By Raul A. Angulo

“Foam will replace all current water application…”

Ron Rochna and Paul Schiobohm are wildland firefighting experts who made this statement back in 1987, just eight years after I joined the Seattle (WA) Fire Department (SFD). In 1980, we were using only water to put out Class A fires (except for the 2½-gallon water pressurized fire extinguishers; then we were supposed to use this additive called “wet water”). I remember thinking, “How can something be wetter than water?” But back then, we didn’t ask a lot of questions, and we did what we were told to do; if the department wanted us to use wet water, then that’s what we were going to use. The only explanation I got was, “It’s supposed to put out mattress fires better than water.” I don’t think the senior guys even knew exactly how it worked, only that we were supposed to use it.

The pump can or “the can” was used primarily for incipient room fires that involved a bed or sofa. My officer always called for a hoseline, so I ended up at the end of a nozzle, not a pump can. My experience with the can included small trash fires and “beauty bark” fires, so I never saw a significant advantage in using wet water. Since that was my background and experience, that is the opinion I held when I made lieutenant on an engine company. Unless we were performing foam operations on a Class B fire, I resisted the move toward Class A foam. I simply felt it was unnecessary; water had worked fine for me since Day One.

It was the understanding of the science of Class A foam that led Rochna and Schiobohm to be visionaries and make such a bold prediction…and it came true. Many fire departments now use Class A foam, including the SFD. Depending on the apparatus, Class A foam reservoirs can carry an average of 20 gallons of Class A foam concentrate. There are numerous discharge ports including all the preconnected lines that can deliver the foam with the flip of a switch. The foam concentrate is injected into the water stream at the pump. As it travels through the hoseline, it mixes with the water, with final aeration happening as the foam exits the design of the nozzle.

Class A foam enhances the effectiveness of water. Following is a list of teaching points and the pros of using Class A foam:

- Bubbles increase the heat-absorbing surface area of droplets.

- Detergent wetting agents (surfactants) reduce the surface tension of water.

- It allows the water to penetrate fuel and inhibit combustion.

- Without foam, surface tension holds the fire stream together with larger water droplets, limiting the heat absorption capability.

- The outer 10 percent of a droplet absorbs heat, while the inner 90 percent runs off the fuel (water runoff).

- When Class A foam concentrate mixes with water, the surfactant molecules spread the water molecules apart. The entrained air forms the bubbles and increases surface area of the water to cool the fire and allows the water to penetrate burning and unburned materials.

- Droplets that are 250-350 microns are more efficient in absorbing heat than larger, heavier droplets. Class A foam increases the effectiveness three to 15 times more than plain water (from National Institute of Standards and Technology research).

- Emulsifying agents added to Class A foam encapsulates the hydrocarbon molecules, rendering the fuel nonflammable.

Results of using Class A foam:

- Faster extinguishment.

- Temperatures are reduced more quickly.

- Less chance of flashover occurring.

- Less smoke production.

- Increases occupant survivability profiles.

- Less water needed to extinguish (less water damage).

- Less water wasted from water runoff.

- Property conservation increases.

- Firefighters exposed to less immediately dangerous to life or health heat and carcinogenics

- Units back in service quicker.

RELATED: Marinucci: To Foam or Not to Foam ‖ Zaitz on Foam Operations ‖ Oke on Onboard Foam Delivery Systems

The Drills

So, how do you teach these results to firefighters so they’re convinced it’s all true? Start by asking your crew about the foam inventory and equipment on their apparatus, as well as the following:

- How many gallons of foam do we carry on the rig?

- Tell me everything you know about foam?

- Tell me everything you know about the eductor?

- What is the maximum lift?

- When do we use one, three, and six percent?

- How do you create a foam blanket?

- What is “ghosting”?

- What is the foam formula? (Ten percent area for 15 minutes.)

Experiment 1

For the next part of the drill, take a piece of plain cardboard (make sure it is not wax-coated) from the lid of a used box. Then, take two small plastic cosmetic travel bottles and fill them both with plain water. In one of the bottles, add 10 drops of Class A foam or wet water. Take the bottle of plain water and begin applying separate water droplets to one side of the cardboard; five to 10 droplets should be fine. Make one water droplet at a time and leave some space between them so they do not join.

The first thing you’ll notice is that the water droplets stay intact. If you apply 10 droplets, you will have 10 small separate globes of water. This is an excellent visual demonstration to explain and see what surface tension of water looks like; for instance, the droplets maintain perfect spheres that do not get absorbed into the cardboard.

