BY JEREMY A. KELLER

Farms and other agricultural occupancies have always been challenging emergency response environments. Every farm is a unique and proprietary operation with an array of potential hazards and risks. Typical farming operations present a multitude of fire, rescue, and chemical hazards, yet these facilities are generally exempt from the hazardous materials, fire prevention, and occupational safety and health requirements that apply to industrial facilities. Commercial agriculture trends over the past several decades have resulted in significant changes in the composition and operation of many farms that have made for an even more challenging environment.

Although there is no definitive standard for what constitutes a target hazard, the term is generally understood to mean any facility that, during an emergency incident, poses an exceptional risk to life safety, property, the environment, or the economic well-being of the community. Incidents at such facilities may also be expected to present a complex management challenge, have the potential to overwhelm local emergency response forces, or require atypical technical skills during response operations. Eric Bachman, hazardous materials administrator for the County of Lancaster (PA) Emergency Management Agency, sums up what constitutes a target hazard: “If it can catch fire, release, or contain a hazardous material; affect the environment; collapse; or harm your firefighters, it is a target hazard. If it will overwhelm your resources, expose your limitations, or exploit a deficiency, it is a target hazard.”1

Modern farming operations readily meet all of Bachman’s considerations for a target hazard in a rural community. A fire, an entrapment, or a chemical spill on a farm can rapidly become a complex and overwhelming challenge for rural departments. In a volunteer-based organization, funding and staff restrictions often make it impossible to maintain the technical skills needed to safely and effectively respond to the range of hazards presented by even a small family farm. The hazardous nature of farm operations, combined with their potential for complex response and widespread community impact, mean that rural departments should be thinking of the modern farm as a target hazard and plan accordingly.

A modern farming operation consists of three basic components: land, equipment, and facilities. Most prominent of these components is the land, which may be fewer than 100 acres for a small farm but may range into the tens of thousands of acres for ranches or large grain operations. The sheer size of the land holdings involved can create challenges, particularly when trauma or medical patients are far from public roads. All farm operations also feature one or more administrative and maintenance headquarter areas, or farmsteads. They are areas where agricultural support facilities are concentrated: barns, silos, grain bins, storage sheds, machine shops, and often residential structures. When not actively in use, much of a farm’s mobile equipment-tractors, combines, and other rolling stock-can also be found here. Although these structures are co-located to support operational efficiency and convenience, it also serves to concentrate many of the most serious farm hazards in a central location. These farmstead areas-the equipment and facilities component of a farming operation-are the focus of this article.

BIG CHANGES DOWN ON THE FARM

Global market forces have driven sweeping changes in agricultural operations in the past several decades, and these impacts are felt even on small, family-owned farms. The U.S. Department of Agriculture (USDA) National Census of Agriculture reveals many trends about farm operations, acreage, and demographics that are of direct interest to those seeking to characterize the potential hazards associated with agricultural operations in their communities.2 Some of the major trends seen in the 2012 (the most recent) agriculture census include the following:

- Consolidation of farming operations. There was a statistically significant decrease of 4.3 percent in the number of farms nationally from 2007 to 2012, continuing a decades-long decline. At the same time, the average farm size increased by 3.8 percent while the numbers of mid-sized farms (10-1,000 acres) declined significantly. For larger farming operations, concentration is the rule. In 2002, 75 percent of U.S. agricultural value was produced by 144,000 farms, but by 2007 the same value was produced by 125,000 farms-a 13 percent decrease over a five-year period. True production agriculture operations continue to grow in size, a phenomenon driven by market forces, facilitated by technological advances, and made inevitable by a younger generation that is less interested in taking over the family farm and taking up farming as an occupation.

- Increased on-farm storage of grain. The value of grain crops, particularly corn, has grown dramatically in the past decade, driven by global food demand and domestic ethanol production for gasoline blending. The value of grain sales nearly doubled between 2002 and 2007 and spiked to unprecedented levels during the 2012 Midwest drought. High grain prices have made it increasingly lucrative for farms to market their grain individually rather than flooding markets at harvest time and depressing prices, resulting in increased demand for high-capacity grain bins for on-farm drying and storage.3 Grain bins of up to 100,000-bushel capacity, a size once found only at community grain elevators, have begun appearing on farms (photo 1). Although the 2007 agriculture census showed a 10.8 percent decrease in the number of farms with on-site grain storage bins, the USDA estimates that between 2003 and 2012, total on-farm grain storage capacity increased by 17.5 percent nationally. During the same period, the on-site storage capacity of the average farm increased by 15.2 percent, reflecting the move toward larger bin sizes and the abandonment of older, low-capacity bins.

