Once you force roll-down gates at commercial building fires and move them out of the way, you are often faced with additional forcible entry challenges in the front of the building, namely glass/aluminum storefront doors. In the rear of the building, you will most often encounter heavily reinforced steel entry doors. This article focuses on storefront door challenges firefighters face.

Storefront Doors Glass/Aluminum

Glass/aluminum storefront doors are also known as “narrow-stile” doors because of the width of the aluminum door’s vertical side rails or “stiles” (Figure 1). The rails on narrow-stile doors are about two inches wide, the rails on medium-stile doors are approximately four inches wide, and the rails on wide-stile doors are about five inches wide. The glass used in these doors is usually a tempered type of safety glass (although acrylic and polycarbonate can also be used). When broken, this type of glass fragments into thousands of tiny pieces.

|

| (1) Photos by author. |

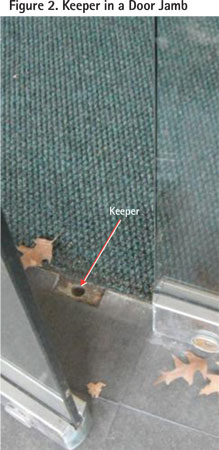

These doors are almost always secured with a lock body that is set or “mortised” into a cavity cut out of one of the aluminum stiles (photo 1). A key cylinder is threaded into this lock body through a hole in the front of the stile; a thumb latch is threaded into the other side. The lock features a heavy-duty deadbolt that can be one to two inches in length and is usually constructed of several layers of steel laminated together. Some of these deadbolts feature a hook-type shape. When the key is operated in the cylinder, the deadbolt rotates out of the lock body and into a keeper in the door jamb (Figure 2).

“Frameless” Glass

Another type of storefront door is the “frameless” glass door. These doors feature thick tempered plate glass with upper and lower rails, but no stiles. They are also often secured with a lock body set or “mortised” into a cavity cut out of one of the aluminum stiles (as described above). However, the locks are usually located on the bottom rails, with the deadbolts extending into keepers mounted in the sill plate and floor (photos 2, 3).

Size-Up

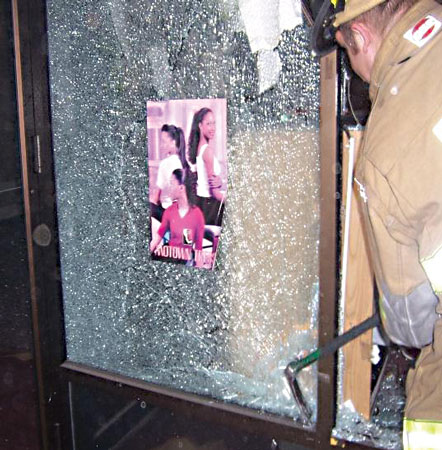

When teaching forcible entry operations, always encourage members to perform a proper size-up. They should look for the weak link in the door-wall assembly and exploit that weak link to gain quick entry. For narrow-stile doors, the weak point is usually the glass. However, breaking the glass is almost always the wrong option at a commercial building fire. There are several reasons for this. First, the numerous glass shards created by this move are a hazard and can puncture hoselines and injure members (photo 4). Second, and more importantly, once the glass is broken, you have now created an uncontrolled ventilation situation. As such, if hoselines are not in position and vertical ventilation has not yet been completed, the fire will most likely intensify.

If conditions allow you to break the glass (i.e., the door is not directly adjacent to the fire area), members should not enter the structure or stretch hoselines through the door frame. Instead, members should reach inside and unlock the door using the thumb latch (photo 5), thus allowing it to be chocked open for safer and more efficient ingress and egress.

Once you have broken the glass, other problems you now face include needing to duck or crawl under an interior horizontal push bar and the significant amount of time it takes to break off or remove the push bar. Because breaking the glass is usually not the best option, you could instead force the door conventionally. However, this will usually create a large amount of force on the relatively weak aluminum door stile and cause the glass to break, which is what you are trying to avoid. So, the more viable options are to cut the deadbolt and to perform a through-the-lock procedure. To cut the deadbolt, you will need a gasoline-powered forcible entry saw equipped with either an aluminum oxide or diamond-segmented blade.

To cut the deadbolt, locate the lock cylinder on the front of the door. The deadbolt is usually a few inches below the lock cylinder and will be visible in the gap between the door and the jamb. If necessary, you can insert the adz of a halligan bar, the blade of an ax, or a door chock (wood or aluminum) into the gap to widen it (photo 6). Once you have inserted one of these tools into the gap, exert slight force on the tool to widen the gap even further, if necessary. (Be careful; too much force can and will cause the glass to break!)

When the gap is sufficiently wide, place the blade of the saw inside and cut the deadbolt (photo 7). Start with a low revolutions-per-minute setting and increase to full throttle once a groove shows in the deadbolt. When the cut is complete, you can open the door when a hoseline is in position and members are ready to begin the attack. Always chock the door to prevent it from closing on the hoseline. In some situations, you may find a guard installed to prevent access to the deadbolt (photo 8). In this case, remove or cut through the guard to gain access to the deadbolt.

Another option is to use through-the-lock procedures. Use a lock cylinder-pulling device such as a K-Tool to pull the cylinder from the door and then a key tool or screwdriver to trip the lock (photo 9). Remember, you will have to place the tool in the 5 o’clock or 7 o’clock position and then rotate it to trip the lock, depending on its orientation. If no key tool or screwdriver is available, you can sometimes use the pike end of a halligan to trip the lock (photo 10).

Note: Don’t be surprised if a cylinder was installed upside down or in another position and you don’t feel the device at the 5 o’clock or 7 o’clock position. If this is the case, move your tool around to locate the cylinder and trip the lock.

You can also unscrew the lock cylinder from the lock by using adjustable locking pliers (photo 11). Place the pliers around the cylinder face and then slightly turn the cylinder clockwise and then sharply counterclockwise. This will (hopefully) break the set screw that is holding the cylinder in position. You can then unscrew the cylinder in a counterclockwise direction and remove it. In some cases, you may have to pry off the trim ring around the lock cylinder with a flat-blade screwdriver to gain a purchase on the face of the cylinder (photos 12, 13).

These are just some of the techniques that you can use to gain entry into glass storefronts. To become proficient in performing these and other techniques, you must become familiar with the types of doors and locks present in your response area.

Get up, get out of the firehouse, and do an area-familiarization drill after business hours to see what types of doors and locks are common in your area. Figure out which techniques work best for you, and drill on them. Make or purchase a through-the-lock prop that will allow your members to practice on a regular basis. Remember, amateurs practice until they get it right. Professionals practice until they can’t get it wrong!

DANIEL M. TROXELL is a 39-year fire service veteran and the captain of Truck Company 13 for the Washington (DC) Fire Department (DCFD), where he has served for the past 30 years. He is a Pro Board Certified Level III instructor; an adjunct instructor with the DCFD Training Academy; the owner of TroxFire Training Solutions, LLC; and an instructor for Traditions Training, LLC, specializing in forcible entry and truck company classes. He has a bachelor of science degree in fire protection engineering and a master of science degree in applied management from the University of Maryland-College Park.

Through-the-Lock Entry for Storefront Doors

MINIMIZING RISK IN FORCIBLE ENTRY OPERATIONS

FORCIBLE ENTRY FOR GLASS STOREFRONTS

Fire Engineering Archives