Coquitlam forms part of the Greater Vancouver region and has a population of approximately 140,000. It has experienced rapid population growth and building development since the 1960s. Much of the new residential construction has been Type 5, wood-frame apartment buildings, designed to increase population densities in targeted urban areas. I have responded to several flat-roof fires that have impacted these types of structures. These fires exposed the challenges associated with fire that extends from the exterior of the building into the flat-roof area. I have developed techniques and instructional materials to aid incident commanders (ICs) in accessing and implementing tactics that can help reduce fire losses while improving firefighter safety.

|

| (1) A four-story apartment fire in Coquitlam in 2015. (Photo by Zenons Photo/Video; all other photos by author.) |

ICs often hesitate to send firefighters to roof areas for offensive operations. If not properly assessed, roofs can be unpredictable and dangerous depending on construction and fire exposure. Flat roofs built with dimensional lumber as part of the Type 5 construction (commonly referred to as wood or stick frame), often seen in condominiums and garden apartments, offer firefighters an opportunity to work safely from roof positions adjacent to the fire area. Too often, a lack of building construction knowledge leads ICs toward defensive tactics that are unnecessary given the inherent safety and support these roof systems provide. This article dispels myths about working on solid wood-beam roofs; these arguments are backed by personal experience; interviews with numerous building experts; as well as information from the preeminent expert on building collapse, Fire Department of New York Deputy Chief (Ret.) Vincent Dunn.

Taming the Flat Roof

Dunn wrote extensively on the prospect and dangers of building collapse. In his book Collapse of Burning Buildings: A Guide to Fire Ground Safety (1988), he noted that the solid wood beam roof (made up of dimensional lumber spaced on 16-inch centers) provides the greatest stability to a flat roof.”1 Dunn added that this type of roof also will show signs of “softening” on the roof deck that can warn firefighters that the roof may be weakening. For the experienced fire officer, this is essential knowledge that can impact tactical choices on the fireground. Understanding that this roof system provides the opportunity for a safe working environment is critical.2 Quick interior attack and search operations coupled with a roof reconnaissance team give an IC the opportunity to quickly assess fire spread into the roof void. From the ground, an IC can be provided a three-dimensional view of the building (exterior, interior, and top) by way of information from officers working on the interior, exterior, and roof. This, in turn, should lead to better strategies and tactics that ultimately will limit fire losses.

What’s in the Roof?

The dimensional lumber (2 × 10) used in a solid-beam roof is known to have a better resistance to fire than open-web, steel-bar-joist flat roofs and parallel-chord, truss-style flat roofs. Both of these latter two styles are common in flat roof construction and may be prone to failure within five to 10 minutes of fire impingement. (1) Metal gussets (plates that are pressed into the wood) that hold truss pieces together can also fail as they separate when heated by fire. Similarly, steel bar joists can elongate and weaken from heat exposure, increasing the threat of roof or wall collapse as these roof supports become compromised.

There are many different styles of roof design, and modern firefighting tactics have evolved to ensure that firefighters working above or below fires that involve roof structures do so safely and efficiently. The issue today seems to be that many fire service leaders have developed a mindset that limits or confines tactical objectives based on a one-sided approach to fighting fires that enter the roof space. Having heard more than one officer say “We don’t work on roofs anymore” has led me to believe that today’s fire officer must have a superior understanding of different roof systems that are common to different types of buildings. Taking this approach will afford ICs better options to assess and attack stubborn fires that enter or may be confined to an attic or a flat roof void.

|

| (2) An open-web steel bar joist, which is common in Type 2 construction commercial and industrial buildings. |

The solid-beam roof in photo 3 was taken during the restoration stage after the drywall had been removed. It shows common burn patterns that occur in flat roofs as the fire moves toward existing roof vents. Multiple bearing points as well as the roof load spread among solid wood beams provide increased safety for firefighters working above and below the roof in areas adjacent to the fire. Most flat roof systems in condos and garden apartments are made of dimensional lumber (2 × 10) spaced on 16-inch centers. As Dunn states, “A firefighter is more likely to plunge a foot through the roof deck than fall through the roof because of the closely spaced joist.” (1) Dunn goes on to say that these flat roofs show signs of failure as heat builds up in the void space. Roofing material begins to spall, and the decks will begin to “soften” as the roof is weakened by the effects of fire. It is important to understand that the multiple load-bearing points and the overall structural integrity of the solid-beam roof make catastrophic failure of the entire flat roof largely impossible. The roof is most dangerous above or below where heat and fire are impacting it. Knowing where the fire is in the building and roof can mitigate against the danger of falling through the roof.

Firefighters must be aware of the I-joist truss system that may be present in a flat roof. These truss joist I-beams consist of a top and a bottom chord of 2 × 3 or 2 × 4 lumber that support an inner core of oriented strand board that is usually about 3⁄8 inch thick. Builders use the manufactured joist mostly in floor systems because they shrink and split less-hence the term “silent floor.” Fortunately, dimensional 2 × 10 remains the wood of choice for the flat-roof structure in Type 5 construction. This is not to say that I-joist manufactured trusses are not used in flat roofs but that they are not as common at this time. That said, future building construction may see an increased use of I-joist trusses in roofs, and firefighters need to stay on top of current construction methods and building design. Walk-throughs and building familiarization for new construction are essential means of educating and staying current with how newer buildings are designed and built. Local building inspectors are also a great source of information with respect to changes that might be occurring.

