By Jeff Chandler

The RAPID HazMat model is designed to change the mindset of operating at hazmat incidents. RAPID stands for Rescue, Assess, Personal protective equipment, Implement an incident action plan (IAP), and Decontamination and demobilization.

Firefighters can do hazmat response safely while doing it quickly. We have been told for decades that we must identify the product before we can make entry. If that is a constant, what do we do when we don’t know what the material is—e.g., during an odor investigation or when responding to a box truck rollover where the shipping papers cannot be accessed?

- Hazmat: Doffing Level B Non-Encapsulated Splash Protection

- Hazmat: Detection and Metering for Civilian Rescue While Wearing Turnout Gear

- Teaching Hazmat in a Pandemic-Driven World

When we arrive at a building fire, we instinctively stretch a line and start a search. When we arrive at a hazmat incident, why do we act differently? The Occupational Safety and Health Administration (OSHA) states that Level B [splash protection with self-contained breathing apparatus (SCBA)] is the minimum level of personal protective equipment (PPE) that can be worn in an emergency. In an unknown atmosphere, OSHA states that structural firefighting equipment with SCBA is the minimum PPE that can be worn in an unknown atmosphere. Today’s gear provides splash protection, but many still teach that turnout gear has no place in hazmat.

In 2022, we can operate safely in turnouts and SCBA; when coupled with metering and detection, this often should be your first choice. Today’s turnout gear offers very effective splash protection and fire protection. The more significant risk for an unknown atmosphere is flammability. You should be protecting yourself from hazards in relation to speed and risk. Protect yourself from these hazards in this order: explosion, fire, high oxygen, radiation, corrosive/oxidizing vapors, inhalation, and liquid contact.

Along with our turnout gear, metering and detection technologies have evolved. We have thermal imaging cameras (TICs), combustible gas indicators (CGIs) and oxygen (O2) sensors, personal radiological dosimetry (PRD), and colorimetric papers (pH, fluorine, and potassium iodide).

The TIC identifies chemical reactions in closed containers that pose a container failure blast and fragmentation risk. The CGI will detect flammable atmospheres. The O2 sensor will detect high oxygen levels that increase the risk of fire and explosion. The PRD will detect gamma and X-ray radiation, from which we cannot shield ourselves. The papers will detect the vapors (acid, caustic, and oxidizing) that can harm our skin before our skin is threatened. Use this basic metering suite on every entry to ensure responder safety.

Level A is the most misused personal protection equipment. Most of the chemicals in transportation and industrial use do not pose a corrosive/oxidizing vapor risk. The first “detection equipment” that a responder should observe is the victim. He can provide important clues as to what chemical family might be involved. This awareness skill just might save your life or, at the very least, your skin.

The following symptoms may indicate certain chemicals:

- Hydrocarbon (organics)

- Generically headaches, nausea.

- Narcotic effect—ketones.

- Anesthetic effect—ethers.

- Vasodilation—nitro compounds.

- Acids/bases (inorganics/some organics) and incapacitating agents

- Respiratory, eye, and skin irritation.

- WMD chemical agents

- Nerve agents: SLUDGEM: Salivation, Lacrimation (tearing), Urination, Defecation, Gastrointestinal upset, Emesis, and Muscle twitching/miosis (pupillary constriction); blister; choking (respiratory); blood (hypoxia).

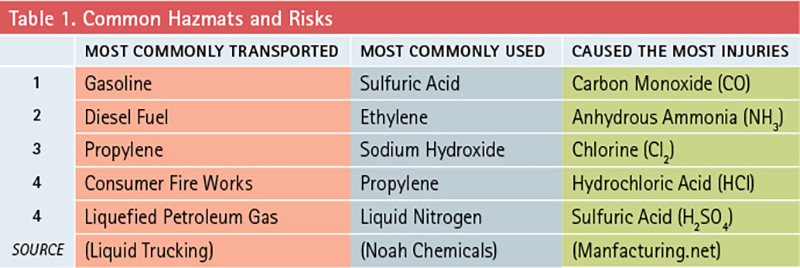

Of the most commonly transported and used hazmats (Table 1), hydrocarbons, the responder is protected while wearing turnout gear and SCBA. The more commonly used and transported materials listed are accidentally released more than those that cause more injuries; there is less risk. The only one that has a skin consequence is sulfuric acid, which is actually a low risk because of its low vapor pressure of .001 mmHg, per the National Institute for Occupational Safety and Health (NIOSH).

