By Jeremy A. Keller and W. Parker Browne

It seems that whenever a discussion about incident command system (ICS) resource management begins, many in the room will start nervously edging toward the nearest exit. This is unfortunate, because a standardized resource management system is one of the most underappreciated aspects of the ICS and has great potential to improve preincident planning, mutual-aid systems, operational efficiency, and accountability.

Mobile water supply apparatus-water tenders or tankers-are indispensable resources for the rural fire service, often serving as the only means of securing a reliable water supply for fire operations. Even in urban settings, these apparatus are occasionally used when municipal water systems fail or prove inadequate or during disasters, such as the time algae bloom on Lake Erie shut down the Toledo, Ohio, water system for several days in August 2014. Mutual-aid water tenders were mobilized to supplement the system.

|

| (1) Water shuttle operations can support flows in excess of 1,000 gpm but require effective planning and management to succeed. (Photos by author.) |

A well-planned and well-executed water shuttle operation made up of several water tenders and supporting engine companies can deliver large amounts of water to the fire scene, often in excess of 1,000 gallons per minute (gpm). The high-capacity water shuttle concept, with its reliance on large numbers of mutual-aid apparatus, is the type of operation that can benefit from a well-designed resource management system. Current standards of resource classification available to the fire service, however, do not adequately meet the needs of the rural water supply officer attempting to plan and implement a high-capacity shuttle operation.

This article discusses the efforts of the Ohio Fire Chiefs’ Association (OFCA) Water Supply Technical Advisory Committee (WSTAC) to address this gap in the system and develop a resource classification system for water tenders that adequately supports the planning and implementation of high-capacity water shuttle operations.

Resource Management in the ICS

During “routine” day-to-day emergency operations, where the capabilities of local apparatus and those of neighboring jurisdictions are familiar and well-understood, the value of an effective system for classifying resources is difficult to understand. However, during those occasions where large numbers of mutual-aid resources are needed from outside the normal range of providers, a standardized means of planning for, ordering, and managing the incoming resources is essential. Anyone who has served on the management team for a large incident will develop an appreciation for effective resource typing as a tool for getting the right resources, managing them efficiently, and maintaining accountability as work on the incident progresses.

The resource management function of the ICS allows for the standardized classification of incident resources such as engines or water tenders by function and capability. Under the National Incident Management System (NIMS), the U.S. Department of Homeland Security issues national standards for resource classification. These standards are developed by discipline-specific working groups and formally published by the Federal Emergency Management Agency (FEMA) as part of the NIMS system. The NIMS resource standards form the basis for interstate mutual-aid resource ordering and serve as the default standard for most local mutual-aid systems as well.

Under ICS principles, resources are classified by “kind” and “type.” In ICS terminology, “kind” refers to the primary function a resource is expected to perform at an incident. “Type,” on the other hand, is a numerical designation referring to the relative capability of a specific resource within a given kind-the lower the number, the greater the capability. For example, an “engine” is a resource kind describing automotive apparatus that pump water to attack fires. Engines may be further classified according to capability by assigning a type from one (highest) to seven (lowest). The engine’s “kind” includes both large, class A structural pumpers (Type 1 or 2), small brush engines (Type 6 or 7), and everything in between.

|

| (2) High-capacity water shuttles are complex operations involving numerous apparatus and personnel from multiple agencies. Water supply officers need an effective resource management system to successfully support incident objectives and ensure the safety of all involved. |

This resource classification system was originally devised for wildland fire resources and has been modified and adapted for all hazards. In the fire service, some issues periodically arise when attempting to use this system because most fire apparatus are not single-role resources; they are multifunctional. This can lead to questions when trying to classify a resource like a pumper/tanker, which under the ICS could serve as an engine or a water tender-so which is it? The answer is, “It depends.”

The trick here is not to think of resource classification as if it were bird watching, where each bird is definitively identified by species and can only be that one species. The ICS/NIMS resource classification system uses broad categories based on anticipated incident missions. Try to figure out all of the possible kind/type classifications that could apply to each of your apparatus. The pumper/tanker could be legitimately classified as a Type 3 engine and a Type 4 water tender, depending on the role it will play on an incident deployment, which may differ from the way it is employed in your department’s day-to-day operations.

