E-ONE. WE INNOVATE EVERY DAY.

At E-ONE, operational excellence combined with a dedicated and skilled workforce, leads to the highest quality fire apparatus in the industry.

For more than 45 years, E-ONE has been the cutting-edge builder of emergency response vehicles using extruded aluminum technology. E-ONE also offers a premium stainless steel body product to further meet customer needs.

To meet the needs of first responders throughout the world, E-ONE manufactures:

- Aerial ladders and platforms

- Custom and commercial pumpers and tankers

- Rescues of all sizes

- Industrial trucks

- Aircraft rescue firefighting vehicles

Each of these vehicles are customized to individual requirements. The E-ONE chassis, cab, body, and aerial device are engineered and manufactured by E-ONE at its headquarters in Ocala, FL or Hamburg, NY facilities.

Established in 1974, E-ONE has grown to become an industry leader, and today employs more than 1,000 people. Innovation has been the company’s driving force and continues to be the impetus behind its pursuit of new technologies. This results in state-of-the-art fire rescue vehicles recognized for superior capabilities.

INNOVATION EVERY DAY

Leading the way with advanced engineering and innovative design, E-ONE is an industry leader in product innovations, new technologies and exceeding customer expectations. Recent product advancements include the Active Air Purification System, Air Transportable ARFF vehicles, AXIS Smart Truck technology, the ECO IDLE-TEC idle mitigation system and clean cab options.

E-ONE’S SUPERIOR AERIAL DNA

The DNA of E-ONE aerials consist of a unique design that gives E-ONE the advantage of stability and brute strength. The welded extruded aluminum construction will never rust or need repainting, resulting in a lower cost of ownership. Key design features include a 2.5 to 1 structural safety factor, crisscross under-slung jacks, integral torque box chassis, and the strongest cab in the industry.

25 PERCENT STRONGER

E-ONE designs are strong. In fact, E-ONE is stronger than minimum NFPA 1901 requirements. All aerial products have a 2.5 to 1 structural safety factor. The NFPA minimum requirement is a 2 to 1 structural safety factor. E-ONE exceeds this minimum requirement by 25 percent, contributing to the E-ONE safety record for over 40 years.

SAFEST CAB IN THE INDUSTRY

Keep your crew safe with the cab that withstands over 5 times the static roof load and over twice the frontal impact required by NFPA 1901. The structural roll cage design provides maximum protection and comfort for firefighters.

UNMATCHED AERIAL STABILITY

Rock solid stability is felt with E-ONE from the core. Even when tested to 1.5 times the rated load over the front, with tires off the ground, you can have confidence in E-ONE’s stability. E-ONE has engineered and built more than 2,500 aerials for customers around the world.

NARROW JACK DEPLOYMENT

Many E-ONE aerials feature a crisscross, under-slung outrigger design that deploys quickly. The fully extended outrigger spread on 100’ ladders is a little as 11’, and only 13’8” on the 95-Platform and 15’6” on the HP 100 Platform. The quick deployment and narrow outrigger stance is critically important when time is vital and space is limited.

INTEGRAL TORQUE BOX CHASSIS

The integral torque box chassis is a unique design that provides a solid foundation and low center of gravity for the truck. This provides outstanding stability and strength, with the same 2.5 to 1 structural safety factor as the aerial device.

RESPONSIVE TO CUSTOMERS

Customer feedback is important at E-ONE. As a manufacturer of customized fire apparatus, we depend on our customers to help us build better, smarter and stronger. That is how the new Typhoon and Cyclone cabs were born. Responding to customer requests, the Typhoon cab features greater visibility for the driver and crew with its new windshield design, reduced profile dash and full size/full opening door windows. The new 100” wide Cyclone cab offers more interior space, including a 4” raised roof for more headroom and a generous 27 inches between door and engine cover for both driver and officer. It provides excellent visibility for driver and crew with its low-profile dash, one-piece door glass, and a reduced profile interior A/C system.

E-ONE is owned by the REV Group, Inc., a leading designer, manufacturer, and distributor of specialty vehicles and related aftermarket parts and services. REV Group provides customized vehicle solutions for applications, including essential needs for public services (ambulances, fire apparatus, school buses, and transit buses), commercial infrastructure (terminal trucks and industrial sweepers) and consumer leisure (recreational vehicles).

For further information on E-ONE apparatus or to find an E-ONE dealer near you, visit e-one.com

No Hydrant, No Problem!

CET manufactures portable pumps, skid units, brush trucks and more to allow fire departments to Adapt, Improvise & Extinguish fire in almost any scenario where hydrants are scarce and static water resources maybe all you have to work with. CET- providing fire ground solutions since 1908!

CET engineers and manufactures firefighting equipment and vehicles that allow you to successfully fight fire in non-hydrant scenarios with static water source scenarios. Our product categories include Portable pumps, skid-units, foam trailers, CAFS, Brush Trucks, Glider Flat-Bed Kits -to mount to your chassis- and firefighting UTV’s.

Most of our products are highly customizable to your specific fire departments needs. Our reliable and efficient craftsmanship provides you with equipment that can last for years and even decades while having affordable upfront costs. CET is always finding innovative ways to help fire departments to adapt, improvise and make things happen on the fire ground to make the most of your limited manpower and financial resources.

CET can be as involved, or uninvolved as you need us to be for both end user fire departments as well as OEM fire apparatus manufacturers. We supply both individual components, such as skid-mounted- pumps and drop-in units, for your chassis, or we can provide the entire vehicle completely outfitted from the wheels up – including lights, sirens and gold-leaf graphics. CET is Practical, Affordable and Customizable.

CET Manufacturing is a family owned- North American- company that has been making firefighting equipment since 1908. The Flow Starts Here, Powerful, Portable Pumps!

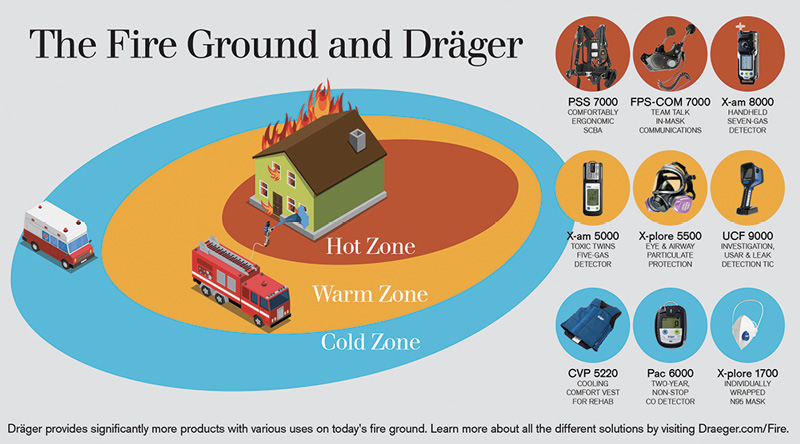

Dräger Up Firefighter Health

& Safety on the Fire Ground

The rise of occupational cancer among Firefighters in recent years prompted several changes. Some behaviors — like letting soot and smoky grime stain turnout gear — have started to fade. This evolution of the Fire Service is just beginning as we learn how to best protect the men and women on the fire ground.

