APPARATUS BID EVALUATION SIMPLIFYING A DIFFICULT PROCESS

The “truck committee” was elated when the town’s governing body approved the chief’s request for funding to replace the department’s aging apparatus. The group had spent countless hours justifying the purchase and even more time traveling to neighboring departments, going to conferences and apparatus shows, and interviewing salespeople to select the best apparatus for the department’s needs.

The salesman for the AIK. Apparatus Company was happy to provide bid specifications, including all the custom features the committee wanted. This document then was used to request and solicit public bids for the apparatus.

On the evening of the bid opening, fire department members excitedly stood by as the town’s administrator called for the bids. To their surprise, three apparatus sales reps handed in sealed documents. As the bids were opened and read, the members’ jubilance quickly turned to confusion. The little-known XYZ Apparatus Company had underbid AIK!! by more than $10,000. The truck committee knew that XYZ could not produce the exact apparatus it had specified, but the thought of saving S 10,000 certainly caught the attention of the mayor and council!

The fire chief and truck committee now would have to enter one of the most difficult processes of apparatus acquisition —bid evaluation. Without extensive technical knowledge of apparatus construction and manufacturing techniques, this can he like trying to compare apples and oranges.

When the bids were reviewed, they found that the low bidder had submitted a complete substitute specification, making its bid difficult to sort through. Unfamiliar and dissimilar terms and descriptions, as well as substitute components, caused massive confusion as to just what had been bid.

With the economy in a decline and politicians looking to save precious tax dollars, the situation is ripe for manufacturers to bid on apparatus that don’t completely meet purchasing specifications. Convincing a governing body to award a contract to the compliant bidder is difficult w hen the low-bid competition states that both apparatus have the same performance characteristics, both will pass the same acceptance tests, and both are N FPA-compliant.

BID EVALUATION BEGINS WITH WRITING SPECIFICATIONS

The first mistake the fire department in this example made was to use as the bid document the specifications provided by a manufacturer. The information contained in sample specifications provided by a sales rep should be used only as a guide to formulate your own bid specs.

The second mistake was allowing the alternate bidder to submit a substitute spec in its order. It is extremely difficult to evaluate such a spec. The specifications should clearly state that all bidders must follow the bid order or be disqualified.

As w ith any difficult task, it is best handled if broken down into smaller, more manageable units. I prefer to divide the bid specifications into three separate categories:

- General requirements.

- Construction specifications.

- Bid evaluation checklist.

Using this format w ill help make the evaluation process much more orderly after the bids have been received.

GENERAL REQUIREMENTS

The general requirements portion of the specifications, sometimes referred to as the “boiler plate,” is equally important as or more important than the construction section when it comes to evaluating an apparatus bid. Information contained in this area will allow you to better evaluate the bidder’s qualifications.

Many items in the general requirements should be considered when laying the groundwork for the bid. They include the following:

- An intent statement describing the type of apparatus the department is seeking and the requirements necessary for compliance with applicable NFPA standards and all state and federal regulations governing vehicles in

- the same weight range.

- Road and performance acceptance tests that will be conducted at the time of delivery.

- Delivery and payment terms for the purchase.

- Special construction requirements, such as the material to be used or type of chassis (custom/commercial).

- Establishing a manufacturer’s experience and reliability by requesting a list of current customers who can be contacted or visited.

- A bid bond submitted with the proposal and a commitment for a performance bond if the contract is awarded. Some departments also specify a warranty bond to help protect their warranty should the bidder go out of business during the warranty period.

BID EQUATIONS

- Requiring proof of product liability insurance and a financial statement from a nationally recognized accounting firm, to help establish the bidder’s solvency.

- Proof of a factory-authorized service and spare parts center within easy travel distance is extremely important to the purchaser. Location, photos, and descriptions of the facility and its mobile units should be required. If purchasing a commercial chassis, verify that the local dealer has a mechanic familiar with fire apparatus to perform warranty work.

- Request the expected delivery date; some departments advocate charging a penalty for each day past the delivery date.

- Clearly outline special requirements of maximum size and weight, as well as the requirement for a factory representative to conduct training for a specified number of days.

- Spell out the expected warranties on the chassis, body, cab, engine, driveline, and pump. (A spec I recently reviewed indicated “all standard warranties.” A “standard warranty” could be 30 days; it must be properly spelled out.)

Many other requirements can be placed in the general portion of the specifications to protect the fire department’s interest. Chances are, the manufacturer’s spec probably won’t have all of them, especially if it is difficult or expensive to comply with some of the items.

For example, I reviewed a specification for a small volunteer fire department and found that the township was prepaying for the chassis without one word about ownership. When I informed the fire commissioner that they very well could lose their sizable investment should the company go out of business, he replied, “The salesman never told me that!” I was not surprised.

CONSTRUCTION SPECIFICATIONS

When you receive the “sample” specifications, first review them for completeness. Be sure everything you considered and discussed with the sales rep is in the spec.

