By LINDA BABCOCK

Recently, a flashover sim-ulator manufacturer investigated the available smoke emission control technologies that it could incorporate into an upgrade of a major New York State fire department’s flashover simulator. After evaluating market offerings, the manufacturer determined that Bionomic Industries’ Series 9000 Preformed Spray Scrubber provided the optimal solution.

|

| (1) Highly visible smoke emission exiting the simulator when the scrubber is turned off. (Photos courtesy of Bionomic Industries.) |

The fire department’s training center uses the flashover simulator to train more than 4,000 firefighters annually. It ignites wood fires in the unit three to four times per day, creating heavy, highly visible smoke. According to the department’s battalion chief, one of the critical requirements of an upgraded simulator was that it significantly reduce smoke and odor emissions.

|

| (2) Visible smoke emission is virtually eliminated when the scrubber is operating. |

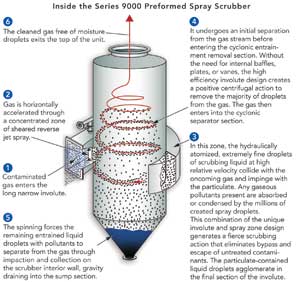

After evaluating available scrubbing and other technological solutions, the fire department determined that the Series 9000 Preformed Scrubber would not only reduce smoke and odor emissions but also provide the most economical solution needed by the department. The Series 9000 represents a major advancement in cyclonic scrubber technology and is capable of outperforming venturi scrubbers on an energy/cost basis for collection of condensable tars with smoke particulate. The scrubber, which uses once-through, mechanically atomized water and a venturi action, virtually eliminates visible smoke. This cost-effective solution is one-third the cost of electrostatic precipitators and one-half the cost of afterburner solutions.

The Series 9000 has a unique, specially designed gas entrance involute section filled with proprietary reverse jet sprays for concentrated and rapid treatment of particles and fumes. The addition of an involute section access panel improved the ability to service the spray components from the exterior of the scrubber to reduce maintenance and the resulting downtime that conventional spray scrubber devices require while providing a major increase in collection efficiency.

The completely unobstructed open design of the scrubber vessel reduces buildup of sticky condensed tars and smoke particles on the vessel walls. In addition, another access panel was installed to aid in cleaning the side walls when offline. The elimination of internal packing elements, turning vanes, or mist eliminator components common to other designs has substantially reduced manual cleaning frequency. With its compact size, it can easily be installed in locations with height limit restrictions.

The installation of the new flashover simulator with the Series 9000 has enabled the fire department’s training center to reduce smoke and odor emissions significantly.

LINDA BABCOCK is the office manager and marketing coordinator for Bionomic Industries.

Fire Engineering Archives