Part of this evolution must include providing today’s Command Staff and Incident Commanders with more information on what’s happening on the Fire Ground.

Dräger recognizes the complexities of today’s Fire Ground and the multitude of incidents that require Firefighters to step into areas of increased risk — both short- and long-term. Some dangers are immediate — fire, smoke, toxic gas, etc. Others cause a long-term harmful effect on First Responders — carcinogen particulates, chemicals, cardiovascular insult and damage, etc.

Several Dräger products — when used in combination with one another — provide an unequaled level of safety and protection:

- Reduce the introduction of particulates to the soft tissue in airways and on the face.

- Provides warning to operators and command of potentially deadly gas allowing for retreat or increased protection.

- Provide vital training in a controlled environment to prepare Firefighter for the multitude of circumstances that could occur.

- Assist Special Operations Teams while conducting high-risk, high-impact, low-frequency evolutions.

- Substantially improve the safety and health of Firefighters and other First Responders.

Dräger adapted a representative illustration of a Fire Ground. Every incident is unique and requires the expertise of experienced Incident Command to best determine how to establish the Zones along with the staging support services, rehab, decontamination, medical support, etc. Every Fire Ground is a dynamic environment. Zone boundaries can expand, contract, or adjust based on many circumstances. Among those adjustments, Command can enhance decisions with additional data including information from Dräger products.

When it comes to the products available from Dräger, the following would deployed widely on the Fire Ground:

- SCBA and related components

- Portable Gas Detection

- Other forms of Airway Protection

Beyond these product categories, Dräger offers some products that fit into certain applications, including the following:

- Fire Training

- Initial, On-Site Cleaning

- Overhaul and Investigation

- Special Operations

By no means are the products listed here comprehensive. As a part of Dräger in Fire Ground Zones, products are introduced where each would be most beneficial. The following is just a partial list of the solutions available from Dräger:

- The Dräger PSS 7000 SCBA provides exceptional ergonomic comfort for less stress. So many features make the PSS 7000 stand out including low cost of ownership, 15-year bumper-to-bumper warranty, and batteries that last a year without replacement or recharging.

- Dräger offers a breadth of Live-Fire Training Systems to fit any budget. From a car prop system that can go anywhere to a multi-story, multi-fire Swede System Phase 5 that’s only limited by the training chief’s imagination, Dräger Live-Fire Training Systems always include a “train the trainers” course and curriculum.

- A diverse collection of portable gas detectors including the Dräger Pac 6000 CO, the X-am 5000, and the X-am 8000. Attach the Pac 6000 CO to every medical kit, turn it on and leave it on non-stop for two years. When your EMS team is responding to a sick person, if carbon monoxide is at an unsafe level, EMTs and Paramedics will know immediately. For Firefighters supporting the front-line workers, include an X-am 5000 on apparatus to check for levels of the Toxic Twins CO and HCN, known to reach dangerous levels outside the IDLH. The X-am 8000 detects up to seven gases and oxygen levels; it’s a versatile tool to determine the presence of toxic gases, LEL, some VOCs, and whether hazmat needs to be called.

- Dräger offers a wide range of air-purifying respirators including the X-plore 5500 and X-plore 1700. The X-plore 5500 provides 99.97% protection from particulates when using a P100 filter, protecting both airways and the eyes. The individually wrapped X-plore 1700 N95 disposable masks protect against 95% of fire ground particulates. Due to recent events, some quantities may be limited or inventory may be on backorder.

Dräger published a booklet about how our products might fit best to enhance the health and safety of First Responders on the Fire Ground. To request a copy of “The Fire Ground and Dräger,” please visit http://bit.ly/thefireground. To learn more about more of what Dräger offers, visit http://Draeger.com/Fire.

Founded in 1983, Fire-Dex is a family-owned and operated global manufacturer of head-to-toe personal protective equipment (PPE) for first responders and a NFPA-UL Independent Service Provider of PPE care and maintenance. Headquartered in Medina, Ohio, Fire-Dex has built a strong brand with a confident team that is passionate about doing a job that protects first responders.

With reliable distribution representation in all 50 states, Fire-Dex offers products that will help meet all demands. Its product lines cover the full scope of protective apparel for first responders, including turnout gear, rescue & wildland PPE, structural firefighting boots, particulate blocking hoods, gloves, helmets, and reusable isolation PPE.

As a pioneer in the development of innovations for the betterment of firefighter health and safety, Fire-Dex offers an exclusive TECGEN71 outer shell that is the only one of its kind to be paired with the lightest thermal liners and moisture barriers available in today’s market due to its unmatched breathability (THL) and thermal protection (TPP). The company also spearheaded the important focus on heat stress and carcinogen exposure reduction by creating an innovative bundle aimed at tackling these concerns. The Interceptor Package combines three products to make it easier for departments to purchase the right gear for the right call.

Maintaining the very core values on which they were founded, the team at Fire-Dex has extended their ability to serve and support the fire community with the acquisition of four major brands; Chieftain in 2008, TECGEN in 2015, Gear Wash in 2019, and Done Right Fire Gear in 2020. Recently, their operations expanded into Pelham, Georgia, while the headquarters doubled.

REQUEST A QUOTE TODAY

Learn more at Firedex.com

Effective Communication for First Responders

Seconds count at every incident. When clear communication happens in real time, without interrupting response activities, help arrives as quickly and safely as possible.

It’s been 30 years since Firecom put its first communication headsets and intercoms into the hands of first responders. Times have certainly changed since then, and while noise is still a concern today, one important factor hasn’t changed—communication between command, crew and dispatch must happen in the most effective way possible to quickly save lives and keep crews safe.

Firecom emerged from the entrepreneurial spirit of founder Brian VanderPloeg. He took his success with avionics headsets and applied it to help firefighters overcome the extremely loud engine and siren noise that interfered with communication between command, crew and dispatch. This significantly improved response times and helped dramatically reduce hearing loss among the firefighter community.

Today, Firecom leads the industry in providing advanced communication technologies to the men and women on the front lines of first response. Through innovation and outstanding customer service, Firecom has built a name for itself in fire and rescue, working closely with departments to develop the products they need to do their jobs.

Firecom is a proud division of Sonetics Corporation; still owned and operated by Brian VanderPloeg and comprised of three divisions: Flightcom, Firecom and Sonetics. The team at Sonetics Corporation spends each day working with customers to uncover new ways to protect individuals and crews through real-time communication and hearing protection. Our ultimate goal: make every day safer, more productive, less stressed and more enjoyable.

You don’t earn the privilege of trust that Firecom has achieved in support of first responders without listening. Using customer feedback, we advance technology and innovation to set new standards for rugged, mission-critical wireless systems that improve first responder safety and effectiveness.

We know what matters to you—being able to reach an expert when you pick up the phone, quick turnaround on repairs, and getting the support you need when you need it. Communication isn’t just what we do; it’s who we are. Tell us what you need. We’re all ears.

Dedicated to Safety and Training Since 1934

The International Fire Service Training Association is an organization of fire service personnel who are dedicated to upgrading firefighting techniques and safety through training. Our mission is to identify areas of need for training materials and foster the development and validation of training materials for the fire service and related areas.

