EVALUATING THE EFFECTIVENESS OF HAZ-MAT DECONTAMINATION

Hazardous-materials responders must always he aware of the potential hazard of becoming contaminated. Despite efforts to avoid becoming contaminated, exposure to a hazardous material is a real possibility. Since responders may not be aware of these exposures, especially since there often is no visible evidence of them, they should always assume that they are contaminated when exiting a hazardousmaterials hot zone, and undergo decontamination.

There are many methods of decontamination. including removing contaminants through dislodging, rinsing, wiping, and evaporation; using chemicals to dissolve or neutralize contaminants; using surfactants; and employing solidification and sterilization. The method may vary from incident to incident, depending on the contaminant, safety concerns, and environmental factors. The methods van in their degree of effectiveness.

EVALUATING DECON PROCESSES

Decontamination methods should be monitored to ensure that employees are not being exposed to hazards. Monitoring should be ongoing and the results should be reflected in revisions of the decontamination program.

The effectiveness of decontamination methods cannot be immediately assessed. Visual clues such as discoloration of or stains on personal protective equipment, corrosion, and the adherence of objects to the equipment may indicate contamination. but the presence of many contaminants goes unnoticed. If not removed, some contaminants may permeate a garment, which then would have to be replaced.

Some methods for assessing decon effectiveness are listed below. They provide after-the-fact information but, when used in conjunction with visual observation, help to evaluate decontamination methods.

Swipe tests. This evaluation method involves swiping the surface of equipment with a clean cloth or paper patch and then using laboratory tests to analyze the cloth or patch for contaminants. This method can be expensive and time-consuming and is impractical for use on personnel.

Analysis of cleaning solutions. Contaminants remaining in cleaning and rinse solutions can be analyzed to determine their types and quantities. A high level of contaminants in the final rinse water would indicate that the decontamination procedures are inadequate. This method also can be expensive and time-consuming.

Permeation testing. Laboratory tests can determine whether contaminants have permeated personal protective equipment. The testing is done after field decontamination. The garment tested, however, must be taken out of service.

The analysis is expensive, as is the garment, which w^ould have to be replaced.

For ultimate effectiveness, decon processes should be evaluated before a hazardous-materials incident occurs. One inexpensive and simple evaluation method employs fluorescent dye and an ultraviolet light. The fluorescent material, called fluorescein sodium salt, is a dry powder that can be purchased from most chemical supply companies. When mixed with w’ater. it forms an orange solution that shows up as bright yellow under an ultraviolet lamp, enabling it to serve as a tracer. The dye is sprayed on responders’ protective clothing before the clothing is subjected to the decontamination process and then is inspected in a dark room for signs of the dye. The dye is not permanent and is completely water soluble.

MADISON FIRE DEPARTMENT EVALUATIONS

The Madison (WI) Fire Department Hazardous Incident Team (HIT) recently evaluated its decon procedures using this trace dye method. The HIT program has been in operation since 1987, but its decon procedures had never been evaluated. We undertook an evaluation to help ensure that our responders were not being exposed to potential health hazards through contaminated gear. In addition, applying the evaluation conclusions to decontamination policies improves responder safety and decon program effectiveness.

The HIT decon line, a polyvinyl chlo: ride (PVC) shower unit on loan from the Portage (WI) Fire Department Hazardous Material Response Team, and other decon methods were evaluated.