- An aging farm workforce. The average age of farm operators has been increasing for the past several decades, a trend that is readily apparent in the agriculture census. The average age of a farm operator in 1978 was 50.3 years. By 2012, the average age had increased to 58.3, with 33 percent now estimated to be over the age of 65, up 7 percent since 2007. This demographic trend has multiple implications for rural emergency services. One potential impact that may not be obvious is that these older farmers will be less able to participate in volunteer fire departments and emergency medical service (EMS) squads, depriving the rural emergency response community of their technical expertise regarding agricultural operations.

- Enduring hazards and risks. The big changes described above are overlaid on enduring features of agricultural operations that have always made them a complex hazard environment. Most farms are family-run small businesses, and the unique status of farming as an American cultural touchstone has resulted in these farms being exempt from many safety and environmental regulations that apply to other similar industries. Because of this, there is little consistency in safety standards, preventive measures, or emergency planning efforts from one farm to the next.

|

| (1) An on-farm, grain-drying and storage complex with several large-capacity grain bins (Ross County, Ohio). (Photos by author.) |

Farming is a hazardous occupation by any measure. In 2011, the U.S. Bureau of Labor Statistics (BLS) reported that from 2003 to 2011, an average of 468 fatal workplace injuries occurred on farms each year.4 BLS also estimates the fatal workplace injury rate for farmers and ranchers to be 25.4 per 100,000. This compares to an overall national average rate of 3.5, ranking agricultural work in the top 10 most dangerous occupations.5 Farmers have been shown to be aware that they work in a high-risk profession, yet proven safety practices are often not implemented because of complacency or time and economic pressures.6-8

Many farming operations, because they fall below minimum employee thresholds and are often family operated, are largely exempt from workplace occupational safety and health regulations governing age restrictions, preventive measures, and injury reporting.9 Preventive farm safety programs are driven by public education programs; the voluntary adoption of best practices is left up to each individual farm operator. In several studies, farmers have been found to be well aware of recommended safety practices through these educational efforts, yet they have failed to adopt them in many cases, citing economic concerns, time pressures, distrust of the government and industry groups promoting the practices, and the difficulty of breaking bad habits. (8)10

Farming families generally treasure their way of life, and the farm workforce will involve all generations of the family. Expect to find both the very old and the very young engaged in potentially dangerous farm work. Farm children often receive on-the-job training in equipment operation and may be found operating heavy machinery as young as age 12.11 On the other end of the spectrum, expect to see older farmers continuing to work well past retirement age, often into their 70s and 80s.12 Driven to keep working by economic necessity and a sense of pride, these older farm workers experience fatal traumatic injuries at rates two to three times greater than those under age 55.13

Agricultural enterprises are subject to the boom-bust nature of the commodity markets. As such, capital improvements and investments in major equipment items are only possible during profitable periods. On many farms, expect to see older machinery and facilities in service next to modern equivalents. Farm buildings are an excellent example of this. New barns, sheds, and grain bins are often added adjacent to older structures, and old structures may be kept in service long past a reasonable service life. In spite of appearances, dilapidated, apparently derelict structures may well still be in active service (photo 2). Residential structures are often in close proximity to outbuildings. Spacing of structures, especially the older ones, will likely have been done with convenience and operational efficiency in mind rather than exposure protection.

|

| (2) This barn, an obvious collapse hazard, remains in active service on a small farm (Hardin County, Ohio). |

FARMS AS TARGET HAZARDS

Rural fire and EMS organizations should think of agricultural operations as target hazards and plan accordingly because of the following combination of factors.

- Concentration of hazards: Farms are essentially weakly regulated industrial facilities. Each farm harbors a variety of potential hazards, yet the safety and reporting requirements binding other industrial facilities do not apply to farming operations.

- Potential impact to the community: Agriculture is the primary economic driver for many rural communities, and most farms are family-run operations. A fatality or serious injury to a farm operator can have serious economic consequences for the family, and effects will ripple through the broader community. The emotional impacts of such events in tight-knit rural communities can be severe.14

- Potential impact to the department: Not only are complex rescue incidents and fires at agricultural occupancies likely to overwhelm small rural departments, these incidents also pose a substantial risk to the department’s reputation in the community. Incidents on farms are likely to be highly charged, emotional events for the family, neighbors, and other members of the community. If the farming community suspects that the department was unprepared for the incident or perceives that a response was mishandled, there can be serious political consequences, particularly when funding levies are up for voter approval.

