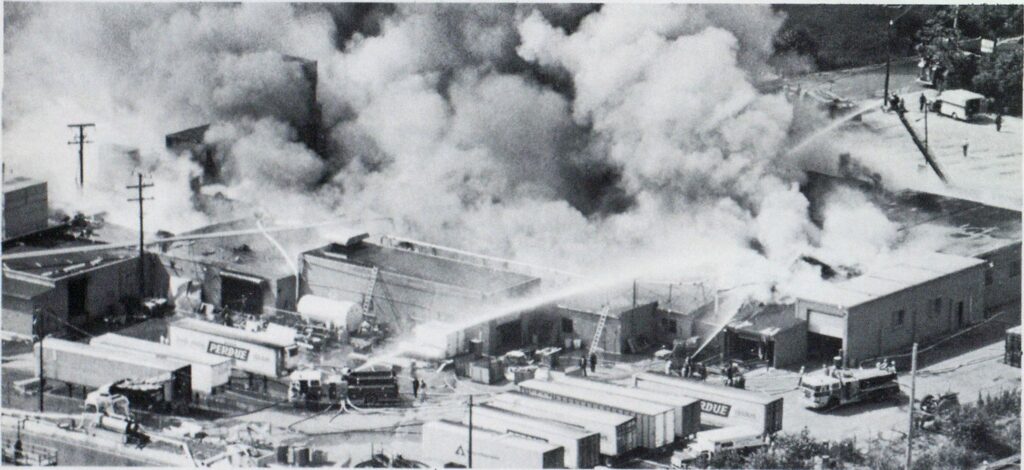

NOT ENOUGH WATER AT CHICKEN PLANT FIRE

FIRE REPORTS

Welders completing the installation of $500,000 worth of chicken-processing equipment at a Frank Perdue plant are believed to have started a multiple-alarm fire in Delaware.

Photo credit: Gary Emeigh/Delaware State News.

Raising and processing poultry is one of the big industries on the eastern shore of Chesapeake Bay. And Frank Perdue is one of the biggest processors.

After the fire started at the Perdue plant in Felton, Del., last July 5, 24 towns in Delaware and Maryland sent 49 units to help Felton’s seven fight the fire. At one point during the attack, two anhydrous ammonia lines ruptured, creating a large fireball and ripping the roof from a small building. But the water quickly became the major problem.

Felton’s 500 residents live 11 miles south of the state capital, Dover. The fire department operates a 1250 and 750-gpm pumper, each carrying 1000 gallons of water, and three tank trucks. Two of them have 3000-gallon capacity and one holds 1250 gallons. The other units are a brush truck and a heavy-duty rescue squad. Felton has the largest fire district in square miles in the State of Delaware.

Chief Wayne Wheeler and his three assistants in charge of Station 48 have accumulated a total of almost 85 years of experience.

The town has a water supply of 70,000 gallons at 50 psi static pressure when the tank is full. Replenishment is by two pumps, each flowing 400 gpm. The hydrant system is old but adequate for normal fire usage.

The department’s principal target hazard was its main industry, the Perdue chicken-processing plant on Lumbard St. It was processing 65,000 Cornish game hens daily, but there were no live chickens at the Perdue plant over the Fourth of July weekend. Instead, the plant was using the holiday time to put the finishing touches on the new processing equipment.

The alarm was received at 2:46 p.m. All fire alarms in the State of Delaware, except for the City of Wilmington, are toned out on the statewide frequency. On the first alarm, Felton responded with all seven pieces of apparatus and Harrington, located 6 miles to the south, dispatched two engine companies. The temperature was 73 degrees with a wind of 10 mph The weather was not a factor.

First Assistant Chief Bill Sipple was the first chief officer on location. Judging the large cloud of smoke in the sky before he arrived, and knowing the plant, Sipple requested the second alarm at 2:48. That called for Magnolia to respond with two pumpers and a tanker, Frederica with two engines and a rescue unit, Goldsboro and Greensboro, Md., each with an engine and tractor-trailer tanker and Houston with an engine and tractor-trailer tanker.

By the time Sipple arrived, Engine 48-4 had laid dual 3-inch supply lines from the main gate to the rear of the plant, a standard planned maneuver. The initial attack was with two 1 1/2-inch lines and one 2 1/2-inch line, using the 9000 gallons of water the department had brought with them.

As the rear door to the cutting room was raised, fire fighters were met by heavy fire rolling up and over the roof. Another overhead door was opened in an attempt to enter the building, but the results were the same.

—photo by Patricia wheeler.

A second-due engine laid two 3-inch supply lines from Engine 48-8 to an inground holding tank containing approximately 50,000 gallons of processed water.

