Article and photos by Eric G. Bachman

Awareness- and operations-level hazardous materials training programs heavily review placards–with good reason, since identifying the cargo, even if it is only the general hazard class, is important for subsequent operations. Not as much emphasis, however, is placed on labels. Labels in this context refer to those used in transportation under the jurisdiction the U.S. Department of Transportation. The label information provided below should not be confused with product labels in the workplace, which fall under the jurisdiction of the Occupational Safety and Health Administration (OSHA) Hazard Communication Standard (HCS).

In one training manual, two paragraphs are dedicated to labels in transportation. The last sentence of the label section states: “Labels are identical to placards, other than their size.” [(1) page 29)] Although placards and labels have many similarities, there are specific intricacies that should be reviewed. Although label colors, numbers, and graphics are similar to those for placards, there are location, placement, and other packaging criteria specific to labels.

49 Code of Federal Regulations (CFR) Parts 100-185 are the hazardous materials and oil transportation regulations. Part 172 addresses hazardous materials communications. Subpart E (172.400) starts the labeling requirements. This volume of the code book includes a hazardous materials table (172.101) that prescribes proper shipping names, assigns product hazard classes, and associated identification numbers. It prescribes the hazard class placard, packing groups, label codes, quantity limitations, and stowage. It also lists special provisions based on mode of transportation. This article is not a comprehensive code review, but instead focuses on basic and common label attributes.

Container Types

In some respects, labeling criteria are more conditional than those for placards. Minimum quantity thresholds apply for both labels and placards. In some instances, labeling requirements are dependent on the mode of transportation. One size certainly does not fit all. The code references package types based on capacity, not necessarily the container material type. The commonly referenced package types include non-bulk, bulk, and portable tanks. Placards apply to bulk packaging, whereas labels generally apply to non-bulk packages.

A non-bulk package contains less than 119 gallons for a liquid (photo 1); a maximum of 882 pounds (or less of the maximum weight of 119 gallons) for a solid (photo 2); or a water capacity of 1,000 pounds for a gas. A bulk package is the greater of the non-bulk thresholds but does not include vessels such as a barge. A portable tank is defined as a bulk package, except a cylinder having less than a 1,000-gallon water capacity loaded onto a transport vehicle with skids, mountings, or other medium to facilitate its handling [(2) page 104]. This does not include a cargo tank, tank car, or a trailer.

(1) 55-gallon drums area a non-bulk package.

(2) Boxes of a powder fungicide are a non-bulk package.

Categories

The nine hazard classes established by federal regulations are the same for both labels and placards. Class 1 represents explosives and is divided into six subdivisions to distinguish detonation characteristics. The lower the subdivision class number, the higher its danger.

Class 2 signifies gases, including three subdivisions that distinguish specific physical hazards. Division 2.1 represents flammable gases like propane and ethylene (photo 3). Division 2.2 indicates a nonflammable gas. Common nonflammable examples include nitrogen and carbon dioxide. Division 2.3 represents poisonous (toxic) gases such as chlorine and phosgene.

(3) Flammable gas cylinder of ethylene.

Class 3 includes flammable and combustible liquids. Although the flash point differentiates flammable versus combustible, there are no hazard class subdivisions.

Class 4 represents flammable solids and contains three subdivisions. Division 4.1 includes solids that are likely to ignite by friction. Examples include aluminum powder and zirconium powder. Division 4.2 is pyrophoric substances that can ignite with contact in air, even without an external ignition source, such as iron oxide. Division 4.3 covers products that become spontaneously flammable or give off flammable or toxic gas when contacted by water. Calcium carbide, for example, produces acetylene gas when wetted.

(4) Buckets of potassium permanganate, an oxidizer, commonly found in wastewater treatment.

Class 5 products are classified as oxidizers (photo 4). A concern with oxidizers is that they yield oxygen in a fire, causing more intense flames. This class is also subdivided: Division 5.1 is an oxidizing agent such as potassium permanganate, often used in wastewater treatment. Division 5.2 represents organic peroxides. These products are known for their fire and explosion hazards and may also be toxic or corrosive.

