A Method of Evaluating High-Performance SCBA

SELF-CONTAINED BREATHING APPARATUS

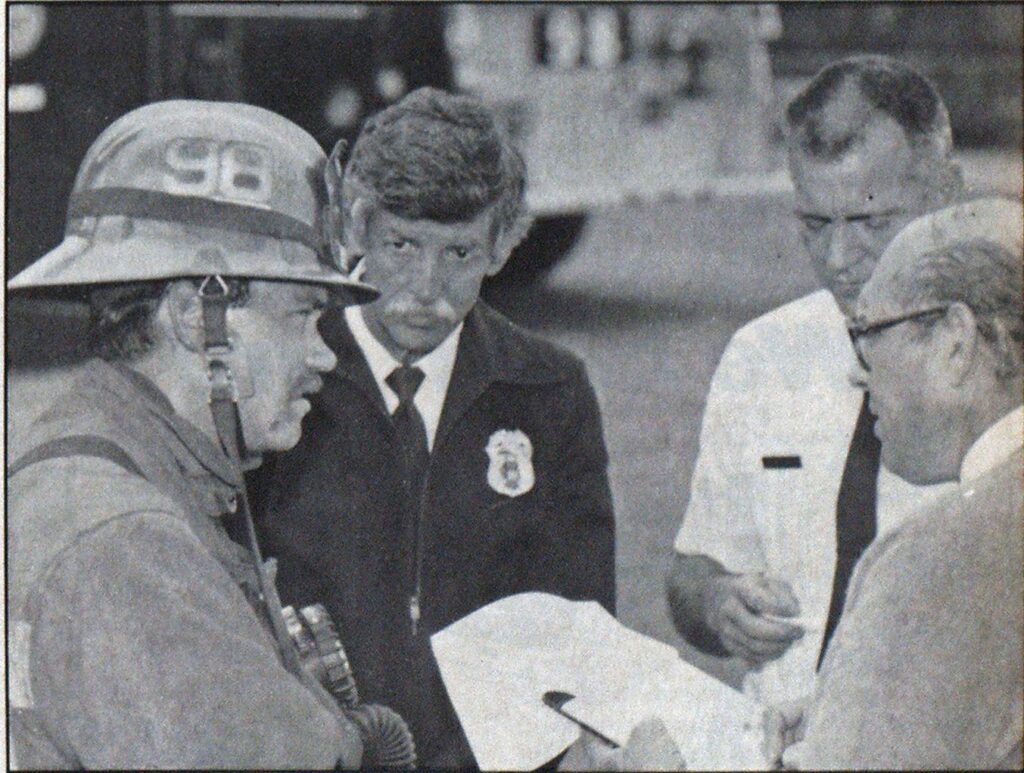

To give its firefighters the best SCBA protection available, the Los Angeles City, CA, Fire Department embarked on an extensive SCBA evaluation and modification process. Firefighters themselves tested the equipment and determined what changes were needed to make the SCBA more comfortable and easier to use.

Providing firefighters with respiratory protection devices used to mean distributing vinegar-soaked sponges as they entered a fire. In contrast, most fire departments now use lightweight, self-contained breathing apparatus (SCBA) capable of delivering lowpressure air for as long as an hour per cylinder (rating).

When California’s Occupational Safety and Health Administration (OSHA) determined in 1980 that positive-pressure SCBA must replace demand-type units, the Los Angeles City Fire Department (LAFD) began searching for an SCBA that would replace existing units and provide maximum protection for the city’s 2,400 firefighters. The LAFD recognized that all breathing apparatus manufacturers would supply state-of-the-art equipment. By inviting several manufacturers to develop prototype SCBA for fireground evaluation, the department would be able to select the SCBA most suitable for its use; the manufacturers would also benefit from the testing their prototypes would receive.

“Our goal,” said Assistant Chief Jack Bennett of the LAFD, “was first to evaluate all SCBA prior to preparing specifications for purchasing for the 1981/1982 fiscal year. Through this evaluation, changes and improvements would be recommended and, ideally, manufacturers would respond with improved products.”

Based on evaluation results and manufacturers’ modifications, LAFD would then accept a bid for SCBA that would be, according to the LAFD evaluation report, “the best in the nation, (providing) a high level of personal protection in the ever-changing hazardous environment firefighters are exposed to.”

For 11 months, the department conducted comprehensive SCBA field evaluations, which included all aspects of both operational and firefighter acceptance.

Early in 1980, the LAFD formed a Breathing Apparatus Committee under the leadership of Chief Bennett to plan the evaluation process and determine SCBA specifications. The committee specified the SCBA be high pressure (4,500 psi), 30and 60-minute duration, lightweight, low-profile, and integrated with other elements of the firefighters’ protective clothing.

