BY SAMUEL HITTLE AND M.R. STEELE

A fundamental concern of first-due fire suppression companies is ensuring that doors do not pinch the hose. If a door swings shut over the line during interior operations, it will ultimately reduce, if not entirely eliminate, water flow; make it extremely difficult, if not impossible, to advance the nozzle; and potentially trap firefighters and occupants. This is a concern to engine companies, especially those companies that practice dry line stretches to the immediate fire area.

REMEDIES

Should this happen, there are a number of remedies. Some companies may roll the hose over itself and apply pressure downward, reducing the pressure enough to kick the hose free. Others may remove the door entirely; this not recommended, since you may need to control that door later. Another solution is for the company to radio the engineer to gate down the line until the problem is eliminated. Although each of these methods is effective, they all delay suppression efforts and put the engine company at risk of being burned while waiting for water.

The point is that any door the hose passes through must be chocked to ensure the door stays ajar, which is critical to a smooth and quick knockdown. A simple solution is to place wedges in the doors as you encounter them and make a steady forward push. However, since firefighters sometimes act like bulls in a china shop, disregarding finesse as they plow through whatever is in their way, including the partially open, chocked door through which the line passes, the effectiveness of the wedge may become compromised.

As interior personnel make their way into the structure, they may routinely bump or jar the door repeatedly, which is especially true of the door through which the first-due line is taken in. Since multiple crews use this particular access/egress point, the standard wedge may often work loose and fall out, allowing the door to close.

Although the hinge chock is very reliable, it is bulky; is not readily accessible, since it is carried in a pocket; and is expensive to replace. Ordinary wood wedges and nails often carried in helmet bands are cheaper and more accessible solutions, but they rely on door pressure to stay in place and can be easily dislodged if the door is bumped or jarred.

THE WICHITA WEDGE

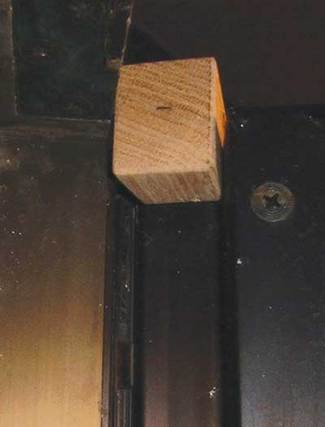

The Wichita Wedge (also called the Luke chock) combines the reliability of the hinge chock and the affordability and easy access of wood wedges or nails (photo 1). It looks and functions like any other wooden wedge, except that it has a notch in the middle large enough to fit over a pinned or piano hinge (photos 2, 3). The wedge is balanced over the hinge, which ensures that it will stay in place without depending on direct pressure from the door. As the door is bumped and jarred during operations, the Wichita Wedge can be relied on to maintain its purpose. Since the Wichita Wedge is similar to an ordinary wood wedge, it can be used at the top or bottom of a door (photos 4, 5 , 6).

Photo 1

|

Photo 2

|

Photo 3

|

Photo 4

|

Photo 5

|

Photo 6

|

Although it is important that a wedge stay in place, it is equally as important that it can be easily removed when necessary. Traditional wood wedges that are driven into place to keep them from falling free may cause the door to remain permanently open. When chocking a door, allow enough swing so pressure on the wedge can be relieved to facilitate quick removal by a crew seeking refuge. Since the Wichita Wedge relies on the hinge and not pressure from the door to ensure constant positioning, forcing a door to its maximum swing is rarely an issue.

The differences between older and newer construction methods make it difficult for any door chock to work every time. If you encounter a situation in which the notch in the Wichita Wedge does not fit on the hinge, simply turn the wedge over, rest it on top of the appropriate hinge, and angle the narrow end downward (photo 7). This angle distributes the weight downward, facilitating its path into the door instead of away if the door is bumped.

Photo 7

|

Figure 1 illustrates the basic design and measurements for making the Wichita Wedge. The measurements are based on the openings commonly found in residential and commercial occupancies. If it does not work for your first-due response area, adjust measurements accordingly. Remember that the more narrow the wedge, the farther back the notch needs to be for balance. Conversely, the thicker the wedge is for commercial applications, the farther the notch should be placed from the thicker end.

|

SAMUEL HITTLE, a firefighter with the Wichita (KS) Fire Department, is a haz-mat technician and has an associate’s degree in fire science from Butler County Community College.

M.R. STEELE, a 30-year veteran of the Wichita (KS) Fire Department, is chief of Battalion 1 and haz-mat co-coordinator. He has a bachelor’s degree in human resource management from Friends University.