Class 6 represents poisons. This class has two subdivisions. Division 6.1 represents liquids and solids (slurries and powders) that are known or presumed to cause death through skin absorption, ingestion, or inhalation. Examples include cyanide solids and solutions. Division 6.2 regards infectious microorganisms or toxins that may cause human or animal diseases.

Class 7 represents radioactive products that spontaneously emit ionizing radiation.

Class 8 includes corrosives such as sulfuric acid, hydrochloric acid, and nitric acid. These products will destroy skin, and some have a severe corrosion rate on steel (photo 5).

(5) Corrosive label includes two graphics to reinforce its hazards.

Class 9 covers miscellaneous materials which do not meet the criteria of hazard classes 1 through 8. They do, however, present a hazard during transportation or have anesthetic, noxious properties. Examples of Class 9 materials include molten sulfur and dry ice.

Labeling Criteria

Labeling criteria is not as recognized or as easily defined as placard thresholds. Comprehensive knowledge or interpretation of the 49 CFR Hazardous Material Table (172.101) is necessary for understanding and implementing proper labeling practices. However, it is not practical to study this lengthy table for response strategies and tactics. Firefighters are not shipment enforcers, but interpreters of the information or circumstances presented by the incident.

Generally, a label shall be affixed (dependent on the hazardous material table prescription) to a non-bulk package. There are other conditions that warrant a label, but they are not specifically listed in this article. There are numerous exemptions; however, it is impractical to define and list them in a single article. Some exemptions are conditional. For example, the doctrine exempts labels from a cylinder containing a

division 2.1 (flammable gas), 2.2 (non-flammable gas), or 2.3 (poison/toxic gas) that is not over-packed, or marked in accordance with Compressed Gas Association (CGA) Pamphlet C-7.

There are other small quantity exemptions as well as conditions for other label markings. The purpose of this article is not for you to recite federal code but to enable you to better understand what you are seeing.

Placement

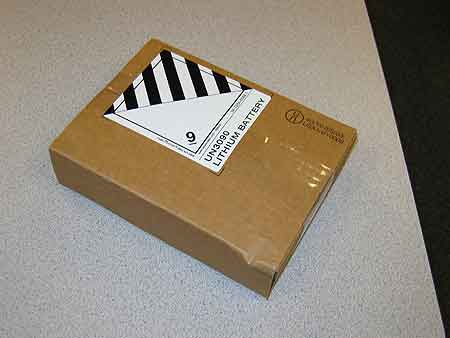

Unlike a placard, which is placed on four sides of the transportation vessel, one label is to be affixed to a package surface other than on the bottom (photo 6). Duplicate labeling is not required except for certain circumstances. However, labels must be displayed on two sides of non-bulk packages containing radioactive material. They must also be displayed on portable tanks with less than 1,000-gallon capacity and on each package or over-pack with a volume of more than 64 cubic feet. The label must contrast with the package background and may not be obscured by other markings or attachments. The regulation allows for a label to be printed on a tag and securely affixed to a cylinder or other irregularly shaped package (photo 7). Depending on the storage practices, the label side of a non-bulk package may not be obvious.

(6) One label is affixed to this non-bulk lithium battery package.

(7) A skid of dimethoate, an insecticide. Because labels are required on one side, stocking practices may hide the label.

Design

The regulations dictate the label specifications, including background and letter coloring. Labels must be at least 3.9 inches on each side and have a solid inner border 0.2 to 0.25 inches from the edge. The size of hazard class numbers and text is also preestablished in the regulations. There are additional hazard class specific labeling criteria.

Labels for explosives vary. On packages containing subdivisions 1.1 through 1.3, the label shall include an orange background, an explosive graphic, a division number, and a hazard class. Explosive labels for subdivisions 1.4 through 1.6 are slightly different. There is no explosive graphic, and the specific subdivision number is printed more prevalent on the top half. A compatibility group letter identifies the kinds of explosives substances and articles which are and are not compatible for transport. This may be included on the label as well as the hazard class.