On the other side of the cardboard, apply droplets from the bottle with the Class A foam. Immediately, you will see the droplets being absorbed into the cardboard. This is another excellent visual demonstration to explain and see how the foam surfactant compounds break down the surface tension of water. With each drop of water containing Class A foam you will see no droplets form and also how the cardboard quickly becomes saturated with the extinguishing agent.

The droplets of plain water will still sit there on the cardboard. The cardboard just outside the surface perimeter of the droplet will remain dry. Allowed to sit, these droplets will remain unchanged for more than 30 minutes! There isn’t a more graphic and convincing experiment as to the claims and benefits of Class A foam than this one. It was this experiment shown to me by SFD Firefighter Joaquin Hubbard, who has an extensive background in wildland firefighting, convinced me—as a captain—of the advantages using Class A foam. Now, I was able to connect all the dots in the bulleted list above. It finally made sense.

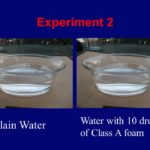

Experiment 2

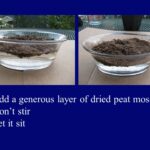

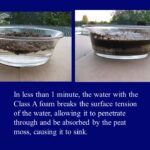

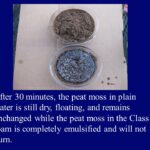

Hubbard also encouraged me to try the following experiment at home (so I did). Buy a small bag of peat moss at your local home and garden store and fill two clear glass bowls about ¾ full with plain water. In one bowl, add 10 drops of Class A foam or wet water and stir it up. Next top off each bowl with a generous layer of dry peat moss. Don’t stir it in; let the peat moss sit.

At first, the two mounds of peat moss will float on the surface of the water. Within 60 seconds, you will begin to see the effects of broken surface tension of the water with the Class A foam. Breaking the surface tension allows the water to be absorbed into the peat moss (the fuel). As each little piece becomes saturated with water, it’s density and weight increases, causing the pieces to sink to the bottom of the bowl. With each passing second, more and more small chunks of peat moss will sink to the bottom of the bowl. Before long, the mound of peat moss has become level with the surface of the water and the entire bowl is a mix of brown substance and mud. The peat moss has emulsified and will no longer burn.

By contrast, the bowl of plain water remains unchanged. The mound of peat moss is still dry and powdery and floating on the water’s surface. The water below the surface will still be clear. The surface tension is so strong, it supports the weight of all the peat moss, and it will continue to do so for well up to an hour.

The surfactant feature in Class A foam is the key to the “magic.” Surfactants are compounds that reduce or eliminate the surface tension (or interfacial tension) between two liquids; in this case, the foam concentrate and the water. Surfactants act as wetting agents, foaming agents, detergents, emulsifiers, and dispersants—this is why you need dishwashing detergent to wash dishes. The surface tension of water and grease does not allow the water to penetrate to the dish. By adding detergent, it breaks down the surface tension so the water can penetrate through the grease and remove it from the dish surface.

These experiments are fun to watch and easy to perform right at the firehouse kitchen table for a “rainy day” drill. They’ll also go a long way in making firefighters believers of the benefits of Class A foam to enhance fire extinguishment. Plus, it will make you look smarter than you really are as a company officer, especially if you’re assigned to the truck and can pull off this drill before the engine officer does!

Drills You Won’t Find in the Books: Bangor Ladder Rescue for H-Shaped Buildings

Drills You Won’t Find in the Books: Stokes Snow Sled Drill

Drills You Won’t Find in the Books: Kid Stuck in a Tree

Drills You Won’t Find in the Books: The Dancing PPV Fan Drill

Drills You Won’t Find in the Books: Bridge Jumper Drill

RAUL A. ANGULO retired from the Seattle (WA) Fire Department after more than 37 years of service and is also Captain Emeritus of Ladder Co. 6. He is a featured author and a member of the Editorial Advisory Board for Fire Apparatus and Emergency Equipment magazine and is a regular contributor to Fireengineering.com with Drills You’re Not Going to Find in the Books.

RAUL A. ANGULO retired from the Seattle (WA) Fire Department after more than 37 years of service and is also Captain Emeritus of Ladder Co. 6. He is a featured author and a member of the Editorial Advisory Board for Fire Apparatus and Emergency Equipment magazine and is a regular contributor to Fireengineering.com with Drills You’re Not Going to Find in the Books.