manholes.

- Street grates.

- Terrain.

Getting in the Block

After you get into the block and have room to set up, you now have to focus on a number of rig-specific items that will affect your position and how you plan to operate now and during the duration of the incident. First, what is the immediate need of the tower—rescue, master stream operations, or a combination of rescue and fire attack? All these require you to possibly set the apparatus up in a number of different positions and angles. Consider whether you are positioning the basket or the turntable. All these setups require the operator to perform size-up to decide where to place the rig.

- Look at the structure (size, shape, height).

- Look at the fire’s location and direction of travel.

- Look at victim location.

- Look at possible victim locations.

- Decide how much of the building you can cover.

- Determine where the smoke is going, which can hamper visibility or be a sign of a smoke explosion.

Positioning the Jacks

Before placing the basket or the turntable, first put out the stabilizers. Depending on your rig’s manufacturer, the jack spread can be anywhere from 14 to 18 feet of landing zones. You will need to get the stabilizers in position and the correct pressure on the ground to support full function, reach, and rotation of your tower.

There are tools to help you ensure proper jack setup and placement. New technology involves cameras mounted where the stabilizers go out and down that can display inside the cab so you can get the proper rig position before you even get out of the cab. This is a fairly new option on apparatus. Just keep in mind that if an apparatus is covered in snow, ice, or road salt, the camera’s lens may be obscured, and you must use another means of spotting the stabilizers.

7. An overview of the “V” showing the scrub surface that can be obtained. The cab is kicked out 150 to 200.

The tried-and-true way of getting your jacks out and down is the trusty six-foot New York rook hook. The crew gets off the apparatus and uses the hook from the side of the spot of the jack to see if it clears all curbs, grates, sewer caps, and cars. You should be able to deploy the jacks out and get contact with the ground.

Many towers have the actual piston and foot of the jack covered behind a protective cover. Members of the Wichita (KS) Fire Department mark the six-foot hook with the total width of the protective cover. Then you can see if the jack and the protective cover will fit between cars or obstacles.

You must ensure that the ground will be able to support the jack pressure, as now the National Fire Protection Association standard for the downward jack pressure is 100 pounds per square inch. When you swing the sheer mass of a tower out over the side, make sure the weight will not make the jack sink into the ground and create an unstable operating position. Use the jack plate and any cribbing to hold the weight of the boom. The entire crew should know the operation of the tower and the requirements for safe operation with regard to the landing zones for the jacks/stabilizers.

Basket/Turntable Position

Most of the time you place the basket for a known or possible victim rescue. Thus, you are going to place it in relation to how the bucket doors open and how you can get a conscious or unconscious victim into the basket for removal. If you don’t take into consideration the basket doors and instead just shoot head-on toward the victim with the front of the basket, you could easily hinder the victim’s entrance into the basket. Placing the master stream in the center front of the bucket creates an obstacle for conscious victims and a host of catch points for unconscious victims as we struggle to get them into the bucket safely.

When positioning the basket or the turntable, the chauffeur/operator must consider the “V” in both placements. The center point or turntable is the bottom of the “V.” This is where you will start to measure out where you will be able to touch the building—also known as the scrub surface. Gaining as much scrub surface as possible is an important skill that has to be taught, practiced, and anticipated every run whether there is a fire or not. Your skills in this placement will need to be sharper and sharper, depending on how short the boom/ladder is on your rig.

The outer tips of the “V” are where we can touch the building to effect a rescue or the points where we can reach with our master stream in a firefight, so we have the “V” scrub surface for rescue and the “V” surface for master stream application. When placing this “V,” we want to gain scrub surface by assessing our placement factors mentioned above and then ensuring we do not let parts of the rig get in the way of the boom/ladder as we try to reach the building.

8. Positioning the turntable to reach two sides of the structure.

9. Goodwill (DE) Fire Department Tower 18 extended over the cab. Some might say this is not the best position for a tower, but since they were a later arriving company, they took advantage of open space in front of the building to deploy and operate.

The design, specification, and purchase of your tower should be based on your response area, street size, and building stock and how you plan to use your tower operationally. Many departments consider below-zero temperatures and having a big scrub surface for that. For the tower to operate as a master stream on the sidewalk of a taxpayer, strip mall, or commercial building on fire requires the design to have a very open deck around the turntable and no compartments that extend past the height of the turntable along the body of the rig. This design will give you a great scrub surface above and below zero. Adding compartments and hose trays in these areas will reduce scrub surface. Now the placement of the cab can become crucial in getting the largest scrub surface you can achieve with the design you have.

When positioning a tower, a big consideration is the ability to hit two sides of the structure and have a scrub surface on each for firefighters to perform rescues, for multiple areas to perform vent-enter-search operations, for numerous secondary means of egress locations, and for the master stream to operate into multiple windows. This is where having the “V” on the corner of the structure becomes important, and then angling the cab either 150 to 200 out or in will help take the cab corner and the compartments out of the equation when working to gain a good scrub surface.

Sometimes the building, the fire, or the victim dictates how we set up. This could be off the front and the rear of the apparatus. By going directly over the cab, we lose a lot of scrub surface just because of the angle we need to avoid crushing the cab. Off the rear, we will get to just 00 with no negative ability, and we lose a lot of ladder length by having to go over the length of the body.

Perfecting the craft of positioning a tower correctly and efficiently requires hands-on work. You have to put this information to use in the street through hours of driving, spotting buildings, setting jacks, and using the boom. Take advantage of every run to practice setups and maximizing scrub surface. The tower is a highly versatile and operationally sound piece of apparatus by design, but without the proper training, preparation, and practice, it just becomes a very large roadblock on the fireground.

RICKY RILEY is the president of Traditions Training, LLC. He previously served as the operations chief for Clearwater (FL) Fire & Rescue and as a firefighter for Fairfax County (VA) Fire & Rescue. He also is a firefighter with the Kentland (MD) Volunteer Fire Department and a member of the Fire Apparatus & Emergency Equipment Editorial Advisory Board.

Ricky Riley will present “Tower Ladders—Tactics and Tips” at FDIC International

in Indianapolis, Indiana, on Monday, April 15, 2024, 8:00 a.m.-12:00 p.m. and 1:00 p.m.-5:00 p.m.