BY GARY BOWKER

Today’s residential structure fire is not your daddy’s residential structure fire. The contemporary lightweight wood-frame structure burns faster and fails sooner-often with tragic results-much more quickly than traditional wood-frame structures built in the past. In the past several years, an increasing number of fires in large lightweight wood-frame apartment buildings and single-family dwellings have resulted in firefighters being injured and killed. As the Ol’ Professor the late Francis Brannigan taught, “The building is your enemy. Know your enemy!” Today the lightweight wood-frame structure fire is the enemy. It has evolved into one of the most dangerous types of structure fires you will encounter.

We must know where we have been in terms of construction and culture in the American fire service to understand and appreciate where we are going. Fire officers must understand the nature of the risk they face to effectively manage it.

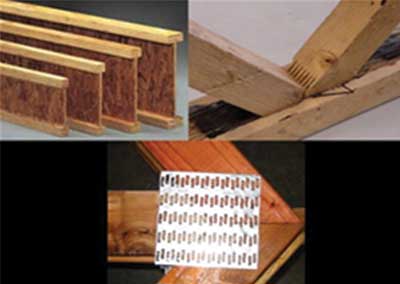

|

| (1) Typical lightweight engineered wood-frame components. Clockwise from top left, truss joist I-beams, fingerjointed wood truss, and lightweight wood truss components connected with a gusset plate. (Photo courtesy of Underwriters Laboratories.) |

Four current residential structure features pose major risks in fires:

1. Extensive use of engineered low-mass (lightweight) wood-frame construction materials.

2. Synthetic fire loading in the interior and on the exterior.

3. Void spaces.

4. Open floor plan/atrium-like design living spaces (lack of compartmentation allows for faster fire involvement throughout and may block escape routes).

Wood frame (Type V) construction has been used extensively in this country since the 19th century for homes and businesses. During the great American expansion westward, many prairie towns were built exclusively of wood-frame material. Lumber was plentiful and cost effective but posed a significant fire problem. As building and fire codes evolved, ordinary (Type III) construction increased for business and industrial use. Quick recovery after a fire was essential for economic survival. Most homes continued to be built of wood-frame construction well into the 20th century. It is essential to understand that wood-frame structural members used in home construction during that time period used full dimension lumber (“legacy construction”), which yielded more mass for structural support during a fire. Floors and roofs were typically built using a minimum dimension of 2- × 8-inch and 2- × 10-inch solid wood. The walls and ceilings were typically covered with plaster and lath, giving the structure reasonably good resistance to a room-and-contents fire. These structures were built to last a lifetime and could generally survive a moderate to serious fire. Typical fire loads during that era were mainly natural materials used for furnishings and contents, which continued into the 1950s and 1960s. Also during this time, traditional aggressive interior firefighting operations became well established in our fire service culture.

|

| (2) The I-stair is just the latest challenge we face in today’s disposable structure. This unprotected stairway may pose a significant risk for occupants trying to evacuate a burning residence. (Photo by Dennis Van Tassell.) |

However, in the 1970s, a significant shift began to occur in the wood-frame construction dynamic. The introduction of smaller 2- × 4-inch lumber in floor and roof truss support systems gave birth to “lightweight” construction. This trend has continued with the use of ever lighter, cheaper materials that have less mass for structural support, which in a fire means quicker failure. The combustibility of lightweight building components is also greater compared to that of traditional wood-frame construction.

Most new homes, apartments, fast food restaurants, hotels, and commercial buildings constructed in the past 20 years are lightweight wood-frame construction. Lightweight or engineered wood-frame support systems include wood products of less than two-inch dimension that are not solid lumber. Glued and finger-jointed wooden trusses and truss/joist I-beams made of wood chips or particleboard that are pressed together with combustible adhesives to eliminate waste are commonly found today. In addition, most of these newer wood-frame structures are wrapped in synthetic insulating material, which adds to the fuel load, speed, and toxicity of a fire. Wood-frame structures today are not built to last like the wood-frame structures prior to the 1960s. Today’s wood-frame structure is “disposable.” Much in our society has become disposable, from diapers to appliances to homes. Time is money, and less material and less waste are money. So it should come as no great surprise that this has occurred within the building industry.

DISPOSABLE STRUCTURE DEFINED

My definition of a disposable structure is as follows: “any lightweight wood-frame construction using engineered wood assemblies/synthetic products of lesser mass that contribute significantly to the fuel load and have a faster flame spread and failure time when exposed to fire or heat than traditional solid dimensional wood-frame construction.” This includes site-built and factory-built structures.

