HOT TOPIC

This month’s Hot Topic begins with the results of the survey we conducted in the April 1991 issue of Fire Engineering concerning newly proposed NFPA # 1, The Fire Prevention Code.

Fifty people from across the country responded. While this cannot be considered a scientific survey, it does give us insight as to what fire service personnel are thinking.

Here are the six questions that were posed along with the number of “yes” and “no” responses. (It was not necessary to answer all questions.)

- If the NFPA promulgates the “new’” code #1, will you adopt it by ordinance? Yes 15 No 33

- If you do adopt NFPA #1, w ill you discontinue the use of one of the three model fire prevention codes? Yes 7 No 20

- If you do not adopt NFPA #1, will you use NFPA as a reference? Yes 33 No 19

- If you do adopt NFPA #1, will you attempt to “mesh” one of the three model building codes with it? Yes 17 No 12

- If the NFPA promulgates code # 1. should it next develop a model building code? Yes 28 No 19

- If it were in your control, would you prefer to see all three model fire and building codes combined into one? Yes 42 No 8

Thanks to all of you w ho responded to the survey. We’ll have another one in a few months.

A topic of recent interest has been fire doors. Fire doors come in many sizes and shapes; they may be rolling, swinging, or sliding. All fire doors have one thing in common—they are installed to permit movement of people and equipment through the firerated barrier while maintaining the fire rating of a fire-resistive partition (wall).

For quite some time (since about 1918), fire doors have been tested in furnaces that are being exhausted — essentially under “negative” pressure. The reasons given for this negative-pressure testing are varied, but the most common reason is to prevent smoke and other products of combustion (including flames) from entering the test facility and endangering test personnel. A code change has been proposed to Uniform Building Code Standard 43*2, the fire door test standard, to require that fire doors be tested under positive pressure. Proponents of this change argue that positive-pressure testing more closely simulates actual fire conditions. Opponents charge that no change is necessary, since fire doors have been in service for decades with minimal records of failure.

More than 1,000 “comments” were received by the International Conference of Building Officials on this code change. A vote was taken on September 12, and the code change was approved.

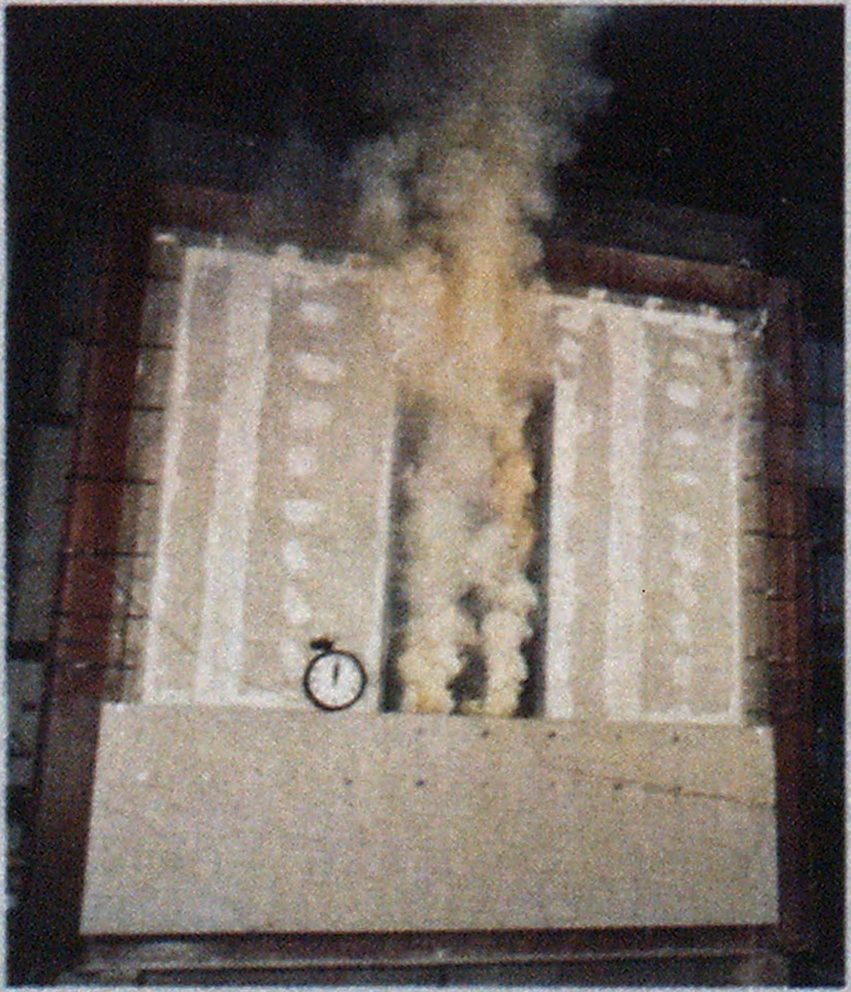

To gain a perspective on positivepressure fire door testing, refer to the photos below. These are photos of a recent positive-pressure test being conducted on a steel fire door with a polyurethane foam core. The door was a commercially labeled 90minute rated fire door. After one minute, thick smoke escaped around the door’s perimeter; after one minute 28 seconds, flames were seen on the unexposed surface of the door at the top and lock side, as w>as thick black smoke; after one minute 45 seconds, flames erupted from the locking mechanism; after three minutes 15 seconds, the door opened into the furnace. At five minutes 45 seconds, the pressure at the top of the door was 0.02 inches of water with the neutral pressure plane at 40 inches above the door sill.

The issues concerning the failure of fire doors during testing and the maintenance of “installed” doors has been studied by Factory Mutual Engineering and Research (FME&R) since the early 1980s Quite a bit of data has been compiled.

During the first six months of 1990, FME&R tested nearly 1,000 installed fire doors of many types. These included rolling steel, horizontal sliding (inclined track, counterweight closure, and spring closure types), vertical sliding, and sw inging doors. FME&R found that the overall failure rate for all doors combined was 18 percent.

Some of the reasons for failure included improperly set spring tension for rolling steel doors, broken closers on swinging doors, and missing posts and rails near doors. These failures during testing prompted the Factory Mutual Research Corporation (FMRC) to reevaluate and modify its rolling steel fire door testing standard.

Essentially, two new performanceoriented tests were developed: a 7,500 open/close cycling durability test and a test in which the door is “dropped” by activating the automatic release device 25 times to test the door’s reliability.

In addition, FMRC requires that detailed installation and drop test/reset instructions be applied to the fire door with an adhesive. Along the same lines, FMRC. also recommends that an annual closure test be performed by a qualified maintenance employee or manufacturer’s representative.