The next step is to divide the specifications into smaller, more manageable units. Many manufacturers’ specs will describe entire portions of the apparatus in one large section, such as under the subhead “body.” To make the evaluation process easier, the “body,” as well as other items, should be broken down into smaller units —subframe, compartment construction, compartment sizes, compartment shelf requirements, steps, handrails, and hosebed size and construction—and all should have separate subheadings. Forcing all bidders to address each individual subdivision, in bid order, will make it easier for you to compare bids during the evaluation process.

When working with a manufacturer’s sample spec, be aware that contradictions may exist. Because the spec may be computer-generated, often the “stock” description will indicate one thing, such as fixed side windows, that an option later in the spec says will be replaced (for instance, with sliding windows). To avoid confusion, clearly state the first time what the department desires.

BID EVALUATION CHECKLIST

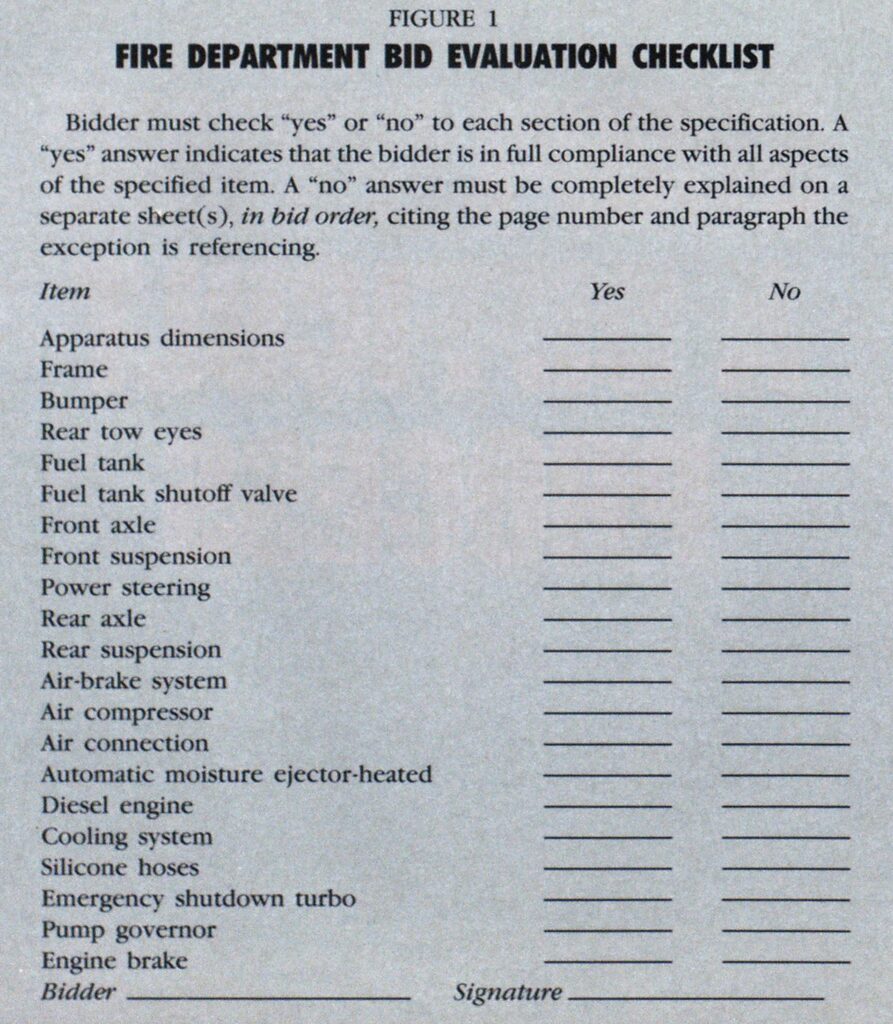

In the third section, the bid evaluation checklist, each item of the general requirements and construction portions of the specifications is listed with a “yes/no” check column at the right side of the page. (See Figure I.)

Begin the bid evaluation checklist with a statement instructing the bidder on flow to use the list. The bidder must check “no” to any exception to or variation on the specifications and fully explain the differences on separate sheets, in bid order, citing pages and paragraphs. A stern warning that “bids that do not follow this procedure will be disqualified” hopefully will place the burden of this comparison where it belongs —on the bidder.

Include a place at the bottom of each page to insert the bidder’s company name and the signature of the person who completed the checklist. This will be most helpful should the sheets get mixed up. In addition, it will fix responsibility for the forms’ completion.

I developed the bid evaluation list instead of including the “yes/no” column on each page of the specifications for two reasons. First, including the “yes/no” column on the pagemeans having to evaluate each and every page of the specification. There is a distinct possibility that you will get one “yes” answer for a whole page on which some of the smaller, noncompliant items may have been overlooked.

Second, the checklist consolidates all of the bidder’s answers on one easy-to-study report, which can be included as supporting evidence with your final recommendations.

SPECIAL REQUIREMENTS

If you have special requirements with regard to the dimensions, turning radius, weight, and so forth, include a page requesting this information. It is always easier to “fill in the blanks” than to dig through the whole proposal to locate this vital information. (See Figure 2.)