Obviously, mutual-aid resource management systems in your area must be able to accommodate such multiple classification concepts for this to work since there is a danger of double counting resources. If this is not the case, then formally designate a primary kind and type, informally track potential secondary classifications, and work to get your local resource management system upgraded.

Water Tender Classification Efforts

As everyone who has taken the basic NIMS training curriculum knows, the initial impetus for the development of the ICS concept came from a series of wildfire incidents in southern California in the early 1970s. The need to integrate and manage large numbers of mutual-aid resources coming from diverse local, state, and federal sources, each with their own terminology and command structures, led to the creation of the FIRESCOPE (Fire Resources in California Organized for Potential Emergencies) organization, which is still active today. This was the genesis of today’s resource management systems.

Growing out of earlier FIRESCOPE efforts, the National Wildfire Coordinating Group (NWCG) has developed, refined, and published resource typing standards for water tenders and many other kinds of resources for decades. Prior to the 9/11 attacks, the NWCG resource typing system was essentially the only game in town and was the gold standard for resource management on large incidents.

|

| (3) In addition to tank size, water tenders must also be classified according to their fill-and-dump rates and whether they are of a vacuum or a conventional design. |

These earlier FIRESCOPE and NWCG systems are also the source of the term “water tender” as an element of the ICS common terminology, when the traditional term “tanker” was first replaced with “ground tanker” and then abandoned entirely because of fears of confusing it with a similarly named but not as widely available firefighting aircraft.

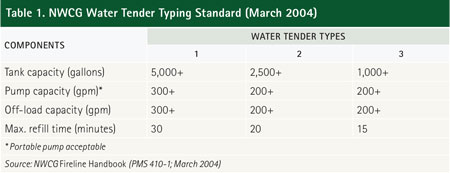

The typing standard for water tenders as presented in the 2004 edition of the NWCG’s Fireline Handbook is shown in Table 1.

Although the NWCG and FIRESCOPE resource typing system was predominant early on, especially in the western states, other fire service thinkers were beginning to realize the need for standardized resource classification systems. Pioneering work on the East Coast by Larry Davis in the 1980s led to a proposed classification terminology for fire apparatus playing a role in water supply operations, as laid out in his 1986 Rural Firefighting Operations, Volume 2 (out of print). Davis’ system proposed standardized names for the most common types of apparatus involved in water supply operations:

- Pumpers with tanks

- Pumper/Tankers

- Tanker/Pumpers

- Tankers with pumps

- Tankers

- Auxiliary vehicles

In his 1994 The Fire Department Water Supply Handbook, William Eckman proposed a classification system for water tenders based solely on the type of pump carried (or lack of pump):

- WST-P: Water supply tanker with a standard fire pump, capable of delivering at least 750 gpm capacity at a net pump pressure of 150 pounds per square inch (psi).

- WST-A: Water supply tanker with an attack pump, capable of delivering at least 250 gpm at a net pump pressure of 150 psi.

- WST-T: Water supply tanker with a transfer pump, capable of delivering at least 250 gpm at a net pump pressure of 50 psi.

- WST-N: Water supply tanker with no pump, with a large gravity dump for unloading and external connections to allow a pumper to draft directly from the tank.

The Davis and Eckman systems, although each captured some key aspects of water supply resources, were not designed for the kind of large-scale resource management needs of large, complex incidents. In each case, the author’s system still relied on having detailed knowledge of specific apparatus in a local area and was not germane to the kind of resource planning, ordering, and management systems enabled by the development of the ICS or to the mass out-of-area deployments required for complex incidents as envisioned under NIMS.

Encompassing some elements of the earlier NWCG standard, FEMA developed and published a classification standard for water tenders in July 2005. This document was part of the broader FEMA effort to promulgate definitive typing standards for interstate resource deployments under the post-9/11 NIMS program. The typing standard is presented in Table 2, recreated as it appears in the original FEMA document.

There are a number of errors and shortcomings in the FEMA standard, including some that seem to stem from a lack of basic proofreading. For example, the standards for Type 1 and Type 4 are identical, apparently the result of a cut-and-paste error. The “metric” column presumably should read “tank capacity” and “pump capacity.” Whether these initial errors were the result of carelessness or haste, they have not been corrected in the near decade since their initial promulgation. The same errors are still present in the current online version of the standard, FEMA’s Resource Typing Library Tool (RTLT).