Fire loads up to the 1950s featured natural fiber materials, whereas fire loads today are primarily synthetic materials. This has contributed significantly to faster-developing fires, with less time to flashover, less time for escape, and less time to structural failure. Another significant risk facing firefighters involves manufactured and modular homes and buildings. In 2009, the International Residential Code began allowing manufacturers to use polyurethane foam construction adhesive in lieu of mechanical fasteners (screws or nails) to install gypsum wallboard to the interior ceilings and walls of these structures. This highly combustible adhesive off-gases at approximately 480°F. As a result, a room-and-contents fire can result in early failure of the compartment walls and ceiling, allowing them to drop and cause very rapid fire spread to occur throughout the structure.

VOID SPACE DANGERS

Firefighters face a very serious threat once the fire in a disposable structure enters the truss void space underneath the floors or in the attic. Large open void spaces are common to all lightweight wood-frame structures. These void spaces provide an abundance of exposed fuel surfaces and plenty of air for a fire to rapidly develop and violently spread throughout the void. Attic and floor voids create very effective “fire boxes” within the structure. Exposed fuels may consist of compressed wood products, polyurethane binding and construction adhesives, PVC plumbing, plastic-wrapped ductwork, and electrical wiring insulation. Fires that start or extend into the void space, especially from the exterior, have a tendency to become violent very quickly with little or no warning, trapping unsuspecting firefighters conducting interior operations. It is well documented that once flames or high heat impinge on exposed wooden lightweight structural components, failure can be expected in as little as four to six minutes. In addition, void spaces filled with heated fuel vapors create an increased risk of a backdraft when oxygen is introduced by unsuspecting firefighters pulling ceilings or from ceiling panel failure.

|

| (3) Today’s lightweight wood frame structures include large commercial buildings, such as this hotel, which can be enormous and include huge unsprinklered void spaces and potentially include huge unsprinklered void spaces. The entire structure is being wrapped in synthetic foam insulation. (Photo by author.) |

Among the dangers a void space fire may present are the following:

- Hidden fire.

- Rapid fire spread throughout the structure.

- Preheating of structural supporting members ahead of the fire.

- Accumulation of fire gases and depletion of oxygen.

- Increased backdraft potential.

- Catastrophic ceiling failure, resulting in full room involvement below, which can trap unsuspecting firefighters.

- Early structural failure.

- Increased fire load from storage and foam insulation.

- HVAC unit installation.

Today’s wood-frame structure demands that firefighters take a different tactical approach. The American fire service culture has been hard-wired for many decades to extend a fast and aggressive interior fire attack from the unburned side whenever possible. Although this strategy has served us well in certain situations and for traditional types of construction, it can be an absolutely lethal approach for the disposable wood-frame structure fires we are seeing today.

A seemingly nonlife-threatening fire originating on the exterior of a disposable structure can quickly spread up the synthetic vinyl siding, breach the soffit, and involve the attic space to become a very violent and lethal fire in a matter of moments, trapping occupants and firefighters. Underwriters Laboratories (UL) testing has indicated that global ceiling failure can occur once attic temperatures reach 1,400°F. This is especially true if the fire becomes wind-driven; it then can occur within a matter of seconds.

RECOMMENDED TACTICS

- Conduct a 360° walk-around before committing personnel (your size-up is incomplete until you do this).

- Follow the 3 Rs: Read the Smoke, Read the Structure, and Read the Risk.

- Check for fire extension into the attic or void spaces between floors by scanning the area with the thermal imaging camera (TIC) during the 360°.

- Determine the wind direction and its impact.

- Immediately attack an exterior fire that is breaching the soffit with a high-flow appliance.

Do not underestimate the danger of an exterior fire spreading into the attic void through the soffits. This appears to have been the avenue of fire spread at the Galleria Apartments in Fargo, North Dakota, that resulted in a Mayday for several firefighters.

