On Wednesday, Indianapolis (IN) Fire Department (IFD) Chief Ernest Malone unveiled “Project Washout,” a comprehensive, in-house, fire gear maintenance, management and repair program, integrated with advanced ozone technology, the first of its kind among fire service agencies in the U.S. Project Washout was created for the sole purpose of better protecting our suppression personnel and implementing cancer preventive initiatives, to help fight the unseen enemies our personnel face every day, including COVID-19. The Project Washout program, is comprised of 5 key safety processes which include fire gear registration and accountability, cleaning, service, maintenance, and repair. The new process utilizes state of the art UniMac industrial size gear washers and integrates the use of the ArtiClean Ozone system. It is this integration of ArtiClean Ozone, into the gear washing system, that now provides IFD firefighters with hospital grade sanitation and cancer carcinogen removal quality, only previously available through outsourcing.

As part of IFD’s cancer initiative’s commitment, each of IFD’s 1220 firefighters are provided 2 sets of turnout gear. Two sets of gear, allows for the availability and use of a second, clean set, should the gear become wet and dirty after a fire, during a 24 hour shift. Prior to December 2019, the National Fire Protection Association (NFPA) 1851 standard for gear laundering, required that all turnout gear go through a department wide registered & monitored cleaning/repair process at least once a year. While IFD has a standard gear washer within 10 of its 43 stations, where crews can wash their gear as needed, the standard still required the department to conduct the official process once a year. In 2016, when IFD moved into their new headquarters (HDQ) building, located at 955 Ft. Wayne Ave, two gear washers and two dryers were purchased and allocated for this yearly function, allowing IFD to meet the NFPA 1851 standard at the time. It was not however, an advanced cleaning.

In early 2019, the IFD Quartermaster, Captain Richard Cook, was asked by Chief Malone to research and evaluate the cost of putting a fire gear washer in every fire house. Later that year, in November of 2019, the National Fire Protection Association (NFPA) announced a standard change to NFPA 1851, addressing how fire service Personal Protective Equipment (PPE) should be serviced and maintained and would take effect in December of 2019. This new standard would require that all PPE must now be cleaned and serviced a minimum of twice a year. That change, and our ability to meet it, would require significant upgrades to our current gear washing system and require a total overhaul of our gear registration system.

The idea of putting a gear washer in every fire station was quickly identified as too costly and for some stations, not logistically possible. The cost of fitting the remaining 33 IFD stations with gear washers came in at over $441,000. A vital consideration to our proposed way of attacking the standard change, was that it must maintain alignment with already established cancer related initiatives, and the safety of our personnel.

For a department of IFD’s size, the cost of outsourcing gear cleaning once a year, was estimated at $840,000 or $350 per 2 sets of gear. Under the new NFPA 1851 standard, the cost to outsource the cleaning twice a year, would jump to $1.6 million. This would not include additional cleanings that may be required after a hazardous materials exposure or any other repairs that may need to be made.

