“Don’t Hit the Steel!” —A Myth

CONSTRUCTION

John F. Kennedy once said, “The great enemy of the truth is very often not the lie, deliberate, contrived and dishonest, but the myth, persistent, persuasive and unrealistic,” Many sailors have been seriously and even fatally poisoned by the myth that denatured alcohol can be made drinkable by straining it through a loaf of bread.

The most pervasive and persistent myth in the fire service is the belief that it is somehow harmful to direct a stream of water onto hot steel. Nothing could be further from the truth.

When structural steel is heated, it starts to elongate. At about 1,000°F, a 100-foot steel member will expand 9 ½ inches. And when it does elongate, the probability that it will push down the bearing wall is great. If the steel is restrained (as by a masonry wall or fixed to columns) it will twist, rotate on its axis. If the steel is cooled before it twists, it will return to its normal dimensions. If it is cooled after it has twisted, the steel will be frozen into the assumed shape. The steel is essentially undamaged, but it may no longer be in a shape adequate to support the load for which it was designed. For instance, a steel beam supporting a wooden floor may simply drop the floor. At higher temperatures, around 1,100° to 1,200°F, the steel is at its critical temperature and has decreased to 60% of its Normal Temperature and Pressure (NTP) value. At this point the steel will soften and fail depending on its load.

The greater the ratio of the actual load to the normal or designed load for a structural element, the faster the steel will fail. This fact makes steel bracing used in structural excavations particularly vulnerable to fire stress.

This steel is usually permitted to be loaded to twice the normal design load because it is only temporary. It is often surrounded by a fuel load usually found in excess at construction sites and the importance of cooling the steel is not often understood. If the steel isn’t cooled, the adjacent buildings may collapse into the excavation.

Cold drawn steel, such as is used in cables in tensioned concrete, elevators, and for “tiebacks” in excavations, are permanently weakened at about 800°F.

Damage to steel may differ markedly from one fire to another. The usual cause and extent of damage depend on ventilation operations. If the fire is fully vented, the temperature of the steel will be much lower than if the heat is confined. The basic function of an engine company is to remove heat with water. But what heat? Is all heat equal? Is the fire itself the most important target?

Consider a fire in one room of a single story, flat roof structure. If the fire has burned through the roof and is vented to the atmosphere, let it go. Despite pictures of some fire operations, we do believe that the sky will not catch fire—or do we?

In any event, we would not attack the top of the fire, and push it down through the roof. We enter the structure. The fire is roaring in the fire room. The radiant heat is raising nearby furnishings to their ignition point (flashover). The obvious point of attack is not the fire but the furnishings about to ignite around us as we make our way to the seat of the fire. By removing the heat from materials not yet ignited or damaged by the fire, we reverse the flashover condition as we advance on the fire.

When unprotected steel is subject to heat from a fire, it is vitally important to cool the steel to keep it below its critical temperature. Cooling the steel can often be accomplished with much less water than extinguishing the fire. In addition, the steel may be cooled even if the fire cannot readily be extinguished.

The contents on fire are already destroyed. Cooling the steel may keep the building from failing and causing a collapse situation.

“But I read just the opposite in …”

I’m sorry. Just because a statement is made by a reputable author in a book published by a reputable publisher doesn’t make it so. Some fire service texts have been published with only sketchy review.

Contrary to widespread belief, heated steel beams do not present a hazard when cooled with streams of water. They will not buckle but will tend to return to their original shape or, if past the point of strain, will keep their deformed shape.

The effects of expansion, however, may present some hazards. Steel expands more readily than do most other building materials. There is the possibility that the expansion of a steel beam could crack masonry walls, making them unsafe. Another point to remember is that all the steel beams used in one building may not be the same size. Smaller beams will contract or expand quicker than large beams. If two sizes of beams are bolted or riveted together, this difference could result in the bolts or rivets shearing.

While beam failure is very significant, column failure can be catastrophic. Only a portion of the column needs to be heated to cause failure, just as a steel rod has to be heated where the blacksmith plans to bend it. Fire resistive buildings with floor and ceiling assemblies that did not have fireproofing material applied to the upper portions of the columns hidden within the plenum space (ceiling void) are real candidates for failure. The ceiling is extremely vulnerable to breakdown and passage of fire into this space. If this occurs where there is a high fireload (as in a stockroom) and the fire department is unable to control the fire, the tops of these columns will be ready for failure.

