How You Will Have Your Oxygen: Gaseous, Liquid or Solid State

1970S CHALLENGING YEARS

Container sizes, relative weights of systems, availability and operational problems to decide

Oxygen is a colorless, odorless, tasteless, innocuous gas which comprises one-fifth of our atmosphere. It is the most indispensable element in our universe, because although we can live for weeks without food, or for days without water, without oxygen we die in a few minutes.

The 21 percent oxygen in our atmosphere is sufficient to supply the metabolic requirements of a physiologically normal individual at altitudes below 10,000 feet. A physiologically subnormal individual may require supplementary oxygen even at sea level and must have therapeutic administration of oxygen by mask, catheter, or oxygen tent. At altitudes above 10,000 feet, the reduction of partial pressure of oxygen may cause hypoxia even in a normal individual, and supplementary oxygen must be provided.

When concentrations of oxygen higher than the 21 percent existing in the atmosphere are desired, then it becomes necessary to have a supply of pure oxygen so that it can be mixed with ambient air to obtain the desired concentration. Pure oxygen is available in three different forms.

Three forms available

Most familiar to all of us is compressed gaseous oxygen in high-pressure containers or cylinders. In the large cylinders in which it is transported and stored, it is usually compressed to 2,400 psi. Small portable cylinders are usually charged to 1,800 or 1,850 psi. To put it another way, the oxygen is compressed to 126 atmospheres. This means that the volume of gas which can be discharged from the cylinder is 126 times the volume of compressed oxygen.

Another form of highly concentrated oxygen is liquid oxygen. In this form, at a temperature below —297°F, oxygen becomes a transparent, pale blue liquid, slightly heavier than water. It is condensed to the point where one volume of liquid oxygen, when vaporized into gas, will give off 860 volumes of gaseous oxygen.

A third form of concentrated oxygen is chemical, or as we term it, “solid state” oxygen. This is oxygen which is combined in a chemical form with a combination of ingredients resulting in a solid, dry mass. When ignited, this mass burns, producing not only the oxygen necessary to support its own combustion, but producing an excess of oxygen. The volume of gas which is produced is 630 times the volume of the solid chemical.

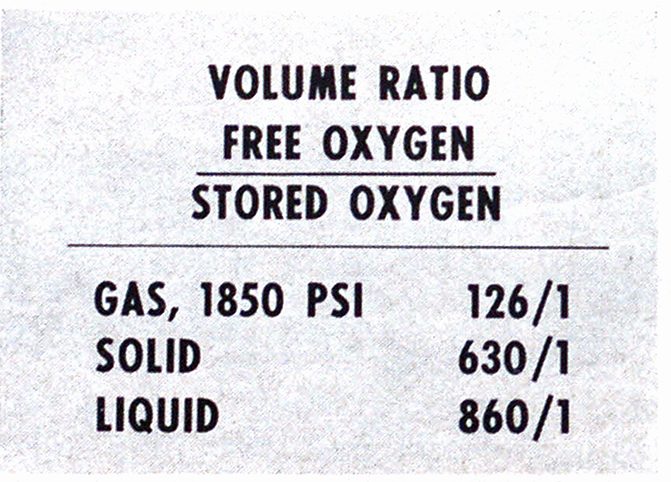

In Figure 1, we have shown the ratio of the volume of free oxygen delivered to the volume of stored oxygen. In Figure 2, we show the relative volume of a given quantity of free oxygen when compressed to 1850 psi, or in solid chemical form, or in liquid form. On a volumetric basis, then, it is obvious that although liquid oxygen is somewhat more efficient than chemical oxygen, both liquid and chemical oxygen are far more efficient than high-pressure gaseous oxygen.

Relative weights

Now let us consider relative weights. A given free volume of gaseous oxygen will weigh the same regardless of the pressure under which it is stored. Likewise, a given volume of free gaseous oxygen will have the same weight when reduced to a liquid form. For either of the two, the weight as shown in Figure 3 is almost 10 pound per 120 cubic feet of free gaseous oxygen. In chemical form, the weight is somewhat higher. A solid state oxygen supply which will produce 120 cubic feet of oxygen weighs approximately 26 pounds.

Please bear in mind that up to this point we have been talking about the oxygen itself, ignoring the container and the means for controlling the discharge of gaseous oxygen. High-pressure compressed oxygen requires a cylinder capable of withstanding the internal pressure. Liquid oxygen requires a container capable of maintaining the liquid at a temperature lower than —297°F to prevent rapid evaporation and evolution into a gaseous form. Chemical oxygen requires a container in which the solid state form can go through the process of ignition and combustion to release its oxygen.

Therefore, we must consider not only the weight of the gaseous oxygen itself, the liquid oxygen itself, or the chemical oxygen itself. We must consider the weight of the oxygen plus the container and the accessory equipment necessary to control its utilization.