In addition to general features, the Breathing Apparatus Committee specified construction of the facepiece, regulator, alarm system, backpack assembly and cylinders. Ease of operation and maintenance were highlighted as key selection criteria.

Specifications were then sent to five SCBA manufacturers who were invited to bid on the contract by submitting prototype or standard SCBA models for testing and evaluation. The selected manufacturer would then supply 1,000 SCBA, 3,000 spare cylinders, 1,600 spare facepieces, and testing and maintenance equipment to the LAFD.

The evaluation

Based on their experience and objectivity in previous evaluations, firefighters in Hollywood and Central Los Angeles were selected by the Breathing Apparatus Committee to participate in the evaluation. Test SCBA were placed on engine companies and squads who have a normally high activity rate. Controlled testing was also accomplished at the station in Los Angeles and in training exercises.

Several aspects of SCBA were closely monitored throughout the evaluation:

- breathing time and duration

- ease of breathing

- alarm system

- frame assembly

- backpack comfort

- facepiece

- firstand second-stage regulators

- cylinder

- communications.

Standard evaluation forms were used to record the results of tests in all exercises.

Each element was rated on a scale from one to five, five being excellent. The highest possible score was 50.

Adaptation continues

Throughout the evaluation, a high priority was placed on individual comfort while wearing SCBA. Firefighters testing the prototypes were asked at every opportunity to recommend changes or modifications in the equipment which would make it more comfortable or easier to use.

After delivery of the selected SCBA, LAFD firefighters were carefully trained in their use. Training films and customer service personnel helped users become acquainted with the new equipment relatively quickly. Observation of the apparatus’ use in “hot drills” indicated that minor modifications in equipment design could improve its use in the field.

One drill was staged to test facepieces for slippage in an extremely hot, controlled fire. Several firefighters’ helmets actually melted in the heat, recorded above 485°F; however, no facepiece slippage was reported.

During the same drill, firefighters used several mask prototypes to determine the best placement of strap buckles to keep the helmet from interfering with the mask. Engineering and marketing management worked closely with firefighters to record their reactions to each facepiece prototype before, during, and immediately after wearing it in the fire. Test results showed that a minor change in buckle placements resulted in less interference with the helmet. Changes were later designed by the manufacturer into existing and subsequent facepiece models.

The LAFD evaluation has had farreaching effects on the design and construction of breathing apparatus. Participating manufacturers, all given recommendations for product enhancements, are now using the input to develop SCBA preferred by one of the busiest fire departments in the country.

LAFD EVALUATION FORM

Self-Contained Breathing Apparatus

- VISUAL APPEARANCE

- USAGE

Ease of donning backpack

Ease of donning facepiece

Ease of opening cylinder valve

Ease of attaching low pressure hose to second stage

Ease of operating bypass control ring Duration of use (in minutes).

- COMFORT

Backpack with 30-minute cylinder

Backpack with 60-minute cylinder

Position of second-stage regulator

Length and flexibility of low pressure hose

Length and flexibility of high pressure hose

Facepiece comfort and fit: prototype

Facepiece comfort and fit: standard

Comments on comfort and fit.

- PERFORMANCE

Inhalation effort: prototype facepiece

Inhalation effort: standard facepiece

Exhalation effort: prototype facepiece

Exhalation effort: standard facepiece

Communication: member to radio

Communication: member to member

Comments or suggestions on performance.

- BACKPACK/HARNESS

Frame contour

Waist strap length

Waist strap adjustment: snap hook and D-ring

Waist strap adjustment: plastic buckle Shoulder strap length

Shoulder strap ease of adjustment Weight

Comments on backpack harness.

- FIRST-STAGE PRESSURE REDUCER/AUDIO ALARM

Integration of audio alarm with first-stage pressure reducer

Size and weight of first stage

Location and mounting of first stage

Reducer concept

Actuation of audio alarm upon first-stage failure

Loudness of audio alarm

Comments or suggestions on first-stage/ audio alarm.

- SECOND-STAGE REGULATOR

Location on facepiece

Location on chest

Location of bypass control ring

Location and visibility of pressure gauge

Location on belt

Concept of chest-mounted second stage

Comments or suggestions on second stage.

- MODIFICATIONS

If you could have a 30or 60-minute SCBA “custom made” to your own personal specifications, what changes would you make in the unit?

- MISCELLANEOUS COMMENTS

Duration of breathing air was monitored before, during and immediately after each exercise.

Facepiece communications were evaluated by comparison; all facepieces were donned by a team sitting behind a screen. Each member of the team spoke and shouted through the speaking diaphragm. A radio was also used to test voice audibility. Evaluators were separated from the team by the screen, and they identified facepieces by number only.