By James A. Leer

The introduction of the household carbon monoxide (CO) alarm in the early 1990s required fire departments to respond to activations of these devices in the home. In a 48-hour period in December 1994, the Chicago (IL) Fire Department responded to approximately 3,500 CO alarm activations. Out of all the responses, only three people were hospitalized for possible CO poisoning. The cause of the activations was the vehicle exhaust and other gases trapped close to the ground because of a weather thermal inversion. This occurrence confirmed the need to improve the devices to minimize false activations. These improvements were effected through standards developed by the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL). The current standards are NFPA 72, National Fire Alarm and Signaling Code (2022 ed.); UL 2034, Standard for Safety Single and Multiple Station Carbon Monoxide Alarms (Edition 4); and UL 2075, Standard for Safety Gas and Vapor Detectors and Sensors (Edition 2). Many fire departments also have purchased detection and monitoring instruments and developed response and investigation procedures.

RELATED FIREFIGHTER TRAINING

Carbon Monoxide: A Silent Killer

Construction Concerns: Carbon Monoxide

Determining the Source of Carbon Monoxide Levels at a Roasted Coffee Facility

Ontario Firefighters Launch Carbon Monoxide Safety Video

Operating Principles

A CO alarm is a device that has a sensor, control components, and a local alarm only and can be a single- or a multiple-station alarm. A CO detector is a device with a sensor that is connected to an alarm control unit that is supervised. CO alarms’ power sources may be batteries, plug-in, or hardwired. Plug-in and hardwired alarms may have backup batteries. They can be stand-alone devices or may be combined with a smoke alarm. They must have contrasting markings to distinguish them from other devices that detect smoke or combustible gases.

Sensors

Sensor technology in these devices can be biomimetic, metal oxide semiconductor, or electrochemical. Earlier alarms used biomimetic sensor technology, which mimics the human body’s exposure to CO. Metal oxide semiconductor sensors change electrical resistance in the presence of CO. The change in electrical resistance represents the concentration of CO. An electrochemical sensor contains an electrolyte solution and electrodes. CO reacts with the electrolyte solution, producing an electrical current that produces a signal representing the CO levels. Electrochemical sensor technology is the more common technology used today.

Investigating Activations

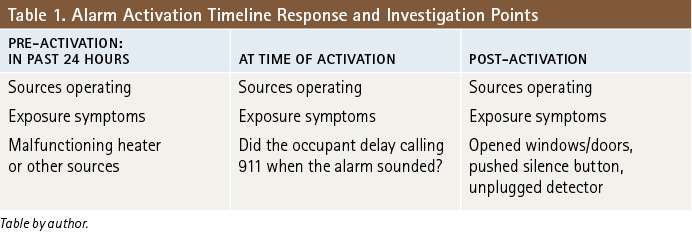

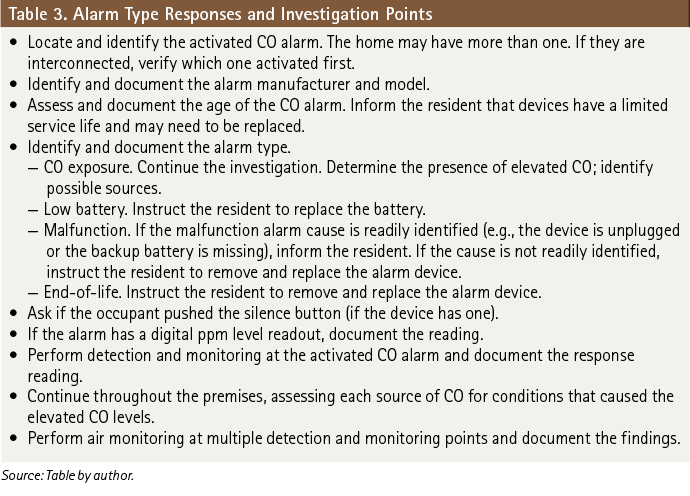

When a CO alarm activates, after determining the level of medical care the occupants need, personnel should go to the activated CO alarm or detector to start the investigation. If the source and condition of the elevated CO are readily identified (e.g., vehicle running inside an attached garage), mitigate the hazard immediately. If the source and condition are not readily identified, develop a timeline of alarm activation (Table 1). The CO alarm will initially tell the firefighter whether there is an elevated level of CO or if there is an issue with the alarm.

