THE 36-INCH PIPE WRENCH

THE TRUCK COMPANY

The pipe wrench is a forcible entry tool that is highly effective on various types of case-hardened padlocks and their protective guards. Its manageability and the safety it provides firefighters make this extra heavy-duty “plumber’s” wrench an excellent tool in many forcible entry applications. For removing padlocks, a good-quality pipe wrench meets or exceeds the results of other forcible entry tools.

The 36-inch pipe wrench is not your only option for removing case-hardened padlocks. Tools such as the duckbill lock breaker also can be used; however, on long-shackle locks, a lock breaker may pass all the way through the shackle without breaking the lock, while on shortshackle locks it may be difficult to insert the lock breaker into the lock’s shackle due to lock placement or shielding devices. With the American Series 2000 lock—the “hockey puck lock”—attempts to force off the lock by placing the lock breaker behind the lock may not succeed if the lock is mounted in front of a flexible background such as a rolldown gate.

Furthermore, modem case-hardened padlocks utilize toe and heel locking— that is, both sides of the lock’s shackle lock in place. These locks can withstand severe pounding (compression force) before they fail. However, they have less resistance to a twisting force (shear stress). The 36-inch pipe wrench permits firefighters to apply such stress, taking advantage of the locks’ inherent weakness.

The size and heavy-duty jaws of the 36inch pipe wrench are critical elements to successfully removing such locks. Shorter wrenches require a much greater physical strength on the part of firefighters, and the jaw depth of shorter wrenches typically doesn’t provide as much surface coverage on the lock. When you add an extension bar to the pipe wrench, you can apply an even greater shear stress on the lock and exert even less physical strength in the process. The 36-inch pipe wrench’s superior ability to remove these locks may surprise some firefighters who have never seen it used before. However, the principle on which it operates is the same as that for all forcible entry tools—exploit the weakness for maximum results.

ADVANTAGES OF THE PIPE WRENCH

Although the concept of twisting a lock to remove it is not new, the pipe wrench’s ability to remove case-hardened locks that at one time only could be removed with a power saw or torch has expanded our forcible entry’ options and decreased entry time. The advantages of using the pipe wrench for forcible entry include the following.

- A single firefighter can use it to remove padlocks, thereby increasing the number of personnel available on the fireground.

- It can be put to work almost instandy, as opposed to a cutting torch or power saw, which at times may be difficult to start.

- Its wide jaw opening can accommodate any padlock in addition to a variety of modern lock-shielding devices.

- It is extremely durable and easy to operate.

- Company members will be eager to test the tool, and its results will gain it quick acceptance.

- It requires litde maintenance and always starts.

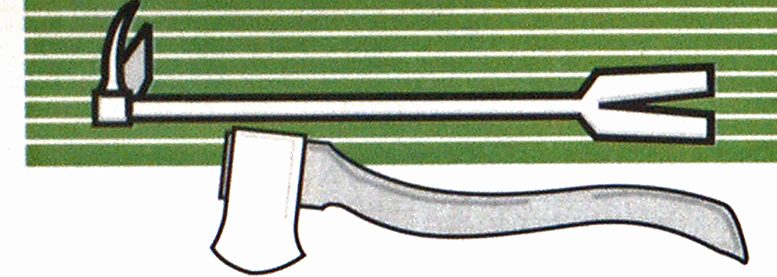

ENHANCEMENT

To increase the wrench’s lock-breaking capabilities, an additional mechanical advantage can be provided. A four-foot piece of thick-walled galvanized steel pipe with a two-inch inside diameter should work fine. The addition of this “cheater” pipe will make it easier tor company members to work with the tool and will provide the additional leverage needed for tough lock assemblies. The thickness of the wrench handle will vary, depending on the manufacturer; however, the length of the extension pipe should be at least twice the length of the overlapping distance of the wrench when inserted inside the pipe.

At times, space restrictions and lock placement will preclude the use of the fourfoot extension bar on certain lock assemblies. In such a case, quickly remove any remaining accessible locks with the wrench while notifying others that additional tools are needed. Tackle die remaining locks when additional resources arrive.

PROCEDURES

It takes practice to become proficient in the handling of a pipe wrench. To avoid losing valuable twisting space and proper setup position, first remove any turning slack in the lock before applying the wrench. The pipe wrench’s jaw opening forms the letter “C.” Place the lock as close to the back of the wrench jaw opening as possible for maximum surface coverage and increased holding power. Tighten the wrench on the lock, turning it in the same direction the wrench’s jaw opening “C” side is facing, to prevent the wrench from slipping off the lock.

When turning the wrench, it is more effective to shock-load the lock with a rapid and forceful twisting motion rather than using a gradual, steady pressure. Put your body weight into the force of pushing down on the wrench; use the power of your legs when pushing up on the wrench. Lock placement—rather than personal preference —usually will determine whether you push down or pull up on the wrench. When a lock is located close to the ground, it usually is most effective to turn the wrench in an upward direction, allowing for unrestricted movement. The opposite is true for locks located several feet or more above ground level. Be aware that at times short-shackle, case-hardened padlocks may not snap after being twisted—only the locking pin holding assembly will fail. The problem with such a situation is that the locking pin may be difficult to remove.

STORAGE AND MAINTENANCE

Keep the wrench readily accessible, mated with the extension bar, and stored with its jaws opened to about three inches wide to save tool setup time on the fireground. To add hand-grip strength capability and prevent tool slippage, wrap the wrench’s handle with rubberized tape; the extension bar end also can be taped. A light oiling of the gear teeth, along with periodic inspections and cleanings, will lengthen tool life.

SAFETY

Pieces of shattered locks can travel some distance. Firefighters must wear proper eye protection during pipe wrench operations. When the tool is not in use, lay it on the ground, since the weight of the wrench and extension bar is significant and could cause painful injuries if they were to tall and strike someone. Do not strike the wrench’s jaws with any tools, and place the jaws down on the ground before letting the handle go. At times, lock assemblies may be difficult to force; remember to let the tool do the work. To gain maximum leverage, apply force at the very end of the tool or corresponding extension bar.

If necessary, seek assistance and set yourself up properly while using the tool to avoid straining your back. If the lock is located near the ground, lower yourself to its level by crouching with your knees bent, not by bending over. Push up with the power in your legs, keeping your back as straight as possible. With the wrench on the lock and all slack removed, take a quick look around to make sure other firefighters are not in the way and that your hands and arms won’t hit any obstructions as you spin the wrench.

Be aware that when a lock you have been straining to break finally gives, you could lose your balance and fall. Be prepared for this possibility. For better balance, use a wide stance when working with the wrench, keeping your feet at least shoulder-width apart. Clear the area of any debris that could cause you to slip or that could interfere with a proper stance. The speed with which you will be able to remove locks will more than compensate for the few seconds you take to ensure you perform the operation as safely as possible.

The pipe wrench, along with the extension bar, is a formidable match for tough case-hardened locks and shielding assemblies. This tool provides reliable results along with a feeling of accomplishment and hands-on satisfaction matched by few tools. Use the tool and experiment with it to learn its capabilities and limits. Once you become proficient at taking locks with this multiuse tool, you will wonder how you ever got along without it.