Although there are numerous hazards to consider for any farm operation, the following items have been identified as common sources of serious injuries and fatalities. They are also hazards that are most likely to present a serious challenge to many rural emergency services organizations.

Grain Storage Bins

Although often mistakenly called “silos” by those not familiar with agricultural operations, grain bins are a distinct farm structure with their own unique purpose and hazard characteristics. Grain bins are designed for the long-term, on-farm storage of dried grain products, most commonly corn, soybeans, and wheat. Some grain bins are also equipped with drying and aeration apparatus. Grain bins are easily distinguished from other agricultural structures by their appearance: hulking cylindrical structures made of standardized corrugated steel panels (photo 3). On-farm grain bins have grown in both number and size in recent years in response to increases in grain commodity prices.

|

| (3) A large grain bin complex with numerous technical rescue exposures (Madison County, Ohio). |

The most common hazard associated with grain bins is the entrapment and engulfment of farm workers in flowing grain. Workers may enter bins during the unloading process to break up crusted grain and become trapped when undetected voids collapse, crusted walls of grain collapse, or unloading augers are inadvertently started by other workers. True engulfment incidents, wherein the victim is entirely submerged in grain, are rarely survivable. These incidents are entirely preventable through use of harnesses and recommended safety procedures. (7)15

Grain bin sizes are defined in terms of their bushel capacity. A bushel in the United States is roughly 1.25 cubic feet, but in practice bushels are defined by the weight of a given grain at a standard moisture content. Corn, for example, has a standard bushel weight of 56 pounds at 15.5 percent moisture content. The different bushel capacities are achieved by varying the diameter, height, and panel strength of the bin.

While on-farm grain bins have tended to become larger in terms of bushel capacity over time, they have also become safer. With increased awareness of the hazards associated with grain bins, newer designs feature built-in safety features that help to reduce the chances of entrapments and engulfments, such as shielded augers, tie-off points for safety harnesses, and larger access hatches. Bushel capacity is a factor to consider as well. Bins with a 20,000-bushel capacity and below (i.e., smaller bins) were found to produce half of all recorded fatalities. (15) Bins in smaller capacity ranges tend to be older and so lack the built-in safety features of newer models (photo 4). Smaller, older bins are also more prone to grain spoilage, leading to entry by farm workers to break up clumping, exposing them to potential entrapment.

|

| (4) Small access hatches and poorly designed ladders complicate rescues on old, low-capacity grain drying bins such as these (Madison County, Ohio). |

A grain bin entrapment can quickly become an overwhelming incident for a small rural department. Grain bin rescue requires specialized skills and equipment that are out of reach for many rural departments. Technical rescue mutual-aid resources are often some distance away. Although most such incidents involve only a single victim, an on-farm grain bin entrapment is likely to be a high-profile event in a rural community, requiring considerable effort to effectively manage the incident.16 These incidents are likely to involve a multiagency response and may require large numbers of personnel: Some incidents have involved more than 40 emergency responders. Expect these incidents to be long in duration and to draw in large numbers of family and neighbors as spontaneous volunteers.

Agricultural Silos

True silos in the agricultural setting are designed for the storage and conditioning of silage-high-moisture-content fresh plant material for livestock consumption (commonly dairy cattle) during winter months. Storage of plant material in a moist, acidic environment with limited oxygen creates a nutrient-rich feed for livestock through a fermentation process similar to the production of coleslaw.17 Silos are closely associated with livestock operations, although many derelict silos remain on farms that have transitioned to a grain-only operation.

There are three basic types of agricultural silos: tower, bunker, and horizontal bag. Each of these designs serves the same purpose of storing high-quality livestock feed, and all pose the same confined-space risks because of the buildup of silo gases and the creation of oxygen-limited atmospheres. Bunker or trench silos are belowground designs, wherein silage is packed into sealed pits. Horizontal bag silos-“ag bags”-are a more recent innovation wherein silage is packed into long, large-diameter plastic tubes. Bag silos are disposable and are placed as needed in locations convenient to livestock feeding. Tower silos, cylindrical structures that are tall relative to their diameter, are the most familiar silo design (photo 5).

|

| (5) A farm with four tower silos of different designs and capacities (Union County, Ohio). |

Tower silos may be constructed of cast concrete, prefabricated concrete panels, or steel. Obsolete tower silos constructed of stone, masonry block, or wood are also sometimes encountered. Tower silos pose fire, explosion, and confined space hazards. Their height and associated material handling equipment also make them a potential technical rescue risk.18 Tower silos, especially very old ones, also pose a risk of collapse when their structural integrity is compromised. Modifications made to tower silos over their long service lives can alter the performance of these structures in unpredictable ways during fires and rescue operations.