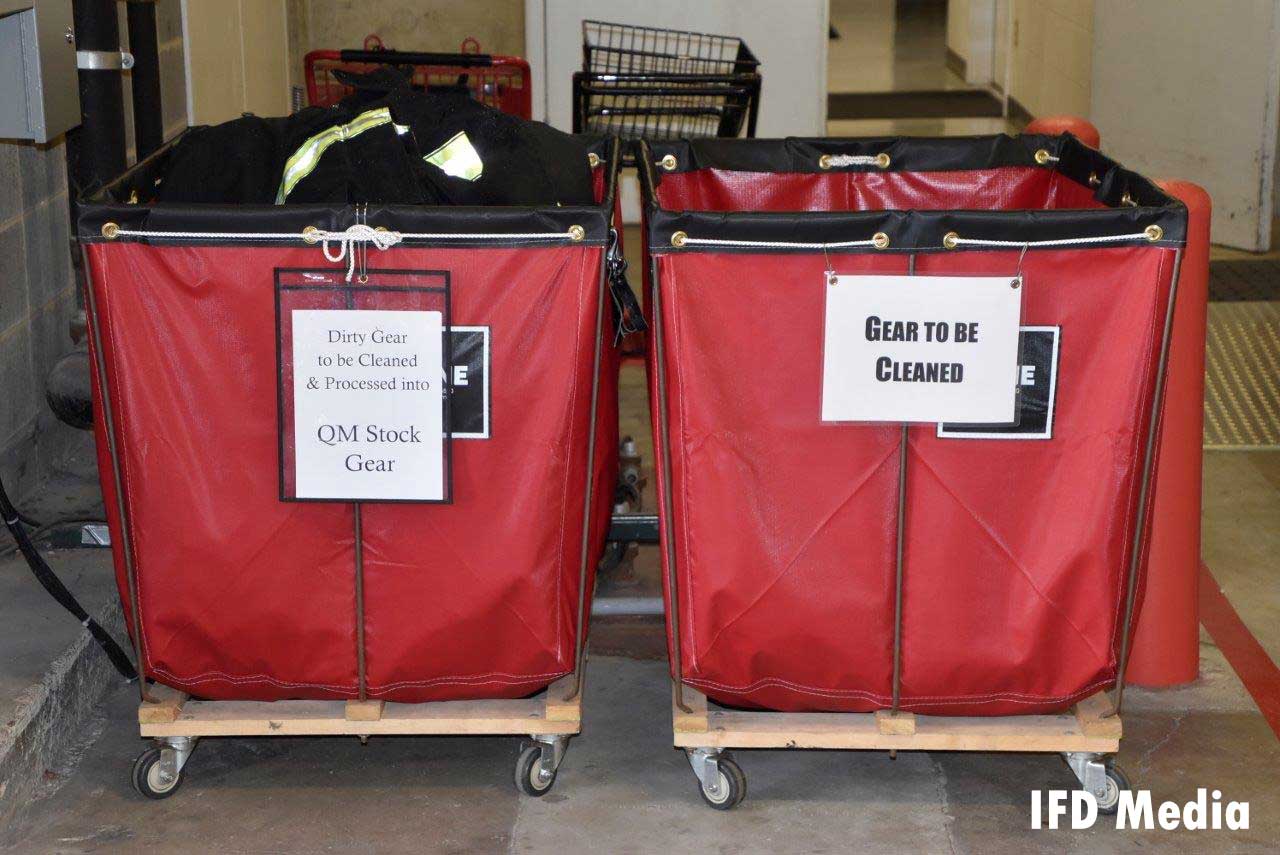

With the Project Washout purchase of 4 state of the art UniMac industrial size gear washers ($15,000 each = $60,000), the ArtiClean Ozone system ($25,000), and installation costs, comprising a total investment of approximately $100,000, IFD now has the permanent ability to meet the NFPA 1851 standard of twice a year, comprehensive, ADVANCED gear cleaning, service and repair – in house. Before Project Washout, the IFD Quartermaster division was able to process about 20 washes and repairs a day. Project Washout allows for 40 sets of gear to be washed and serviced per day.

Additionally, as part of the quartermaster system, the department maintains a full-fledged gear repair shop at IFD HDQ. The shop continues to help fulfill the NFPA 1851 repair and maintenance requirement and allow for the department, twice a year, to visually inspect, clean and repair, each set of gear assigned to our firefighters.

However, the gear washer component, would still not meet the NFPA 1851 standard requirements of gear registration, accountability and record keeping. To meet that standard, IFD upgraded their gear registration system and implemented QR coding (barcoding) into each set of new fire gear. The new gear was purchased as part of the 2018 budget in compliance with the NFPA 1851 standard for mandatory gear retirement, after 10 years of service. The barcoding allows for better accountability, accounting of service and maintenance along with providing efficiencies to our service requests. The barcoding system and subsequent data, will also help with future forecasting and budgetary preparation of gear needs going forward.

RITA L. REITH is a battalion chief with the Indianapolis Fire Department (IFD) and serves as the agency’s public information officer.

MORE

Photos: Indianapolis Firefighters Deal with Multiple Fires, Water Main Break

Indianapolis Firefighters Control Tanker Truck Fire