Since 1934, IFSTA has been the worldwide leader of the fire service in developing fire and emergency responder training materials. IFSTA produces training manuals, eBooks, curriculum, test prep, workbooks, skill sheets, interactive courses, instructor resources and more.

IFSTA training content is validated by firefighters, for firefighters. Current and retired fire service professionals serve as subject matter experts on IFSTA validation committees and work alongside writers and FPP staff to produce technically accurate and visually appealing publications that meet its respective standard.

IFSTA works in partnership with Fire Protection Publications, an extension department in the College of Engineering, Architecture and Technology at Oklahoma State University. FPP is the world’s leading publisher of training materials for fire and emergency services. FPP’s primary function is to publish and disseminate training manuals as proposed and validated by IFSTA. Additionally, FPP researches, acquires, produces and markets high-quality learning and teaching manuals to complement IFSTA-validated manuals.

PRODUCT FEATURE: FPP’s Live Fire Instructor serves as a structured template for instructors tasked with the important responsibility of facilitating live fire training. Like all training evolutions, live fire training requires instructors strictly follow guidelines and mandates due to the potential of injury or death among participants. This manual has been constructed to meet current recognized guidelines and practices in the field, with a specific focus on leadership, safety and supervision.

To ensure the highest level of safety, all live fire training evolutions must meet the requirements of the appropriate sections of the most current edition of NFPA 1041, Standard for Fire and Emergency Services Instructor Professional Qualifications. The fifteen included Skills Sheets address the relevant standards in NFPA 1041. Comprehensive curriculum is also available for this manual, which includes presentations, templates, quizzes and more. If you prefer digital format, an eBook is available as well.

IFSTA.ORG | 800-654-4055

Founded in 1898 and headquartered in Dayton, Ohio, LION is a family-owned company with a legacy and ongoing vision of introducing new products and services designed to ensure the health, safety, and performance of the first responders worldwide. From game-changing personal protective equipment (PPE) and professional gear maintenance to state-of-the-art fire safety training tools and facilities, LION’s mission is to make sure that you’re READY FOR ACTION. To learn more, visit www.lionprotects.com.

Fire Training Products

We are the only provider of “clean” digital fire training tools in the world. From cutting-edge digital fire props to made-to-order training structures, LION keeps firefighters prepared for whatever dangers they may face on the fire ground.

• Digital Fire Simulation

• Advanced Live Fire

• Training Structures and Centers

• Incident HazMat Simulation

• Rescue Manikins

• Smoke Generators

• Fire Extinguisher Training

• Safety Trailers and SmartProps

PPE Products

LION offers more models and styles of turnouts, boots, helmets and firefighter essentials than anyone in the industry — and more innovation in each of our PPE product lines.

• Turnout Gear

• Helmets

• Hoods

• Gloves

• Station Uniforms

• CBRN

• Rescue Wear

• Boots

• FASET

o Asset Tracking Software

PPE Maintenance – LION TotalCare®

TotalCare provides fire departments with customized solutions to more efficiently maintain turnout gear and other PPE, which optimizes their protective performance, improves firefighter safety, and provides cost-savings to the fire department.

• UL Certified to NFPA 1851, 2020 Edition Advanced Cleaning, including Ozone cleaning in every extractor in every wash

• Advanced Inspection Service all brands of PPE

• Repair

• Custom Care and Maintenance Programs

• PPE Retirement

Education and Advocacy

LION partners with several industry non-profits and thought leaders who are addressing firefighter challenges. By partnering with these organizations, we are able to understand the issues facing first responders around the world and work together to address these issues.

• LION Fire Academy – training certified to meet the NFPA requirements.

• Not In Our House – firefighter cancer awareness program

When you go in, we go in with you

At MSA, our business is safety. We’ve been the world’s leading manufacturer of high-quality protective equipment for firefighters and industrial workers since 1914.

Our commitment to developing innovative safety solutions is founded on one singular and unchanging mission: “that men and women may work in safety, and that they, their families, and their communities may live in health throughout the world.”

We bring this mission to life through a relentless focus on listening to customer needs, countless hours spent on R&D and product testing, and a never-ending commitment to product quality.

Our core fire service products include:

- The revolutionary G1 SCBA

- Cairns® fire helmets

- Globe® turnout gear and boots

- Altair® portable gas detection instruments

- Evolution® TICs

Visit us for more information at

www.MSAfire.com.

Pierce Manufacturing:

Perform. Like No Other.

At Pierce Manufacturing, fire trucks are built to live up to the demands of firefighters and the communities they serve. It’s not some nine-to-five-go-home-and-forget-about-it kind of thing. Too much rides on what they do.

Performance

Behind every highly customized, carefully-designed and engineered pumper, aerial, tanker and rescue unit is a team of professionals whose mission is to build a truck, exactly how it’s ordered. To Pierce, every step of the process is personal; from innovation and expertise, to customization and service. When the best people you know are the very people you serve, there is only room for exceptional.

As a single-source manufacturer with over one million square feet of state-of-the-art production space, there’s a reason you’ll find more than 27,000 Pierce trucks on the road today. Facilities are ISO-9001 certified, showing the company’s dedication to meet world-class standards for quality.

Proven Technology

Performance-driven design means that Pierce is continually evolving to provide firefighters with industry-leading advancements and unmatched innovation. As a subsidiary of Oshkosh Corporation, the experienced team has access to an arsenal of cutting-edge technologies and revolutionary processes that have contributed to the development of six custom chassis and best-in-class innovations.

- Ascendant® Class of Aerials: The Ascendant technology has expanded into six innovative products: 100’ tower, single or tandem rear axle 107’ ladders, 107’ tractor-drawn aerial and single or tandem rear axle 110’ platforms. The Ascendant Class of Aerials is brilliantly engineered to equip firefighters with more aerial choices than ever before. Whether it be height or weight restrictions, compartment space, preference to ride rather than climb or rescue capabilities, the Ascendant technology provides flexibility and a wide range of options to meet departments’ needs.

- Command Zone™: Cutting edge electronic system that makes it easier for firefighters to maintain their vehicles, prepare for calls and monitor performance on the scene. It also delivers the industry’s first prognostic capabilities.

- Idle Reduction Technology: Incorporating high-performance lithium-ion batteries, main chassis engine auto-start, and full Command Zone™ integration, Pierce’s Idle Reduction Technology allows the apparatus to be on scene with zero air and noise pollution while maintaining mission-critical on-scene loads.

- Foam Systems: Pierce’s integrated foam systems help firefighters perform beyond the capabilities of water alone. Whether it’s Pierce’s innovative Husky™ foam system or the Hercules™ compressed air foam system, these systems are designed to improve the fire-extinguishing capabilities of water, enhance on-scene efficiencies and promote water use reduction.

- Pierce Ultimate Configuration (PUC™): An innovative apparatus solution designed to simplify firefighters’ actions and reduce unnecessary risk. The PUC eliminates the traditional pump house, is easier to operate, maximizes compartment space and simplifies service.