ON-FARM MANURE STORAGE

Livestock operations are required to have on-farm storage for the manure produced by their animals to manage water quality impacts. In large concentrated animal-feeding operations, the amounts of manure can be considerable. The manure is stored until weather conditions allow for it to be sold and spread as a fertilizer on agricultural fields. Poultry operations generally produce friable manure referred to as “poultry litter,” which is commonly stored and composted in large stockpiles. Cattle and swine operations produce large volumes of liquid manure that may be stored in three basic ways: storage tanks below livestock housing areas, in open lagoons or ponds (Figure 1), or in aboveground silo-type structures.19 Up to several million gallons of liquid manure may be stored on an individual farm.

| Figure 1. Dairy Operation Aerial View |

|

| Figure 1. An aerial view of a dairy operation showing the associate manure storage lagoon (Champaign County, Ohio). (Aerial image source: State of Ohio, 2007.) |

Large volumes of manure, regardless of the storage medium, pose a confined space hazard to farm workers and emergency responders. Decomposition of manure produces the gases ammonia, carbon dioxide, hydrogen sulfide, and methane, each of which can be hazardous in its own right; they also create an oxygen-depleted atmosphere. Manure storage-related incidents commonly involve the asphyxiation or drowning of workers who enter confined spaces without following recommended safety practices. (19) These incidents can become compounded by well-intentioned rescue attempts by other unprotected workers, creating multiple-casualty events. Even the open areas around outdoor manure storage lagoons can become de facto confined spaces. Under the right weather conditions, high-vapor-density toxic gases can accumulate in the areas around lagoons, displacing oxygen and creating a deadly atmosphere in an apparently benign location.

OTHER CONSIDERATIONS

Access and mobility concerns. Farmstead areas are generally located near public roadways to facilitate operations, but they may be located at the end of long driveways. These driveways are designed with farm operations, not emergency response, in mind; as such, they tend to be narrow and dirt- or gravel-surfaced. Bridges on farm roads are often built on the cheap and without proper engineering plans and may not be adequate to allow safe passage of emergency apparatus (photo 6).

|

| (6) This farm bridge looks solid, but would you trust it to support your fire apparatus (Hardin County, Ohio)? |

Barns and machine shops. Farmsteads generally have one or more barns or other large buildings on site to support agricultural operations. These utilitarian structures can be a real Pandora’s Box of hazards for responding crews, and responders should not become complacent when operating around them (photo 7). Barns vary widely in construction, may be extremely old, and are often filled with large amounts of combustibles. They may also house considerable quantities of hazardous materials with no outside indications of the contents. Machine shops, storage sheds, and other support buildings are also often found at farmsteads; they vary greatly in terms of contents and fire resistance.

|

| (7) Complacency can lead to disaster: SCBA must be used and collapse zones respected even when it is “just” a barn fire (Logan County, Ohio). |

Agricultural hazardous material. Modern farming operations make use of a large number and a large volume of agricultural chemicals in the form of fertilizers and pesticides. Additional hazardous materials likely to be found on farms include large quantities of gasoline, diesel, and propane, as well as maintenance-related chemicals such as oils, greases, and paints. Quantities stored on farms often fall below the thresholds necessary to trigger mandatory hazardous materials reporting. Because of this, significant quantities of hazardous chemicals may be stored on site without any planning data available to public safety forces. While a farm’s 1,000-gallon diesel tank may fall below the U.S. Environmental Protection Agency (EPA) reporting threshold of 1,320 gallons20, this tank may be of great interest to responding crews during an emergency incident. Farm operators can be reluctant to voluntarily share specifics regarding on-site chemicals for fear of governmental regulation or theft or to maintain proprietary secrecy; consequently, they may regard requests for information with suspicion.