I will focus primarily on the information the CO alarm or detector device provides itself and on alarm activation. Additional information on the response and investigation can found in Responding to Residential Carbon Monoxide Incidents: Guidelines for Fire and Other Emergency Response Personnel, from the U.S. Consumer Product Commission, developed in 2002. This document provides guidance for the 911 dispatcher and for the response and investigation of a CO alarm activation in the home. It offers guidance on identifying elevated CO sources and conditions, the occupant level of care, the safe level at which occupants can return to the building, and actions and guidance for occupants. The document provides a six-step process for investigating alarm activations.

Alarm Types

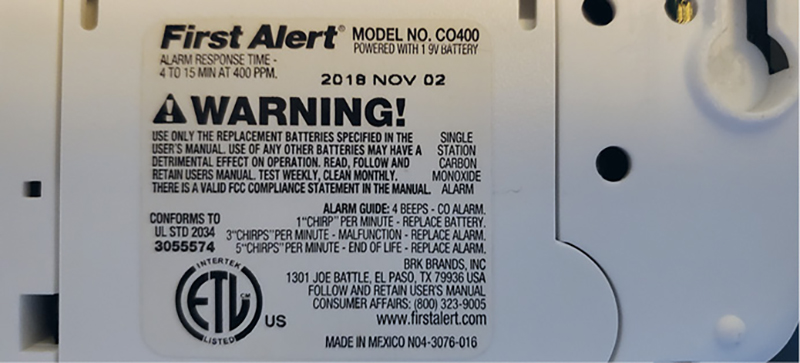

Distinctive audible and visual alarms (i.e., the number of beeps and LED flashes) are required to indicate the presence of CO, low battery power, alarm malfunction, and alarm end of life. The alarms are also required to be distinct from smoke detector alarms. Some manufacturers’ devices include supplemental voice announcements of the time of alarm and occupant instructions regarding actions to take in response to the alarm. An alarm type description is required to be on the back of the device and in the user’s manual.

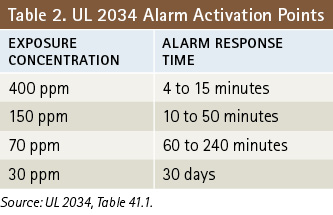

Elevated CO will activate the alarm in accordance with UL 2034 specifications for concentration levels and response times (Table 2). These concentrations and response times are based on 10% carboxyhemoglobin (COHb) in the blood. COHb represents the inhalation of CO and its combination with oxygen in blood. Physicians recognize 10% COHb as a confirmation of CO poisoning even if there are no symptoms. This is an action level at which to protect healthy adults from the harmful effects of CO. At this level, a healthy person should be able to act to minimize CO poisoning. The 30 parts per million (ppm) or less threshold for alarm activation helps to minimize alarms resulting from temporary spikes resulting from outdoor inversions if the use of an appliance increases for a brief time. At levels of 30 ppm or less, a healthy adult is unlikely to have adverse health effects. There are no distinctive alarm types for the concentration level. Some devices may have a digital readout in ppm. A “peak button” present on some alarms would show the peak level of concentration when pushed.

CO alarms have a limited service or operation life. End-of-life alarms depend on an internal timer or self-diagnostic testing. The back of the device will have device’s the date of manufacture and its end-of-life date (photo 1). The life span varies by manufacturer and model but ranges from six to 10 years. Malfunction alarms originating from self-diagnostics indicate that the alarm must be replaced because of a failure. A malfunction alarm can result from a power surge, a plug-in device being unplugged or loose, an attempt to override a tamper-resistant feature, or an internal error or fault. Devices using a replaceable battery as the main power source or as a backup will have a distinctive alarm to indicate that the battery must be replaced.

An alarm silence button is an allowed feature. By pushing the button, the occupant can silence and reset the detector alarm for a preset period determined by the manufacturer, generally less than 10 minutes. After the established time, the alarm reactivates if CO levels persist or remains silent if CO levels decrease or are no longer present. Table 3 outlines alarm type responses and investigation considerations.