However, don’t become complacent because of the low vapor pressure. Sulfuric acid is extremely water reactive: The resulting reaction is exothermic, and the vapor pressure is directly proportionate to temperature. Water is almost always around us, so expect an increase in vapor pressure and subsequently a higher vapor concentration. Except for carbon monoxide (CO), acids and bases are the chemicals that cause the most injuries. Three of them—NH3, Cl2, and HCl—have high vapor pressures; the last, H2SO4, may have vapor issues as previously stated. As a result, they can cause damage to the skin. It is not surprising that these less commonly transported and used hazmats cause the most injuries given their chemical and physical properties. Emergencies involving materials with high vapor pressures and skin consequences are true Level A/vapor-tight events.

The first due must be appropriately equipped and trained in RAPID HazMat. Remember our incident priorities: LIP—Life safety, Incident stabilization, and Property conservation. Take an aggressive, safe approach. Our awareness skills precede operational skills and operational skills precede technician skills. Use your awareness skills to keep yourself in a safe location, look for container shapes and markings, and observe victims’ symptoms of exposure.

Rescue is an operational skill. Waiting for a hazmat team and plastic suits will not prove successful if there is a victim. Waiting for a technical decon line to be established will not prove successful if there is a victim. NIOSH defines immediately dangerous to life or health (IDLH) as exposure to airborne contaminants that is “likely to cause death or immediate or delayed permanent adverse health effects or prevent escape from such an environment.” The key is that it may impair a person’s ability to escape, which means that the victim may be alive and might be a viable rescue, not just a recovery. As a material continues to release or evaporate, the higher the vapor concentration will be in the atmosphere that the victim is breathing. The longer the victim remains in that harsh environment, the less likely he will be viable.

Rescue

- Site management: Implement an incident management system.

- Establish control zones: Isolate and deny entry.

- Incident command post: Locate it in the cold zone, 200 feet from the decontamination line (the length of a standard preconnect).

- Decontamination line: Locate it in the warm zone.

- Single-station emergency decontamination: Locate it at the edge of the hot zone.

- Hot zone distance from the material:

- Solid: 75 feet from the spill.

- Liquid: 150 feet from the spill.

- Gas (unknown) or toxic flammable solids: 330 feet from the spill.

- Explosives 1.1, 1.2, 1.3, or 1.5: 1⁄3 mile.

If the material is known, follow the initial and downwind distances indicated by the green pages in the Department of Transportation’s Emergency Response Guidebook.

Consider responders and civilians not involved or not exposed. For civilians exposed, symptoms they exhibit will give some indication of the material involved.

Perform a primary search if there is an obvious urgent life hazard and rescue is required or if the status of civilians involved in the incident is unknown.

Ready an urgent rescuer/patient decontamination area—i.e., a preconnect and a salvage cover or simply set up on the lawn.

- Ready the patient removal device.

- Don full turnout gear with SCBA.

- Bring the basic metering suite and have a bottle of eyedrops to wet papers.

- Bring the TIC or IR thermometer.

- Bring the four-gas meter (CGI, O2, H2S, CO).

- Tape the pH paper to the face piece.

- Tape fluorine (F) paper to the face piece.

- Tape potassium iodide (KI) paper to the face piece.

- Bring a PRD.

While making your approach, avoid pooled liquids, listen for high pressure gas, and observe vapor clouds.