Livestock. Large animals, cattle in particular, pose a safety risk to farm workers and emergency responders. Many farms will have some livestock on site. Some farms may have only a handful of animals, and others may have large numbers of cattle, sheep, horses, swine, or poultry. Swine and poultry are often housed in confined feeding facilities, distinctive long, low structures with feed hoppers at the ends (photo 8). Larger grazing animals such as cattle and sheep will generally spend some time in pasture areas. Livestock represent a major capital investment and may require protective evacuation during fires and other emergencies, requiring careful planning beforehand.

|

| (8) Feed hoppers are evident in this high-capacity hog barn operation (Hardin County, Ohio). |

Exposure issues. Structures are generally added to farmsteads piecemeal over time as needs and financial constraints dictate. Property layout is often governed more by convenience than fire safety considerations. Farmsteads contain a mix of barns, utility buildings, grain bins, silos, and residential structures all in close proximity, potentially presenting serious and multiple exposure issues during fire, explosion, and hazardous materials incidents. Technical rescue operations may also be complicated by the crowded arrangement of many farmsteads, limiting work space and complicating scene access and lighting.

Open storage. Farm operators have a reputation for being reluctant to part with items; with plenty of available storage space, expect to find areas where “good stuff” is kept in “open storage.” Items that are typically retained far beyond their useful service life in hopes of eventual repair may include farm implements and machinery, construction equipment, and trucks. Be alert for neglected open storage areas that are overrun with weeds and brush, as they can pose entrapment hazards, especially in the case of fires spreading into these areas.

PREINCIDENT PLANNING

Identify agricultural occupancies within your response area, and note their specific hazards in plans. You can collect location data for each hazardous feature using a global positioning system (GPS) unit or by estimating from aerial photography. Consider collecting as much of the following additional information as possible for each of the common hazards discussed above:

- Grain bins: bushel capacity, diameter, height (eave and peak), access characteristics, loading/unloading machinery, aeration and drying machinery, and integral safety features.

- Agricultural silos: height, diameter, access characteristics, function, loading/unloading machinery, construction type, structural integrity, operational status, and known modifications.

- Manure storage: storage design (tank, pit, lagoon); capacity, safety features, and access.

- Hazardous materials: identity and quantities of chemicals stored on site, seasonality (some chemicals, such as anhydrous ammonia, are only stored seasonally), security measures, containment measures, and potential downwind/downstream exposures.

- Livestock: type of animals on site (cattle, sheep, swine, poultry, and so on), number of animals, location of animal housing buildings, quality of fencing and gates, and points of contact to manage animals and conduct potential livestock evacuations.

Aerial imagery can be very helpful in planning for emergency response to farmsteads. High-quality aerial photos can be used as an initial reconnaissance tool to identify those agricultural occupancies with the highest concentrations of potential hazards. You can then prioritize individual occupancies for more intensive, on-site hazard surveys.

Farm operators may be reluctant to permit extensive access to their property for preincident surveys and may be under no legal obligation to do so. Such reluctance may stem from a fear of regulatory interference, worries about theft, or simply out of a strong desire for privacy. Planning efforts in rural areas will benefit greatly from partnerships with trusted members of the local agricultural community. Extension agents, the local conservation district, and the local Farm Bureau office can be helpful partners in your efforts and can help you make your case with local farm operators.

Another potential source of assistance in your planning efforts is the Future Farmers of America (FFA). Nationally, the FFA sponsors the Saving Area Farms Effectively (SAFE) program, an effort that equips local FFA chapters with GPS units and mapping software and trains members to collect hazard information on farming operations. Participation in SAFE is on a chapter-by-chapter basis, so you will have to contact your local chapter to see if they can assist you.

Farming families can often benefit from first aid and cardiopulmonary resuscitation skills; providing training on these topics for local farm families may represent a means of building trust and demonstrating good will. Consider offering these classes at no cost in locations and at times that are convenient for farm workers and their families as a way of making connections in the local farming community.

Finally, the preincident planning process will likely reveal that most rural emergency services organizations are not capable of handling the potential agricultural hazards in their area alone. Review mutual-aid arrangements with neighbors in light of the planning outcomes. Identify your regional technical rescue, hazardous materials, and other specialty teams, and ensure that you understand the procedures for requesting these resources and the time lag that may be involved. Contact commercial grain elevator manufacturers in your area for potential mutual-aid partners and technical experts. Many of these facilities have access to technical rescue resources and may even have trained staff and equipment on site.