(1) Photo by author.

Activation by Other Gases

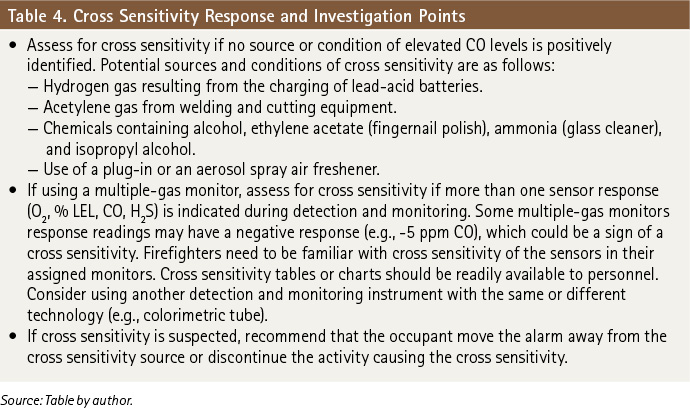

As noted, most CO alarms use electrochemical sensor technology, which is subject to cross sensitivity with other gases and vapors. UL 2034 requires the alarms to distinguish between CO and other gases to prevent false activations caused by substances such as butane, heptane, isopropyl alcohol, methane, carbon dioxide, and ethyl acetate. Some device manufacturers’ manuals may list the tested materials and the concentration levels at which they were evaluated to minimize false activations. Table 4 outlines cross sensitivity activation investigation considerations.

Placement and Location

The location of a CO alarm or detector could be a contributing cause of activations. Manufacturer instruction manuals provide guidance on placement of the CO alarms/detectors in the home and where to locate them to avoid exposure to normal CO levels and to environments that can damage or limit the devices’ operation life. During the investigation, assess if the CO alarm is positioned in a detrimental environment. Instruct the occupant to consult the manufacturer’s manual for placement recommendations. To minimize false activations or device damage, manufacturers’ manuals recommend installing devices a minimum distance from the following locations or not installing them in such places at all, as follows:

- Dusty, dirty, or greasy areas.

- The immediate area in which there are other CO sources (e.g., a furnace, a garage).

- Areas where high humidity or water vapor is present (e.g., a bathroom, a laundry room, or a utility room and areas where a humidifier, a vaporizer, a sauna, or a dishwasher operates.

- Areas where the temperature is below 40˚F (4.4˚C) or above 100˚F (37.8˚C) (e.g., unconditioned crawl spaces; unfinished attics; or uninsulated/poorly insulated ceilings, porches, and garages).

The CO alarm supplies various information for the response to and investigation of alarm activations. Firefighters need to take time to look and listen to what the activated alarm is telling them. Alarm activations may indicate an elevated CO level or an issue with the alarm itself. This information helps to determine what actions the firefighter must take with the investigation, air monitoring, mitigation, and terminating the incident.

References

Davis, R. (1994, December 24). “Detector False Alarms Fade Away.” Chicago Tribune. https://bit.ly/3trC8u8.

National Fire Protection Association. NFPA 72, National Fire Alarm and Signaling Code (2022 ed.).

Underwriter Laboratories, Inc. (2017). UL 2034, Standard for Safety Single and Multiple Station Carbon Monoxide Alarms (Edition 4).

Underwriter Laboratories, Inc. (2013). UL 2075, Standard for Safety Gas and Vapor Detectors and Sensors (Edition 2).

United States Consumer Product Safety Commission. (2002) Responding to Residential Carbon Monoxide Incidents: Guidelines for Fire and Other Emergency Response Personnel. https://www.cpsc.gov/s3fs-public/coguide.pdf.

JAMES A. LEER is an insurance senior loss control consultant and certified safety professional. A 32-year veteran of the fire service, he is a firefighter with the Somerset (PA) Volunteer Fire Department and a hazardous material technician for the Somerset County (PA) Hazardous Materials Response Team 600. He is a Pennsylvania local level state fire instructor and has an associate degree in fire science, a bachelor’s degree in safety management, and a master’s degree in safety sciences.