BY CHRISTOPHER A. DICUS, THOMAS KORMAN, CASEY GRANT, STEVE LOHR, DAN MADRZYKOWSKI, FRED MOWRER, CHRIS PASCUAL, AND DAN TURNER

A new study, funded by the Department of Homeland Security’s Assistance to Firefighters Grants, is investigating the effectiveness, limitations, and potential safety concerns of compressed air foam systems (CAFS) for structural firefighting. CAFS use a designated mixture of water, Class A foam, and compressed air that is applied through a hose and nozzle to control a fire (photo 1). CAFS were originally used for wildland firefighting in the early 1970s and then later gained popularity for fighting structural fires because of their many purported benefits, which included faster knockdown time, rapid heat reduction, lowered potential for flare-ups, and reduced water use.

|

| (1) When CAF is applied on a vertical surface, it can adhere to it for an extended time. (Photo by D. Madrzykowski.) |

Although used in various fire districts throughout the world, CAFS technology and use have not evolved as fully as had been anticipated. Despite generally favorable reviews of the overall effectiveness of CAFS in extinguishing interior structural fires, questions remain about their efficacy compared to water, which is of particular concern given that compressed air foam (CAF) is more expensive than water. Further, there are safety concerns (based largely on limited anecdotal evidence) associated with CAF, such as the potential for splashback, which might subsequently obscure vision and increase slip hazards and heightened hose kinking and rupture.

Although some independent research by individual fire districts and organizations exists, comprehensive and peer-reviewed science is limited at present. Given the current interest in and concerns with CAF, a simultaneous, scientifically sound investigation of its positive and negative aspects is needed, the results of which should be readily available to the public.

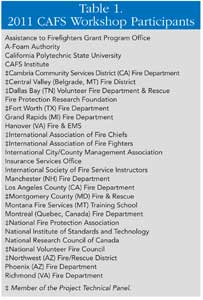

To ameliorate the lack of empirical research, this two-year study is comprehensively examining the capabilities and limitations of CAF for interior structural firefighting to better understand its effectiveness and the safety implications for fire service personnel. Researchers at California Polytechnic State University-San Luis Obispo are leading this project in collaboration with the National Institute of Standards and Technology and the Fire Protection Research Foundation. Also involved are fire service partners from across the United States and Canada, with a Project Technical Panel of high-level fire service personnel experienced in CAF and the specific needs of firefighters to provide guidance to the researchers (Table 1).

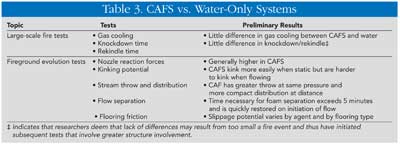

This collaborative team is working on a comprehensive literature review of previous scientific work germane to CAF use, including unpublished, in-house studies not readily available to the public. Additionally, it is conducting various large-scale enclosure fire tests that will investigate CAF efficacy in controlling interior structural fires compared to water. Further, scientific fireground evolution tests are underway to investigate various characteristics of CAF that influence firefighters’ efficiency and safety, including the amount of force a firefighter experiences when nozzles are fully opened, the potential for hose kinking, and the potential for slipping on various flooring surfaces.

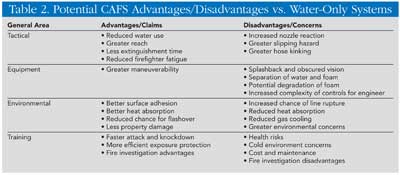

In December 2011, 38 researchers, selected to provide a well-balanced representation varied in geography, experience, and support of CAF use, attended a two-day workshop at the Montgomery County (MD) Public Service Training Academy. Participants reviewed previous and ongoing CAF use and research, multiple case studies illustrating success stories and concerns, a hands-on CAF demonstration, and an overview of proposed experiments. In open discussions, they considered the potential advantages and disadvantages of CAF (Table 2). In general, it was agreed that all scientific tests should focus on specific aspects of CAF use that was most pertinent to firefighter safety, to keep attendees informed of research progress, and to solicit additional feedback as needed. A comprehensive report of the workshop is available at http://www.nfpa.org/assets/files//Research%20Foundation/RFSummaryCAFSWorkshop.pdf.