If the incident has a material in a closed container that is increasing in temperature, it is reacting and building pressure. We have no idea of knowing if/when the container will fail; discontinue efforts immediately.

If indoors and the CGI alarms [at 10% of the lower explosive limit (LEL) indoors], discontinue efforts immediately.

If the O2 alarms for elevated levels (23.5%), discontinue efforts immediately.

If the pH paper changes color, discontinue efforts. Check and observe dry first, then wet: red, acid; blue, base, but when exposed to caustic vapors, the paper will take a greenish color instead of a stark blue.

If the fluorine paper changes color (pink to yellow), discontinue efforts.

Wet the potassium iodide (oxidizer) paper; if it changes color (white to black/blue), discontinue efforts.

If the PRD/radiation pager alarms, determine the level (maximum: 25 R; 25,000 mR) for rescue; you can exceed 25 R voluntarily.

If the mission is discontinued while operating indoors and there is no risk of explosion, search adjoining rooms.

The outside team should deploy a positive pressure ventilation fan and a pike pole to rapidly change a flammable or toxic atmosphere by breaking windows. Apply new papers and reattempt the rescue. This aggressive posture will save lives.

The above readings of the detection/metering equipment indicate that your turnout gear may not be protecting you.

Assess

Assess the chemical and physical properties. After the rapid primary search with or without a rescue/removal, we now switch to our next incident priority: incident stabilization. Assess the scenario with the new information gained in the rescue efforts.

Did the detection/metering equipment indicate an unsafe atmosphere? If, during the rescue entry, the detection/metering indicated corrosive (caustic/acidic, especially hydrofluorous) or oxidizing gases/vapors, the incident requires an ensemble that meets OSHA/EPA Level A PPE equivalent or NFPA 1991 (2005 ed.) “Class 1” PPE.

Did you determine the identity of the released material? If so, what is the size of the container? Is it still leaking? What is the nature of the breach? How much is in the container? What is the quantity of the release? What are the receptors?

We must protect catch basins and floor drains; secure heating, ventilation, and air-conditioning systems; and consider downwind risk factors from vapor clouds.

You have already gained a tremendous amount of information from that first entry. Now you can employ operational skills even without knowing the chemical’s identity. Remember, your turnout gear and SCBA are protecting you if the colorimetric papers have not indicated the presence of their target gas/vapor. It doesn’t matter what the chemical is if it can’t hurt you. So, even if you don’t know the name of the chemical, it is safe to perform operational-level skills to protect the receptors listed above with damming/diking/diverting, rolling the drum with a six-foot pike pole to stop the release, activating a remote shutoff valve, or taking other operational actions.

(1, 2) For a rapid setup of an emergent decon, loop a 1½-inch handline with an adjustable fog nozzle, wrap a salvage cover, and add some cribbing and a patient removal device. (Photos by author.)

Why operational skills before technician skills? I have seen numerous well-intentioned technicians attempt to plug a leak, only to worsen it by their efforts. Without protecting the receptors before attempting to plug the leak, more fuel impacted the catch basin and floor drains.