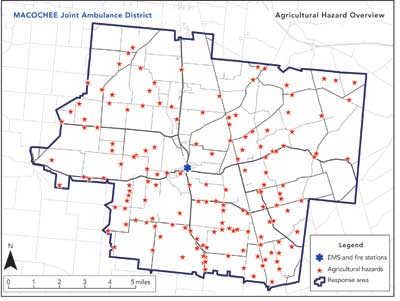

CASE STUDY: AGRICULTURAL HAZARDS SURVEY

The Macochee Joint Ambulance District is a small EMS provider in rural west-central Ohio. It provides emergency medical response to the Village of West Liberty and all or parts of five surrounding townships in Logan and Champaign Counties. The district covers a response area of 89.3 square miles and protects a population of approximately 6,400. The district staffs one advanced life support (ALS) ambulance on a 24/7 basis and has an additional reserve ALS ambulance staffed by paid-on-call crews. Macochee EMS and its sister agency, the West Liberty Fire Department, respond to rescue incidents within their shared coverage areas, although neither agency is trained or equipped to provide more than basic technical rescue capabilities or hazardous materials response.

Operating in a rural area with significant farming activity and a high potential for farm-related emergencies, we began a process of preincident planning for the numerous agricultural occupancies in our coverage area. Although it was understood that the district had a high exposure to agricultural emergencies, a lack of information on the scope of the problem made even basic response planning impossible. To begin addressing this critical knowledge gap, an agricultural hazard assessment process was initiated to gather information, prioritize sites for preincident planning, and identify mitigation strategies.

The first phase of the preincident planning process was a “big picture” survey of the agricultural hazards in our response area. The goal of this survey was to determine the overall number of agricultural occupancies, their locations, and the specific hazards present at each site. This survey was accomplished using geospatial information system (GIS) tools to analyze aerial imagery of the district. Farming operations have distinctive visual signatures on aerial imagery, and using a GIS-based approached allowed us to rapidly canvass our response area for potential agricultural hazard sites.

We used a combination of low- and high-resolution imagery to locate farming operations and identify potentially hazardous structures, specifically grain bins, silos, large barns and storage buildings, chemical storage areas, evidence of livestock, and manure lagoons. Low-resolution (one-meter) imagery was used to conduct a broad-area initial survey using a one-half-mile search grid. Use of low-resolution imagery in the initial search minimized delays in processing and display refreshing that would be experienced with higher-resolution imagery. Once a candidate property was identified on the low-resolution imagery, a more detailed assessment was conducted using high-resolution (one-foot) imagery, which allowed the identification of the specific structures of interest listed above. Once likely agricultural hazards are located on aerial imagery, knowledge of the facility can be refined through a combination of ground-level imagery, on-site surveys, and local knowledge.

There are many potential sources of quality aerial imagery available for use in the preincident planning process. The resolution, currency, and cost of available imagery will vary depending on your geographic location. In our case, we were able to take advantage of two no-cost, public domain sources. Our low-resolution imagery was downloaded from the National Agricultural Imagery Program (NAIP) of the USDA. NAIP imagery has a resolution of one meter, is in full color, and is collected on an annual or biannual basis during the peak growing season for most of the continental United States. The most current NAIP imagery for our area was collected in autumn 2011. We also made use of imagery from the Ohio State Imagery Program (OSIP), a project that collected high-resolution, leaf-off imagery across the entire state in 2006-2007. OSIP imagery for our area was collected at a one-foot resolution during the early spring of 2006 and 2007.

Our areawide assessment revealed a total of 151 agricultural occupancies within our response area (Figure 2), broken down as follows:

- Two commercial grain elevator facilities.

- Two agricultural chemical facilities (anhydrous ammonia distribution sites).

- One concentrated animal feeding operation (CAFO).

- 16 major grain bin complexes.

- 65 farms with large livestock operations.

- 58 small, noncomplex farms.

- Two small, standalone grain bin sites.

- Six derelict farms.

| Figure 2. Agricultural Occupancies-Macochee EMS Response Area |

|

| Figure 2. The distribution of the 151 agricultural occupancies in the Macochee EMS response area, as identified by the author using aerial imagery. (Map graphic by author.) |

Although we were aware that there were a large number of agricultural occupancies in our response area, the number of sites identified in our wide area survey was much larger than anticipated. Within the identified sites, the following specific hazards were identified using high-resolution imagery:

- 245 grain bins (all sizes).

- 160 tower silos (active and derelict).

- 418 barns and other large buildings.

- Eight large chemical storage areas.