- TAK-4® Independent Suspension: Independent Front Suspension (IFS), stops faster, corners better, improves handling, offers better ride quality and is far more maneuverable than any straight-axle truck on the road. Independent Rear Suspension (IRS) operates like IFS but provides power to the wheels. With the ability to add TAK-4 T3, the 100% mechanical steering system further improves control and mobility.

- Pierce Situational Awareness System by Fotokite: An actively tethered aerial device that can be deployed from any apparatus to live stream and document mission-critical aerial views of the scene.

Customer Support

Pierce’s dealer network is the strongest in the fire industry and is always there to listen to what’s needed, provide guidance and offer support. Fire departments count on the Pierce Service Brigade, a coast-to-coast network of more than 600 factory-trained technicians, to ensure the right service is done at the right time. It’s only fair. Firefighters pour everything they’ve got into fighting fires. The Pierce team pours everything they’ve got into making sure a fire truck is ready to perform.

Experience

With more than 100 years of manufacturing experience, Pierce’s unwavering commitment to quality is not just a promise. It’s ingrained into who they are. Employees, from the assembly team to the unmatched dealer network, are driven to serve firefighters. Why? Because many Pierce team members are firefighters themselves.

Community

Commitment to performance extends beyond Pierce’s factory walls and into the communities served. A significant part of the Pierce legacy involves giving back to the community and the fire industry through contributions and events like the annual 9/11 Memorial Stair Climb event that takes place on the steps of Lambeau Field, in Green Bay, Wisconsin. All funds raised benefit the National Fallen Firefighters Foundation.

The Pierce team doesn’t think of building fire trucks as just another job. That’s evident every time you walk through a Pierce facility and have a conversation with the people who build these rigs. Visit Pierce before you settle on your next apparatus.

Celebrating a Century of Innovation

Bullard

Bullard is an internationally known manufacturer of high-quality personal protective equipment and systems designed to help save lives around the world. Serving workers in the fire service and industrial markets, Bullard is a leader in manufacturing firefighter and rescue helmets, thermal imaging cameras, head and face protection products, and respiratory protection equipment.

Legacy

This year marks Bullard’s 100th anniversary of the invention of the hard hat. Since inventing the hard hat in 1919, we began a legacy of creating safety products that are uniquely designed with input from customers. We are a company that knows the specific needs of the fire service because we listen to first responders who rely on our products.

Market Leader

Bullard maintains its competitive edge through advanced engineering technologies, research and development, and value-added services to develop the most sophisticated, quality-driven products designed with worker safety in mind. With Bullard products, you’ll find the ultimate in toughness and durability. You’ll also find extraordinary service and the most innovative designs that are simple to operate. Bullard products are built Bullard Tough and proudly Made in the USA.

Fire Service

Bullard entered the fire service market with the introduction of its first fire helmet in 1930. Since then, we have led the market in product safety with the development of the first fiberglass fire helmet in 1947, followed by the first NFPA-approved thermoplastic fire helmet in 1983. In 2009, we introduced TrakLite®, the industry’s first integrated helmet lighting system that blends engineering, functionality, and safety to help firefighters see in dark or smoky conditions.

In 1998, we introduced our first high-resolution thermal imager to the fire service. This breakthrough in thermal imaging technology quickly secured our market position as the industry’s leading thermal imaging manufacturer. In 2003, we introduced the T3 Thermal Imager as the first palm-size, lightweight imager offering innovative features including Electronic Thermal Throttle® and Super Red Hot colorization. In 2009, we launched the Eclipse® as the industry’s first low-cost, lightweight, personal-issue thermal imager for every firefighter.

Innovation

Today, Bullard continues to lead the industry with innovative fire helmet and thermal imaging products and accessories designed specifically to meet the needs of firefighters. In 2017, Bullard launched its ReTrak® Fire Helmet Series offering emergency responders a fire helmet with an integrated visor. Bullard’s newest line of thermal imagers, the XT Series, features the NFPA Certified NXT and the QXT. Both models are equipped with X Factor image clarity technology and the industry’s longest battery run time. The X Factor Series of thermal imagers, in addition to the NXT and QXT, include the LDX, T3X, T4X and EcoX.

Family-Owned Company

Headquartered in Cynthiana, Kentucky, with offices in Lexington, Kentucky and sales offices in Europe and Asia-Pacific, Bullard is led by CEO Wells Bullard and Chairman of the Board, Edward “Jed” Bullard. The Company’s products are available throughout the world from a network of distributors operating in most major country markets. For more information on Bullard products, e-mail info@bullard.com, call Bullard Customer Service at 877-BULLARD/+1-859-234-6616, or visit www.bullard.com.

DARLEY–TRUSTED WORLDWIDE SINCE 1908

Founded in 1908, W.S. Darley & Co. (Darley) has been providing the highest quality equipment solutions to its military and first responder customers. With origins in Midwest manufacturing of fire pumps and apparatus, Darley has added a family of brands to distribute innovative capabilities by partnering with leading brands. Darley prides itself on delivering the highest quality solutions and services from its corporate headquarters in Itasca, Illinois and company divisions operating in Chippewa Falls, WI, Janesville, IA, and Grand Rapids, MI.

The Darley difference is in how we treat you, our customers, with the philosophy that our sales approach is really relationship development. At Darley, your problems are our own, and a satisfied customer is our mission. For a reliable source of all your equipment needs, look no further than Darley. Learn more on www.darley.com.

Lightweight Perfected!

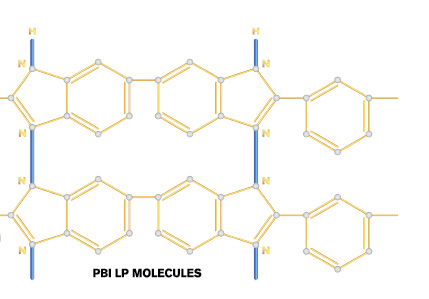

For years firefighters have relied on PBI fibers to provide unparalleled break open and thermal protection in their turnout gear. However, this advanced protection was limited to firefighting fabric weights exceeding 7.0 osy — until now. The advent of the revolutionary PBI LP fiber, combined with Safety Components’ patented Filament Twill Technology, will now empower lower weight fabric blends while offering the same or even greater break open protection as heavier or traditional weight PBI fabrics. Introducing PBI Max™ LP™, weighing only 6.0 osy, an ultra-light addition to the proven line of PBI Max outer shell fabrics, exclusively from Safety Components.

Enhanced Comfort and Flexibility

Built on the legendary PBI Max design, PBI Max LP is a lightweight, protective, and reliable fabric that will not compromise personal protection. In fact, Safety Components’ Filament Twill Technology and the inclusion of PBI LP fibers make this one of the industry’s most comfortable and flexible outer shell fabrics. By improving comfort and flexibility you enhance mobility. When seconds count, better mobility can make all the difference. Firefighters looking for premium protection no longer have to sacrifice comfort or mobility as PBI Max LP sets a new standard in lightweight protection.