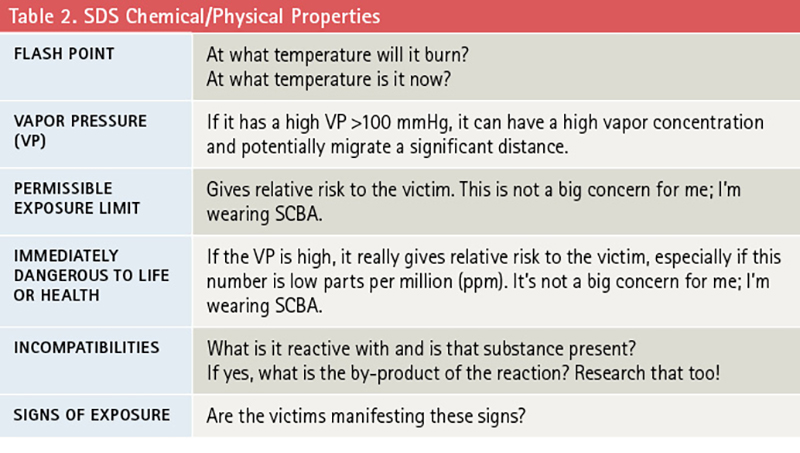

The following fact finding should be ongoing from the time of arrival, but do not delay life safety and incident stabilization efforts. Gain information from facility representatives, workers, and bystanders. Obtain the safety data sheets (SDS) from the facility. If you have determined the identity of the chemical, perform your risk analysis of the chemical. Is this facility already in a preplan because it is a target hazard? Table 2 includes the most important chemical and physical property information listed on the globally harmonized system SDS.

The other chemical and physical and property terms may also prove worthy, but generally they’re not that critical in handling an emergency. The one major exception to that is if the material has a maximum safe storage temperature (MSST). If you notice that the material is stored refrigerated, then research the MSST. This could be in a laboratory refrigerator or in a refrigerated box truck. If there is an MSST, then identify the self-accelerating decomposition temperature (SADT). Per CFR Title 49, the Emergency Temperature is 18°F/10°C below the SADT; consider evacuation when ambient conditions are approaching this temperature.

Assess your metering and detection needs for an incident based on the chemical and physical properties.

PPE

I have separated the PPE by suit type coupled with respiratory protection. OSHA 29 CFR 1910.120(g)(3)(v) states the level of protection provided by PPE selection shall be increased when additional information or site conditions show that increased protection is necessary to reduce employee exposures below permissible exposure limits (PEL) and published exposure levels for hazardous substances and health hazards. NOTE TO PARAGRAPH (g)(3): The level of employee protection provided may be decreased when additional information or site conditions show that decreased protection will not result in hazardous exposures to employees.

So, if you start as recommended in turnout gear and any of the colorimetric papers indicate the presence of a corrosive or oxidizing gas, you either abate the hazard with aggressive ventilation or increase to Level A/vapor-tight PPE. Conversely, if your entry and metering/detection indicate a clean atmosphere during the investigation or post-cleanup, then you can decrease your level of protection. Contractors will often do this to lessen the PPE requirements during a cleanup operation. I have seen contractors try to start at Level C before air monitoring. This is unsatisfactory, as you will see below.

Suit Selection

Level C, NFPA 1994 Class 3 or 3R, NFPA 1994 Class 4 or 4R, or NFPA 1999 Single-Use or Multiple-Use (Non-Encapsulated Splash Protection with Cartridge Respirator):

This is for use with a known contaminant. A cartridge is available for use with the released material and the concentration is known and above the PEL but below the IDLH and the ambient oxygen level is between 19.5 and 23.5 and with no chance that the above criteria may change or rapidly become hazardous. There is a chemical warning property (odor or acute symptom) or an end-of-service life indicator on the cartridge. Develop a cartridge replacement program.

This is not for use during any emergency response efforts or if any portion of the event is unknown—i.e., material, airborne concentration, or oxygen content; above IDLH concentration of the material; above the Cartridge’s Maximum Use Concentration (MUC); for a material where a CGI meter indicates >1% of the LEL; when oxygen concentration is <19.5 or >23.5%; when there is a change in ambient pH (wet or dry); or when there is a change in ambient oxidation (wet KI). Consult PPE permeation data to determine suit/chemical compatibility and stay times. Use chemical tape to seal seams.

Level B Bunker Gear (Non-Encapsulated Flash/Splash Protection with SCBA):

This is for use when coupled with basic metering suite rescue operations; for initial reconnaissance with a low probability of splash contact; for initial air monitoring of unknown atmospheres; and for flammable liquid and flammable gas emergencies.