This tank is part of the plant’s waste treatment system. Water was drafted to feed the already laid 3-inch lines. One of the first lines was used as an attack line, and the other was later used to feed an elevated platform stream. Second Assistant Chief David Wood and Third Assistant Chief Bill Chandler arrived and took command positions directing and placing incoming equipment.

Chief Wayne Wheeler arrived on the fireground at 3:00 p.m. and, after conferring with Sipple, took charge of the operation.

The principal hazard on the west side of the plant was three 250-gallon tanks of anhydrous ammonia. Engine 50-1 was assigned the west side of the plant to attack the fire and also to cool down the tanks. It was not the tanks themselves that caused trouble. It was the ammonia lines. About 20 minutes into the fire, the two 2½-inch anhydrous ammonia lines ruptured.

As the fire raced through the one and two-story cinder block structures from the cooler to the chilling room and dressing and eviscerating areas, Wheeler called for Camden-Wyoming to respond with their 85-foot elevating platform to be set up and for his own company to place a 500-gpm deck gun in service on the south side. The platform was later moved from the southeast corner to the south side of the building and remained there for several hours.

The fire raced through the dropped ceiling into the various rooms of the approximately 200X200-foot irregular plant, unhampered by any fire wall that extended through the roof area.

Even though the town water pumps were on, they could not keep up with the estimated 4000 to 5000-gpm flow being used to combat the fire. After about 1½ hours, the system was rendered useless by lack of water.

Felton’s rescue squad was set up at the rear of the plant as a command post and also for use of its cascade air system. Wheeler called for more assistance at 3:08, asking South Bowers to respond with a tractor-trailer tanker. Six minutes later he asked for Marydel to be dispatched with an engine and tanker and Dover to respond with an engine and an air unit.

At 3:18 an urgent request went through the Kent County dispatch center for Milford to respond with two engines and an 85-foot ladder truck. The Milford units were assigned to the northeast corner of the building.

But, still, water was the problem. Not enough water. Like other fire departments without enough readily available water, Felton knew they were going to have to go to any other possible sources.

Brush unit 48-1 was sent to a ditch about 1 mile to the south and set up a drafting operation there. Harrington’s Engine 50-4 commenced drafting from a ditch to supply the Camden-Wyoming platform. They had to shut down operations three times during the course of the fire to clean out their pump and strainer

Milford Engine 42-5 drafted from the untreated waste water of the plant, which contained much eviscera, feathers and other debris — as well as odor — but water was water.

Sipple was designated to act as a water supply officer from a point on Main St. opposite the fire station. Three trac tortrailer tankers were set up at this point as reservoirs. Two companies stretched two 3-inch lines and one 4-inch line down the railroad tracks, a distance of 1500 feet, to the east side of the fire to supply other attack units and to attack the fire

Fifteen pumpers, each with a minimum tank capacity of 1000 gallons, were designated to shuttle back and forth to Killen’s Pond State Park, about 3 miles from the fire, where pumpers from Farmington and Goldsboro were drafting from the pond.

The operation required a lot of additional apparatus. At 3:13, calls went out for a 4000-gallon tanker from Hartly (20 miles distant) and Leipsic From Sussex County, Bridgeville, Ellendale, Greenwood and Slaughter’s Beach sent units. Sudlersville, Md., sent an engine company. Georgetown engine had the longest run to the fire, 36 miles.

Continued on page 46

FIRE REPORTS

Continued from page 27

Cooperation was excellent between the state police, fire police and Delaware Park Police in covering the shuttle run. All apparatus had to cross busy U.S. Highway 13

twice, once in responding to the pond and again returning via a different route.

A major problem was in communication. All transmissions on the fireground were on Kent County’s radio frequency, and it did present some problems in coordinating the shuttle service and in getting requests for apparatus through to the Kent County dispatcher.

The fire was attacked aggressively, enabling the saving of a portion of the office, the pump room, storage room and receiving room 1. None of the outside supporting walls was damaged, except for the boiler room where the wall appeared to bulge out as fire fighters trained hose lines into the area between it and the completely involved frame lunchroom.

The cutting room containing most of the new processing equipment was completely destroyed. This was to be placed in service on the day following the fire.

At 7:52 p.m. Wheeler declared the fire under control. Fire units were on the scene until 11:00 p.m. when all but two were released. The last stayed until 10:24 a.m. the next morning, extinguishing spot fires.

In all, 32 pumpers, 13 tankers, seven rescue units, a ladder truck, an elevating platform and two brush trucks responded to the alarms. They used a total of 20,400 feet of hose.

Four ambulances responded. Injuries were initially reported to six fire fighters, but that number grew in the week that followed to 14 as men from outside units reported injuries caused by ammonia mixed with smoke.