Fires originating on the exterior or that vent and extend from an opening of a disposable structure must be controlled quickly, especially if the exterior is covered with vinyl siding. The blitz attack may be your best option for a quick knockdown, followed by an assessment of the floor and roof support systems if the quick knockdown is successful.

|

| (4) Polyurethane foam adhesive was used to attach gypsum ceiling board to the wooden structural frame in the void space between floors. The floor voids are typically 14 feet × 48 feet × 20 inches per modular unit, which equals approximately 1,300 cubic feet, and may have multiple attached units. It is doubtful that the code developers thought beyond the 1,000-square-foot requirement using the length × width standard when developing the trigger for draftstopping of concealed spaces. Also, note the small dimension finger-jointed truss and the exposed back side of the foam board wall insulation. This void space creates a very effective “fire box.” [Photo courtesy of the Acushnet (MA) Fire Department.] |

These high-heat-producing fires will quickly breach the soffit into the attic void. If the fire is wind-driven, this is a fire on steroids and may blow fire back through the structure from the windward (pressurized) side to the firefighters’ entry (vent) point, overrunning them and cutting off their escape route. A wind speed of as little as 10 miles per hour can create a wind-driven structure fire.

Exposures are also at an increased risk with the use of vinyl siding. The September 2010 Everyone Goes Home® newsletter presented research on the dangers of wind-driven residential structure fires conducted by retired San Antonio (TX) Fire Department Captain William Mora. He estimated that approximately 24 firefighters have died in structure fires over the past decade where wind was a factor, some involving lightweight wood-frame construction.

Fires that gain possession of the void space doom the structure as unsavable in most cases. However, during a working structure fire in 2000 involving a lightweight wood-frame apartment building in Winfield, Kansas, an elevated master stream was applied early to an attic fire that was rapidly developing through the structure’s attic void. Initial fire attack with 1¾-inch handlines from the interior had little or no effect on the fire. Quick use of the master stream from an aerial platform stopped the fire dead in its tracks, saving the structure and limiting the fire loss to the attic space above the apartment of origin. This is contrary to what we’ve been taught for many years, and breaking old cultural habits is difficult, especially if we fail to understand the nature of the fire problem.

FIRE SPREAD INTO VOID SPACES

Situations that seem minor should be viewed very pessimistically until thoroughly checked out and overhauled. TICs are essential for checking hidden locations. It is noteworthy to point out, however, that UL, in “Structural Stability of Engineered Lumber in Fire Conditions,” an accompanying live fire testing video, indicates that TICs may not be able to effectively “see” through wooden floor decks covered with carpet and padding. The test shows a raging basement fire burning directly underneath the wooden floor deck constructed with wooden I-beams. Catastrophic failure of the floor occurs six minutes after fire exposure begins, plunging two firefighter manikins into the inferno. The UL video dramatically illustrates what can happen to unknowing firefighters who “rush through the door and then fall through the floor.”

In addition to extending into the void space from the exterior, fire can also extend through the following avenues:

- Combustible dryer vents and air ducts.

- Anchor points in modular structures.

- Failure points where polyurethane glue attaches gypsum wall and ceiling panels in modular structures.

- Basements or rooms missing or without drywall ceilings.

- Gaps in construction and around electrical outlets and light fixtures.

- PVC plumbing fixtures.

- Fires originating within the void space.

PROTECTING OUR OWN

In the fire service in the 1970s, little was known about “lightweight” construction or why firefighters died in the line of duty. The primary prerequisite for being a “good” firefighter then was to be aggressive regardless of the situation. Since the 2004 introduction of the “16 Firefighter Life Safety Initiatives” by the Everyone Goes Home® program, we have learned much about the causes of firefighter line-of-duty deaths (LODDs). But not all firefighters are getting the message. We now know the top three killers of firefighters are cardiac-related events (about 48 percent), motor vehicle accidents (about 31 percent), and lack of situational awareness or failure to know or react to situations that kill firefighters (21 percent).

![(5) Fire entering the void space can become a structure fire on steroids, especially if it becomes wind driven. This fire started on the exterior of the structure and rapidly spread up the vinyl siding, breaching the vinyl soffit, and quickly involved the attic voids. The building's sprinklers did not activate because of the fire's location. [Photo courtesy of the Sterling (VA) Volunteer Fire Company.]](https://emberly.fireengineering.com/wp-content/uploads/2013/03/bowker5-1303fe.jpg) |

| (5) Fire entering the void space can become a structure fire on steroids, especially if it becomes wind driven. This fire started on the exterior of the structure and rapidly spread up the vinyl siding, breaching the vinyl soffit, and quickly involved the attic voids. The building’s sprinklers did not activate because of the fire’s location. [Photo courtesy of the Sterling (VA) Volunteer Fire Company.] |

SITUATIONAL AWARENESS

This article has focused on lightweight wood-frame construction dangers, which fall under situational awareness, which should also include hostile fire events, such as flashover and backdraft, and wind-driven fire conditions.