One of the reasons we need to stay on top of building construction techniques with respect to roof structures with I-joists (specifically the flat roof) is that the manufactured joist poses hazards for firefighters working directly above or below a fire. A 2008 study by Underwriters Laboratories (UL) highlighted the dangers and early failure rates of the manufactured wood joist. The study also confirmed the superior fire performance of the conventional solid joist over the lightweight I-joist floor system that was impacted by heat and fire. Solid wood joists performed very well, especially when protected by a ½-inch gypsum ceiling.3 The study showed that dimensional lumber (2 × 10) protected by ½-inch gypsum failed at 44.45 minutes compared with lightweight I-joists (2 × 12), which failed at 26.45 minutes.

Prevention

Fires that extend from the exterior of a garden apartment or condo into the roof area are usually started on balconies and decks from flammable objects like candles, barbeques, or cigarettes discarded into exterior mulch areas that contain shrubbery. These fires start on the outside of the building and can travel up exterior siding into the soffit. The soffits in newer buildings often are made of vinyl or wood, and they offer little protection as the soffit melts or burns, allowing flames to enter the roof space. The current edition of National Fire Protection Association 13R, Standard for the Installation of Sprinkler Systems in Low-Rise Residential Occupancies, calls for exterior fire protection (sprinklers and blocking) on Type 5 buildings higher than four stories. However, depending on the jurisdiction, many local governments are enforcing stricter building codes and becoming more proactive by insisting on exterior dry type sprinklers on all decks and balconies regardless of the building height. These dry sprinklers will not freeze during cold weather. Unfortunately, this does not help to alleviate the threat in thousands of apartment buildings that were constructed during times when building codes did not have these requirements.

|

| (3) Burn patterns in a flat roof joist space after a three-story apartment fire. Dimensional lumber used in flat roof construction is common to modern and older buildings. |

Fire departments must be proactive in creating offensive tactics that lessen the threat an exterior fire will pose. Public education concerning the dangers of flammables and smoking on decks is also a key to reducing the likelihood of fires starting on the exterior of a building. Building and property managers can also help by enforcing rules that ultimately forbid flammables and candles on decks while providing common barbeque areas that lessen the need for individual barbeques.

Boxing It In

The flat roof void is an open system of purlins and strapping that creates a perfect vent-limited space for fire to conceal itself while traveling toward ventilation points (be they roof vents or soffits that exist in the roof or on the other sides of the building). I have heard the void described as placing a pallet above the ceiling joist and covering it with roofing material. The void created by the pallet allows air to ventilate the roof area, increasing its ability to release heat and moisture, much like a pitched roof. An aggressive roof operation can box the flat roof fire in at its source and reduce temperatures in the roof (slowing down the fire) while providing final extinguishment.

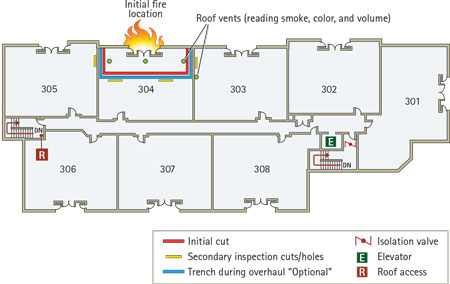

A four-person crew equipped with a chainsaw or cut-off saw, a 1¾-inch hose stream with a piercing nozzle, and a flathead ax can complete this operation easily. Having backup tools and equipment (saws, flathead ax, and piercing nozzle) is a great option to ensure operations are not slowed because of broken-down gear. Creating a cut that passes through the roof membrane and plywood is easier than trying to drive the piercing nozzle through multiple layers of roof material (photo 4). Read smoke from the roof vents, or use a thermal imaging camera (TIC) to ascertain where the roof is affected by fire before you make decisions about containment. Cut a quick inspection hole to see what’s going on beneath you and to determine the depth of cut necessary to get water into the void. Next, score the roof on three sides away from the seat of the fire to box in the fire. Speed is a key as temperatures in the hot dry roof can quickly exceed 1,000°F (free burning), promoting spread through blocking that may exist between units or at party walls. ICs must also ensure that a second means of egress for the roof team is established, often by an aerial device or a hatchway.

|

| Figure 1. Three-Story, Wood-Frame Multi-Family Fire Extending from Exterior into Flat Roof |

This technique is much quicker than trenching, which can be done during overhaul. The main aspect of this operation is introducing water into a ventilation-limited area, dropping temperatures, and promoting confinement. If there are many roof vents, they can be used as an access point into the void space for the piercing nozzle. This is a quick technique that can assist in cooling temperatures, but it may be difficult to get water exactly where you want it, depending on the spacing of vents.