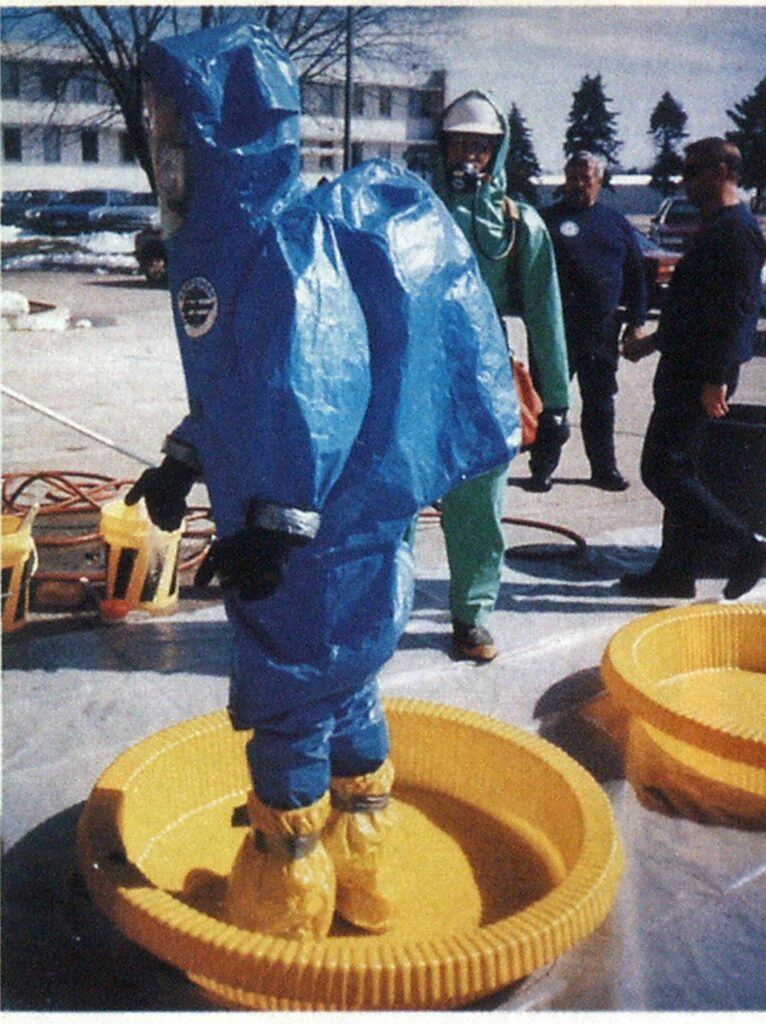

Personnel from the department’s HIT team were trained to perform the evaluations. Some wore Level A and others, Level B protective equipment. Level A equipment included a total-encapsulating chemical Responder” front-zipper suit, a hard hat. gloves, boots, booties, duct tape (to secure juncture points), and a onehour SCBA. Personnel in Level B equipment w ore a one-piece green PVC chemical splash suit with a front zipper, a hard hat, gloves, boots, duct tape, and a halfhour SCBA.

(Photos by author.)

Responders’ clothing was sprayed in predesignated areas with a common aerosol spray bottle containing a fluorescein sodium salt solution. Approximately 0.25 ounce was delivered per two complete sprays One spray was defined as the complete travel of the nozzle from its starting position to the lowest position in its travel to its release. The suits of personnel wearing Level A protection were sprayed in four separate locations, and the suits of personnel wearing Level B protection were sprayed in two locations. After the decon, the suits were assessed for leftover contamination in a dark room under a handheld 110-volt, four-watt, high-frequency ultraviolet lamp. Two evaluators recorded the results on forms devised specifically for that purpose.

Four methods of decon were assessed: the HIT decon line, the PVC shower, a combination of the HIT decon line and the PVC shower, and “dry decon.”

Decon line

The Madison HI T decon line consists of two four-foot-diameter wading pools, garden hoses, nozzles, five-gallon buckets, 30-gallon containers, long-handled brushes, sponges, and a long plastic tarp.

Personnel in Levels A and B equipment were evaluated after having been sprayed and then decontaminated. The trained decontamination workers used for this evaluation were instructed to complete their assignment as they normally would and were not told the locations of the sprayed squares.

The decon sequence was as follows. The responder begins the decon process by discarding the outermost layer of protective gear, gloves, and booties with attached duct tape into a five-gallon bucket. Next, the responder steps into the first wading pool and is rinsed down with water, if compatible, and then washed with dishwashing detergent or tri-sodium phosphate (TSP) applied with a sponge or brush (garden pneumatic sprayers can also be used). After a final rinse, the responder steps into the second wading pool and undergoes the same procedure. The actual rinsing and scrubbing with brushes was done by HIT team members trained as decon workers.

After emerging from the second wading pool, the responder doffs the protective equipment, which is placed in a 30-gallon container. The self-contained breathing apparatus is the last item to be doffed, leaving the responder in coveralls at the end of the decon line. At that point, the responder receives a postincident medical evaluation.

Evaluation results: Personnel in Level A protective equipment had some con-. taminants remain on their suits, especially in the midchest areas. Level B personnel had residual contamination in both spray square areas as well as on and under the SCBA straps.

PVC shower

The PVC shower was constructed of 1.5-inch-diameter tubing, and water was supplied by a garden hose at low pressure. The shower flowed at a rate of eight gallons a minute from drilled holes located in two overhead cross-member pipes. The shower was encapsulated with plastic sheeting to minimize overspray and placed in a retaining pool.