What is PBI LP

With an improved thermal degradation temperature of 1500 °F vs traditional PBI fiber at 1300 °F, PBI LP is a revolutionary new PBI fiber that raises the bar on flame resistance. Compared to traditional PBI fiber, PBI LP exhibits stronger molecular bonds (shown in blue above) for unmatched break open protection. While any PBI shell outperforms competitive fabrics under dynamic flame, an outer shell with traditional PBI fiber breaks down after 25-35 seconds of flame exposure. The cutting-edge PBI Max LP outer shell, powered by PBI LP fiber, lasts over 50 seconds under dynamic flame for unmatched flame protection.

Engineered with MAX Strength + MAX Durability

Firefighters agree longevity in personal protective ensembles comes from its ability to withstand rips, tears and abrasion.

And, with PBI Max LP lightweight doesn’t mean light-duty. PBI Max LP incorporates 30% DuPont™ Kevlar® filament designed to increase tear resistance by up to four times that of competitive PBI fabrics. PBI Max LP fabric is not only stronger new, but just as important, it is stronger throughout the life of the garment after exposure to ultraviolet light (the element most damaging to FR fabrics). Lightweight, comfort twill PBI Max LP outer shell is available in gold or black. For comfort, protection and durability, join the movement to lightweight performance perfected, specify PBI Max LP exclusively by Safety Components.

safetycomponents.com

facebook.com/safetycomponents.fire

800.896.6926. ext. 25

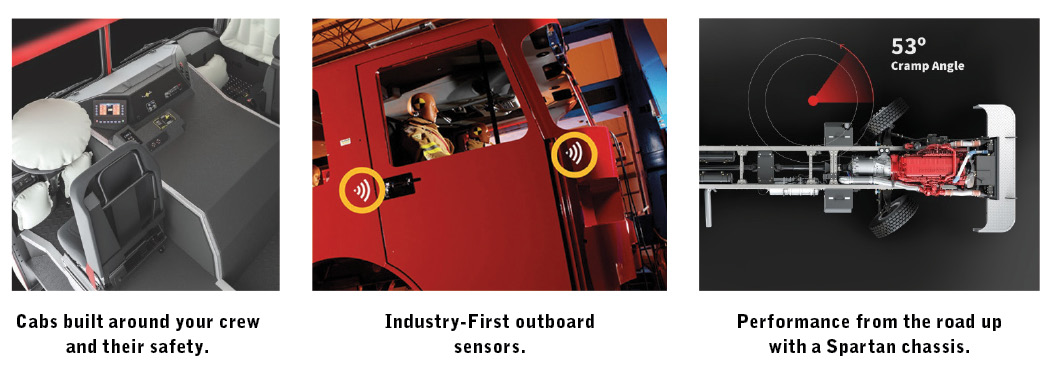

Safety Driven.

Response needs are changing. New technologies and increasing demands on productivity and safety are putting even more pressure on getting the rig right the first time. Spartan understands these changing needs, and is looking ahead with agile designs, enhanced safety features, and a focus on building fire trucks faster and more reliably than ever before.

Our legacy of chassis expertise means your apparatus is built from the ground up on a foundation ready to handle your specific response equipment and route needs. We work with you to strategically configure your truck’s specs into a design that represents the best possible mix of safety, speed, agility, ergonomics, and serviceability. And we don’t stop once the truck is delivered. This paired with five decades of over 6000 aerials and counting. Spartan provides a series of high-performing aerial solutions to meet virtually any fire departments needs, no matter the operational environment. After fifty-five years and thousands of aerials, we have more combined experience in engineering, building, testing, and supporting aerials than any competitor. For over thirty years, Spartan has remained staunchly committed to training service technicians across the country on how to quickly and efficiently service and maintain rigs to last, so firefighters can reliably keep fighting the good fight. Visit us at spartaner.com

Fabrics Made for Life

TenCate Protective Fabrics

As the leading global producer of protective fabrics, TenCate Protective Fabrics enables millions of people worldwide to be great at what they do. Generations of industry professionals — servicemen and women in fire, healthcare, military and police — rely on our fabrics for safety, comfort and confidence.

At the forefront of delivering innovative fabric solutions to the world for over 300 years, and always directed by market-driven desires, we have striven to maintain our ongoing ability to engineer the finest protective fabrics in the world.

Since the beginning, we’ve been making history in protective textiles. In the mid-1960s, TCPF was the first company to spin aramid fibers into yarn for weaving inherently flame-resistant fabrics for a variety of applications. This innovation changed the face of the protective fabrics landscape forever and has proven invaluable to countless North American end-users – from firefighters, to industrial workers, to military personnel.

Additionally, TenCate Protective Fabrics provides textiles to real world applications in a vast array of markets across the globe. In the E.U., middle-east, and Asia-Pacific regions, our fabrics serve the fire service and first responders, militaries, industrial workers, security forces and police. Outside of emergency response and industrial safety, we also provide fabrics to the medical field and food service industries, as well as standard workwear for a vast array of people overseas.

TenCate Protective Fabrics creates all fabric at four state-of-the-art manufacturing facilities located in Georgia in the US, as well as a dyeing and finishing facility in The Netherlands. By closely controlling, monitoring, and testing our fabrics at every stage, we are able to ensure the quality and performance of every yard of fabric that gets delivered to the market. A completely vertical manufacturer, TenCate Protective Fabrics is able to keep our hands on every stage of production.

As a truly global company with offices and facilities all across the globe, we have the unique ability to identify and meet the unique needs of end-users throughout a wide range of challenging work environments. Protecting people is what we do – no matter what challenges stand in the way.

From the harshest working conditions, to the welcoming sight of home, we recognize the people we’re protecting are unique individuals whose lives extend beyond work. Supporting a world of evolving needs, our innovations lead the way in user-centered design, technology and sustainability. At TenCate Protective Fabrics, we’re proud to continue our 300-year-old manufacturing tradition as we design, develop and produce solutions that bring out the best in professionals — in work, as well as in life.

PortaCount® Respirator Fit Tester Helps Protect You

TSI imagines, designs, and develops products that solve measurement problems. We collaborate with colleges and universities, research groups, and businesses around the world to set the standard for measurement expertise.

At TSI, our global team strives to provide not only instruments but also innovative solutions. We operate at both a global scale and a human scale—instruments that measure everything from atmospheric aerosols to the fit of a personal respirator. Turning data into actionable information enables our customers to do their jobs more efficiently. TSI understands the science, the data, and the processes that support your work.

Headquartered in Minnesota, TSI has a global network with sales, service, and support locations in the UK, Singapore, China, India, and Germany. Wherever you are, we are there to support you. Since 1961, we’ve set the standards for precision instrumentation and software solutions. Every day, our dedicated employees turn research into reality.

The reality for our customers is that they are exposed to respiratory hazards every day. To ensure safety and health, fire departments have respiratory protection programs in place that include fit testing for respirators. TSI’s PortaCount® Respirator Fit Testers deliver safety by utilizing the most effective quantitative fit testing method available to identify poor-fitting masks. PortaCount® instruments simplify fit testing with one consistent and objective testing experience across any respirator type.

The PortaCount® Respirator Fit Tester evaluates respirator fit during movement, breathing and talking. This data provides an accurate reflection of how a respirator will protect staff on the job. Measuring your staff’s respirator fit during action increases safety and provides mask wearers with confidence that their respirator will provide real-world protection.

