FORCIBLE ENTRY TOOL STORAGE AND MAINTENANCE RAY MCCORMACK

THE TRUCK COMPANY

Successful forcible entry operations begin in the fire station. The company whose members keep their forcible entry tools organized in a logical manner and follow a systematic inspection program for their tools increases its chances for fireground success.

TOOL STORAGE

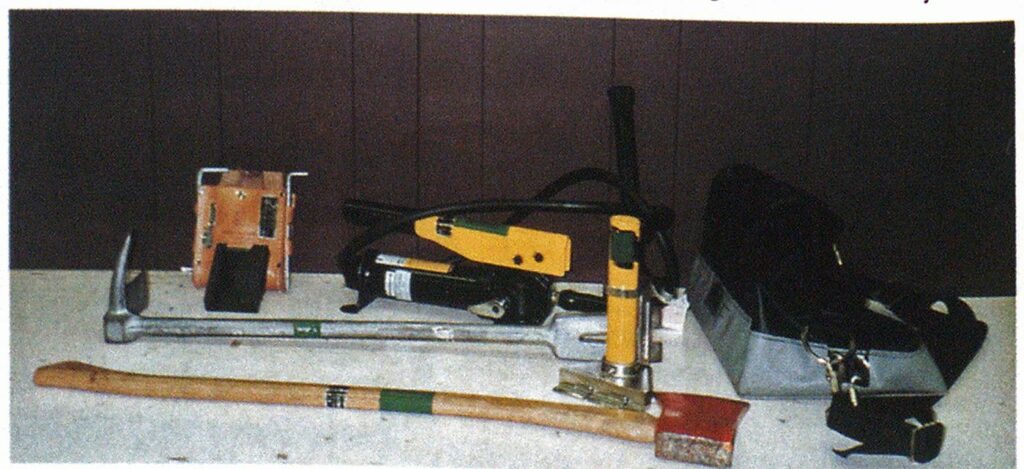

The basic forcible entry tool set consists of a flathead axe and a halligan tool. However, modern lock technology and the increasingly diverse situations fire departments respond to require that this basic tool set be augmented with a K-tool and a small hydraulic forcible entry tool. These four tools should be placed inside the crew cab so that they are available to the forcible entry team prior to leaving the apparatus.

Additional forcible entry tools, including bolt cutters, lock breakers, mauls, pipe wrenches, and bam-bam tools, should be grouped together in a single compartment. The forcible entry power saw and cutting torch should be stored separately. To maximize your company’s overall storage capability, use as few compartments as necessary to store these tools. If possible, all forcible entry tools should be located on the same side of the apparatus; this way, the forcible entry team can gather the tools required quickly and maintain team integrity. The compartments chosen should be large enough to safely store the forcible entry tools and should be used exclusively for that purpose.

All members of the company must be thoroughly familiar with each tool’s capabilities and storage location on the apparatus. Failure to know these two basics will cause a delay in forcible entry operations and may lead to injuries.

STORAGE AND INVENTORY

When forcible entry tools are stored carelessly, the company runs the risks of tools failing and time being wasted on the fireground. Forcible entry tools scattered about in numerous locations show a lack of planning and confuse company members. Forcible entry tools should be organized in a way that allows for quick identification and rapid tool removal. This will speed up operations and lessen the stress of searching for specific tools.

All apparatus compartments should be numbered. Use a system of alternating numbers (odd numbers on the officer’s side and even numbers on the chauffeur’s side) or of continuous clockwise numbering. Exterior compartment labeling by general tool category is convenient for company members and assists other companies who may need to access tools in your apparatus in an emergency situation or at extended operations.

Compartment inventory’ cards listing the tools contained in a specific compartment will assist members with their scheduled tool inspections and help identify misplaced or lost tools. These detailed lists can be placed in a holder and mounted on the interior of the compartment. They should be updated to reflect any changes in the company’s tool inventory.

A master tool list that includes all tools kept on the apparatus should be filed in the office. A copy of this list should be kept on the apparatus. This master list also should be updated as needed to reflect the company’s current tool inventory.

A company blackboard is an excellent way to inform members of which tools have been placed out of service and which the company has recently acquired. This board also should reflect changes in tool locations and the dates on which the changes occurred.

These storage and inventory techniqucs will greatly assist company members on the foreground and will benefit the forcible entry team specifically.

TOOL MAINTENANCE

In some departments, maintenance of the forcible entry tools occurs at the change of tours and is performed by a single member; in others, it is a weekly task effected as a group. Whenever it is performed, certain standardized tool inspection procedures must be followed to ensure optimum performance from the company’s forcible entry tool arsenal.

To some firefighters, it may seem excessive to inspect a tool that has been sitting in a compartment “undisturbed.” However, successful forcible entry operations mandate that members do not become complacent about maintaining these life-saving tools. Company officers must ensure that all members are made aware of the benefits of in-house tool inspection activity.

Hand tools should be cleaned and inspected for loose or missing parts, cracks, burrs, and other defects. Lubrication should be done at this time. This also is a good time to re-mark the tools according to the company’s identification system, using colored tape or paint.

Departments invest large sums of money in modern forcible entry tools such as power saws, cutting torches, and small hydraulic tools. T hese tools drastically reduce the time spent on forcible entry; however, it takes more time to keep these tools in proper working order. Any of these tools can develop leaks on the fireground or during storage on an apparatus. These types of tools, as well as all others used at an operation, should receive a quick inspection-before members leave the scene-to determine serviceability.

In the fire station, a more detailed maintenance program is required. A forcible entry power saw must be inspected for structural damage, such as a broken handle or connecting arm or a damaged protective shroud or trigger. As you would for all forcible entry tools, clean saws to discover any hidden problems and maintain peak performance. Immediately replace damaged or worn saw blades. Check the blade for tightness after and prior to starting the saw. Make sure the saw’s fuel level is full at all times. Keep a spare fuel supply on the apparatus with the saw. A properly operating saw will come to an idle after being brought up to speed and released.

Your small hydraulic door-opener should be removed from its bag so a thorough inspection can be made. Only the tool itself should be in the bag-do not place extra door chocks, K-tools, or other equipment that could impede its operation inside the bag. Conduct a visual inspection for possible fluid leaks. Examine the hose for cuts, kinks, and excessive wear. Check the jaw tips for deformities and cracks and, as a final check, do a pump test.

Examine the cutting torch for damaged hoses, pressure gauges, control knobs, and cutting tip. Mark the fuel tanks to reflect current fuel status. Clean the torch’s cutting tip and check additional fuel inventory. Protect this tool from damage and store it in an upright position.

If you discover that a tool is not operating properly, check it thoroughly. Use the manufacturer’s guide booklet, if necessary, and leave problems you cannot repair to trained technicians. If you have any doubt about a tool’s serviceability, place it out of service. When a much-used tool is placed out of service, the forcible entry’ team may suffer some hardship; but carrying and using a tool that has a history of erratic performance is unsafe and can make matters much worse.

Time is compressed on the fire scene-especially for the forcible entry team, which must gain access to avoid fatal consequences. The firefighters assigned to this task must be knowledgeable and resourceful to succeed. We owe it to ourselves and the public we protect to ensure that the tools we use operate safely and effectively when called on-in short, that they match the people who use them. The company whose members efficiently organize and regularly maintain their tools will receive the future dividends of reduced entry time and safer operations on the fireground.