Personnel in Levels A and B equipment then underwent gross decontamination. They were allowed two minutes in the activated shower after having been sprayed with the dye. In the shower, they were instructed to make two complete* revolutions (one with legs together and the other with legs apart), alternating the position of their hands from over their heads to down at their waists. They were allowed 10 seconds of drain time after the shower was shut off. On exiting the show-, cr. they immediately went to a nearby dark room for evaluation.

Evaluation results: Level A personnel had some residual contamination on their knees and feet; one suit showed some contamination in the crotch area. Level B personnel showed some contamination on the left shoulder strap of the SCBA and , minor spots on the lower legs. (One Level B responder received copious quantities rof water inside the front of the suit because the neck area was exposed.)

Decon line-PVC shower combination

Personnel in Level A equipment were sprayed with the dye. proceeded through the PVC shower (they had been given the same instructions as above), and then continued through the HIT decon line. After exiting the second wading pool in the HIT decon line, the responders went to the dark room for evaluation.

Evaluation results: Except for some ■ minor spots on one responder’s left glove and the suit’s left knee area. Level A personnel showed no residual contamination on their protective equipment. Personel in Level B protective suits did not participate in this test.

Dry decon

This relatively new decon process entails only the responder’s taking off the psuit safely without touching the contaminated areas of the suit. Members of our department’s HIT team are trained in this .method, which has proven effective and is used in industry. Dry decon is appropriate for situations involving water-reactive contaminants or a cold environment that precludes the use of traditional wet methods. Only responders in Level A equipment participated in this decon process. f

They were sprayed with the fluorescein sodium salt solution described above and then they doffed their personal protective equipment without touching the outside of the garments. This decon method takes practice, but it can be done without transferring contaminants to the wearer

Evaluation results: Except for a small amount of dye on one responder’s hand, Level A personnel exited their protective equipment without contamination.

Other evaluations

Suit storm flaps also were evaluated to determine how well they keep liquids out of the disposable booties.

Evaluation results: Personnel wearing disposable booties under the suit leg storm flap did not have any liquids on the insides of their booties. When the booties were worn on the outside of the suit storm flap, however, the insides of the booties were very wet.

The level of cross-contamination from responders to decon workers resulting from the decon process also was evaluated.

Evaluation results: The decon workers from the HIT decon line were evaluated after their assignment had been completed and found to be uncontaminated except for a few spots on the right-knee area of the suit and the right glove of one worker.

Decon workers used for the HIT line decon-PVC shower assessment were uncontaminated except for some spots on the right glove and on both knees of the same worker who showed contamination in the HIT decon line evaluation. It is possible that the contamination to the left knee occurred during the decon line evaluation.

CONCLUSIONS

The following was concluded from the evaluations:

- The PVC shower by itself had no advantage over the wet decon line in ⅜ terms of decon effectiveness. Evaluations for both show nearly the same level of contamination after decon. The shower is not recommended for responders in Level B equipment unless exposed skin areas are sealed.

- When the PVC shower was used in conjunction with the HIT decon line (combination method), the effectiveness of decon was enhanced. Personnel who proceeded through both of these methods were found to be virtually clean.

- Dry decontamination was found to be effective. Only one decon worker showed any remaining contaminants —very little on one hand. With practice and when used with discretion, this method has merit.

- Decontamination workers received some cross-contamination from the responders in the HIT decon method. However, it is possible that the one decon worker who showed contamination after the combination-method evaluation may have been contaminated during the earlier line-decon evaluation. This may indicate that the combination method is safer for decon workers because the PVC shower may flush off most of the contaminants before the responder comes to the wet decon line.

- The storm flap on response suit legs will do its job if the bootie is tucked under it. When the flap is worn in this manner, the boot stays completely dry.

The evaluations conducted by Madison Fire Department HIT personnel provided much useful information that will be used to improve the decontamination program and better protect personnel. Evaluations such as these help to make hazardousmaterials responders feel more confident that they are clean when they take off their suits.

References

- Dept, of Labor. OSHA 29 CFR 1910.120, “Hazardous Waste Operations and Emergency Response’ Final Rule. Federal Register. March 6. 1989.

- Environmental Protection Agency Standard Operating Safety Guides, Nov. 1984.

- NIOSH/OSHA/t’SCG/EPA Occupational Safety and Health Guidance Manual for Hazardous Waste Site Activities Oct. 1985.