BID EVALUATION

If all bidders follow the outlined procedures, it should be relatively easy to make comparisons. The first step in the bid-evaluation process is ensuring that all required documentation (bid bonds, insurance certificates, financial statement, and so forth) arc included with the bid —in order. You may need help if you plan to evaluate a financial report.

If you are evaluating several bids, make master evaluation sheets by photocopying the blank checklist. Instead of indicating “yes/no,” make a “yes/no” column at the right for each bidder. (See Figure 3 )

Next, check the bidder’s checklist against the corresponding page on the master list (fold if necessary). Mark all of the “no” answers on the appropriate line. This will provide a list that will indicate, at a glance, how many of the bidders are deviating from each individual item of the spec.

After transferring all of the “no” answers, evaluate the description of each exception or substitution provided. In some cases, a “no” might indicate an item equal to or exceeding the original spec. In the latter case, you would put a “ + ” next to the item to indicate that it is something better than what was specified. Likewise, you would use “ — ” or “ = ” to indicate deviations that are deficient and acceptable, respectively.

EVALUATING CONSTRUCTION METHODS

The evaluation of construction materials and methods is a subjective process. If, for example, a fire department’s members are convinced that aluminum is a better construction material than stainless steel, the opinion probably is based on personal experience or information conveyed by other purchasers. But for each department that selects one type, another will prefer the other.

The truth of the matter is that most manufacturers use their own particular methods of construction. Evaluating one against the other is a very difficult task. If a manufacturer’s technique of building apparatus were flawed, you could rest assured that the company would not remain in business for verylong.

Some items in the specifications, however, can be evaluated against common ground. For instance, the thickness of the metal used in sheet areas such as doors, diamond plate surfaces, compartments, and the cab can be compared for compliance, provided that they are made of the same material.

Some characteristics of the apparatus, including overall length, width, height, wheelbase, turning radius, and weight, are items appropriate for comparison. Cab interior measurements, including head room from the seats to the ceiling, seat sizes, and door openings, also can be easily compared.

You also can evaluate components based on individual specifications. As an example, the size and rating of items such as the alternator, axles, and suspension, as well as an item’s manufacturer, can be compared with the specifications. Substitutions possibly could exceed the fire department’s specifications.

In some cases, the department’s reasons for specifying a particular component make a substitute unacceptable. As an example, the major pump manufacturers all produce a quality product that, if properly maintained, will provide years of reliable service. A purchaser may reject an otherwise acceptable substitute pump simply because of the department’s needs for maintaining uniformity in training and operation, parts inventory, and ease of maintenance.

DETERMINING “EQUAL”

Determining if components are equal or exceptional is up to the purchaser. Several years ago, the U.S. Supreme Court upheld the decision handed down by the U.S. District Court of Massachusetts in the case of Whitten v. Paddock. This case upheld the right of a purchaser to specify a particular product, even when competing products are claimed to be equal. It clearly stated that the specifying source is charged with the right and responsibility for determining whether a proposed substitution is equal. (This information is being provided as a reference for research. Consider current changes in the law and the impact of state or local regulations before proceeding with a legal defense.)

GENERAL CONSIDERATIONS

When reviewing the bid proposals, prepare an overall evaluation of the bidder based on the following:

- commitment to the conditions of the specifications,

- manufacturing and delivery schedule,

- manufacturer’s capabilities and qualifications as well as past performance and experience with the purchaser,

- the dealer’s capabilities and qualifications to maintain the apparatus and provide service,

- parts availability,

- design and reliability factors,

- case of maintenance, and

- warranty commitment.

- When you are through, the check-

- list should give you a good idea of just how the units compare.

Remember, during this process you are evaluating the bidder as well as the bid. Irregularities or deficiencies in the general requirements portion of the bid could mean trouble during the lifetime of the apparatus. A bidder that will not produce a financial statement or that is unable to secure proper bonding or liability insurance might not be in business long enough to deliver the apparatus, let alone honor the warranty! Unfortunately, many long-standing and reputable apparatus manufacturers have gone out of business in the past few years as well.

FINAL REPORT AND RECOMMENDATION

Prepare a final report that contains an outline of exceptions and deviations and lists the page numbers of the proposal where the differences are described. Include copies of the master evaluation checklist as well as the bidder’s checklist as supporting evidence, l ull written justification for the rejection of a low bidder is absolutely essential.

Finally, you must present your case to the purchasing authority who will decide on the bid award.

ACCEPTING LESS THAN SPECIFIED

Considering acceptance of a bid that is substantially lower than the original specifications could be cause for rejecting all bids, modifying the specifications, and beginning the process all over again. It is unfair to the compliant bidder when a substandard product is accepted on the basis of price alone.

Regardless of the bid evaluation process used, remember: The low bid does not automatically provide the best value. The fire department must consider all aspects of the bid, including reliability, reputation, financial stability, and ability to provide parts and warranty service. Only after you have seriously considered these factors with regard to each bid can you realistically compare prices.