Hazard class 2 (gases), 3 (liquids), 4 (solids), and 5 (oxidizers) labels for each respective subdivision mimics placard required elements. Although not different in presentation, the 5.2 organic peroxide label (photo 8) on packages, unlike those for over-the-road placards, became mandatory on January 1, 2011. The over-the-road transportation 5.2 placard is not mandatory until January 1, 2014. Class 6 (poisons), except for the color and size, have slight variations. If the product poses an inhalation hazard, that text must be affixed to the center of the label. For other poisons, the word “toxic” or “poison” must be noted in the label center. For those substances deemed an infectious substance, the biohazard symbol and infectious substance text will be affixed to the label.

(8) This chlorine cylinder has a tag affixed to the cylinder to reveal the subsidiary hazard labels.

Class 7, radioactive, includes several labeling formats based on an index of the maximum radiation level emitting at any point on the external surface. The emission of radiation, within specified guidelines, is legal. A Radioactive White I label emits less than a 0.5 mrem/hr at the package surface. The background color is white with black radioactive text. The Roman numeral I will be printed in red. The Radioactive Yellow II label represents emitting levels greater than 0.5 mrem/hr, but less than 50 mrem/hr. The top half background color will be yellow and the bottom half white. The radioactive text will be black and the Roman numeral II will be red. The Radioactive Yellow III label can represent two emitting levels. It will be affixed to a package emitting levels greater than 50 mrem/hr, but less than 200 mrem/hr. The Yellow III label also applies to emitting levels of greater than 200 mrem/hr but less than 1,000 mrem/hr. Such shipments, however, are subject to additional regulations and special handling requirements. On each radioactive label, the classic trefoil graphic is required. [(2) –page 360]

Another associated radioactive label is fissile, which refers to a material that is a fission capable (nuclear reaction) nuclide. A fissile label may be required depending on the material. Primarily this includes uranium-233, uranium-235 and plutonium-239. The fissile label background color is white with black lettering. The hazard class is noted at the bottom corner, and a criticality safety index is provided in the center under the fissile lettering.

Other Labels

Other specific labels may be required such as the ‘”Cargo Aircraft Only” label. This label applies to aircraft used only for transporting cargo. The craft does not engage in carrying passengers. This label is black and orange.

Subsidiary Hazards

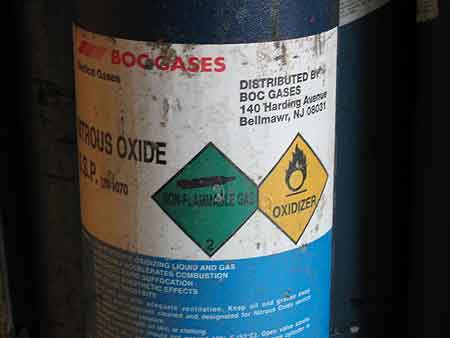

Hazardous materials do not always meet only one of the nine hazard classifications. Some present multiple hazards. The regulations categorize hazardous materials by their primary hazard class. When applicable, the regulation also denotes a subsidiary hazard, or a hazard other than its primary listing. DOT regulations prescribe special label requirements for specific products that present a primary and a subsidiary hazard. When required, the labels must be displayed next to each other. Compressed carbon monoxide is a primary hazard class 2.3 (poisonous/toxic gas) with a subsidiary hazard of flammable gas (2.1) (photo 9). Nitrous oxide also is a primary hazard class 2.2 (non-flammable gas) with a subsidiary hazard of oxidizer (photo 10). The example at photo 8 shows an explosive subsidiary hazard. Label formats typically do not include the product’s four-digit identification number. This can be challenging when the product is not readily identifiable. Effective incident management requires comprehensive research on the physical and chemical hazards and characteristics for which appropriate actions can be taken.

(9) This new style organic peroxide label became effective for packages on January 1, 2011.

(10) A carbon monoxide cylinder with primary and subsidiary labels attached. Note the condition of the flammable label.

Packing Groups

Another placard and label caveat packing groups. Packing groups are applicable to all hazard classes except 4 (solids), 5 (oxidizers), and 7 (radioactive). The groups are based on respective flash

points, boiling points, and toxicity. A purpose of these groups is to differentiate the degree of hazard as well as prescribe to the transporter certain protective packaging methodologies.