The numerous issues present in the FEMA standard have severely limited its acceptance and utility within the fire service. It is not unfair to say that in the broader fire service, this standard is hardly known or used at all, yet it still stands as the single, definitive standard for general purpose, interstate resource deployments.

At the same time that these resource typing discussions were taking place, an appreciation of the value of well-run, preplanned, high-capacity water shuttles was taking hold, mainly in rural areas. Tactical and technological innovations made the idea of 1,000-gpm water delivery systems based on shuttles an achievable goal for many rural fire districts, offering opportunities to improve fire protection and firefighter safety. The advances in water tender design needed to achieve high-capacity shuttles were not well reflected by the existing resource typing systems, so they were not used.

One of the great strengths and principal advantages of using the ICS is its proven framework for managing resources during complex incidents. The lack of a workable typing system for water tenders in shuttle operations has meant a gap in the toolkit of the rural water supply officer when estimating water shuttle resource needs during preincident planning or when trying to tap into regional and statewide mutual-aid systems during a large incident. This gap in the resource typing system has left the rural water supply officer without access to some of the most useful features of the ICS.

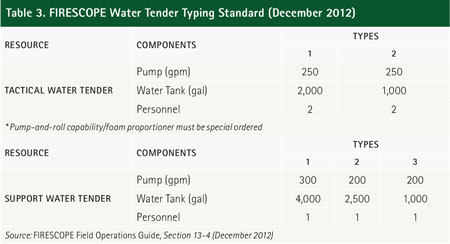

Recent efforts by the fire service have moved in the direction of mitigating this situation. By 2012, the open secret that the lumping of all mobile water supply apparatus into a single resource category was not workable was formally recognized, with the wildland fire community making a break from the NIMS typing standard. The December 2012 edition of the FIRESCOPE Field Operations Guide presents a two-tiered system for typing water tenders, breaking them out into two broad categories: Tactical and Support, as shown in Table 3.

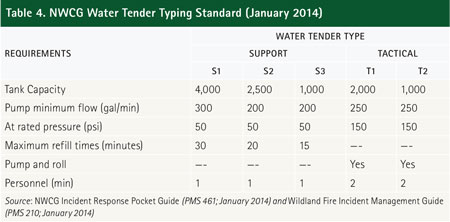

In early 2014, the NWCG released the current version of the Incident Response Pocket Guide (IRPG) and the Wildland Fire Incident Management Guide (a new publication). Both of these NWCG documents provided a water tender typing standard that expands on the one put forward by FIRESCOPE and maintains the tactical/support distinction, as shown in Table 4.

In both the NWCG and FIRESCOPE typing standards, each of which is oriented toward wildland fire incidents, the “support” category essentially carries forward the older 2004 NWCG water tender standard, which can be thought of as encompassing older fire tanker apparatus and civilian water tankers pressed into service as auxiliaries on large incidents. The “tactical” category may be thought of as representing modern, purpose-built fire department water tenders and tanker apparatus as well as cross-functional pumper-tanker apparatus.

Resources for High-Capacity Water Shuttles

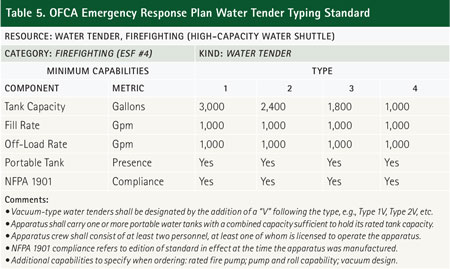

So today, the fire service basically has two water tender typing standards to choose from: a FEMA system rife with errors or an NWCG/FIRESCOPE system designed with wildland fires in mind. Neither of the available options really meets the needs of the rural water supply officer trying to plan for a high-capacity water shuttle operation. With this in mind, the OFCA’s WSTAC has developed its own typing standard for water tenders, designed to support high-capacity water shuttle operations, for use in Ohio’s intrastate, mutual-aid Emergency Response Plan.