Based on input from the workshop, researchers subsequently adjusted their original test plans to better meet the needs of the fire service (Table 3). All tests adhered to the following standards, which the Project Technical Panel deemed the most likely conditions under which firefighters would use CAFS:

- Nozzles: Fog (1½ inch and smooth bore (7⁄8 and 13⁄8 inch)

- Hose: 1¾ inch

- Foam concentration: 0.3 percent

- Flow: 120 gallons per minute (gpm)/60 cubic feet a minute (cfm)

- Water/air pressure: 100-120 pounds per square inch (psi)

Initial fireground evolution testing began in March 2011; various firefighter safety and efficiency concerns were explored. For example, nozzle reaction tests (photo 2) examined how much force a firefighter would experience when using CAFS vs. water-only systems, which influences firefighter fatigue. Kink force testing (photo 3) evaluated differences in hose kinking, which is of special concern when the hoseline goes around corners in a structure. Friction testing examined differences in slipping hazards that firefighters may experience on a variety of flooring surfaces. Separation testing (horizontal and vertical) determined the time it takes for CAF to separate from water in a hose when no water is flowing, which could lead to an unsafe delay in foam flow on opening a nozzle.

|

| (2) A California Polytechnic State University fire protection engineering student conducts a test on nozzle forces that a firefighter would experience. (Photo by D.R. Turner.) |

|

| (3) California Polytechnic State University fire protection engineering students conduct a test to measure hose kinking associated with CAFS. (Photo by D.R. Turner.) |

Large-scale fire tests began in September 2012 at the Live Fire Training Building at the Delaware County (PA) Emergency Service Training Center. Researchers replicated identical conditions for each of the individual tests by fixing nozzles on mounts. Gas-cooling experiments tested how multiple agent/nozzle combinations varied at reducing temperatures in a nonburning room connected to a burning room by an open doorway (photo 4). Knockdown experiments evaluated CAF effectiveness in extinguishing flames in a fully enveloped, confined room with limited ventilation and the time needed for any subsequent rekindle (photo 5).

|

| (4) A facility used for gas-cooling experiments. Temperature changes were recorded during and following flow into a nonburning room connected to the burning room by an open doorway. (Photo by C.A. Dicus) |

|

| (5) A knockdown/rekindle time test facility. To simulate probable firefighting tactics, flow was initiated down a hallway leading to a fully enveloped room (simulating attempts to cool a gas layer), halted for 15 seconds (simulating a firefighter moving down a hall), then was recommenced into the burning room. (Photo by C.A. Dicus.) |

Some preliminary results are included in Table 3. Note that data analysis is ongoing and results presented here may vary after further statistical analysis. Final reports for all experiments will be publicly available by the end of 2013; articles in scientific journals will follow. Also, a comprehensive literature review to encapsulate all previous work on CAFS is underway; it contains experiments from the scientific literature and from in-house studies. On final completion of all stages of this project, the researchers hope that this will be the most comprehensive and applicable research project ever conducted on CAF.

● CHRISTOPHER A. DICUS is a professor and graduate coordinator for the Natural Resources Management & Environmental Sciences Department at California Polytechnic State University.

● THOMAS KORMAN is an associate professor in the Construction Management Department at California Polytechnic State University.

● CASEY GRANT is the research director of the Fire Protection Research Foundation.

● STEVE LOHR is the chief of Montgomery County (MD) Fire & Rescue Service.

● DAN MADRZYKOWSKI is a fire protection engineer with the National Institute of Standards and Technology in Gaithersburg, Maryland.

● FRED MOWRER is professor-in-residence and is the director of Fire Protection Engineering programs at California Polytechnic State University.

● CHRIS PASCUAL is a professor and graduate coordinator for the Fire Protection Engineering program in the Mechanical Engineering Department at California Polytechnic State University.

● DAN TURNER is a chief (ret.) with CAL FIRE and a researcher at California Polytechnic State University.

Fire Engineering Archives