By JOHN CERTUSE

Preventing the freezing of piping outside of a building’s heated interior spaces can be a significant challenge. Recent National Fire Protection Association changes severely curtail the practical use of antifreeze, and the need to install and freeze protect wet fire protection systems will continue to be a challenge for fire suppression contractors.

When using insulation to protect piping, you must consider coordinating the pipes’ placement, positioning, and insulation. The farther a pipe is installed from the interior heated gypsum board or drywall, the less heat that will be available to protect it. For example, this is evident if the pipe is installed on top of building framing members (be it a 2×4, 2×6, 2×8, and so on) as well as the point where it is fastened to this framing.

|

Loose fill and fiberglass batting insulations are susceptible to movement and compression, which reduces their effectiveness. This increases their potential for freezing as well as becoming inoperable during a fire. Likewise, full wrap pipe insulation will only delay the time it takes for pipes to reach freezing temperatures unless water flows through them frequently enough to prevent ice formation.

FREEZEBLOCKER™ is the first engineered piping insulation system specifically designed to prevent pipes from freezing. The FREEZEBLOCKER system coordinates the location where the pipe is fastened to building framing with an appropriately shaped, nonair-permeable, rigid foam insulating component that encapsulates the pipe in a rigid shell of nonflammable insulation.

Whether the piping is secured on top, passed through drilled holes, or fastened adjacent to building framing with pipe hangers, an appropriately shaped FREEZEBLOCKER insulation component is used for each installation condition. Each insulation component fits snugly into the building cavity between framing members and against interior gypsum board or drywall surfaces, eliminating the potential for drafts and building air leakage, reducing heating and cooling energy costs as well as making the pipes more resistant to freezing.

|

| Click to view video |

Enhanced thermal performance is achieved because of the use of an inner heat flow path geometry. Additionally, the use of a foil layer enables each insulation component to retain radiant heat losses, increasing the efficiency and effectiveness of each insulation system component.

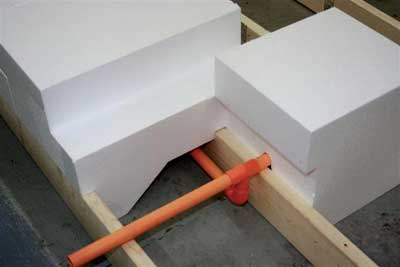

The FREEZEBLOCKER insulation system consists of the universally applicable Direct Contact FBB [FREEZE-BLOCKER Block (slot on block)] method and the Attic Tenting Module System. For sprinkler piping installed in unheated attics, FREEZEBLOCKER’s Attic Tenting Modules are placed over pipes installed on top of and between framing members. This system protects piping with a resilient shell of interlocking R-40 rigid insulation. Tenting modules are resistant to compression, movement, drafts, and inadvertent contact.

Assembling these modules can be done easily, within seconds, and simultaneously while installing piping. This can also be done prior to installing a building’s drywall. It eliminates the need to depend on separate fiberglass insulation contractors to insulate piping and return trips to the job site.

The Direct Contact Insulation System consists of a block of rigid insulation that contains a slot to receive the pipe when it is placed within the building’s framing. Used in conjunction with FREEZEBLOCKER’s specially-designed pipe hanger, the Direct Contact System can be used while pipes are installed away from colder wooden building framing and relocated into the warmer middle region of the wall cavity.

For building framing construction of nonstandard dimensions, FREEZE-BLOCKER linear insulation stock can be custom fit when needed. With a system of rigid, noncompressible insulation modules and components sized for a variety of building framing sizes and pipe fastening locations, pipes installed in unheated attics, cathedral ceilings, and outside walls can be quickly and more reliably protected against freezing to a level not previously seen. Additionally, based on each house’s framing dimensions as well as the FREEZEBLOCKER system used, you can achieve a consistency of performance and identify a minimum safe building temperature.

JOHN CERTUSE, P.E., is president of Insulation Systems LLC and ISE Engineering Inc. Certuse is a registered professional engineer and a certified fire and explosion investigator. He has patents for pipe insulation and energy analysis in buildings and has authored several papers regarding causes of building damage.

Fire Engineering Archives