Today’s firefighter must be thoroughly aware of these situations and be able to quickly identify and react properly to changing and dangerous conditions. Firefighters must be intelligent first and aggressive second when dealing with today’s structure fires.

Following are some integrated risk management methods to use in managing today’s risks:

The only proven method for stopping a fire in the preflashover phase is to install a residential sprinkler system.

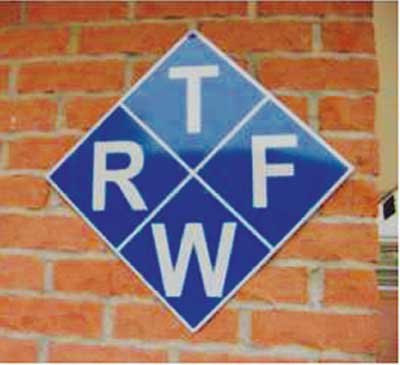

|

| (6) The Blue Diamond Hazard Identification System placard. In this instance, it indicates the presence of truss components in the building’s roof and floors. (Photo by author.) |

Firefighters must know the facts regarding the cost and effectiveness of residential sprinklers and continue to advocate for their installation despite the home building industry’s efforts to the contrary nationwide. The industry has a very well-funded lobby in many states, and it is working overtime to spread inaccurate information and prohibit local jurisdictions from adopting residential sprinkler legislation. This has recently happened in Kansas.

|

| (7) The blue diamond is located on the front corner of a lightweight wood-frame apartment building to alert firefighters. (Photo by author.) |

I am aware of at least one Kansas department that has proactively adopted a “No Enter” policy regarding lightweight wood-frame structures to protect its firefighters. If no life hazard exists and the fire has extended into the void space of the attic or basement, a defensive or transitional approach is taken to control the fire before firefighters enter. After an assessment of the floor- and roof-support system, the decision is then made whether to allow firefighters to enter.

THE BLUE DIAMOND HAZARD ID PROGRAM

The Blue Diamond Hazard ID Program alerts responding firefighters on arrival at a fire involving a commercial or industrial structure to the presence of lightweight construction. One or more blue diamond placards are placed in conspicuous locations on the building’s exterior. The program was incorporated into the 2008 Winfield City (KS) Municipal Code for communitywide use. The blue diamond’s design was inspired by the diamond used in the National Fire Protection Association 704, Standard System for the Identification of the Hazards of Materials for Emergency Response. The all-weather reflective blue diamond measures 14 inches square. The top quadrant indicates the presence of truss construction with a “T.” The left quadrant indicates that trusses were used in the roof (“R”). The right quadrant indicates the trusses are present in the floor (“F”). If floor trusses are not present, the quadrant is blank. The bottom quadrant indicates the presence of either wood (“W”) or metal (“M”) construction components. This system is used in buildings that include trusses or I-beams.

This information is included in the department’s automated quick-access prefire incident plan. The blue diamond placard provides four key pieces of critical information about the building’s construction immediately on the firefighters’ arrival, prior to their entry. It is also a constant reminder to firefighters during their preplanning and familiarization training in the community.

This is a good example of a fire department’s being proactively involved in the community and receiving support from local government leaders to promote firefighter life safety initiatives. We must first take the time to educate the community leaders if we want to succeed in promoting that cultural change within the department and throughout the community.

If we fail to stay current and well-informed in today’s changing firefighting environment and continue to rely on 20th-century tactics for 21st-century fire risks, we will continue to experience preventable LODDs and injuries in America. And that’s not acceptable. As firefighters and fire officers, we are responsible for many important things on the fireground. I cannot think of anything more important than the life of a firefighter-especially if you’re the dad of three firefighters.

● GARY BOWKER has served with the fire service for more than 38 years, most recently as the chief of Sumner County (KS) Rural Fire District #10 and previously as a chief with the United States Air Force and as a fire marshal for Winfield, Kansas. Bowker has taught at the National Fire Academy, United States Department of Defense, and University of Kansas Fire & Rescue Training Institute. He is the Kansas advocate for the National Fallen Firefighters Foundation’s Everyone Goes Home program and speaks and writes frequently on firefighter life safety and health issues.

Gary Bowker will present “Firefighting in Disposable Structures” on Monday, April 22, 2013, 8:00 a.m.-12:00 p.m., at FDIC 2013 in Indianapolis.

Fire Engineering Archives