STANDPIPE ROLL

Standpipe systems are prevalent in our 63-square-mile protection area, which is a mix of residential (including a 4,000-resident retirement community), light commercial, and heavy commercial structures. The standpipe rolls we used for years to advance hose into and through stairwells or from columns in commercial buildings were a double donut roll of two 50-foot sections of 1 3/4-inch doublejacketed hose, which easily became twisted and knotted. The double donut, moreover, was slow to advance and awkward to lay out in stairwells.

Our new approach keeps the same hose size and nozzle gpm but uses one 100-foot section of 1 3/4-inch doublejacketed high-rise hose, a lighterweight nozzle, and a 2 1/2-inch-by 1 1/2-inch reducer in place of a 2 1/2-inch-by-1 1/2-inch wye. These revisions reduced the weight of the “standpipe pack,” as we call it, by 24 pounds. We then devised a new roll that would lay out neatb without twisis and tangles.

The follow ing guidelines make advancing the standpipe roll virtually foolproof:

- Begin with one 100-foot section

- of 1 3/4-inch hose.

- Grasp either end coupling and carry it to the opposite end to form a

- loop section that is laid out flat and untwisted, with parallel lines.

- Facing the coupling ends, roll the

- hose toward the couplings (to eliminate air in the hose).

- After the hose is rolled, connect the couplings to prevent air from entering.

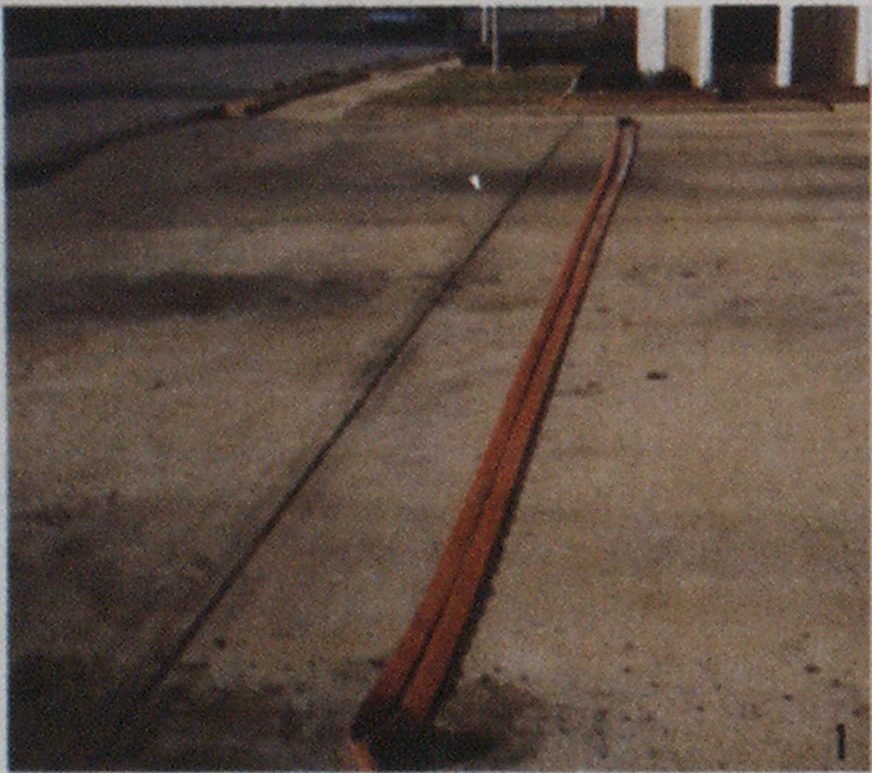

- Unroll the hose to its original, parallel position. (See photo 1.)

- Fold the hose over itself into thirds in a “Z” pattern to form three double-wide layers. (See photo 2.) Note: It doesn’t matter if the couplings end up on the top or on the bottom —the hose will unroll either way.

- Start the hose roll at the loop end and roll toward the couplings. (See photo 3.) After the hose is rolled, uncouple and attach the nozzle and wye or reducer.

- Place the hose roll in its canvas

- pack for storage and carrying.

To advance the standpipe pack, the nozzleman unstraps the canvas pack and grasps the nozzle and both loops. (See photo 4.) The nozzleman advances the hose until one of the loops comes to a stop. He then drops that loop and continues to advance the hose. Meanwhile, the second firefighter attaches the wye or reducer and prepares to turn on the standpipe. The hose is now ready to be advanced. The hose load can be deployed within a minimum of 20 feet of the working area, compared with approximately 50 feet needed for the double donut —an advantage when working in tight areas such as stairwells and rack-storage systems.

The standpipe pack can be deployed up stairs, down stairs, and through hallways without kinks, twists, or other common double-donut traits.

We evaluated the hose load in many test cycles and hose drills. It performed better than our old system in all tests. The load may be slightly more time-consuming at the station, but its advantages are well worth it in the long run.

Note: The hose load can be made from two 50-foot sections, but we chose 100-foot sections to eliminate the additional coupling weight.

We found this hose load to be beneficial in extending preconnected handlines, advancing hose from a ladder tip, and quickly applying foam from a 1 1/2-inch eductor.