technology today ❘ By THOMAS HACKETT

Along with the safety of a building’s inhabitants, the safety of firefighters is paramount when approving and selecting products for construction applications. Building products need to be fire resistant and, in turn, reduce the spread of fire.

Every year, new and better methods of construction are developed for residential applications. As the use of the new applications grows, we learn about the benefits and drawbacks. Ultimately, with our increased understanding and knowledge, code requirements change to reflect the safest ways to build and remodel homes.

Stone wool is fire resistant, delays the spread of fire, and does not contribute to the release of toxic gases. It is a type of insulation comprised of basalt rock (a common fine-grained hard rock that forms from lava from volcanoes) and steel slag, which is a recycled by-product of the steel industry. To manufacture stone wool, these raw materials are melted down into lava and then spun into fibers, which then form the insulation. ROCKWOOL stone wool resists temperatures of up to approximately 2,150°F.

Although combustible insulation can fuel a fire, stone wool insulation actually impedes the spread of fire as a fire stop and provides valuable extra minutes to save people and property as well as reduce the the resultant environmental damage.

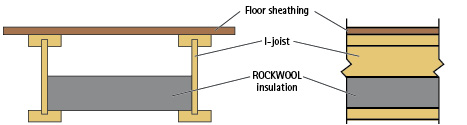

You can use stone wool insulation in several applications within a home or other types of buildings, and the number of these applications continues to grow. I-joists are an example of an application that has changed the building industry dramatically and, in turn, has driven changes to the building code requirements. Invented in 1969, I-joists are engineered wood joists that offer many benefits while eliminating many problems that regularly arise with conventional wood joists. I-joists can support heavy loads with substantially less lumber than solid wood joists. In addition, I-joists are far less prone to bow, crown, twist, cup, or split than traditional lumber joists. Problems with squeaky floors are far less prevalent with I-joists because of their overall dimensional stability. Because of the benefits of I-joists, their use and application has grown dramatically. In the Fundamentals of Building Construction, Volume 4, authors Iano and Allen stated that approximately 50 percent of all wood light framed floors used I-joists.

Figure courtesy of ROCKWOOL Insulation.

However, one of the drawbacks that has become evident is that I-joists are prone to fail sooner in fires than conventional joists. In response, the 2012 IRC Section R 501.3 code requirements were changed to address the issues related to fire safety. Currently, 32 states have met or exceeded the 2012 IRC code. For information on the code and the status of the legislation in each state, visit https://www.iccsafe.org/wp-content/uploads/stateadoptions.pdf.

A variety of options are available for home builders and remodelers to use to meet the new code requirements when building with I-joists. For example, basement ceilings can be finished with drywall, or a sprinkler system can be installed. However, both options come with substantial budget implications for the homeowners and, in the case of sprinkler systems, home builders are obligated to change their traditional methods of construction. Fortunately, stone wool insulation batts provide a solution that meets the requirements of the code. Installing stone wool batts between I-joists is faster and easier than employing drywall or sprinkler systems. And using stone wool batts falls easily within the traditional methods of construction that builders and remodelers use, resulting in no changes to the processes typically used by these professionals.

The assembly shown in Figure 1 was tested and approved to provide alternate fire resistance per the 2012 International Residential Code, section R 501.3, exception 4. The system was tested per International Code Council Acceptance Criteria AC-14 section 4.4, following American Society for Testing and Materials E119.

In addition to the benefit of meeting the fire protection code requirements for basement ceilings, stone wool insulation offers many other benefits to homeowners. For example, the unique, nondirectional structure of ROCKWOOL stone wool and—in particular—the Safe ‘n’ Sound product will provide effective sound absorption, thus reducing the sound transfer between floors. Also, because stone wool is made from natural and recycled products, the insulation provides an environmentally sustainable solution that the homeowner can feel comfortable using. In addition, the inorganic characteristics of stone wool resist water and will not promote the growth of mold or mildew, enhancing the desired healthy features of a home.

The use of I-joists in residential applications continues to grow. Combining stone wool insulation with I-joists provides the highest level of construction standards, fire safety, and many other benefits to homeowners, construction contractors, and firefighters.

THOMAS HACKETT manages the technical support center at ROCKWOOL Insulation. He oversees the technical support function for ROCKWOOL products in various applications throughout North America.