The initial roof team read smoke coming from existing vents and used a TIC to detect heat in the void space. They made an initial inspection cut to guage the depth of the roof void and then made cuts that extended beyond the estimated affected fire area, boxing in the fire (Figure 1). The initial cut helps the piercing nozzle pass through the top-level roof material into the void. This material is usually roof membrane and ¾-inch plywood, but it may also consist of some two to three inches of Styrofoam®-hence, the need for the inspection. Be careful during the straight cut not to damage or pass through joists or perlins.

Instead of the straight cut, you can use a small cross cut approximately every two feet in the same three-sided pattern. An extra chainsaw or cut-off saw will speed up the cutting procedure, since blades dull quickly. These narrow cuts are not trenches; you do not want to create additional exit vents for the fire until water is applied. Trenching can be done during overhaul once the fire has been contained. Once the intitial cuts are made, follow with piercing nozzle impingement into the void. Insert the piercing nozzle into the gap created by the saw cut approximately every two feet. Short applications of water at each entry point should be sufficient for cooling. Finally, maintain close communication with the IC so the interior teams will know that roof operations are underway.

Interior Crews

Once interior crews have confined the fire on the interior, they may become involved in void space operations as well. Make small probing holes through the ceiling drywall, and remove insulation to create an indirect or direct water attack. Piercing, cellar, or Coast Guard nozzles are all good choices for applying water to the void roof from the interior of the structure. Interior teams should also communicate with the IC with respect to the unit and room in which they are working so the IC can ensure a systematic approch to the firefighting. Keep holes small to reduce oxygen flow to the fire in the void.

Once the fire is eliminated in the roof, make small inspection holes in adjacent suites and hallway areas to ensure the fire has not spread. You can do this operation in rapid fashion, but one disadvantage interior teams may face is that working below the roof fire they may lack the vision that benefited the roof team, who can read vents. They will also have to fight their way through drywall, vapor barrier, and insulation to get to the void.

Extinguishment

Once the fire is out on the exterior of the building, a two-pronged attack (interior and roof) can turn a fire that may last several hours into a routine operation. It’s all about knowing the construction and where the fire wants to go. Also, once the fire is contained (and sprinklers no longer support extinguishment) on the interior, shut down the sprinkler system to the existing unit. This will help lessen the water damage to adjacent suites and the building as a whole. It will also help improve working conditions for interior teams working to extinguish the fire in the roof. Preincident planning should identify the sprinkler shutoffs in the buildings.

Fires in the flat roof or attic area are ventilation limited. Oxygen is primarily controlled through sofffits and exterior roof vents. Recent UL experiments with attic fires highlight the positive effect of water into the roof void for these types of fires. One of the tactical considerations of attic fires from UL’s “Study of Residential Attic Fire Mitigation Tactics and Exterior Fire Spread Hazards on Fire Fighter Safety” was timing water application before any vertical ventilation and flowing water from the bottom up, avoiding the use of master streams.

|

| (4) This top roof layer, common in older apartment buildings, has poor insulation in the joist space. The roof depth will vary, hence the need for inspection when cutting. |

Essentially, the flat roof is much like an attic space, but it is even more ventilation limited because of a lack of depth and height. This presents challenges for water application. By applying water through piercing nozzles horizontally into the void, you can essentially direct water in a similar manner from above or below. The key is getting water into the areas you can’t reach through the soffit. If specialized nozzles are not available, try indirect application by deflecting a straight stream through a small ceiling hole into the roof void from the interior.

Keeping holes small on the interior and limiting openings on the roof exterior will help control the amount of oxygen that can get to the fire. Carefully plan ventilation to ensure that you are not forcing air into areas of the void space where flame may still exist. This helps to control heat while lessening the risk of a smoke explosion.

By understanding building construction, we can help to ensure the safety of firefighters working on flat roofs. Different types of roofs present varying degrees of risk for operating personnel. The IC must recognize those roofs that are safe for members to work on.

There is no substitiute for caution whenever we go to the roof. There will always be danger from heights or a potential fall. However, by understanding what works in our favor in this type of roof construction, we are better able to make tactical decisions that can lead to positive outcomes with respect to reducing fire losses while better serving our customers whose homes we protect.

Endnotes

1. Dunn, Vincent. Collapse of Burning Buildings: A Guide to Fireground Safety. 1988. Penwell Publishing, New York, 124.

2. Bridge, Terry, structural collapse technician and instructor, Justice Institute of British Columbia. Personal interview, January 2015.

3. Underwriters Laboratories, 2009. Retrieved from: http://www.ul.com/global/documents/offerings/industries/buildingmaterials/fireservice/NC9140-20090512-Report-Independent.pdf.

JOHN MACDONALD is a training captain for Coquitlam Fire Rescue in British Columbia, Canada. He has been a member of the fire service for 23 years. He has a master’s degree in disaster and emergency management from Royal Roads University and is a certified Fire Officer 4.

Primary Roof Ventilation Operations for Flat -Roof Structures

Flat -Roof Operations: From the Street to the Roof and Back

Building Construction Concerns for Firefighters: Flat Roof Membranes

Fire Engineering Archives