It is not for use with skin absorptive or skin-damaging gases; a material where a CGI meter indicates >10% indoors; when the oxygen concentration is >23.5%; when there is a change in ambient pH (wet or dry) or when there is a change in ambient oxidation (wet KI); there is a high risk of engulfment of skin-absorptive or skin-damaging materials; there is a high risk of engulfment of an unknown material; when victims show signs of exposure to WMD chemical agents; or with a suspected WMD biological incident where the dissemination method is unknown or if dissemination was via an aerosol-generating device that is still occurring or has stopped but there is no information on the duration of dissemination or what the exposure concentration might be.

Level B-Low B, NFPA 1994 Class 2 or 2R, NFPA 1992 (Non-Encapsulated Splash Protection with SCBA outside the suit):

This is for use with the following when coupled with the basic metering suite: a material that poses a low risk of contact; during air monitoring or investigative measures; when manipulating a small quantity of a material; or when handling small containers.

It is not for use with corrosive gases or a material when a CGI meter indicates >1% of the LEL (the garment may be constructed to protect against chemical flash fires for escape purposes); the oxygen concentration is >23.5%; there is a change in ambient pH (wet or dry); there is a change in ambient oxidation (wet KI); there is a high risk of engulfment of skin-absorptive or skin-damaging materials; there is a high risk of engulfment of an unknown material; victims show signs of exposure to WMD chemical agents; or for a suspected WMD biological incident where the dissemination method is unknown or if dissemination was through an aerosol-generating device that is still occurring or has stopped but there is no information on the duration of dissemination or what the exposure concentration might be. Consult PPE permeation data to determine suit/chemical compatibility and stay times. Use chemical tape to seal seams or inherent gloves.

Level B-High B, NFPA 1994 Class 2 or 2R, NFPA 1992 (Encapsulated Splash Protection with SCBA inside the suit):

This is for use with the following when coupled with the basic metering suite: a material that poses a high risk of contact; when ensuring the SCBA is not exposed to a material; and while manipulating large containers or while sealing/opening dome covers on tank vehicles.

It is not for use with corrosive gases or a material where a CGI meter indicates >1% of the LEL (the garment may be constructed to protect against chemical flash fires for escape purposes); the oxygen concentration is >23.5%; there is a change in ambient pH (wet or dry); there is a change in ambient oxidation (wet KI); there is a high risk of engulfment of skin-absorptive or skin-damaging materials; there is a high risk of engulfment of an unknown material; victims show signs of exposure to WMD chemical agents; or for a suspected WMD biological incident where the dissemination method is unknown or if dissemination was through an aerosol-generating device that is still occurring or has stopped but there is no information on the duration of dissemination or what the exposure concentration might be. Consult PPE permeation data to determine suit/chemical compatibility and stay times. Use chemical tape to seal seams or inherent gloves.

Level A, NFPA 1991 or NFPA 1994 Class 1 (Vapor and Splash Protection, may or may not be fully encapsulating):

This is for use with the following when coupled with the basic metering suite: nonflammable corrosive gases; a high risk of engulfment of known skin-absorptive or skin damaging-materials; a high risk of engulfment of an unknown material; an ambient pH (wet or dry) change; there is a change in ambient oxidation (wet KI); a material when victims show signs of exposure to WMD agents; a suspected WMD biological incident where the dissemination method is unknown or if dissemination was through an aerosol-generating device that is still occurring or has stopped but there is no information on the duration of dissemination or what the exposure concentration might be.

It is not for use with flammable corrosive or oxidizing gases or a known material where a CGI meter indicates >1% of the LEL. Consult PPE permeation data to determine suit/chemical compatibility and stay times.

Flash Level A, NFPA 1991 or NFPA 1994 Class 1 (Fire Resistive Vapor and Splash Protection, may or may not be fully encapsulating):

This is for use with the following when coupled with the basic metering suite: all skin-damaging, skin-absorptive flammable, corrosive, or oxidizing gases; a known material where a CGI meter indicates >1% of the LEL; a high risk of engulfment of known skin-absorptive or skin-damaging materials; a high risk of engulfment of an unknown material; an ambient pH (wet or dry) change; there is a change in ambient oxidation (wet KI); a material when victims show signs of exposure to WMD agents; and a suspected WMD biological incident where the dissemination method is unknown or if dissemination was through an aerosol-generating device that is still occurring or has stopped but there is no information on the duration of dissemination or what the exposure concentration might be.