The premise of the system is that when participating in a high-capacity water shuttle operation, only a limited number of characteristics of a water tender actually matter to the planner. They are the following:

- Tank capacity (gallons),

- Off-load (dump) rate (gpm),

- Fill rate (gpm), and

- Apparatus design (conventional or vacuum).

These characteristics are needed to calculate the continuous flow capacity formula (in gpm) as laid out in National Fire Protection Association (NFPA) 1142, Standard on Water Supplies for Suburban and Rural Fire Fighting, section C.11 (2012 edition):

Q = V / (A + T1 + T2 + B) × k

Where

Q = maximum continuous flow capability (gpm).

V = tank volume of the water tender (gallons).

A = dump site time (minutes); includes dumping water as well as positioning and handling time.

T1 = empty travel time (minutes); fire scene to water source.

T2 = loaded travel time (minutes); water source to fire scene.

B = fill site time (minutes); includes time to fill as well as positioning and handling time.

k = a coefficient to account for residual water and spillage (1.0 for vacuum apparatus, 0.9 for conventional design).

With this in mind, the OFCA typing standard for water tenders is as shown in Table 5.

During the development of this standard, there was considerable debate as to the optimum number of types and what factors to consider when setting the standard. Ultimately, tank capacity was deemed to be the primary defining characteristic for purposes of a high-capacity water shuttle. At this point, the question became where to set the breaks between resource types. Ultimately, this matter was settled by running notional water tenders with different tank capacities through a simulation process to see how different sizes grouped out.

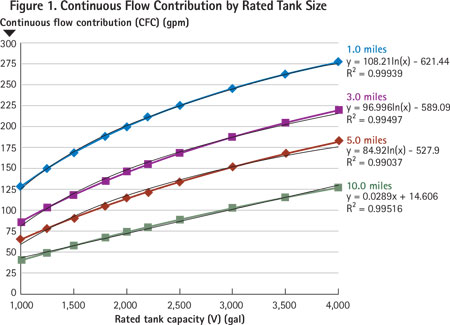

First, we conducted a survey of apparatus manufacturer literature to determine the most common tank sizes available for water tenders being manufactured today. The 10 most common tank sizes were run through a model of a simple, looped water shuttle based on the NFPA 1142 formula described above. The resulting output curves for notional 1-mile, 3-mile, 5-mile, and 10-mile shuttles are shown in Figure 1. Across the range of four modeled shuttle distances, they tended to cluster into four general groups, which became the Types 1, 2, 3 and 4 in the typing standard.

Additionally, the four types can be informally grouped into general categories. The larger, Type 1 and 2 water tenders, representing those with a capacity in excess of 2,400 gallons, will generally be tandem-axle designs optimized for use on mostly flat terrain. The smaller Type 3 and 4 water tenders, with tank capacities between 1,000 and 2,400 gallons, generally represent single-axle designs best suited for use on hilly terrain.

Benefits of the OFCA Typing Standard

The OFCA water tender typing standard is not designed to specifically classify every fire service water supply apparatus in great detail. It is intended to provide baseline planning numbers based on minimum performance standards, allowing water supply officers the ability to plan for, order, and manage mutual-aid resources on complex incidents. The standard is intentionally conservative in design so that a water supply officer can be confident in knowing that the resources ordered will perform at or above the level expected, never below.

This standard will be especially useful as a preincident planning tool, but it will also be applicable for resource management for ongoing incidents. Water supply officers may use this standard to develop general planning guidelines regarding how much a generic mutual-aid resource may be expected to contribute to a planned water shuttle. An example of this is shown in Table 6. So long as the shuttle route distance (miles) and the needed fire flow (gpm) are known, the water supply officer can quickly calculate how many water tenders, by type, will be required to meet the incident’s water supply needs.

This standard also supports the creation of preorganized and ad hoc strike teams and task forces. Using this standard, these units may be more readily organized for mutual-aid assignments, and their capabilities are more universally understood. Likewise, the standard may be used to more easily form strike teams and task forces on the fly, to ease span-of-control issues under emergent conditions.

