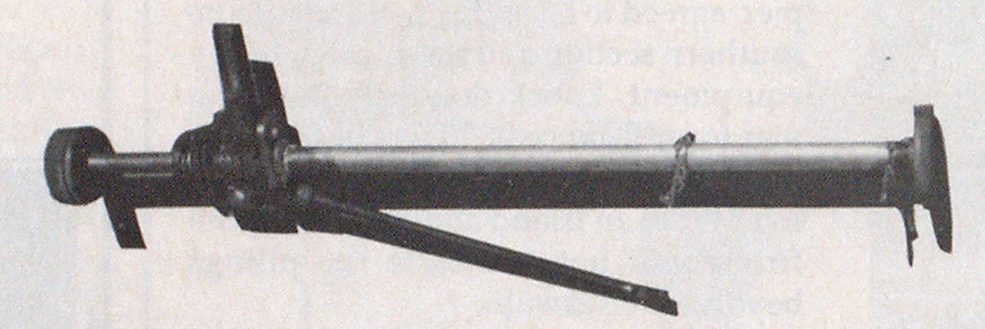

Adjustable exhaust fan support

DEPARTMENTS

DISPATCHES

When mechanical ventilation is necessary, it’s not always easy to position a blower or exhaust fan in just the right location to effectively remove smoke. Often, firefighters are forced to wedge a fan in a partially opened window or door, or balance it on a ladder angled in a door frame.

An adjustable support mechanism for suspending exhaust fans in door and window openings can be easily constructed. The essential materials for constructing the support are:

- Volkswagen jack (can be obtained from an automotive wrecking yard);

- Adjustable tubular steel closet rod (28 to 48-inch extension with nominal 13/32-inch inside diameter);

- 1/2-inch National Pipe Thread (NPT) X 12-inch steel pipe nipple;

- 1/2-inch NPT X 3-inch diameter railing support flange;

- Two 3/16-inch diameter cotter pins three inches long;

- 1 1/2-inch diameter key ring;

- 30 inches of link chain;

- Three 3 X 3-inch rubber squares 1/2-inch thick.

Assembly. Remove the circular snap ring from the jack end to permit the inner portion of the tubular closet rod to slip over the shaft. To secure this tube to the movable jacking mechanism, a 13/64-inch hole is drilled through the closet rod mounting flange and into the jacking mechanism.

The hole in the jacking mechanism is taped with a 1/4 X 20-inch tape and the hole in the mounting flange is enlarged to 1/4-inch. The inner tube is joined to the jacking mechanism by a 1/4 X 20-inch bolt and lock washer and the tube is cut to 21 1/4 inches. The mounting flange on the outer tube then is cut down to a circle approximately ¼ inch in radius larger than the outer tube radius and this tube is cut to 22 1/4 inches

A 1-inch length of the inner tube material is inserted into the outer tube so that both ends are flush and soldered in position with a propane torch. The flange end of the outer tube is slid onto the inner tube until it touches the secured mounting flange bolted to the jacking mechanism.

To construct a movable base at the free end, the 12-inch pipe nipple is threaded onto the 3-inch diameter pipe support flange and cut to a 10 1/2-inch length. The free end of the pipe is slightly chamfered with a grinder so that it slides easily into the inner tube. A rubber cushion is fabricated for this end by contact cementing a ¼-inch thick piece of rubber to the flat surface of the pipe support flange and trimming it to size. A similar cushion is made for the circular jack end by making a 3-inch outside diameter X 1-inch inside diameter annulus from a 1-inch thick piece of wood, contact cementing two pieces of trimmed rubber (3inch outside diameter X 1-inch inside diameter) to both wood faces, and drilling two diametrically opposed holes through the wood-rubber assembly and the jack base to bolt the two together. The jack handle can be inserted inside the jack body for storage.

Adjustment hole drilling.

Using a 3/16-inch drill bit, two holes are drilled diagonally through the assembled support system at distances of 1/2 inch and 7 1/2 inches from the end of the circular pipe support flange to accommodate cotter pins for adjusting the support to various lengths. To secure these pins to the assembled support mechanism, they are joined in series to a 1 1/2-inch diameter key ring by a length of chain, and the key ring is slipped over the outer tube prior to installing the removable end piece and cotter pins.

Operation. With both cotter pins in position, the support mechanism may be positioned between supports ranging from 28 3/4 inches to 38 ¾ inches, typical of most domestic doors and some windows, by using the normal jacking mechanism. To increase this range to 46 ¾ inches, both cotter pins are removed, the 1/2-inch pipe is pulled out until the 3/16-inch hole through the inner and outer tube lines up with the hole 7 1/2 inches in from the end and both cotter pins reinserted. Additional lengths up to 62 inches may be continuously obtained by removing the second cotter pin nearest the jacking mechanism and extending the outer tube and reinserting the cotter pin in the exposed hole in the inner tube.

To attach the exhaust fan to the positioned support, bolt clothesline hooks to the tubular fan frame with four U-bolts and hang the fan on the support.