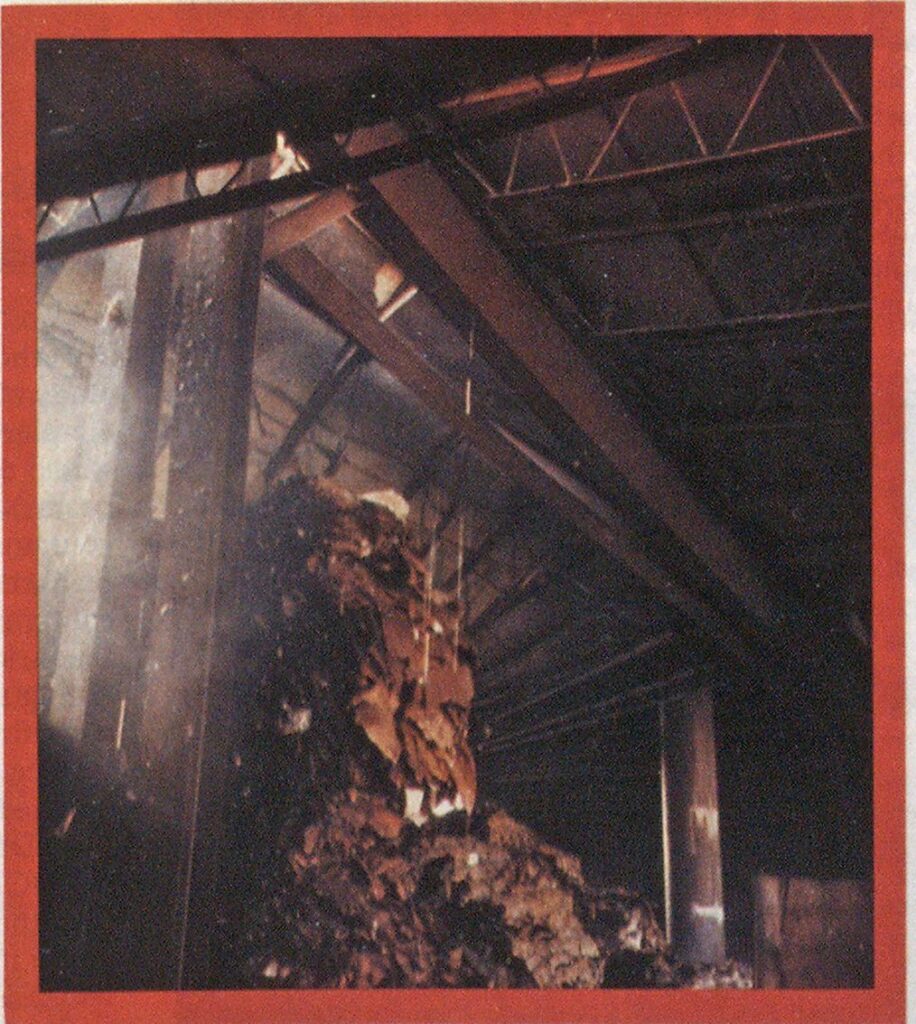

Cooling steel is vital when the heat exposes steel trusses. Trusses are made of lightweight metal and are interconnected to provide strength and stiffness. These interconnections can provide undesigned torsional or shear stresses from one truss to another and cause collapse some distance from the fire area.

Cooling is an absolute necessity in a metal deck roof fire. The underside of the roof must be cooled to stop the production of flammable fuel gases from the asphalt vapor seal.

How did this myth of never cooling heated steel get started? It is possibly due to a confusion between the behavior of cast iron columns and steel Ibeams. In the 1920s, there was a cellar fire in Butler Brothers building. This New York City structure, relying on cast iron columns for support, ran from one street through to another street. As the units began to fight the fire in the basement, the entire rear of the building collapsed. Had the alarm been received from the opposite street location, the entire responding assignment would have been at the opposite street side and buried by rubble. So the collapse received much media attention. The cause of the collapse was laid to water hitting hot cast iron.

When unprotected steel is subject to heat from a fire, it is vitally important to cool the steel to keep it below its critical temperature. … Cooling steel takes less water than what is needed to put out the fire.

Perhaps this was the case, but my study of cast iron buildings provides a simpler cause. Wooden girders (a girder is any beam supporting other beams) are attached to round cast iron columns by setting the girder on a bracket cast into the column. To fit the column, the girder is cut away in a half moon, leaving just two “horns” of wood sitting on the bracket. It takes only a little fire to burn away the wood and initiate collapse. This hazard was recognized as far back as 1920 in the HANDBOOK OF BUILDING CONSTRUCTION. The book recommends that the fitting for holding a wood girder in place on a cast iron column be reduced to a solid pintle (pin) so that the maximum amount of wood mass may be retained. I have never seen this done.

In 1949, a major historic cast iron building, Wanamaker’s, was under demolition. All the wooden floors had been thrown into the sub-basement. The fire that occurred was fought with massive heavy caliber streams. Not one piece of cast iron was damaged. There is good and bad cast iron, and it is very difficult to distinguish one from the other. Therefore, all cast iron is very suspect to shattering. However, look to the connections rather than at the material itself.