For flammable liquids, packing group I represents liquids with a boiling point less than or equal to 95º Fahrenheit (F). Packing group II represent liquids with flash points less than or equal to 73º F and boiling points greater than 95º F. Packing group III represents liquids with flash points above 73º F and boiling points above 95 º F. [(1) – page 20]

Specific groups for toxic/poisonous gases are delineated by Hazard Zones, which contain categories that run A through D. They define the lethal concentration measured in parts per million (ppm). The lethal concentration 50 (LC50) means death results to 50 percent of the exposed population. For Hazard Zone A, the LC50 is less than or equal to 200 ppm. Hazard Zone B is greater than 200 ppm but less than 1,000 ppm. Hazard Zone C represents concentrations between 1,000 and 3,000 ppm. For Hazard Zone D, the LC50 is between 3,000 and 5,000 ppm. [(3) page 360] The respective hazard zone can be found on a material safety data sheet (MSDS) or safety data sheet (SDS) in the toxicological section and/or the transport information section. The hazard zone level may be found on other markings such as above the subsidiary hazard at photo 11.

(11) A nitrous oxide cylinder with primary and subsidiary labels of nonflammable and oxidizer, respectively.

(12) “Hazard Zone B“ is noted on the tag above the subsidiary hazard.

For solid and liquid poisons (Division 6.1), lethality is defined as Lethal Dose 50 (LD50) and measured in milligrams per kilograms (mg/kg). There are oral, dermal, and inhalation values for each Division 6.1 packing group. For the purpose of reviewing its criteria, oral toxicity packing group I is less than or equal to 5 mg/kg, and packing group II is greater than 5 mg/kg but less than or equal to 200 mg/kg. Packing group III addresses solids and liquids. For solids, packing group III represents greater than 50 mg/kg and less than or equal to 200 mg/kg. For liquids the values are greater than 50 mg/kg and greater than or equal to 500 mg/kg. [(1) – page 20], packing group information can be found on shipping papers, on the MSDS, and, in some cases, printed on the placard or label.

It certainly is not practical to memorize the packing group parameters, but it is important to recognize there is significance and know the resources that define the hazard group parameters. Also be aware that there is more to labels that what has been noted above.

***

Awareness of a potential hazardous material incident is the first line of defense. That defense starts with effective identification size-up. Recognition of placards and labels is a basic competency for all response levels, but basic does not mean easy. Package labels present many caveats, and some of their nuances may not be readily recognized or understood. This article is not intended to make you an administrator of these regulations but to help you to understand that labels are not identical to placards. Being cautious and safe at a potential hazardous material incident goes without saying, but it is also important to be thorough. For more information and graphical examples of labels, visit the U.S Department of Transportation Pipeline and Hazardous Materials Safety Administration Web site at http://phmsa.dot.gov/hazmat .

AUTHOR NOTE: Label format, content, and graphics that fall under the OSHA HCS will be changing. OSHA has adopted elements of the Globally Harmonized System (GHS) for workplace hazard communication. The GHS is an international effort that began in 1992 to standardize workplace hazardous chemical labels and information documents. The term MSDS has been a mainstay in emergency service hazardous material training. The GHS elements pertaining to these documents will change their name to safety data sheet (SDS).

The adopted GHS elements, including references to SDS, are in effect as of May 25, 2012. This does not mean that MSDS will automatically be known as SDS: When an MSDS is reauthored to comply with content criteria, the SDS reference goes into effect. There are, however, compliance date benchmarks. An overview of the GHS and how it affects the emergency services will be offered in another article.

Eric G. Bachman, CFPS, a 29-year-veteran of the fire service, is former fire chief of the Eden Volunteer Fire/Rescue Department in Lancaster County, Pennsylvania. He is the hazardous materials administrator for the County of Lancaster Emergency Management Agency and serves on the local emergency planning committee of Lancaster County. He is registered with the National Board on Fire Service Professional Qualifications as a fire officer IV, fire instructor III, hazardous materials technician, and hazardous materials incident commander. He has an associate degree in fire science and earned professional certification in emergency management through the state of Pennsylvania. He is also a volunteer firefighter with the West Hempfield (PA) Fire & Rescue Company.

Endnotes

- Hazardous Materials Handbook Awareness & Operations Level, Delmar Cengage Learning, 2008.

- 49 CFR, Parts 100 to 185, revised as of October 1, 2010.

- 2008 Emergency Response Guidebook