It is not for use with a known material where a CGI meter indicates >10% of the LEL while indoors or the oxygen concentration is >23.5%. Consult PPE permeation data to determine suit/chemical compatibility and stay times.

Glove Selection

All entries require inner nitrile surgical gloves. In determining outer glove selection, consult the permeation charts published by the glove manufacturer. Consider glove liners for pressurized liquefied gases. Cryogenics require specific gloves. Consider outer abrasion and cut resistant gloves when there is a possibility of damage. Use Silver Shield for tertiary protection (middle layer) for Level A and Flash A.

Boot Selection

Always use safety toe/shank boots. Disposable boots are adequate for use with Level C or low-level B incidents, but approved footwear is required under the suit. Reusable boots may be worn. Reusable outer boots are required for use with high Level B and Level A.

Implement an IAP

For your operational and technician entry, you must develop an IAP. There are so many tactical missions in both the operational and technician areas, but whatever the task, make sure all personnel know their assigned roles. Brief the entry team, decon team, and rapid intervention team to ensure all parties understand the entry/exit points, meter/tool assignment, point person for radio communications, decon plan, emergency evacuation signal, and Mayday procedures.

The IAP can be written or verbal. I have found that most entries can be conducted on verbal orders. However, if there is extreme risk or it will be a long-duration event, having a written IAP is best. It lessens confusion, which lessens risk and allows for good documentation for the person who later has to write the after-action report.

Decontamination and Demobilization

Decontamination

OSHA is quite vague on its guidance for decontamination. OSHA 29 CFR 1910.120(k) states that a decontamination procedure shall be developed, communicated to employees, and implemented before any employees or equipment may enter areas on site where potential for exposure to hazardous substances exists. Standard operating procedures shall be developed to minimize employee contact with hazardous substances or with equipment that has contacted hazardous substances. All employees leaving a contaminated area shall be appropriately decontaminated; all contaminated clothing and equipment leaving a contaminated area shall be appropriately disposed of or decontaminated. Decontamination procedures shall be monitored by the site safety and health supervisor to determine their effectiveness. When such procedures are found to be ineffective, appropriate steps shall be taken to correct any deficiencies.

First and foremost, keep yourself clean while operating in the contaminated area. Second, keep your decon efforts as simple as possible for the hazard present. The decon efforts will vary depending on what the chemical is and what you are doing.

Urgent patient/rescuer decon. This is quick, single-station decon on a tarp for runoff collection or to divert runoff to pavement or soil. Use the trash line for quick actions. Remove clothing and rinse.

Mass decon. Don’t wait for a decon trailer if decon is required. Use hand-lines for small crowds and master streams for large crowds. If the ambient temperature is low, plan to treat for hypothermia; quickly move victims to a heated building and have EMS blankets at the ready. Control decon water, if possible. Direct it to paved areas to allow pooling for recovery or to an open area to collect in soil for future remediation. Avoid allowing it into sanitary sewers, surface waters, and storm water catch basins. If you are unable to keep it out of the waterways, people come before the environment.

Technical decon. This is after rescue efforts. In the OSHA standard, “All personnel and equipment shall be appropriately decontaminated” does not mean an elaborate line is required for all materials. The selection of decon methods and procedures must be risk-based. Consult the SDS on known materials or observe the symptoms of exposure to unknown materials to determine risk. All decon lines should incorporate a nonambulatory decon component to facilitate decon of a down responder.

The decon line used by many departments incorporates a 2½-inch supply line feeding a shower or garden hose system. It generally has three containment pools—gross rinse, wash, and rinse—followed by a doffing area with applicable receptacles for reusable items and waste.

