Standardized Shape-Coded Controls Makes Pump Operator’s Job Easier

features

Most fire apparatus is custom built to each department’s specifications and job requirements. The rigs are also bid competitively. In this process most of the technical specifications for pumps, chassis, bodies and controls are left to the manufacturer to fill by the use of the phrase “or equivalent.” For this reason and others, standardized placement of operating controls for all fire apparatus has not been possible.

The United States Air Force had the potential for a similar problem with aircraft controls. There were many different types of aircraft, made by as many different manufacturers. But they all were built with one thing in common to solve the problem. The tactual display was the same in all aircraft. The aircraft had shape-coded controls unique in touch and appearance. I believe this is where touchsensitive controls can help the fire service.

In some departments like my own, an engineer may be asked to travel to a different station or a fire fighter may be asked to step up to fill an engineer’s place. This happens due to sickness or other absence of the regular engineer.

Different pumper controls

Unless extremely well-trained, the engineer who is confronted with a different pumper than he is used to working with may have difficulty knowing where the controls are located. He may reach for the tank suction but instead pull the tank fill or start priming the pump. Valuable time may be lost.

Why not consider the Air Force lesson and minimize the problem? Standardized shape-coded controls could have alerted the engineer to what was happening. For the fire fighter filling in for the engineer, tactual feedback can shorten the time required to gain proficiency and confidence.

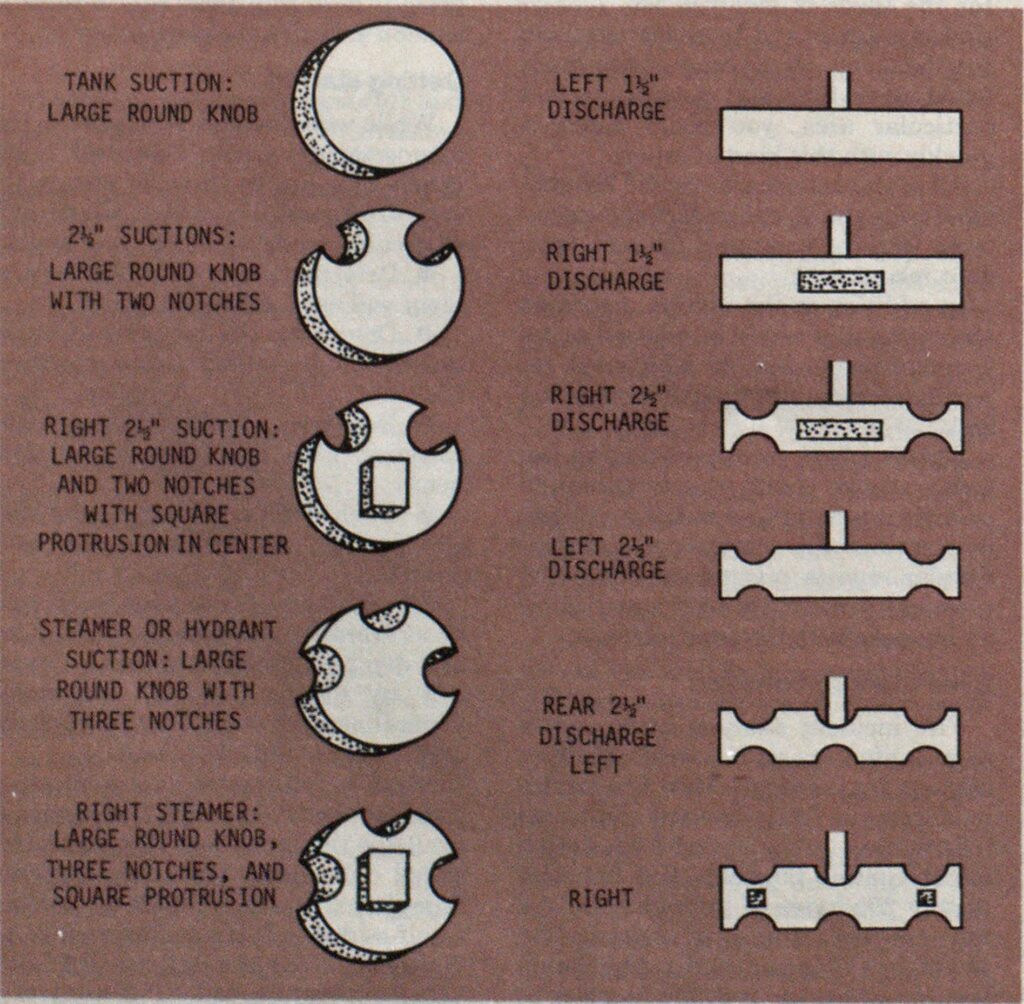

Tactual controls coding cannot make up for bad pumper operations, but it would greatly reduce the opportunity for engineer errors. A tactual display might be set up as follows: Right and left can be denoted very quickly by having one (let’s say “right”) coded with a square protrusion in the center of the handle or knob. This protrusion would tell the engineer immediately it was a “right” gate opening or closing.

Coding knobs and handies

The booster is common to most departments. It could be symbolized by an elongated round handle. The right booster would be coded in two ways: an elongated round handle with a square protrusion in the center.

Suction or inlets could be coded with a large round knob with modifications. A 2 1/2-inch inlet could have two notches that could easily be felt. A right 2½inch inlet would have the two notches plus the square protrusion meaning “right.” A steamer suction would get three notches.

There is one other suction designation to make. This is the pump primer, which could be a smaller round knob. This is in keeping with the symbol for suction.

The discharges could be designated with a symbol that is unique in touch and appearance, for example long rectangles modified with the similar logic as on the inlets. Two notches on the handles denote 2 1/2-inch discharge. A third notch can be used for rear 2 1/2-inch discharge.

Tank fill is a type of discharge, but specialized. Let’s use a square knob.

With gloves, in the dark

This theme of notches and protrusions can be used on all types of levers, “T” handles and knobs. Being unique in touch, even a gloved hand could tell which gates were opening. During electrical failure, the pump operator on the apparatus without lights could properly identify all controls and—by listening to the pumper and men on hoses—determine what pressure to pump at.

With tactual coding, the engineer could reach without looking and know for certain which controls are being activated. Engineers on Pumper 4 would know the tank suction on Pumper 58 (big round) even if it is in a different location.

I believe that we should make equipment more compatible to the men operating them. Machines can and should be modified to complement the human operators. Where both function together, tasks can be performed that machine or man could not do alone, at all.