Let us assume 120 cubic feet of oxygen stored in gaseous form at a pressure of 1,850 psi. The lightest cylinder available with today’s technology (and this would be of the ICC-3HT or so-called “super lightweight” class) would weigh 33 pounds. The valve necessary for closing and opening the cylinder to control the discharge of oxygen would weigh 1½ pounds. So we have 10 pounds for the oxygen itself, 33 pounds for the cylinder, and 1.5 pounds for the valve, making a total of 44.5 pounds.

Liquid oxygen converter

Now let us consider a liquid oxygen converter holding sufficient liquid to produce 120 cubic feet of gaseous oxygen. This container, of the Dewar type, with the necessary heat exchanger or evaporator coil, and the flow control and pressure relief valves, would weigh approximately 9 pounds. This gives us 10 pounds for the liquid itself, plus 9 pounds for the converter and accessories, making a total of 19 pounds.

The solid state oxygen form requires a container within which the solid pack can be burned and an ignitor mechanism to ignite the pack, as well as an insulating shroud to reduce the conduction of heat to the exterior. With a weight of 26 pounds for the solid state chemical required to produce 120 cubic feet of oxygen, plus 2 pounds for the container, the igniter and the insulating shroud and outer shell, we have a total of 28 pounds.

Our comparison then on a weight basis is shown in Figure 4—for 120 cubic feet of free gaseous oxygen, stored in high-pressure gaseous form, 44.5 pounds; in liquid form, 19 pounds; in sold state chemical form, 28 pounds.

Dimensions compared

Another factor to be considered is that of overall dimensions, Figure 5. The hypothetical high-pressure cylinder which I used as an example while comparing weights would be 34 inches in overall length, including the valve, and 9 inches in diameter. The liquid oxygen converter would be approximately 12 inches high and 13 inches in diameter. The solid state chemical generator would be 12 inches high and 7 inches in diameter. If we consider the space occupied by each of these as being a cylindrical envelope, then the high-pressure container would occupy 2,160 cubic inches; the solid state generator, 460 cubic inches; and the liquid converter, 1,355 cubic inches. In Figure 6, we have tabulated the relative expansion (from the volume as stored to free gas), the weight of the storage unit plus the oxygen, and the space requirements for each of the three types of oxygen supply.

Continued on page 156

Oxygen

Continued from page 141

We must also consider the mechanical and other problems involved in the utilization of each of these three methods of providing highly concentrated oxygen. Gaseous oxygen has an advantage in that it can be turned on or off at will—to use a little at a time when and as required, or to use it all at one time if necessary. Since the rate of flow can be regulated to match requirements, there need be no waste.

Some problems

On the other hand, high-pressure gaseous oxygen poses several problems. One is the problem of loss by leakage. A slight leak at the cylinder valve, or elsewhere in the system, can result in the loss of a considerable portion of the supply. In handling highpressure oxygen cylinders, specifically in refilling them, and in the process of turning the cylinder valve off and on, there is always an inherent hazard of ignition and explosion should there be any contaminant present.

Liquid oxygen has an advantage over both high-pressure gaseous and solid state chemical oxygen from the standpoint of weight. However, it has some serious drawbacks. One is the problem of availability. With the exception of military air bases and large metropolitan and industrial areas, it is not readily available. In addition, because of the continual loss through evaporation of the liquid, whether it is being used or not, the converter must be continually replenished. Also, there are serious hazards in the handling of liquid oxygen. There is the danger of possible frost injury to personnel and the danger of explosion and fire if the liquid should come in contact with organic materials.

Solid state oxygen

The solid state chemical oxygen generator can be stored indefinitely. It eliminates the refilling of cylinders or converters. It also eliminates the hazards associated with the handling and use of both high-pressure gaseous and liquid oxygen. Because of its infinite shelf-life, the generating canisters can be stored in a fire station, or spare canisters can even he carried on trucks.

The solid state oxygen generator in its simplest form, when once activated, cannot he shut off. Hence there is no control of the rate at which oxygen is delivered nor of the duration of flow. These are governed entirely by the composition, the geometrical shape, and the mass of the chemical canister. Work is under way toward the development of a system utilizing a multiplicity of small canisters to he activated either sequentially or in multiples to provide control of both the oxygen production rate and the duration of flow.

The solid state generator produces heat at a rate of between 80 and 90 Btu for each cubic foot of oxygen produced. The maximum temperature is in the core of the canister, and the exterior can he readily insulated to prevent excessive jacket temperature.

A cost comparison between these three methods of storing and utilizing oxygen is not practical, because to have any validity such a comparison should take into account not only the oxygen supply, but the total system. When a total system concept has been established, then the costs of the initial installation and the costs of operation and maintenance can be compared.

In summary, of the three forms of concentrated oxygen I have described, the solid state oxygen generator offers significant advantages over both liquid and compressed oxygen from the standpoint of minimum space requirements; simplicity; maximum safety; ease of handling, storage and transportation; unlimited shelf-life; and ready availability.

From a paper presented at the 38th Annual Scientific Meeting of the Aerospace Medical Assoc., Washington, DC., April 11, 1967.