- 10 open manure storage lagoons.

Another aspect of our area’s agricultural occupancies studied during the initial assessment was access. Using GIS tools, we were able to estimate the length of access roads for all of the identified sites. The average access road length was 570 feet, consistent with the need for farming operations to be near public roadways for logistical reasons. There were several outliers, however: 27 sites have access roads exceeding 1,000 feet, including one farmstead 4,300 feet from the closest roadway.

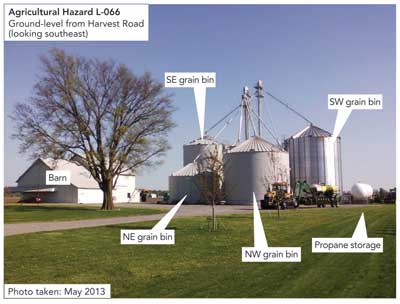

This initial agricultural hazard assessment, making use of GIS tools, provided valuable preincident planning data at minimal cost and with limited staff time. With the overall scope of the hazard defined and locations identified, specific sites can be prioritized for more intense planning, including on-site surveys. Annotated imagery products will be worked up for high-priority hazard sites (Figure 3), supplemented with annotated handheld imagery (Figure 4) to support potential incident operations. Clean, non-annotated imagery for each site will also be provided as part of the target hazard planning package.

| Figure 3. Grain Bin Complex Aerial View |

|

| Figure 3. An example of an aerial image annotated to support preincident planning for a grain bin complex in Logan County, Ohio. (Aerial image source: State of Ohio, 2006; names and addresses changed to protect landowner privacy.) |

| Figure 4. Grain Bin Complex Ground View |

|

| Figure 4. Annotated image taken at ground level to support preincident planning for the facility in Figure 3. The image was taken from the A/D corner of the property. |

Most rural communities have some exposure to agricultural hazards, and the degree of exposure may be much more than anticipated by the public safety forces charged with protecting these communities. Emergency responses to agricultural occupancies have the potential to rapidly escalate into major incidents for rural departments for a variety of reasons, outstripping the capacity of many organizations and their local mutual-aid partners. For these reasons, rural emergency services organizations should consider modern agricultural operations to be target hazards and devote commensurate preincident planning effort to these facilities.

GIS and remote sensing tools can greatly facilitate the preincident planning process, and this is especially true for agricultural hazards. There are a number of high-quality aerial imagery sources available to assist in the planning effort, and many of them are in the public domain and available without cost. Departments lacking in-house GIS capabilities would be well served to develop them, but developing meaningful partnerships with GIS-capable agencies may be an effective alternative. Many conservation and agricultural agencies have significant GIS capability and may be interested in supporting efforts aimed at improving the safety of farming operations in their jurisdictions.

Although GIS tools may facilitate the planning process and rapidly generate baseline information, on-the-ground follow-up will always be required to develop a true understanding of the hazards that may be faced at a given agricultural occupancy. Emergency responders in the rural setting should be prepared to visit local farm operations to collect detailed information to flesh out GIS-derived products and to support safe and effective emergency incident operations.

Most of all, emergency responders in rural communities must always treat agricultural hazards with a healthy respect. Complacency can easily take root in rural departments, but a “typical” response to a local farm can quickly turn into a major incident because of the array of hazards present at many of these facilities.

Author’s note: Thanks to Terri Gravatt, Union County (OH) Soil and Water Conservation District, and Eric Yoder, former assistant chief of the Macochee Joint Ambulance District, for their insights and perspectives regarding family farming operations.

ENDNOTES

1. Bachman, Eric G. (2004), “Preplanning Utility Target Hazards,” Fire Engineering 157(11):95-96.

2. National Agricultural Statistics Service (NASS), U.S. Department of Agriculture (dynamic site). Data and Statistics Web Portal. Web Link: http://www.nass.usda.gov/Data_and_Statistics/index.asp.

3. Masterson, Kathleen (2012). “Farmers Buy Grain Bins to Play the Commodities Market.” Harvest Public Media. Online article: Feb 6, 2012. Web Link: http://harvestpublicmedia.org/article/1005/farmers-buy-grain-bins-play-commodities-market/5.

4. U.S. Department of Labor, Bureau of Labor Statistics (2012). “Census of Fatal Occupational Injuries, All-Worker Profile: 2003-2011.” Web Link: stats.bls.gov/iif/oshwc/cfoi/all_worker.pdf.