Extrapolating the baseline capabilities of typed apparatus allows for the estimation of the capabilities of ad hoc or preplanned water supply strike teams and task forces. For nontraditional missions, such as supporting a major city’s drinking water system for extended periods, estimates of gallons-per-hour (gph) capability can also be made. An example of this is shown in Figure 2 where a gph vs. shuttle distance performance curve was developed for two hypothetical water supply task forces composed of five water tenders (Type 2 or 4), a supporting fill site engine (supplying 1,000 gpm), and a task force leader for command and control.

Application Examples

The following two hypothetical scenarios demonstrate the usefulness of this resource typing system. The first, a preincident planning scenario, shows how the system can be applied in support of tactical fire operations in a rural/suburban setting. The second, a disaster response scenario, demonstrates the utility of standardized water supply task forces in support of a nonfire emergency situation, where fire department resources are called in to help.

Example 1: Preincident Water Supply Planning for a Subdivision

As part of a districtwide preincident planning effort, the water supply officer (WSO) for a small combination fire department is working up a water supply plan for Maple Ridge Estates, an isolated residential subdivision of 15 single-family homes in the district’s rural coverage area. Using NFPA 1142 as a guide, the WSO determines the minimum water supply requirement for the subdivision to be 11,700 gallons, to be delivered at a rate of 750 gpm.

The nearest water source capable of supporting the requirements is a dry hydrant accessing a large lake. A water shuttle route has been preplanned from the hydrant to a designated dump site in the subdivision, with a total round-trip distance of 4.9 miles.

The initial water supply plan makes use of the district’s own 1,800-gallon water tender as well as the two closest mutual-aid water tenders that have tank capacities of 2,000 and 2,300 gallons, respectively. All three of these water tenders are classified as Type 3 under the OFCA system.

After all calculations are done, the WSO determines that although the water supply source can easily provide the 11,700 gallons, the 750-gpm delivery rate will not be achieved. The three water tenders will provide only an estimated 396 gpm-about half of the requirement. This rate can only realistically be increased by one of two means: development of a closer water supply source or adding additional water tenders to the shuttle. Since developing a new water source will be a long-term project, the WSO opts to determine how many additional water tenders would be needed to meet the delivery rate requirement.

Using standardized resource type capabilities, the WSO can quickly work out different scenarios to meet the 750-gpm requirement. Any of the following four solutions will meet the minimum requirement:

- Adding three Type 1 tenders will yield a total of 893 gpm (each unit adds 166 gpm to the shuttle).

- Adding three Type 2 tenders will yield a total of 822 gpm (each unit adds 142 gpm to the shuttle).

- Adding four Type 3 tenders will yield a total of 854 gpm (each unit adds 115 gpm to the shuttle).

- Adding five Type 4 tenders will yield a total of 750 gpm (each unit adds 71 gpm to the shuttle).

Armed with these estimates, the WSO can begin the process of developing a workable preincident water supply plan. In areas where dispatch procedures are sufficiently sophisticated to allow requesting resources by standardized type (rather than asking for specific apparatus), these estimates allow the plan to be quickly completed. In areas where it falls on the WSO to identify specific mutual-aid resources for box assignments, these estimates at least provide a valid starting point.

The estimates themselves are conservative, and apparatus that exceed the minimum standards for their type will actually perform better. Knowing this, the WSO can either lower the number of resources in the plan or maintain them to provide an additional margin of safety. Some of the solutions may not work given local conditions, and they can be excluded from consideration. For example, in hilly areas, the road networks may not support large, tandem-axle apparatus, so any solution involving Type 1 or 2 water tenders could be ruled out.

Although this example has the WSO working up the full water shuttle estimates using the NFPA 1142 formulas, this is not realistic for emergency situations. Under time pressure, a simplified planning guide such as that shown in Table 6 can be developed to provide reasonable, conservative estimates for on-the-fly water shuttle planning.

Example 2: Supporting a Municipal Water System During a Disaster

A city with a population of 50,000 relies on a large, impounded reservoir for its drinking water supply. A toxic algae bloom in the reservoir renders the water supply unusable because the city’s antiquated water-treatment plant is unable to reduce the toxin to safe levels. The local emergency management official needs to access the statewide mutual-aid system to bring in sufficient resources to haul water from a different, uncontaminated source to supply the city’s treatment plant until the algae issue can be addressed.

