AMMONIA LEAK

HAZARDOUS MATERIALS

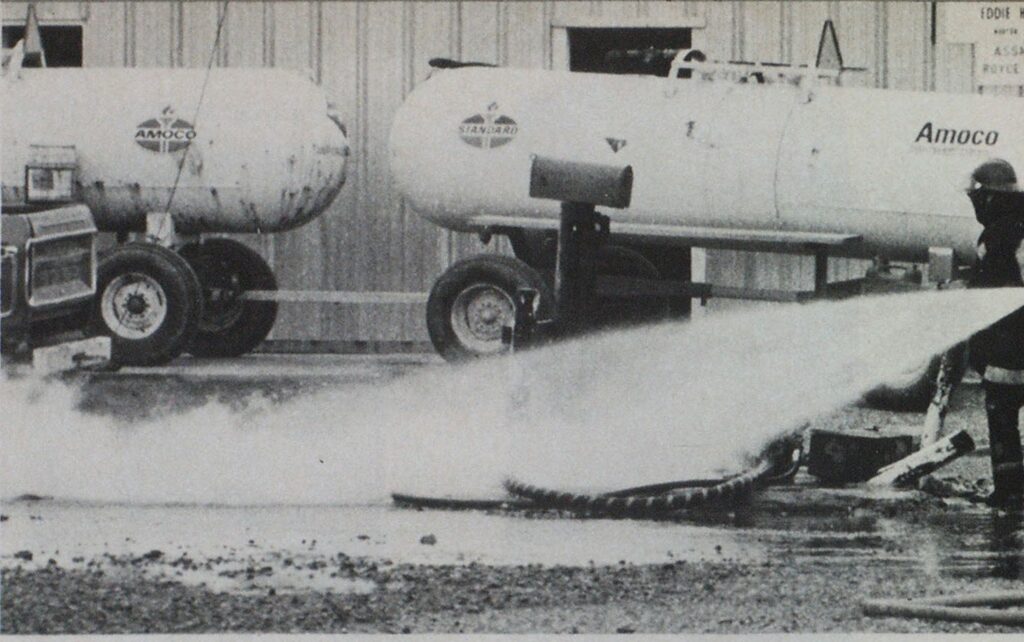

With industry assistance, Morton, III., fire fighters trained specifically for an ammonia leak. Then a real emergency occurred.

The local Amoco fertilizer plant in Morton, a town of 15,000, provided the ammonia for the training sessions, discharging enough to create a small cloud. Fire fighters donned protective chemical suits and went in. They gained the experience and confidence to handle any spill, according to Fire Chief Dick Campbell.

Then last May 5, a truck backed into a feeder valve on the Amoco plant’s main 12,000-galion ammonia tank. The valve broke, permitting a white cloud of super-cold and noxious gas to escape into the air.

—photos by John Cary.

Amoco employees called for assistance at 6:06 p.m. on that Wednesday. It may have been about the ideal time for such an emergency. Fourteen members of the fire department were already at the fire station, located about seven blocks from the leak site. It was election night for a new chief and officers. And the meeting was just about to start.

Weather was about as cooperative as it could be, too. Wind direction was from the southeast, blowing the growing ammonia cloud away from populated areas and a major interstate highway, I-74. The site had been chosen by Amoco because it was on the north side of town, where prevailing winds would usually blow any leaks away from populated areas. Temperature was a moderate 72 degrees and it was cloudy. Not bad conditions for fire fighters to work in air packs and closed chemical suits.

Two pumpers and a rescue truck arrived at 6:10 p.m. Evacuation was considered because a new residential subdivision was within one block of the leak site. Calm winds blowing away from the site, however, made evacuation unnecessary.

The next consideration was traffic and crowd control. Ammonia fumes can freeze the unprotected skin up close and cause lung and eye damage even at a distance. At least two persons driving past the site on nearby Main St. were overcome by the fumes. They ran off the road, but no one required hospitalization or serious treatment.

HAZARDOUS MATERIALS

Continued from page 11

Units of the Morton Police and Morton Emergency Services and Disaster Agency were called as soon as fire officers saw the nature of the emergency. They set up a safe zone and blocked traffic while fire fighters worked on the leak.

Fire officers quickly determined no one was injured or close to the leaking fumes. Two fire fighters, Bob Cloyd and Jim Arnold, put on SCBA and enclosed protective suits.

The leak should have been easily stopped by following the line back to the main tank where another shutoff valve was located. That valve malfunctioned, however, and did not shut down the flow.

Meanwhile, four other fire fighters using SCBA set up a cross stream with each team of two using a fog nozzle on the end of a 1½-inch line. They were supplied by a new 1000-gpm pumper with a 2500-gallon tank. Another support truck was moved into position to provide more water.

The cross-stream fog screen did a lot to dilute the escaping ammonia and prevent the cloud from spreading. Meanwhile, the two fire fighters in chemical suits moved in to assess the damaged valve.

It was broken and had to be replaced or plugged. Luckily the fertilizer plant manager had another standard-size valve on hand in the office. It was located and given to the men in the chemical suits. They removed the damaged valve, installed the replacement and shut down the leak.

Since that leak, the fire department has acquired some tapered wooden plugs that would have quickly jammed into the fire opening to plug the low-pressure leak, had the replacement valve not been available.

The fire department estimated that between 200 and 300 gallons of ammonia was lost. The entire incident was complete and trucks were back in the station by 7:10 p.m., just an hour after arrival.

During training sessions with the ammonia, the men always work in pairs. “You learn to trust the person you’re with. It really helps the men be closer, feel good about their job and capable,” Campbell said.

The department has four chemical suits and drills with them regularly. Each time they are checked for leaks or tears that might mean injury to those inside.

HAZARDOUS MATERIALS

Continued from page 12

Campbell also warns of operating equipment around ammonia. The ammonia can break down the oil inside truck engines and pumps and cause them to run hot or freeze up very quickly. So don’t drive through the ammonia cloud or position a truck where the escaping fumes might engulf it.

Training materials for the Morton department, now celebrating its 100-year anniversary, are obtained from the International Fire Service Training Association. And drills are held every Tuesday night on some aspect of training.

The department recently obtained A, B and C kits to handle chlorine leaks. A is for 150-pound vessels, B is for 1-ton and C is for rail car or transport repair.

A task force made up of men within the department is being established to handle any leak at a swimming pool or water or wastewater plant.