By improving staff training and mask selection, users begin fit tests with respirators shown to fit and staff who know how to don and wear them. Better training increases your percentage of passed fit tests, improving safety, and saving time.

With the release of OSHA’s modified CNC protocols, PortaCount® instruments are now able to complete a fit test in less than 2 ½ minutes. Now the best respirator fit tester is now also the fastest.

For more information, please visit tsi.com/portacount4.

United Communications

United Communications is the Authorized Motorola Paging Distributor in the USA and the Motorola Solutions Accessory and Energy Distributor. United Communications also provides consultative services and pager repair for thousands of Fire, EMS, Hospitals, Rescue and Public Safety Departments across North America. In 1986 our company was founded as McManus Communications located in Blytheville, Arkansas. The company provided regional paging services and pager repair. In 1992, the Paging Division of Motorola named the company one of the very first focused Motorola Paging Dealers. In 1997, due to superior performance in our results as a paging dealer, the company earned the opportunity to take on more responsibly in a new role as a Motorola Paging Distributor. Shortly after being named a Paging Distributor for Motorola, under new ownership, significant investments were made to step up to the new role as a distributor for Motorola. In 1998, the company name was changed to United Communications Corporation (UCC). In 2003, UCC moved our operations, technical, and logistics facility to St. Charles, MO. In July of 2016, UCC was named the Motorola Solutions Authorized Accessory and Energy Distributor here in US market. In this trusted role, UCC has the honor of providing two-way radio accessories, batteries and parts to over 480 US based Motorola Solutions Accessory and Energy Resellers. Today UCC is led by a sales and management team that has over 150 years of combined communications market experience and is recognized as an expert in distribution, logistics and emergency paging. UCC and Motorola Solutions combined have served for over 75 years as the most trusted names in emergency paging; supporting first responders with the iconic Motorola Minitor pager and pager repair solutions.

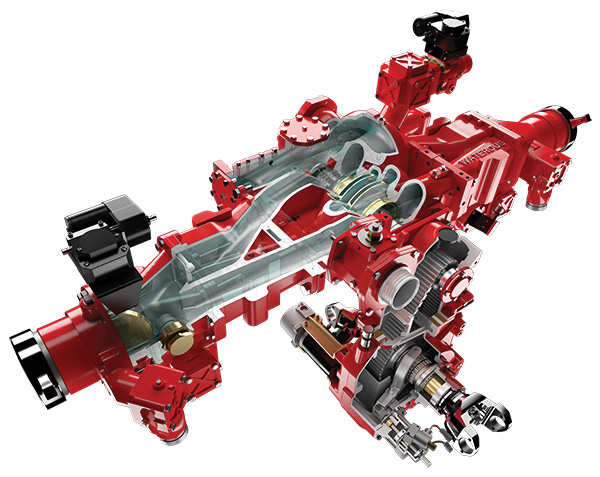

Waterous Fire Pumps – Home and Away

Waterous has talked a lot about providing fire pumps to the largest cities in the USA. We also pride ourselves in being in the largest cities to our friends to the North, Canada. While we talk about large cities, we also cover the USA from coast to coast from the smallest townships in South Carolina to the mountains of Colorado and westward to the Pacific Ocean state of California. Waterous not only blankets the United States and Canada, we are a world-wide company with fire pumps in China, Indonesia, Australia, Peru, Colombia, Brazil, Chile, Argentina, Mexico, South Africa, Cyprus, Saudi Arabia, Taiwan, Russia, Italy, Croatia, Romania, Poland, Vietnam and many more. Why Waterous? They can trust us.

Waterous purchases castings from foundries in the USA, and in our factory, machines the castings and other raw stock material into gears, impeller shafts, coupling shafts and other parts that make up a fire pump. Why is this important? Waterous can control our quality internally, we are not subject to international issues that may create delays in castings and parts, we can provide you answers on orders by visiting the factory (located in the same building as our offices) and it keeps jobs for hard working people.

To bring you the highest quality fire pumps on the market today, Waterous continually invests in its people and machinery. Recent purchases of robots, machining centers and critical measurement devices, Waterous assures you that our pumps are made to strict standards, standards that are required to meet and usually exceed NFPA Standards.

Waterous not only builds fire pumps, we have been the leader in Compressed Air Foam Systems for over 20 years starting with the ECLIPSE in 1996. Today, we continue to enhance and add products to our CAFS line to meet the demand of the firefighter. Waterous also serves the ARFF, Wildland/Urban Interface, Industrial, High-Rise Fire Fighting and Decoking/Descaling industries with products that meet the critical demands of these rigorous environments.

With over 134 years of manufacturing experience, Waterous brings you the quality you deserve, the performance you demand and the support you need. Waterous, The Force Behind the Fight.

KME WORKS FOR YOU

Since 1946, KME offers an unwavering dedication to our customers and a passion for offering products and services that make a vast difference in communities across the nation. Each day, KME prides itself on working for our customers in a way that offers several unique benefits:

CUSTOMIZED SOLUTIONS TO MEET YOUR NEEDS

KME is genuinely a sole source, custom, manufacturer of specialized vehicles. We manufacture cabs, chassis, bodies, and aerial devices. Our engineering, sales, production, and service functions have a dedication to providing solutions, customized for our clients. Lots of companies say they’re custom, but KME suggests you examine the product. With over 300 cab designs, construction utilizing aluminum, steel, or stainless steel; and, no manufacturer offers more styles, models, and features than KME.

ATTENTION TO YOU

Every KME apparatus is assigned a Contract Administrator that works in conjunction with the local sales representative and customer from preconstruction through final delivery. This strategy ensures that the customers’ needs are known, understood, and communicated to our engineering and production teams and that regular communication takes place every step of the way. Also, having stable points of contact at the local sales representative office and the KME factory means customers can have confidence their needs don’t need to be explained repetitively to new faces throughout the process.

COST OF OWNERSHIP

Fighting fire is only half the battle; maintaining your apparatus is the other. A fire apparatus with costly maintenance and replacement parts is like a fire that burns out of control. But when you choose KME, you get the security of knowing that we build every truck with heavy-duty commercial components in place of proprietary parts-which protects you from having only a single parts-supplier.

NATIONWIDE COVERAGE WITH LOCAL SERVICE

AND SUPPORT

KME’s factory locations in Pennsylvania, and Virginia, have teamed with our national dealer network to offer local support for sales, service, warranty, maintenance, training, and parts. Many locations offer in-house service, mobile service, and pump test. Because KME is a REV Group Company, we have one of the nation’s most innovative, dealer aftermarket, parts sales programs at www.firetruckparts.com.

SAFETY AND QUALITY ARE THE DRIVING FORCE

IN EVERY DESIGN

KME has invested millions in design, development, and testing that not only protect operators and occupants but also help to prevent accidents in the first place.

In working with leading third-party safety specialists, KME fire chassis have met and exceeded all crash test standards for frontal and side-impact and roof crush tests. KME also offers over fifty other safety features, including frontal impact protection, occupant rollover protection, electronic stability control, rollover warning devices, smart steering wheels, and camera systems. All KME facilities are ISO 9001 certified and feature a quality policy system. Not only does this system help KME to be more productive and efficient, but our customers also benefit through higher quality products and services, operational excellence, and a consistent, documented processes throughout the Organization.