5. U.S. Department of Labor, Bureau of Labor Statistics (2012). “Occupations with High Fatal Work Injury Rates, 2011.” Web Link: stats.bls.gov/iif/oshwc/cfoi/cfch0010.pdf.

6. Pate, M.L. and A.S. Merryweather (2012). “Utah Farm Owner/Operators’ Safety Practices and Risk Awareness Regarding Confined Space Work in Agriculture.” Journal of Agricultural Safety and Health 18(4)273-284.

7. Kingman, Douglas M., Gail R. DeBoy, and William E. Field (2003). “Contributing Factors to Engulfments in On-Farm Grain Storage Bins.” Journal of Agromedicine 9(1):39-63.

8. Hall, Alan (2007). “Restructuring, Environmentalism and the Problem of Farm Safety.” Sociologia Ruralis 47(4):343-368.

9. Berkes, Howard and Jim Morris (2013). “Should Grain Bins on Farms be Regulated, Too?” National Public Radio. Online transcript of story broadcast March 24, 2013. Web Link: http://www.npr.org/2013/03/24/175052055/should-grain-bins-on-farms-be-regulated-too.

10. Neufeld, Steven J. and Jennifer L. Cinnamon (2004). “Farm Parents’ Attitudes Towards Farm Safety Experts.” Rural Sociology 69(4):532-551.

11. Neufeld, Steven, Sue Marie Wright, and Jolene Gaul (2002). “Not Raising a ‘Bubble Kid’: Farm Parents’ Attitudes and Practices Regarding the Employment, Training and Supervision of Their Children.” The Journal of Rural Health 18(1):57-66.

12. Mitchell, Jim, Don Bradley, Jim Wilson, and R. Turner Goins (2008). “The Aging Farm Population and Rural Aging Research.” Journal of Agromedicine 13(2):95-109.

13. Fiedler, Douglas, Susanna Von Essen, David Morgan, Robert Grisso, Keith Mueller, and Catherine Eberle (1998). “Causes of Fatalities in Older Farmers vs. Perception of Risk. ” Journal of Agromedicine 5(3):13-22.

14. Scheerer, A. and V. Brandt (2001). “Interviews with Widows Following Fatal Farming Incidents.” Journal of Agricultural Safety and Health 7(2):75-87.

15. Roberts, M.J., G.R. Deboy, W.E. Field and D.E. Maier (2011). “Summary of Prior Grain Entrapment Rescue Strategies.” Journal of Agricultural Safety and Health 17(4):303-325.

16. Berkes, Howard (2013). “Why Grain Storage Bin Rescues are Risky and Complex.” National Public Radio. Online transcript of story broadcast March 28, 2013. Web Link: http://www.npr.org/2013/03/28/175541626/why-grain-storage-bin-rescues-are-risky-and-complex.

17. Beedle, Peggy Lee (2001). “Silos: An Agricultural Success Story.” University of Wisconsin Agricultural Extension Publication G3660-4. Web Link: http://learningstore.uwex.edu/Assets/pdfs/G3660-04.pdf.

18. Halpin, Ted (2010). “A Different Animal: Agricultural Silo Fires Present Unique Challenges and Dangers to Firefighters.” Fire Chief 54(10):30-36 (September 2010). Web Link: http://firechief.com/industrial/different-animal.

19. Beaver, Randy L. and William E. Field (2007). “Summary of Documented Fatalities in Livestock Manure Storage and Handling Facilities – 1975-2004.” Journal of Agromedicine 12(2):3-23.

20. U.S. Environmental Protection Agency (2011). Oil Spill Prevention, Control, and Countermeasure (SPCC) Program: Information for Farmers (fact sheet). Web Link: http://www.epa.gov/emergencies/docs/oil/spcc/spccfarms.pdf.

JEREMY A. KELLER is the community risk reduction officer for the Macochee Joint Ambulance District in West Liberty, Ohio, and the state geospatial information systems specialist for the United States Department of Agriculture Natural Resources Conservation Service in Ohio. Involved in rural fire and emergency medical service planning since 1999, he served as wildland-urban interface specialist for the United States Fish and Wildlife Service and as a fire prevention officer for the United States Forest Service, among other wildland fire positions. He has a bachelor’s degree in fire administration from Western Oregon University and a bachelor’s and a master’s degree in natural resources management from the Ohio State University. He is a certified forester and a retired naval intelligence officer with more than 23 years of active and reserve service.

Fire Engineering Archives