Decon needs to be commensurate with the risks (i.e., the level of contamination coupled with the toxicity of the chemical determines the level of decontamination). When chemicals are encountered, there are various levels of risk. The lesser the volume of a material, the lesser the risk. How much product could possibly be taken with you into the decon area that would require a 15- to 20-gallon-per-minute shower to wash you off? Toxicity and routes of entry absolutely factor into risk, and these coupled together are the most significant characteristics.

During the doffing process, accidental contact of a material with a route of entry of absorption, which can cause serious injury or illness, is the greatest risk. Again, vapor pressure is a major deciding factor. Gases and highly volatile materials are not persistent, and decon efforts are minimal. The lower the vapor pressure, the more persistent the material. The resultant toxicity in the event of accidental exposure will also drive how comprehensive the decon line must be.

When an entry team member arrives at decon, he informs the decon member if he is contaminated and, if so, where the contamination is located on his suit.

If there is no contamination, proceed to the metering/detection station for quality assurance. If deemed clean, begin doffing.

Demobilization

Prior to demobilizing personnel, it is important to convey the name of the chemical and the associated signs and symptoms of exposure. Inform all personnel that if they exhibit symptoms to immediately seek medical assistance and, most importantly, document the exposure in accordance with department policies. I have seen a significant exposure go unreported and later workers’ compensation denied the claim after the employee had significant health-related problems. The most important part of demobilization is to send the troops home healthy.

references

Liquid Trucking, Most Transported Hazardous Materials – Aug. 25, 2020. Retrieved December 11, 2021. https://liquidtrucking.com/most-transported-hazardous-materials/.

Noah Chemicals, 5 Most Common Industrial Chemicals – Aug. 21, 2017, Retrieved December 11, 2021. https://noahchemicals.com/blog/5-most-common-industrial-chemicals#.

Manufacturing.net, The Top 5 Chemicals Involved in Injury Causing Accidents – June 13, 2016, Retrieved December 11, 2021. The Top 5 Chemicals Involved in Injury-Causing Accidents | Manufacturing.net.

Sulfuric Acid CDC – NIOSH, Retrieved December 11, 2021. CDC – NIOSH Pocket Guide to Chemical Hazards – Sulfuric acid.

OSHA 29 CFR 1910.120, Retrieved December 11, 2021. 1910.120 – Hazardous waste operations and emergency response. | Occupational Safety and Health Administration (osha.gov).

Firefighter Injuries in the United States, Retrieved January 29, 2022, https://www.nfpa.org/News-and-Research/Data-research-and-tools/Emergency-Responders/Firefighter-injuries-in-the-United-States” https://www.nfpa.org/News-and-Research/Data-research-and-tools/Emergency-Responders/Firefighter-injuries-in-the-United-States, National Fire Protection Association.

Hazmatology: Hazmat Response: History Repeats Itself, https://www.firehouse.com/rescue/hazardous-materials/article/21118049/hazmat-response-history-repeats-itself” https://www.firehouse.com/rescue/hazardous-materials/article/21118049/hazmat-response-history-repeats-itself.

Code of Federal Regulations – Title 49, Retrieved January 29, 2022, https://www.ecfr.gov/current/title-49/subtitle-B/chapter-I/subchapter-C/part-173/subpart-B/section-173.21.

NFPA Risk Based Selection of Chemical Protective Clothing, Retrieved February 27, 2022, https://www.nfpa.org/-/media/Files/white-papers/WhitePaperRiskBasedSelectionOfChemicalProtective

Clothing.pdf.

JEFF CHANDLER has been in the hazardous materials field since 2003, with six years in the field as an environmental contractor followed by 20 years with the CT Department of Energy and Environmental Protection’s Hazardous Materials Emergency Response Unit, serving as supervisor for 16 years. He has served in both the career and volunteer fire service and is the chief of General Dynamics-Electric Boat Fire Department in Groton, CT. He also is a safety professional and supervisor and the technical training coordinator with First Choice Safety Solutions, LLC.