KME is easy to do business and has experienced consistent growth over the years by focusing on what’s important to our customers: custom apparatus, personal attention, low cost of operation, safety, and quality-driven products. We believe our history, philosophy, and passion make a difference to first responders around the globe. Go to www.kmefire.com or to contact your local KME sales representative to hear how KME Works For You.

The year was 1938 and under the original name of Boston Novelty Company we made leather tags, name plates, cases, bags, etc. In the early 1940s the name changed to Boston Leather and the focus turned to law enforcement.

We have expanded into other areas but always with an accentuation on the public service market. We have broadened our fire-related line and have introduced police K-9 items. We have the ability to manufacture custom leather Products, but our bread and butter is the “Uniformed Professional.”

Leather remains the material of choice. It is the best material for the items that we manufacture. When worn or carried leather becomes a part of you. It is comfortable, long lasting, very strong, and good looking.

All items sold by us are made in our plant in Sterling, Illinois. All leather used is full grain from U.S. steers. All leather is tanned in the U.S.A. We manufacture a quality item and stand behind it fully. You will not buy a better Product anywhere.

We have chosen to market our Products through dealers only. We feel they can service your total needs on a local basis. A list of dealers by state is located on our site. However, if there are any questions about our Products do not hesitate to contact us. We will give you the information to make an informed decision.

Thank you.

Tony Valentino

Boston Leather, Inc

Hot Shield USA

Hot Shield USA produces firefighting face masks for wildland firefighting. Hot Shield started in 1994, when two Southern California firefighters realized no device or mask was available for purchase, that would provide legitimate protection for the face and respiratory tract against the dual hazards of flame & smoke. They created the Hot Shield line of masks & shrouds, safety garments that to this day, have no equal.

The Hot Shield line up of wildland/brush fire face masks have passed several relevant industry tests. In independent third party testing, the following four tests were performed: the RPP or Radiant Protective Performance ASTM F1939-NFPA 1977(2011), and the TPP or Thermal Protective Performance ISO 17492-NFPA 2112., the Char Length ASTM D6413-NFPA 1977(2011) and the After Flame ASTM D6413-NFPA 1977(2011).

The results of the RPP test showed the Hot Shield mask with CarbonX scored 11.1, far greater than the NFPA standard of 7. The TPP test scores were dramatic…scoring a 10.2 vs the NFPA minimum of 3. The Char Length test was superior at 1” vs the 4” NFPA minimum and the After Flame was incredible at zero seconds vs NFPA minimum of 2 seconds.

Especially gratifying are the firefighters that write or call to express their appreciation for a life saving face mask; that the Hot Shield either saved their life or made the difference in their personal health and safety. Hot Shield USA has continued to pioneer innovative personal protection equipment including wildland face masks, helmet shrouds and more. Hot Shield USA can be reached in Camarillo, CA (310) 710-2624 or on their website

www.hotshield.com

Portable X-ray from MinXray

Since 1967, MinXray, Inc. has been the leader in portable diagnostic X-ray imaging. Our complete portable systems can be used in multiple applications where it is more efficient to bring the X-ray unit to the patient instead of the patient to the X-ray unit. MinXray products are used in a variety of medical, veterinary and military applications.

The Impact wireless portable digital radiography system from MinXray provides superior diagnostic imaging capabilities for emergency medical responders in remote locations, at trauma scenes, or during transport to a medical facility. Impact from MinXray closes the treatment gap for patients by obtaining imaging studies that are critical to fast and appropriate emergency care. This handheld, 100% battery-powered technology enables in-the-field and in-transport imaging.

For patients being transported over great distances by ambulance or Flight for Life, adding X-ray capabilities brings an extra layer of care and support. Patients are stabilized are prepared for better outcomes when admitted to the emergency room due to the real time information provided to the medical team ahead of their arrival.

The addition of Impact to any emergency medical services program expedites and increases diagnostic capabilities for first responders. It’s the only battery-powered X-ray unit available that is Food and Drug Administration (FDA) certified for full-body imaging.

Insights gained from imaging patients before they arrive at a hospital saves time and better prepares doctors receiving those incoming patients. According to the World Health Organization (WHO) Manual of Diagnostic Imaging, 70-80% of all clinically relevant medical questions may be solved by radiography or ultrasound imaging.

The mobile capability of MinXray’s on-board Impact system gives ambulance crews the ability to answer questions regarding injuries or traumas and consult with doctors to receive a diagnosis in real time. With hotspot access, emergency medical responders can use the Impact unit to send X-ray images to off-site radiologists for immediate review. This instant communication expands and improves overall medical care.

To learn more about MinXray’s portable X-ray solutions for emergency response and Flight for Life, visit www.minxray.com, email info@minxray.com or call 1-800-221-2245.

Grant Assistance for Exhaust Removal System

Fire/EMS departments can rid their firehouses of dangerous diesel exhaust emissions and receive free grant assistance. Sponsored by MagneGrip Exhaust Removal Systems and AirHAWK Air Purification Systems.

Through the Grant Assistance Program, departments can receive personal assistance by grant experts including grant alerts (local, state and national), grant writing training and narrative review, as well as optional grant writing at a 50% discount, Additional information is available at www.magnegrip.com.

Cancer and Chronic Illness Protection

Because firefighters and EMTs have a high risk for several cancers, this program offers the potential to eliminate exposure to toxic diesel exhaust in firehouses. In addition to cancer, harmful exhaust gases and sub-micron particles are know to cause respiratory diseases and contribute to heart disease and other chronic illnesses.

MagneGrip Exhaust Removal Systems are source-capture systems and 100% effective in removing exhaust emissions from the firehouse. The systems are easy-to-use, fully automatic and won’t slow down response time. Systems are available for every firehouse application and every type of vehicle.

Ceiling-mounted Air Cleaner

MagneGrip Group also manufactures ceiling-mounted AirHAWK Air Purification Systems, which remove exhaust gases and soot, airborne viruses, mold spores and bacteria. The systems operate automatically 24/7 to remove or neutralize airborne contaminants and return clean, purified air. AirHAWK units are available for the bay area, turnout gear room and living quarters. AirHAWK Air Purification Systems can be used alone or with MagneGrip Exhaust Removal Systems for the most complete protection from diesel exhaust, off-gases from equipment and turnout gear, toxic air and airborne contamination.

Made in the U.S.A.

MagneGrip Exhaust Removal Systems and AirHAWK Air Purification Systems are manufactured in the U.S. They are the first choice of U.S. fire departments. For a free proposal and free grant assistance visit www.magnegrip.com. Or call 800-875-5440 for additional information.

Performance Advantage Company

Performance Advantage Company (PAC), established in 1992, is a privately owned company which manufactures and markets high quality tool mounting brackets. PAC has over 600 points of distribution in North America and sales in 38 countries around the globe. We are highly recognized in the industries we serve for our attention to detail and overall customer service. PAC’s primary market is the Fire Industry, providing specialty tool mounting solutions for fire apparatus. Our other markets include Law Enforcement, Military, Homeland Security, EMS, Landscaping, Utility, and Towing/Racing.