Assuming that residents will require an average of 50 gallons of drinking water per person per day, the emergency manager estimates that a total of 2,500,000 gallons of water will need to be delivered to the water treatment plant around the clock over a period of several days, with a sustained delivery rate of 105,000 gph.

Knowing that the total round-trip shuttle distance will be 10 miles, the emergency manager refers to a planning guideline (such as Figure 2) and determines the following:

- A Type 2 Water Supply Task Force can deliver approximately 27,000 gph (all water tenders are Type 2 or better).

- A Type 4 Water Supply Task Force can deliver approximately 12,000 gph (all water tenders are Type 4 or better).

The emergency manager requests four Type 2 task forces through the statewide mutual-aid system, knowing that together they should be able to deliver a minimum of 108,000 gph to the treatment plant and will probably deliver more, providing a margin of safety if there are mechanical issues or other problems.

Limitations of the OFCA Typing Standard

The standard does not attempt to categorize all features of water tender apparatus. Notably absent is any attempt to characterize water tenders based on the presence, absence, or capability of pumps. The reason for this is that the standard is intended specifically to support high-capacity water shuttle operations. The presence or absence of a pump is immaterial when discussing a water shuttle operation where engine companies are typically assigned to handle all drafting and relay pumping needs. During these operations, the emphasis for water tenders will be to remain in motion as much as possible. A division of labor is required to manage resources on such incidents. When you want engines, order engines. Water tenders should not be expected to serve as all-purpose apparatus.

The model used to develop the standard tops out at 4,000 gallons, so it does not accommodate very large apparatus, such as 18-wheeler-based water tenders. This limitation was not seen as a major issue. Although such “mega-tankers” are certainly out there, their effectiveness in a high-capacity shuttle is questionable because of their long fill and dump times and the limited terrain over which they can easily operate. The numbers of these large apparatus are relatively small, and the OFCA system effectively addresses the vast majority of existing and future fire service apparatus.

The OFCA standard assumes an across-the-board 1,000-gpm fill-and-dump rate, based on requirements in chapter 18 (Water Tanks) of NFPA 1901, Standard for Automotive Fire Apparatus. Many older or less-well-designed apparatus will not be able to be classified under this system. As these older apparatus age out of the fleet and are replaced by NFPA 1901-compliant water tenders, this will eventually cease to be an issue.

Since the standard is based on minimum capabilities, there is no “credit” given for apparatus with dump-and-fill rates exceeding 1,000 gpm. The true capabilities of such rigs tend to be underrepresented by the system.

The standard is meant to represent true fire service apparatus only, not auxiliary vehicles pressed into service as water tenders. Construction industry water trucks, cement mixers, and other vehicles that could conceivably be used in a pinch are not classifiable under this standard.

Moving Big Water, Buckeye Style

The lack of an effective national typing standard for water tenders assigned to high-capacity water shuttle operations is a major impediment to effectively planning, ordering, and managing mutual-aid resources in these complex incident operations. The OFCA’s WSTAC developed the water tender resource typing standard presented here specifically to fill this gap in the ICS toolbox.

By implementing this standard for intrastate mutual-aid assignments in Ohio, we expect to more efficiently use our fire service resources while providing a sound basis for water supply operational planning. Ultimately, this system should contribute to improved effectiveness, better water supply support on major incidents, and better situational awareness of the available resources in the state.

JEREMY A. KELLER has been engaged in rural and wildland fire planning since 1999. He is a wildland fire manager and a firefighter/EMT with the Bellefontaine (OH) Fire Department and has previously worked as a wildfire mitigation specialist with several state and federal wildland agencies. He is an active member of the Water Supply Technical Advisory Committee of the Ohio Fire Chiefs’ Association Emergency Response Plan and the National Fire Protection Association’s Technical Committee on Wildland and Rural Fire Protection.

W. PARKER BROWNE is a certified fire protection specialist. He is retired from a life-long career in the fire apparatus and equipment industry and fire service education. He specializes in rural/suburban water supply issues. Browne continues to serve as an educator, a mentor, and a part-time fire chief. He is chairman of the Water Supply Technical Advisory Committee of the Ohio Fire Chiefs’ Association, Emergency Response Plan.

Fire Engineering Archives