The products PAC offers are designed to mount tools safely and securely. Versatile and flexible mounting options provide the most efficient and accessible solutions for tools and equipment. Our history of innovation and our collective experience guide PAC to create products that outlast and outperform. Whether new or in-service vehicles, PAC products can be customized for individual needs and requirements. PAC utilizes the best possible materials and manufacturing methods which result in long lasting service. You can expect high quality and value when purchasing PAC products.

In addition to offering the very best tool mounting brackets on the market, we reinforce our value to our customers by supplying them with a Lifetime Warranty on all our products, customer support in assisting them in finding solutions to their tool mounting needs, and access to marketing support materials and live-time training through technology and internet. Best of all, we offer these services at no cost to our customers.

Check us out at www.pactoolmounts.com. You can also call our highly experienced and professional customer support team at 1-888-514-0083. Performance Advantage Company is located in Lancaster, NY, a suburb of Buffalo and sells its products direct or through a worldwide network of dealers. All PAC products are proudly made in the United States!

The RollNRack Hose Management System

A hose related back injury led firefighter Javier Fernandez to design and patent a tool that would prevent back injuries for all firefighters. Since back injuries are the number one cause of early duty disability retirement across the US, his goal was to exceed NFPA safety standards throughout the process and eliminate the potential for injuries during hose management. This system prevents loading hose while riding precariously on top of moving apparatus. This dangerous and antiquated practice has led to injuries and deaths. “The goal was to improve a firefighter’s quality of life by working smarter, more efficiently and being as safe as possible. Heavy rolls of LDH are rocked into or out of the units and loaded onto stationary rigs with minimal firefighters. No one rides on moving apparatus to load hose, ever.” Fernandez states.

The RollNRack was introduced in 2003, an LDH drain attachment in 2004. In 2007, the Power Roller, the industry’s only battery-operated LDH roller was introduced. It drains & rolls a 100’ length of LDH in under thirty seconds! The System can handle up to 7 ¼” hose. Loading hose off any unit is accomplished with two or three firefighters. The Efficiency Package saves budget dollars and cuts scene time in half. This allows a department to respond to other calls. In 2011, the FASTBACK, a manual roller for hand lines was introduced. In 2012, the GO-Pack, a collapsing, stowable ‘Rack and LDH drainer were added. All components of the RollNRack System are innovative, patented and designed for durability and ease of use. RollNRack Tools are made of aluminum and stainless steel. The customizable system is portable and fully independent of the apparatus.

With shrinking budgets, higher workman’s comp insurance, an aging work force, the current shortages in the volunteer ranks and expanding coverage, the RollNRack system makes a difference. Videos show how they can help any department. “It’s the safest system on the market and has streamlined hose management for volunteer, career, industrial and military firefighters all over the world.” The RollNRack System is MADE IN THE USA and demonstrated at all shows attended.

Contact info

Javier Fernandez

CEO/Owner RollNRack, LLC

Ph: 262-363-2030

Fx: 262-363-2034

Dedicated to saving lives throughout the world

Skedco was founded in 1981 by Bud and Catherine Calkin for the purpose of manufacturing the SKED® stretcher. Skedco immediately targeted the Military and Fire Service as the obvious market. They very quickly found that cavers, industry and wilderness rescue teams needed the Sked too.

By 1984 Skedco produced the Oregon Spine Splint. It was necessary to create their own immobilizer as the only other one was produced by a competitor. It was added to the Sked System. Shortly after the OSS came a flotation kit. It makes the SKED® float nearly vertically and will “self right” when capsized. The complete system fits into one backpack that doubles as a towing harness when it is necessary to drag the SKED® in a hands free mode. Later, they developed the inflatable floats which made the system even smaller for storage and transport. The complete system was then standardized by the military but it still wasn’t understood by the end users.

When “Operation Just Cause” occurred and the U.S military invaded Panama to capture Manuel Norriega the Army purchased a very good number of SKED® systems. SKED® performed very well during that operation. Lives and at least one spinal cord were saved.

The U.S. Army Rangers were the first to use the SKED® to haul equipment. They would drag mortars, mortar rounds, ammunition, many other critical items and sometimes a patient faster and easier than carrying them.

In the early 1990’s OSHA mandated that industry be able to respond and affect a confined space rescue in a very short time. SKED® was the natural choice for confined spaces as it will bring victims through smaller, more confined areas than any other stretcher, even when the patient is immobilized.

The Fire Service also began using the Sked a lot more frequently. They saved lives using the SKED® when no other stretcher would work.

SKEDCO now produces over 200 products some of which are SKED® Stretcher, Oregon Spine Splint, Sked-Evac Tripod, SKEDCO Rescue Hauler and SKEDCO Microhauler 4:1 mechanical advantage rescue pulley systems, HALF SKED, SKEDCO Window Escape Anchor, Hazmat SKED Stretcher systems and a wide array of Military rescue and emergency medical products. The company and its’ employees remain dedicated to saving lives throughout the world.

Skedco wishes to thank all of those brave men and women who are risking their own safety to save others. They are truly the world’s greatest treasure.

If You Want Quality You Want Zico

For over 50 years, Ziamatic Corp. has dependably provided first responders with the tools and equipment they need to make their jobs safer and easier every day.

Quality. With every new design, Zico strives to meet the ever-evolving demands of the fire service with fresh forward thinking and cutting edge development. New products are put through rigorous and extensive in-house and third-party testing to confirm they exceed the highest standards of safety and durability. Then, using only the highest quality materials, virtually everything is crafted and assembled with care right here in the USA.

Innovation. As an industry leader, the company works diligently to stay at the forefront of firefighting technology, with exciting new engineering designed to make tasks faster, safer, and easier than ever before. In addition, older products are continually upgraded and improved upon as opportunities arise and standards change.

Flexibility. From color, material, and mounting location to size, drop distance, and so much more, Zico offers a level of choice and customization that simply cannot be matched. Whether a department is building a new apparatus or laying out a single compartment, Zico is prepared with solutions specific to their needs.

Ziamatic proudly introduces the following new products –

QUIC-STRAP 1” Variable Straps, Various Models

With five different lengths to choose from, this new, thinner line is an excellent choice for securing smaller equipment, shelf slots, and compartment cubby-holes. Constructed of the same heavy-duty materials as their wider 2” cousins, the all-weather, UV-resistant hook and loop straps provide extraordinary holding power at an extremely cost-effective price.

5 lb. Fire Extinguisher Holder, Model QR-FEH-1

A safer way to secure extinguishers in the apparatus or ambulance. Better protect patients and personnel by reducing the risk of dangerous projectiles in a crash. Engineered specifically for moving vehicles, this powerful steel bracket is SAE-J3043 compliant and third-party tested to hold strong against a massive 39G force.

Want to try before you buy?

Many of Ziamatic’s products can be requested for 30 days of test and evaluation before purchase. For more information please call 1-800-711-FIRE or visit Zico on the web at www.ziamatic.com